Patents

Literature

54results about How to "Easy plastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

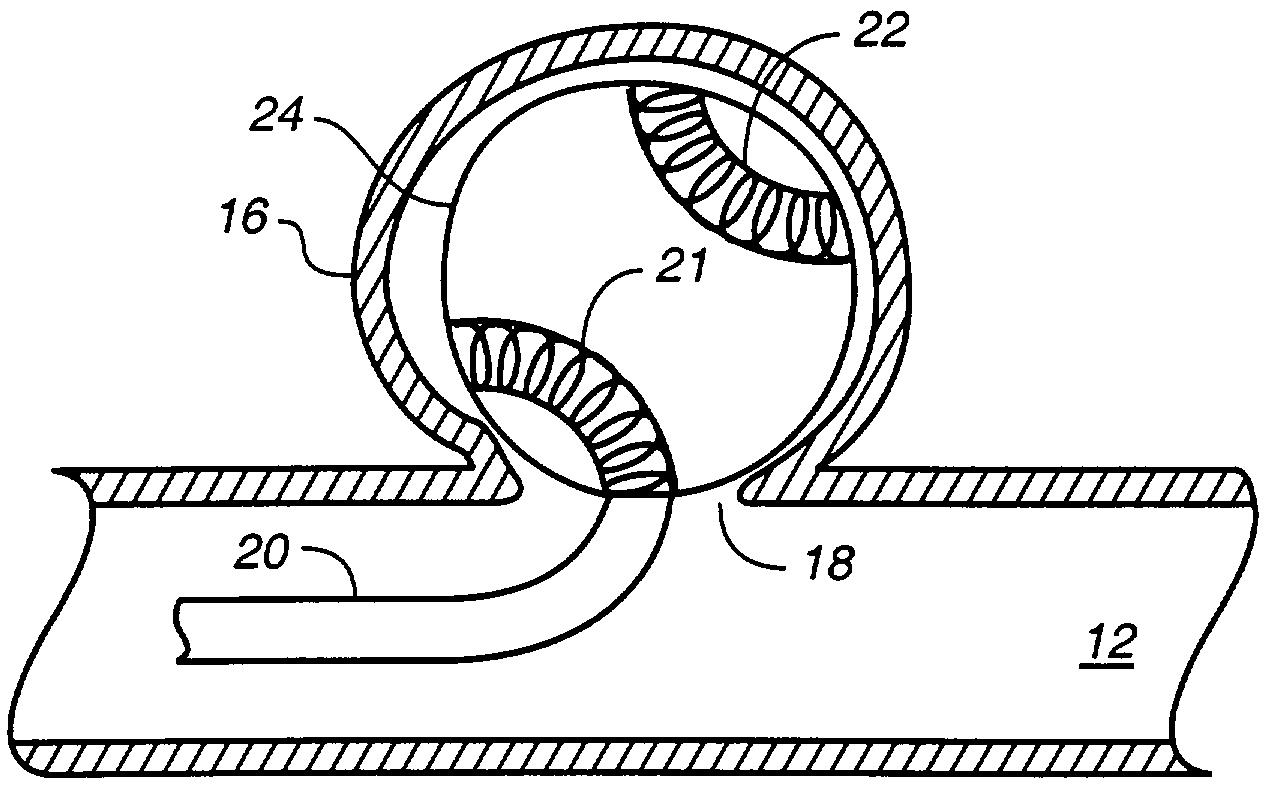

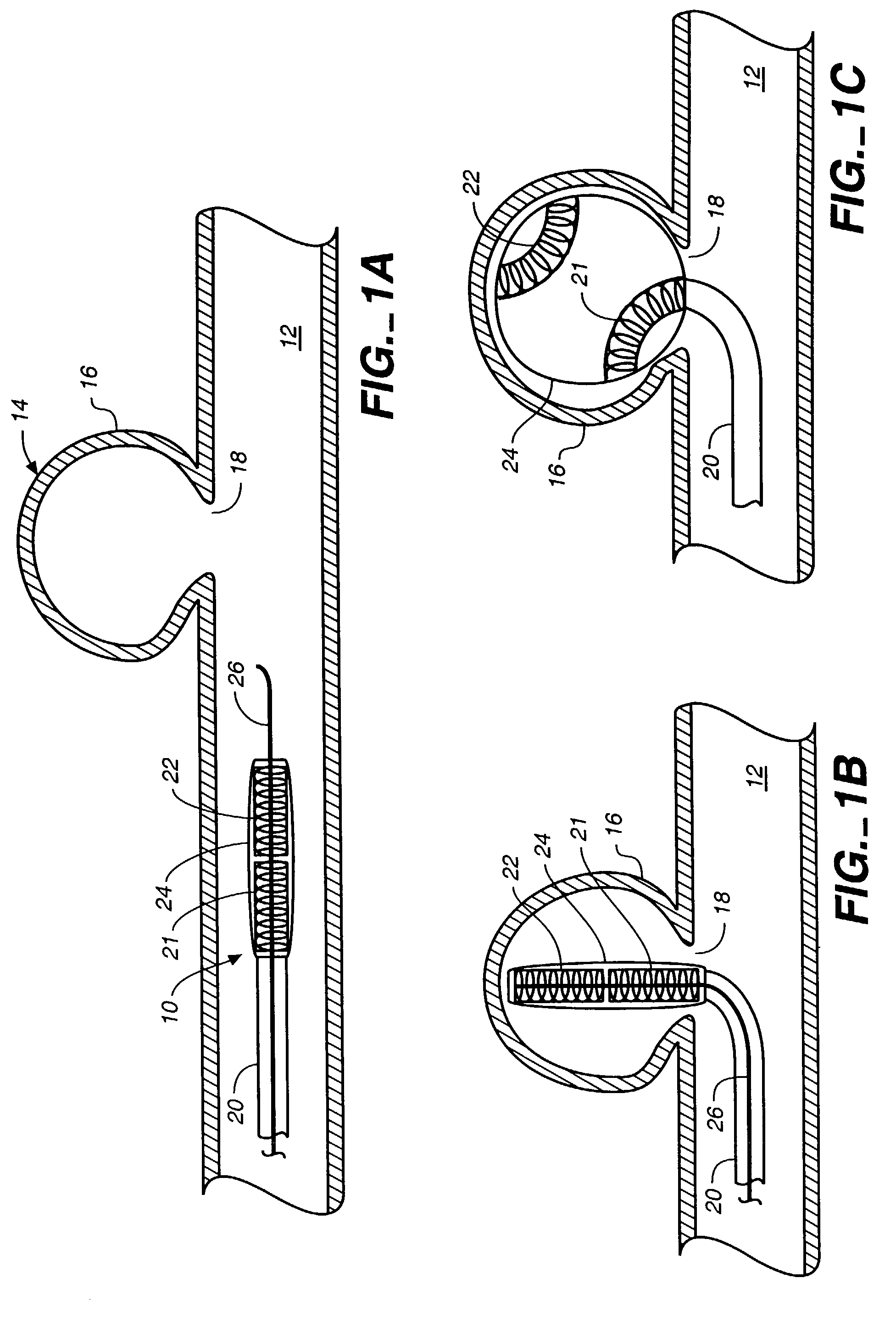

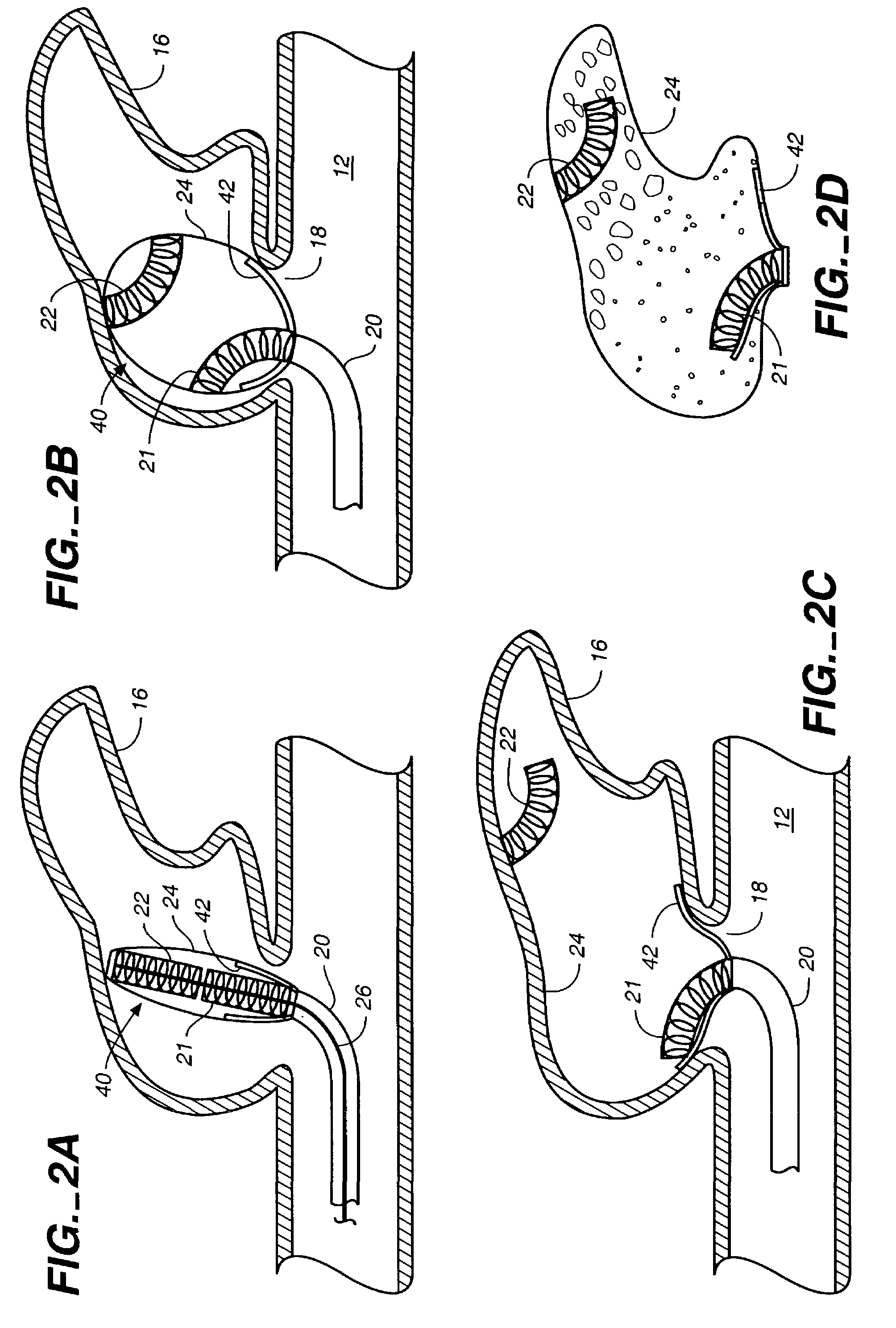

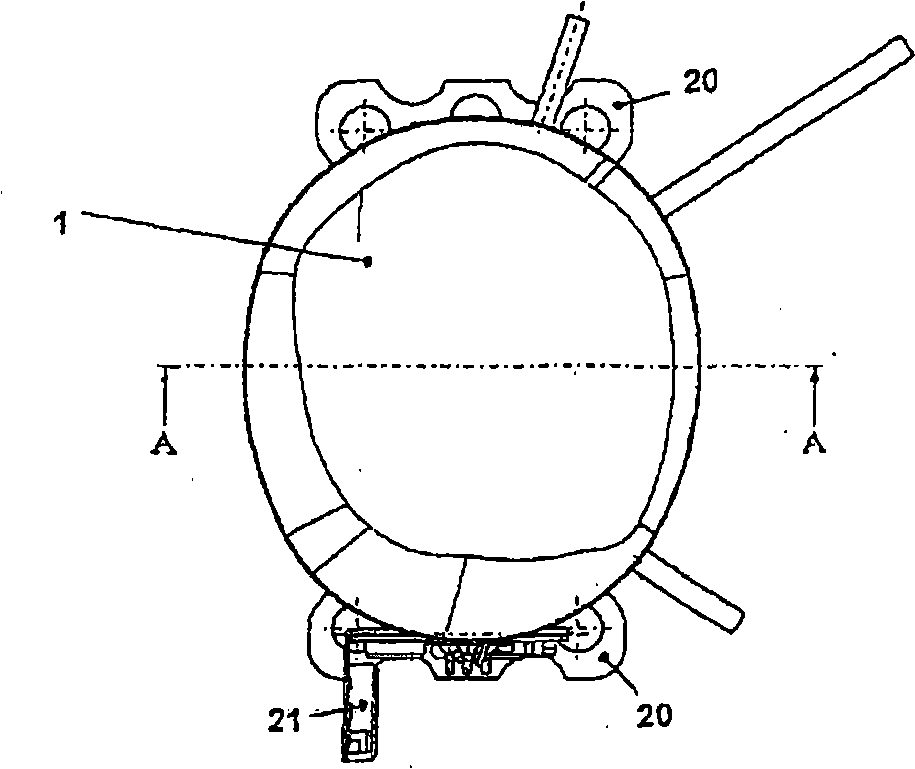

Expandable body cavity liner device

InactiveUS7695488B2Lower yield strengthEasy plastic deformationDilatorsCatheterAnterior Cerebral Artery AneurysmIliac Aneurysm

The present invention is an aneurysm treatment device for treating aneurysms of various shapes and sizes.

Owner:STRYKER CORP +1

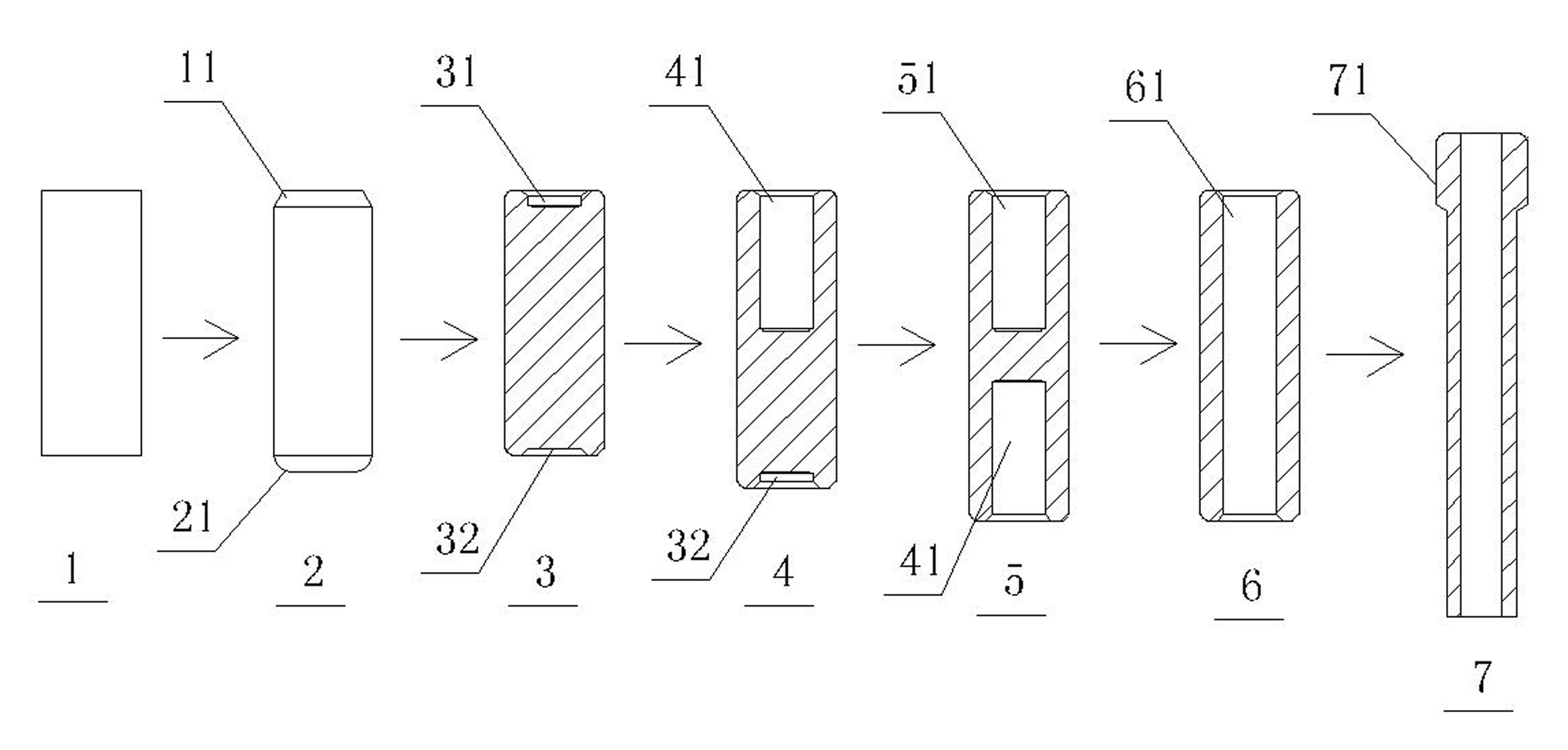

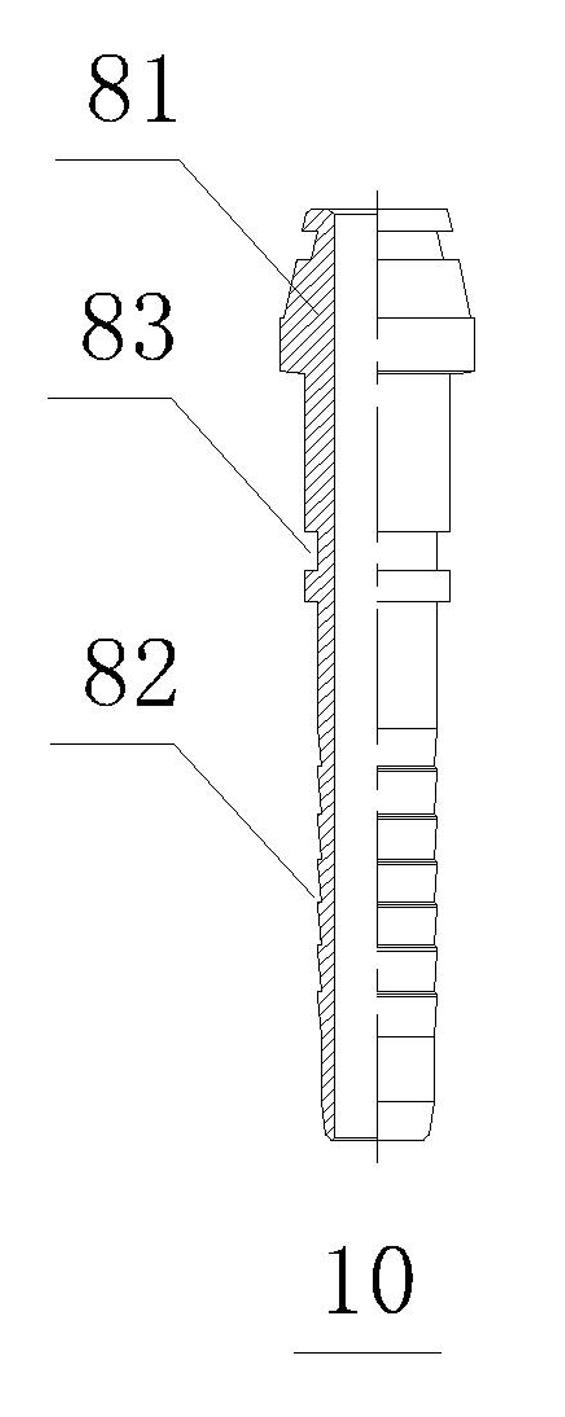

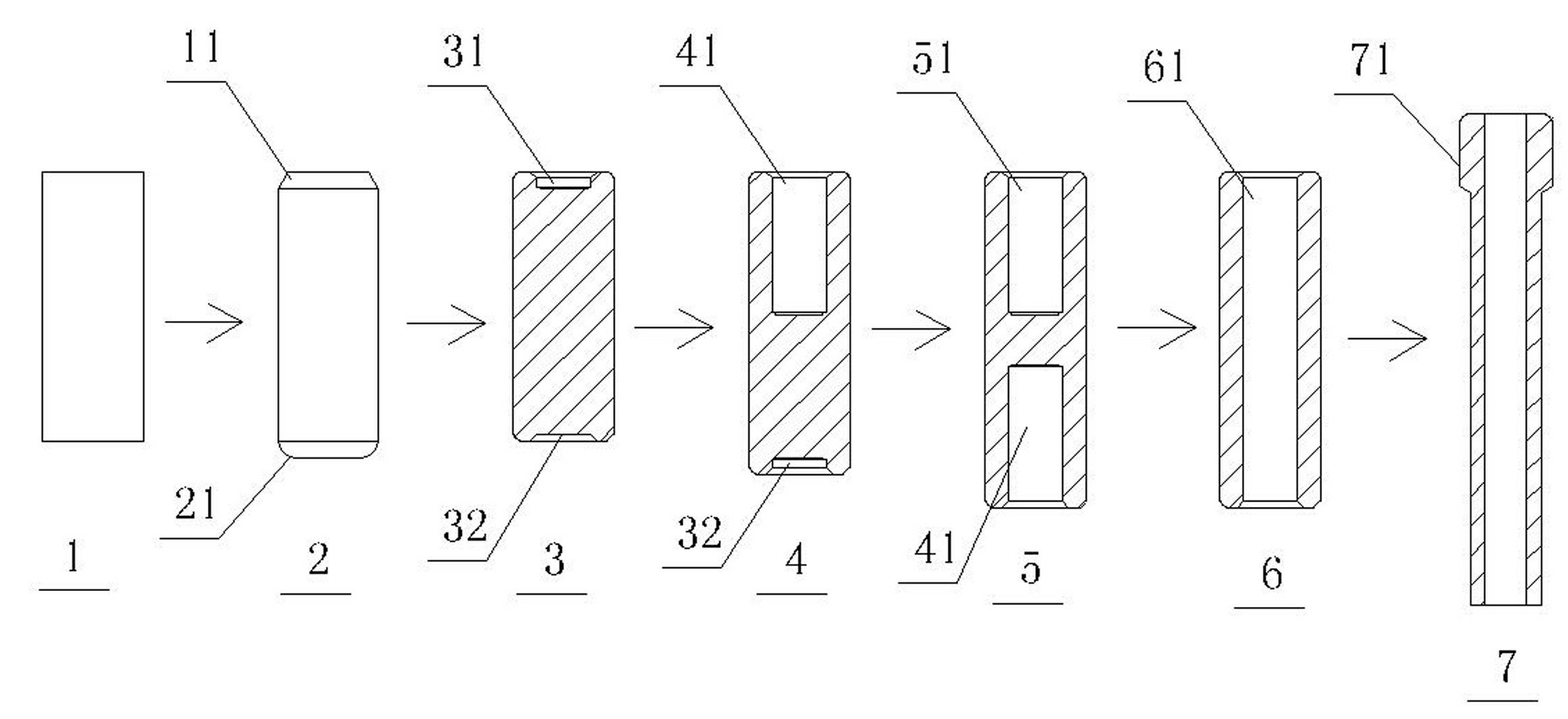

Method for manufacturing hose connector core

The invention provides a method for manufacturing a hose connector core, which comprises the following steps of: performing spheroidizing annealing on a wire rod blank material serving as a raw material; performing phosphate coating surface treatment on the wire rod blank material subjected to spheroidizing annealing; performing fine drawing sizing, and cutting a wire rod finished product material subjected to fine drawing sizing into single hose connector core blank materials; and manufacturing the blank of the hose connector core by using a seven-station cold heading method and a cold heading machine. The wire rod material is used for replacing a straight bar material and a broken material, so that the requirement of multi-station cold heading continuous production can be met, and the loss of a material head and a material tail is reduced; stations are reasonably designed, so that the physical property and the quality of a product are improved, and the product has good surface appearance; a material part is easily subjected to plastic deformation in the cold extrusion process, and the loss of a die is low; and finish machining production speed is doubled.

Owner:YUYAO HANGYI AUTOMOBILE PARTS

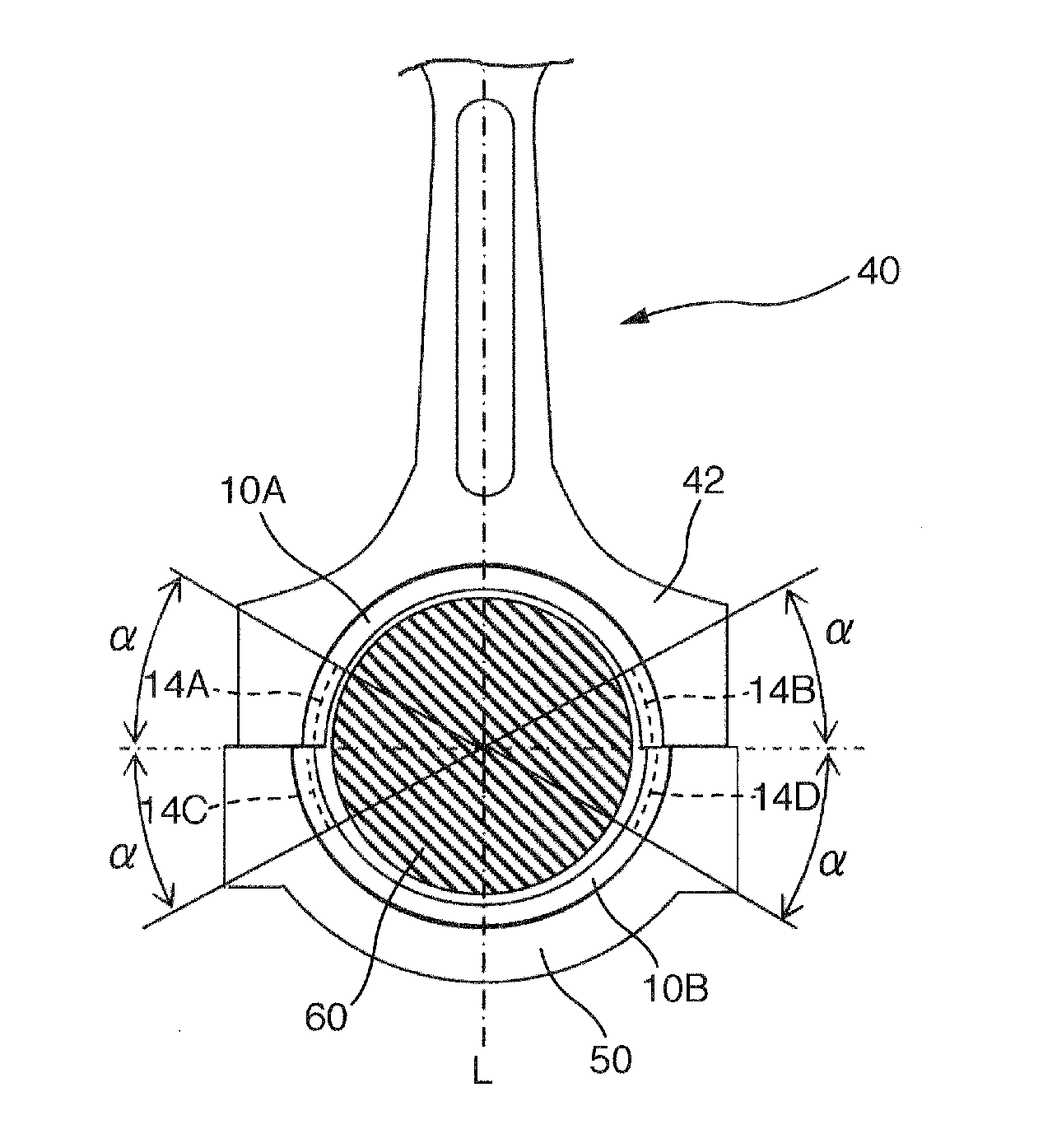

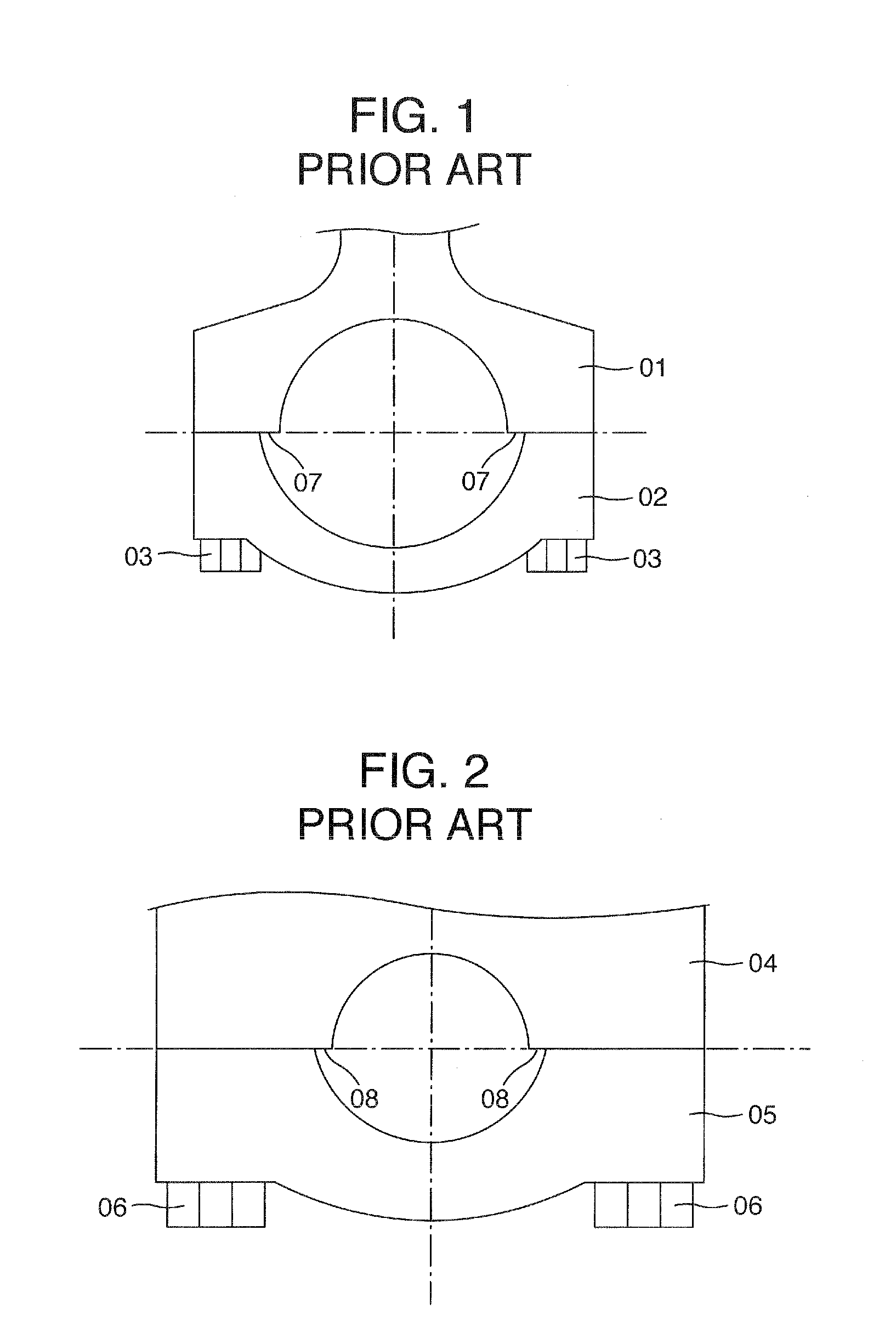

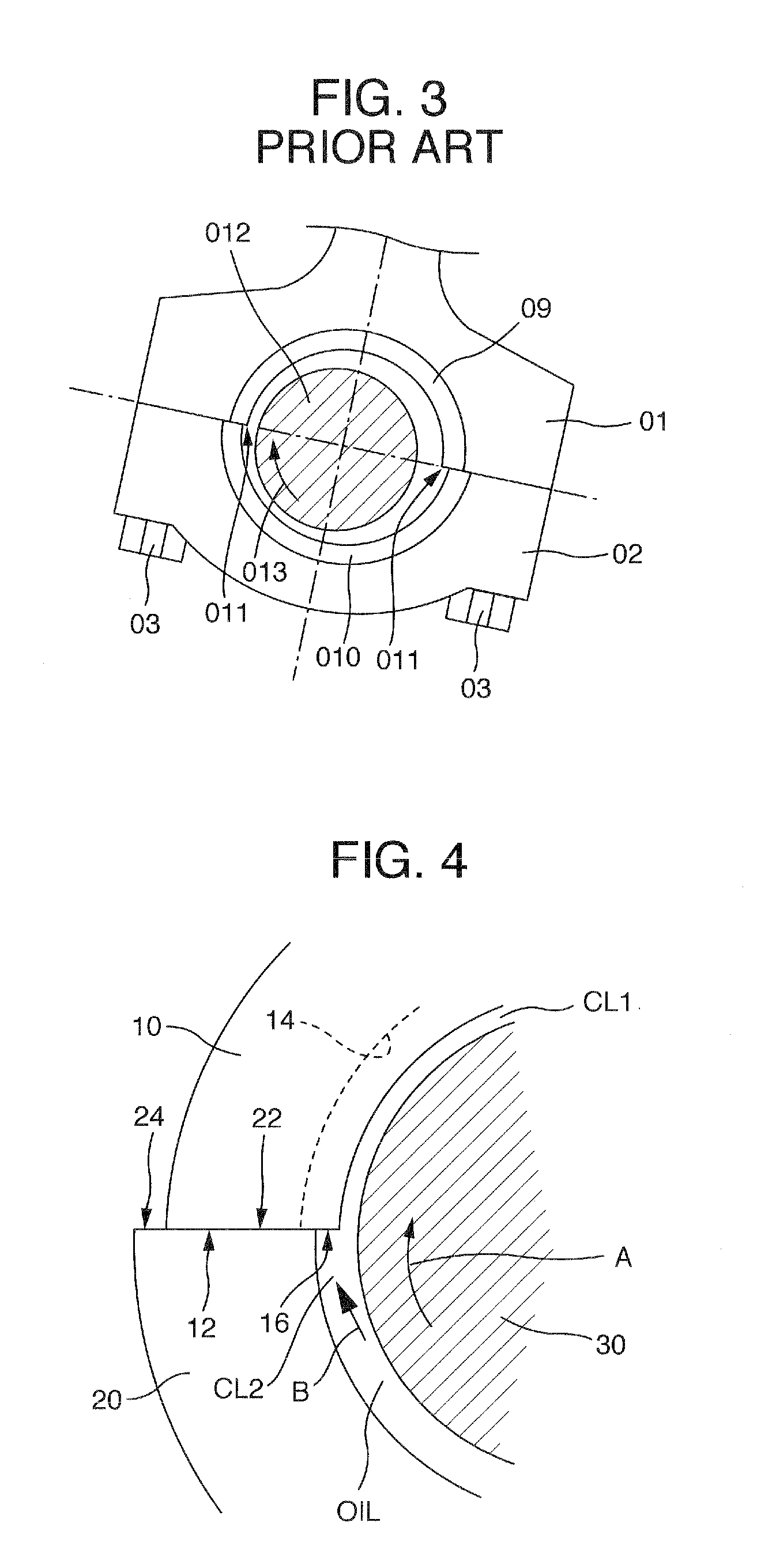

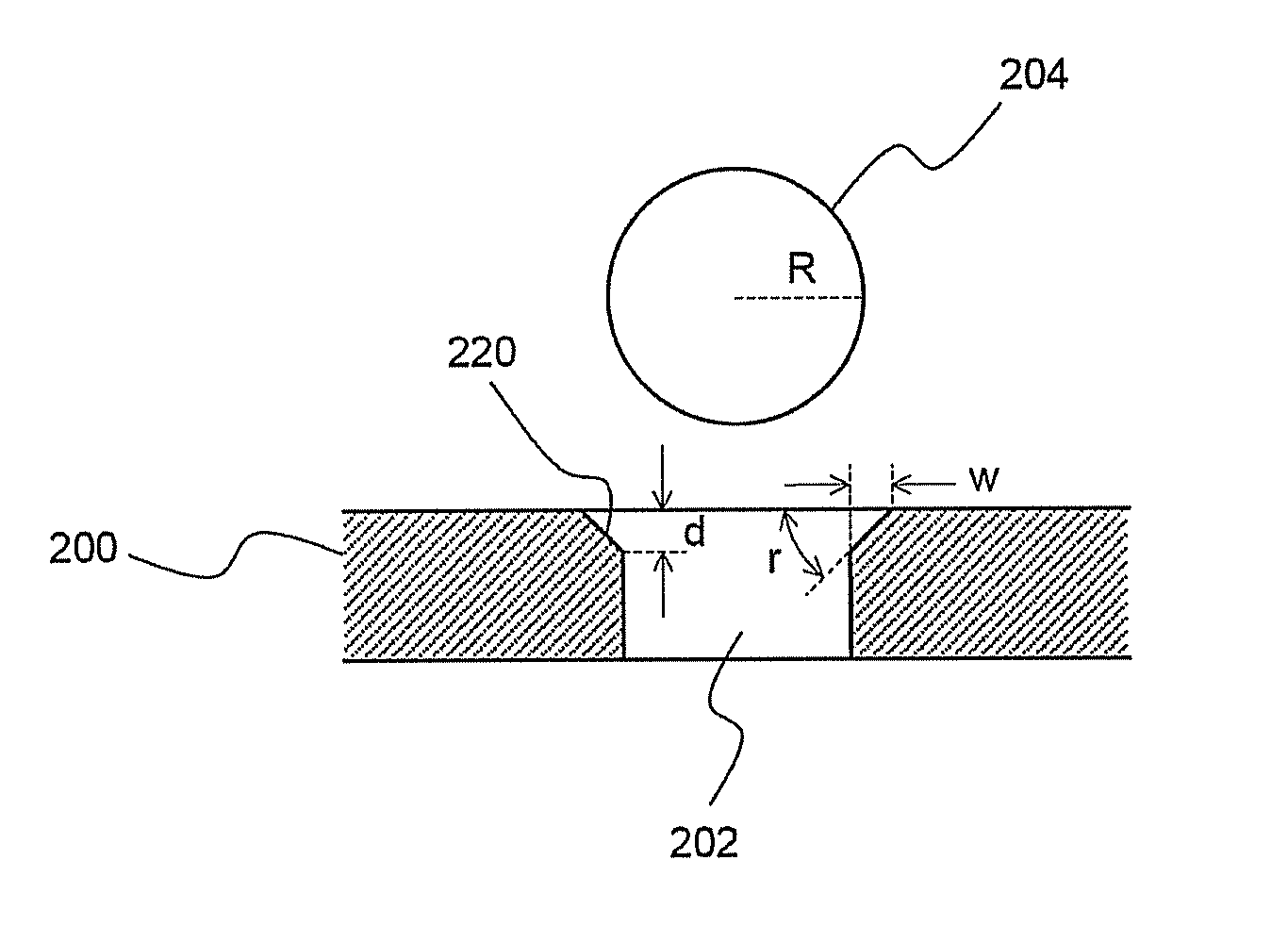

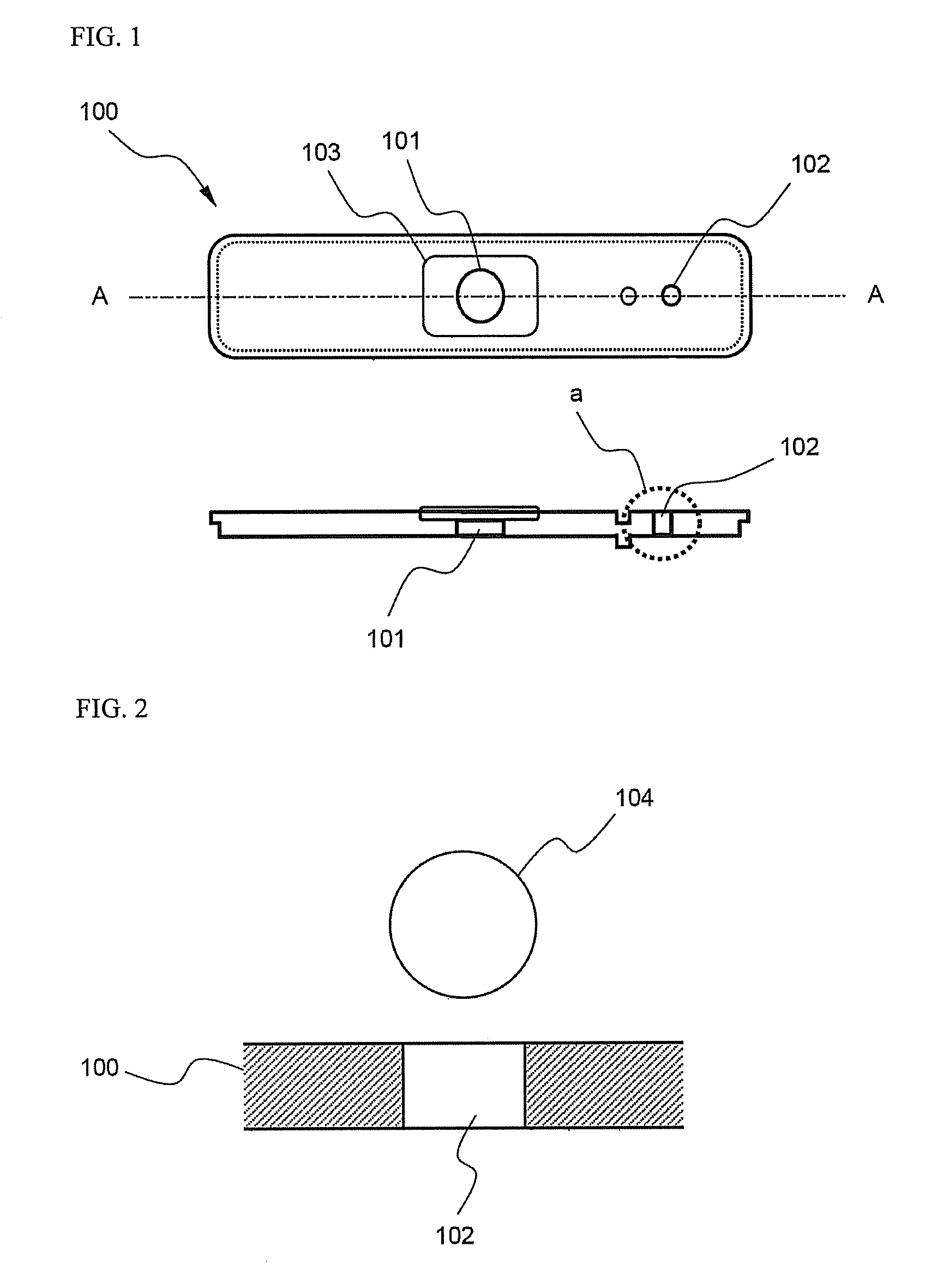

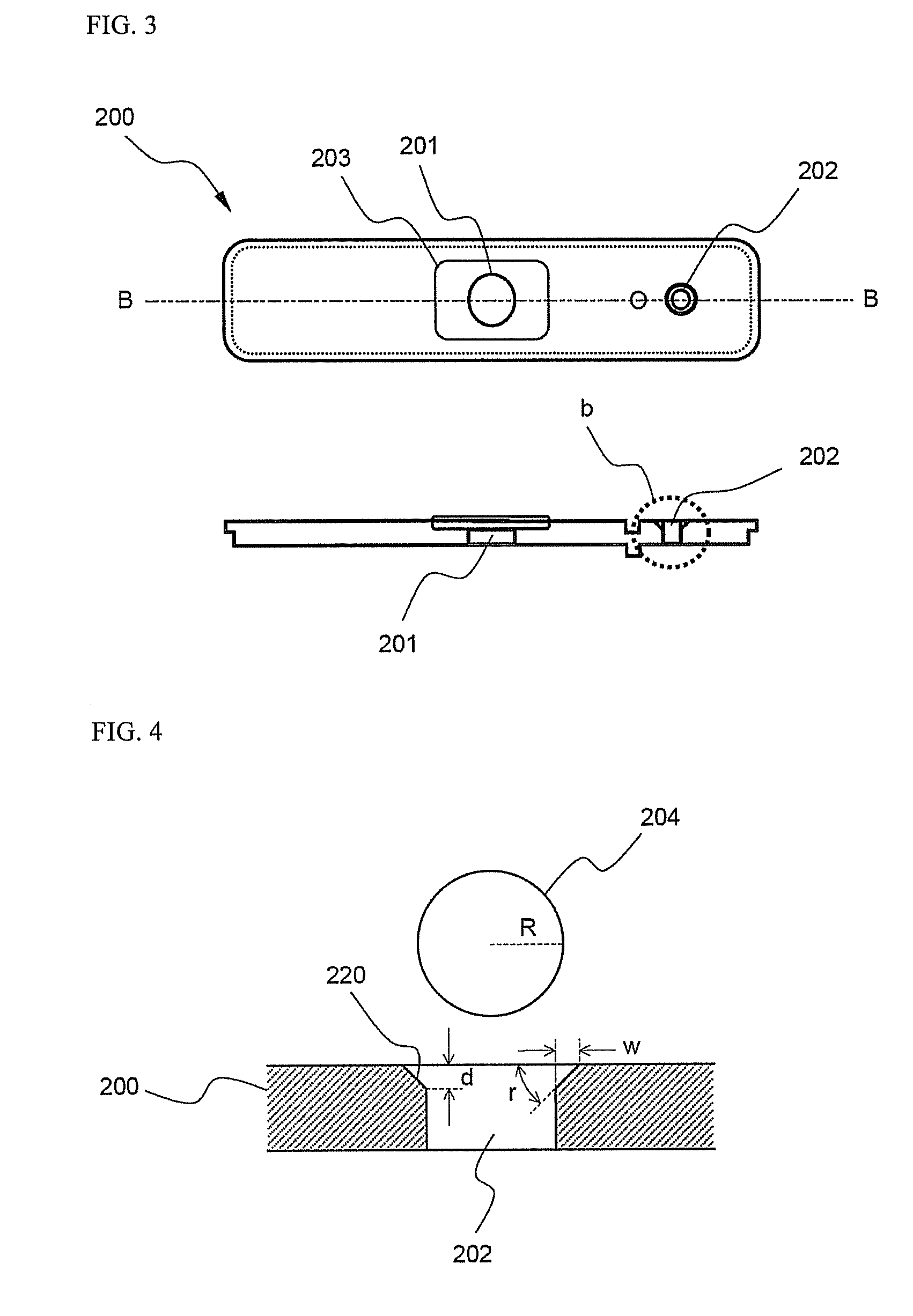

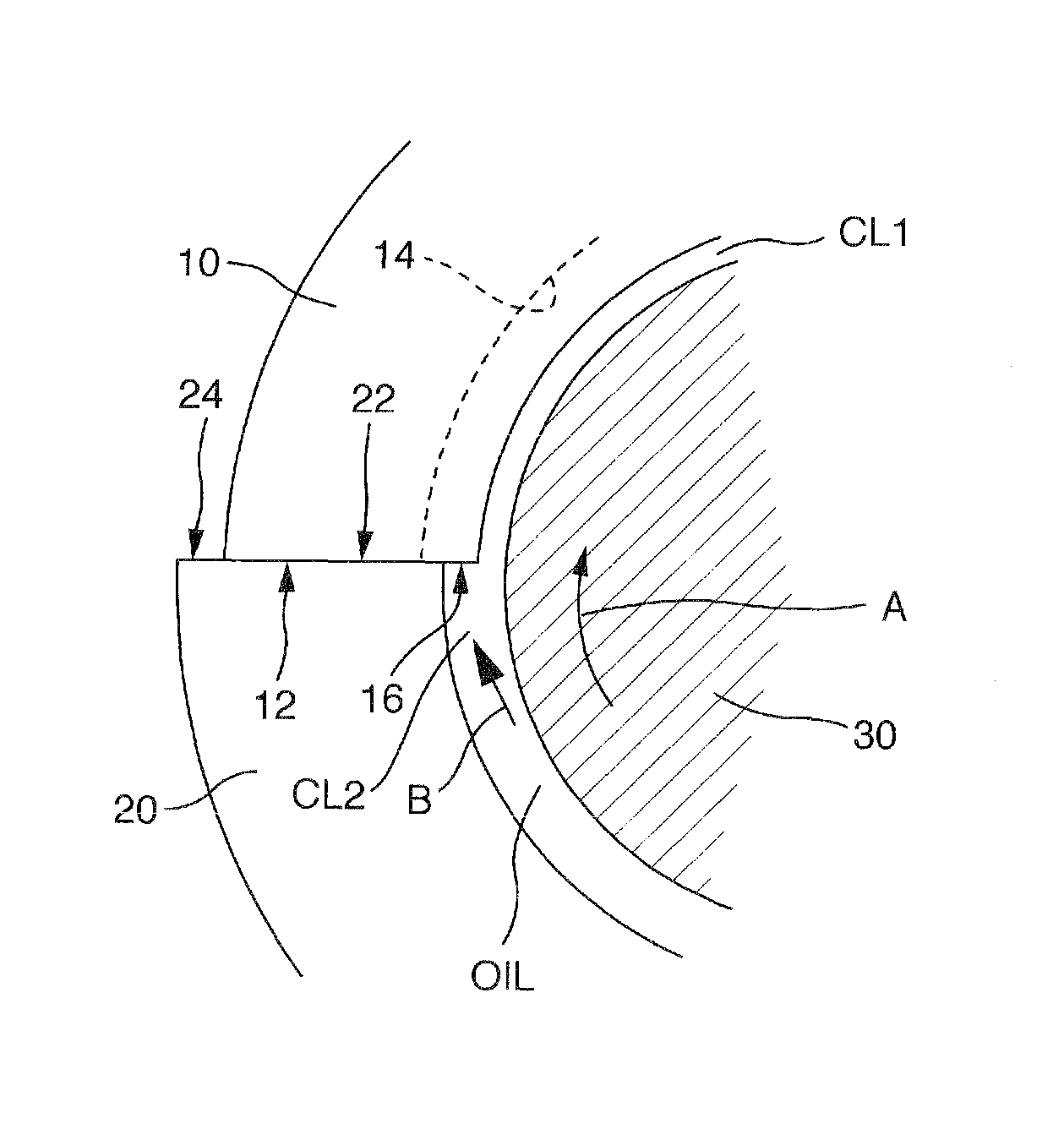

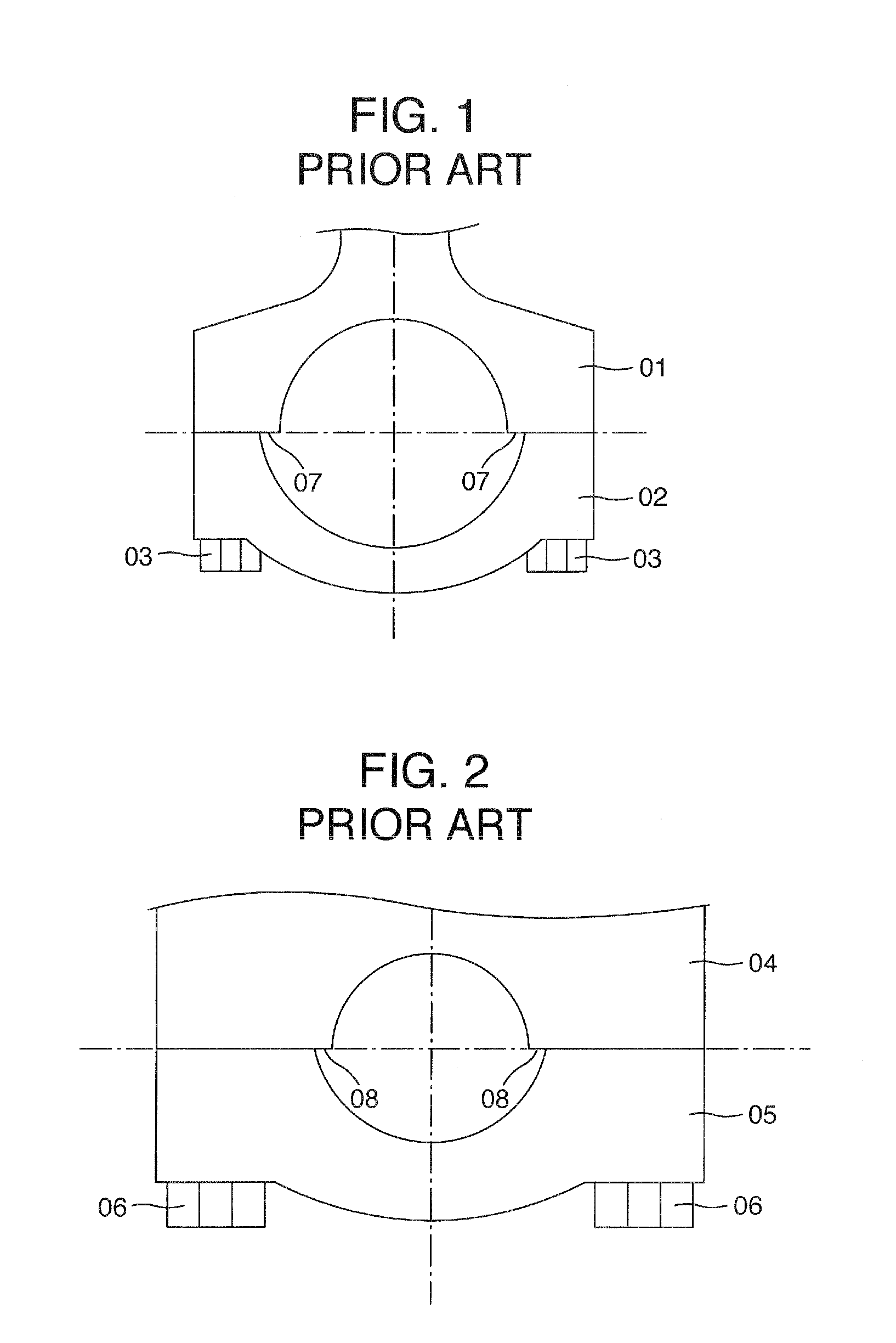

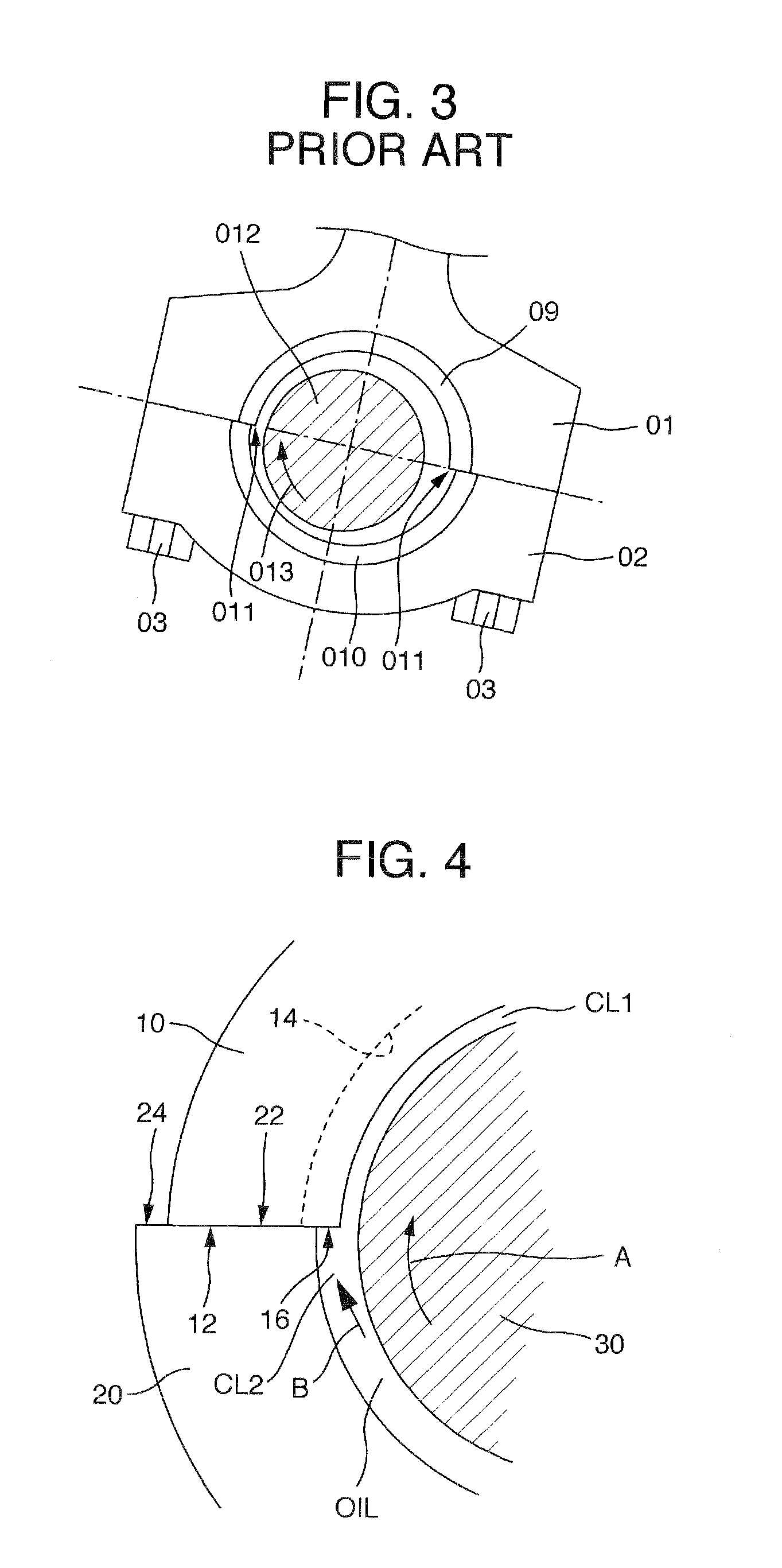

Sliding bearing for internal combustion engine and sliding bearing device

InactiveUS20100119181A1Increase stiffnessInhibition effectConnecting rod bearingsCrankshaft bearingsHigh stiffnessEngineering

Disclosed is a sliding bearing consisting of a pair of semi-cylindrical bearings for supporting a crankshaft or a crank pin in an internal combustion engine. The sliding bearing is incorporated in a split-type bearing housing. One of the semi-cylindrical bearings being incorporated in at least one of the pair of housing halves, which one housing half has a relatively higher stiffness, is provided with a number of circumferential grooves on an inner surface of the semi-cylindrical bearing so as to extend circumferentially along the inner surface of the semi-cylindrical bearing. The circumferential grooves existing at least one circumferential end region of the inner surface of the semi-cylindrical bearing have a depth of not less than 10 μm, the circumferential end region including a circumferential bearing end face orientating a direction opposite to the rotation direction of the shaft or pin.

Owner:DAIDO METAL CO LTD

Heat-insulated degradable polypropylene foaming material and production method thereof

The invention provides a heat-insulated degradable polypropylene foaming material and a production method thereof. The heat-insulated degradable polypropylene foaming material comprises the following components in parts by weight: 60-85 parts of long-chain branched polypropylene resin, 0.1-30 parts of high-crystallization polypropylene resin, 0.1-10 parts of polyethylene resin, 0.1-5 parts of nucleating agent, 0.1-5 parts of antioxidant, 0-5 parts of coloring agent, 1-3 parts of slipping agent and 0.1-5 parts of chemical foaming agent, wherein according to the ISO 16790-2005 regulation, the long-chain branched polypropylene resin has melt strength of 30Pa.s-40Pa.s, a melting temperature of 160 EG C-240 DEG C, a branch chain carbon atom number of 20-30 and a molecular weight multi-dispersion index of 5.0-7.0, and is continuously produced by a two-order serial-connection extruder. During the preparation process, the physical foaming agent is added, wherein the physical foaming agent is one or more of carbon dioxide with a supercritical fluid form, nitrogen gas, helium gas, argon gas, hydrogen gas, pentane and butane; and the filling amount of the physical foaming agent is 1-10 parts.

Owner:顾建生

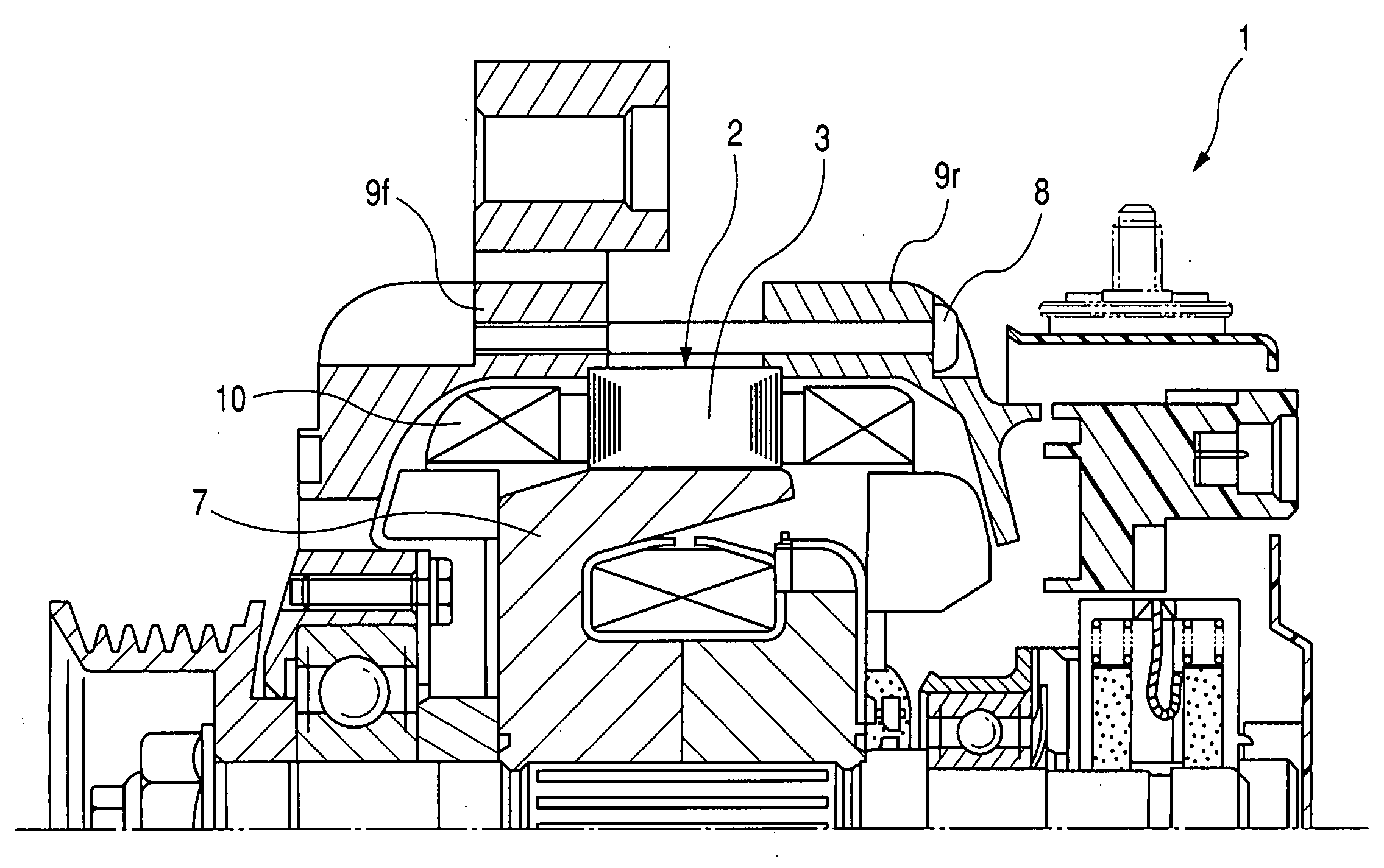

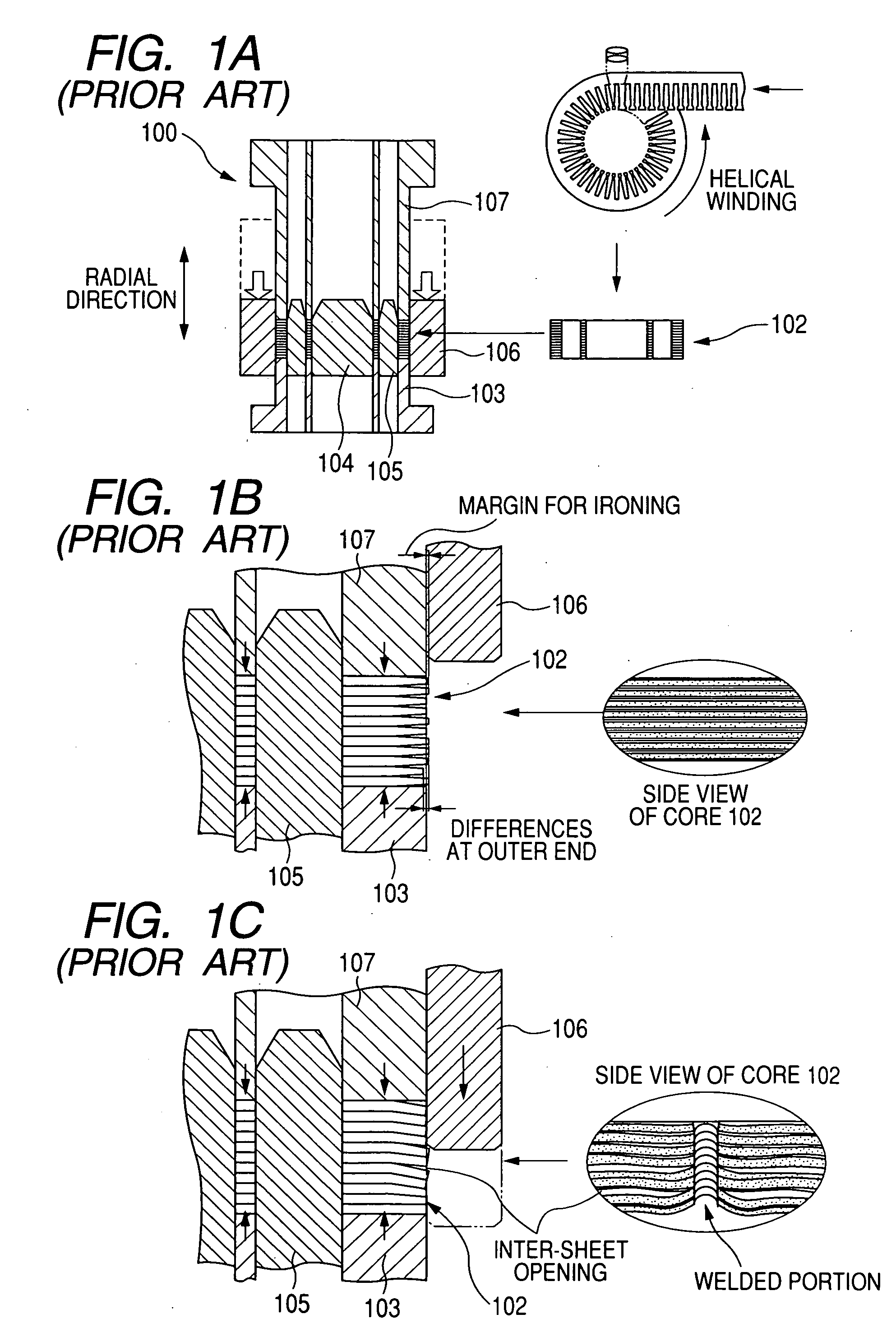

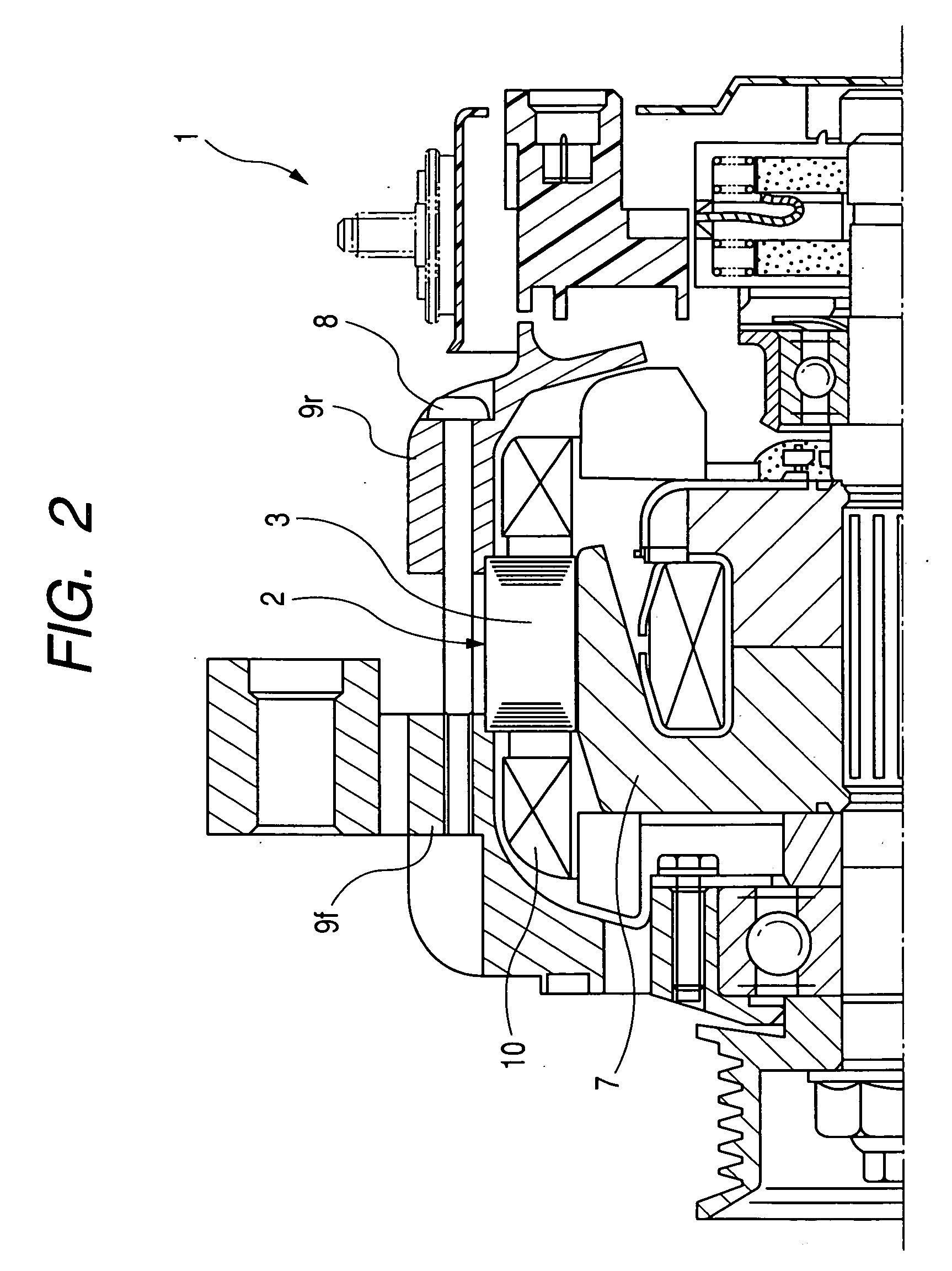

Method of manufacturing stator core of electric rotating machine

InactiveUS20090077789A1Easy to adjustInhibition formationManufacturing stator/rotor bodiesElectromagnetsElectric machineMagnetic poles

In a method of manufacturing a stator core of an electric rotating machine, a cylindrical laminated core is formed by thinning a side portion of a steel plate with magnetic pole teeth and helically winding the steel sheet, and the stator core is manufactured by performing ironing for the laminated core. This laminated core has steel sheets aligned along the axial direction thereof, and the sheets have respective thinned outer end portions spaced apart from one another on the outer side of the laminated core. In the ironing, the thinned outer end portions of the steel sheets are brought into contact with one another in a forming apparatus, and an ironing load is given to the thinned outer end portions to shorten lengths of the thinned outer end portions in the radial direction of the laminated core at a predetermined value.

Owner:DENSO CORP

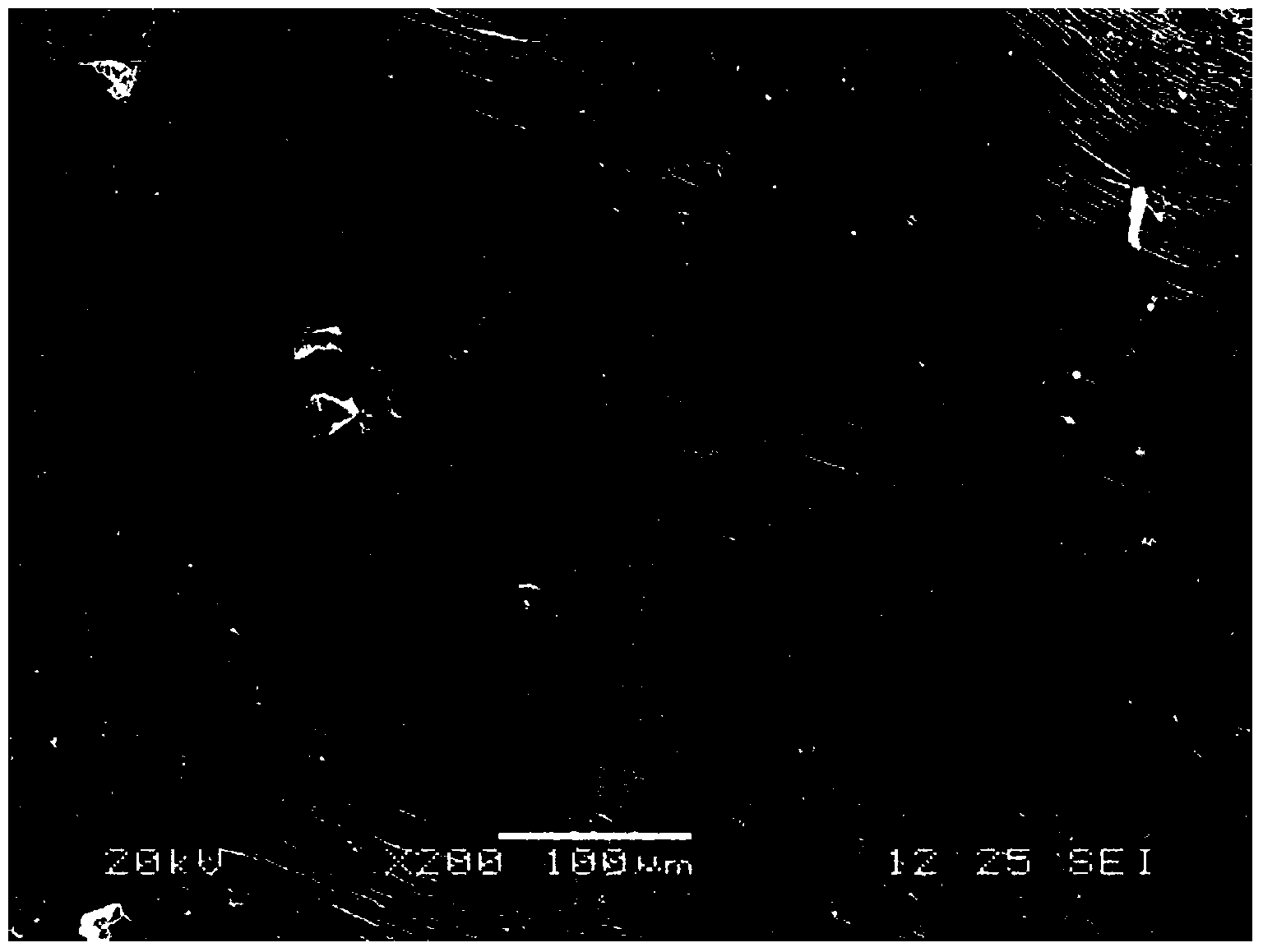

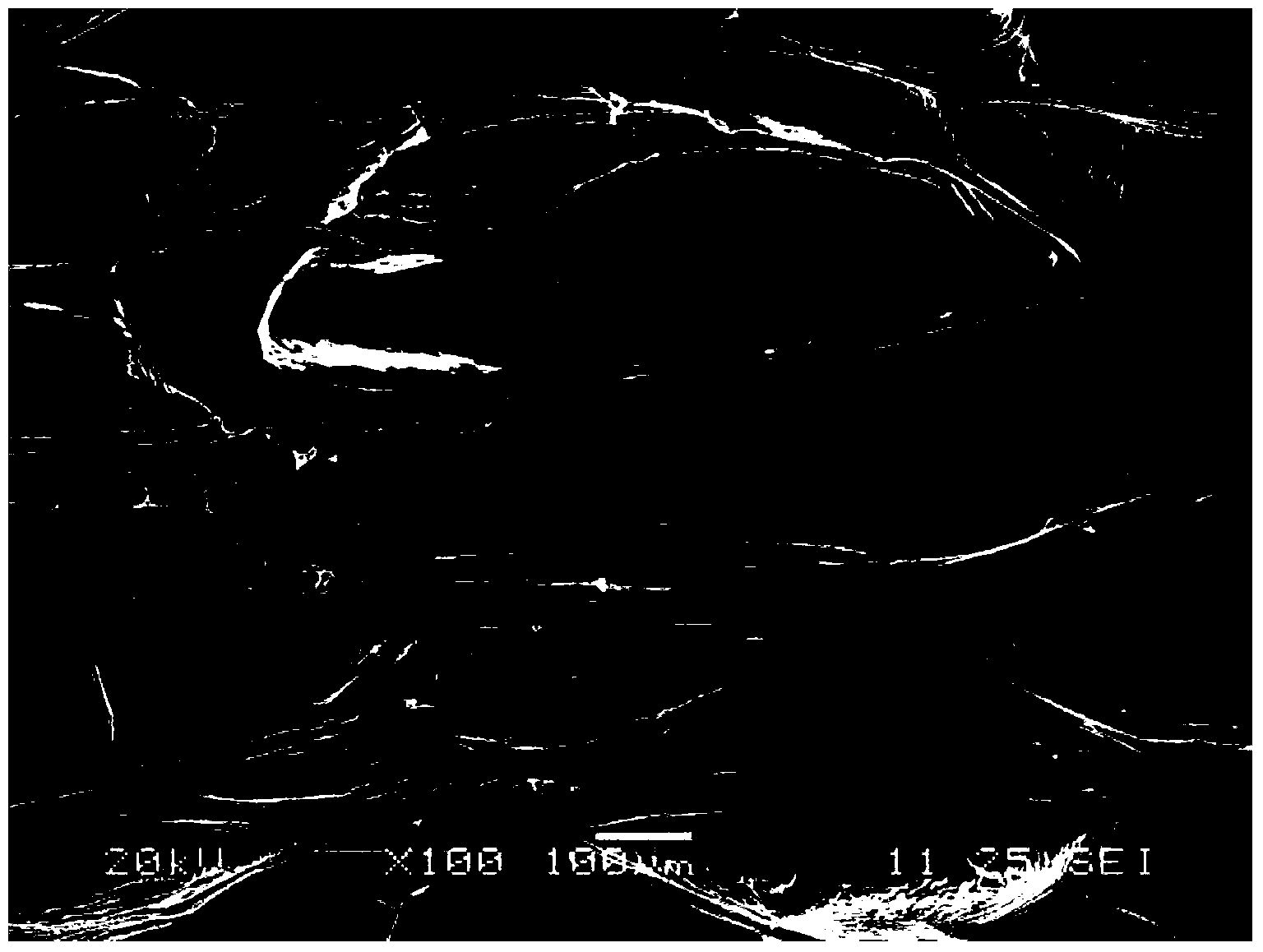

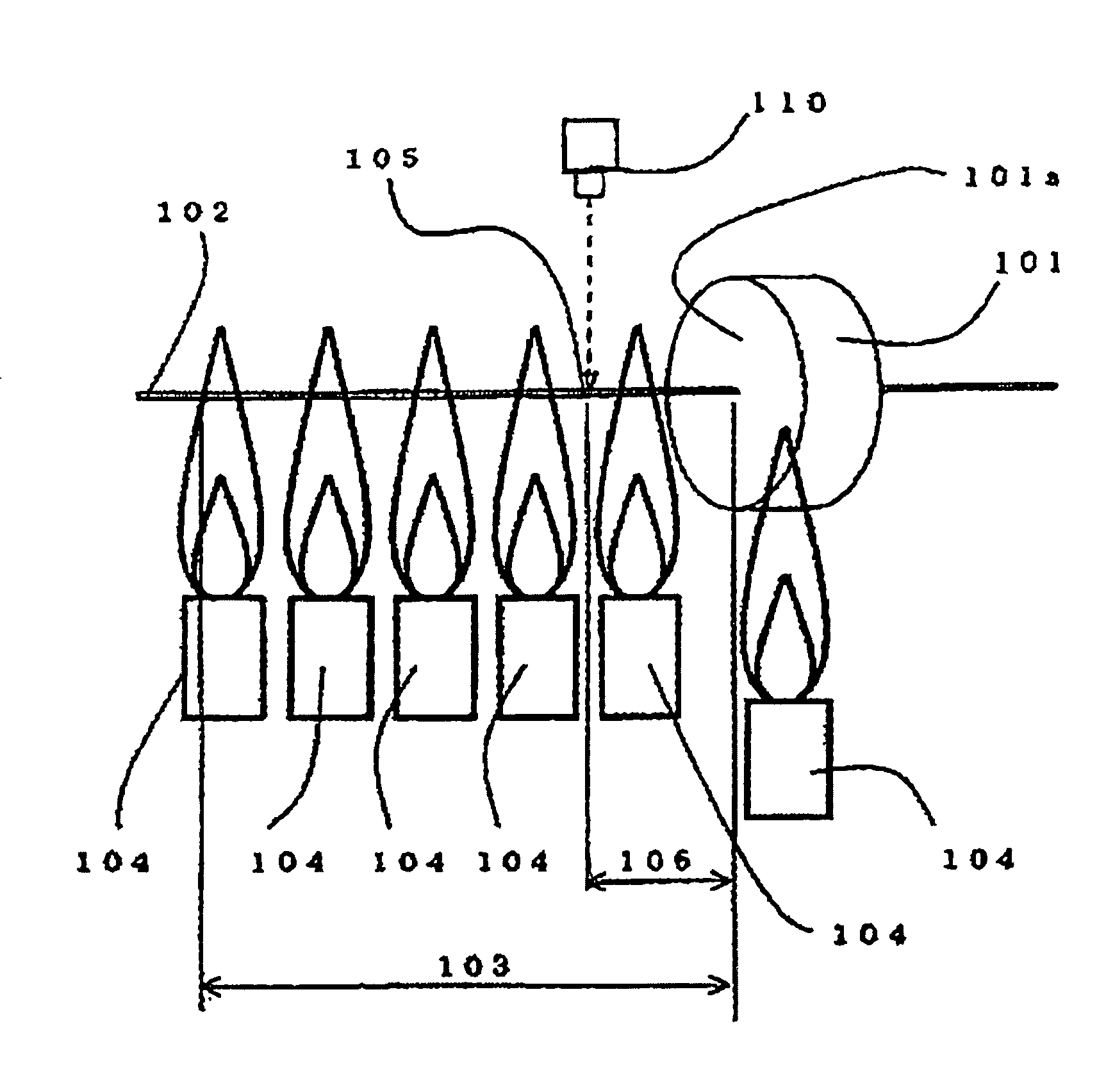

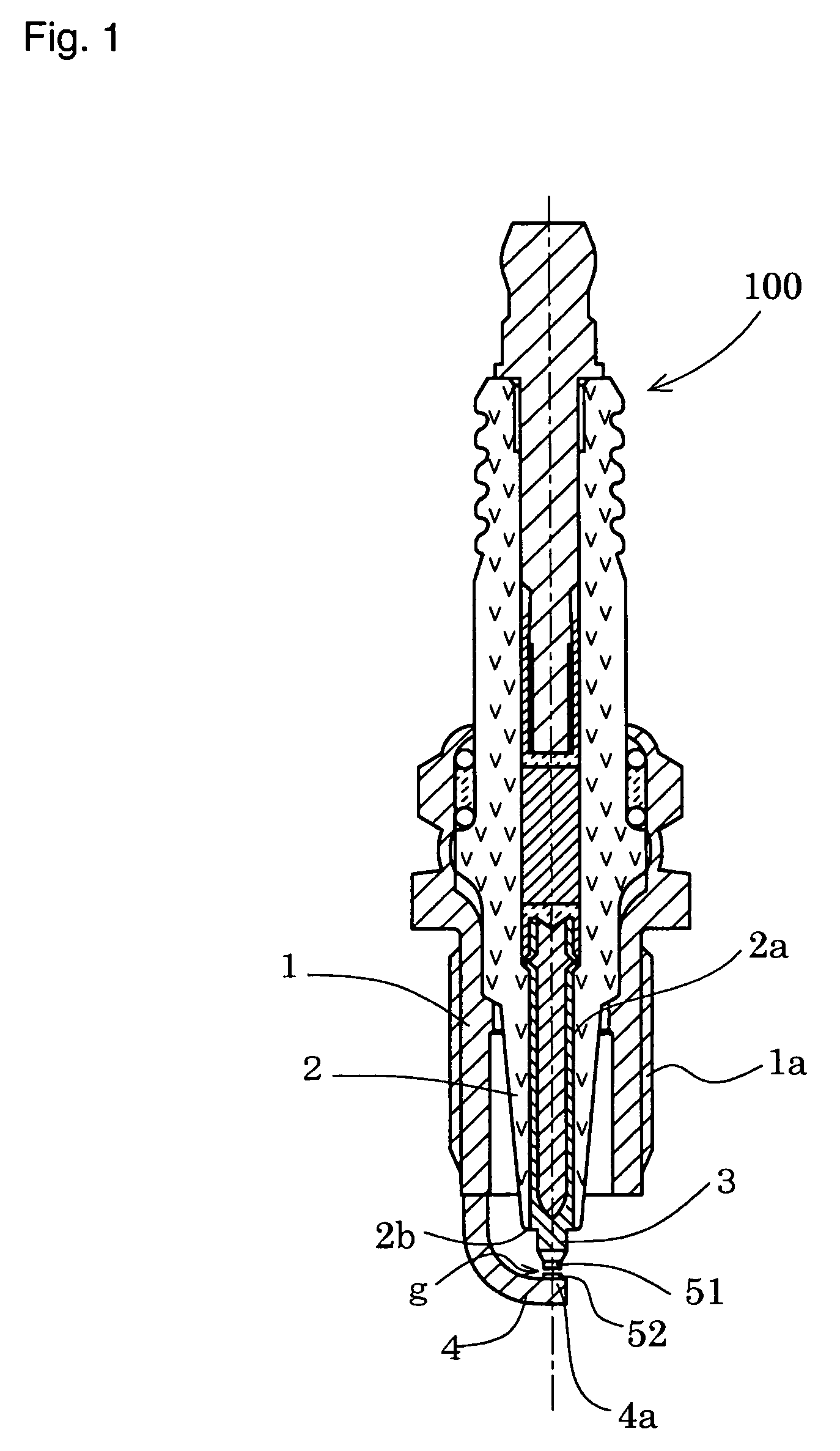

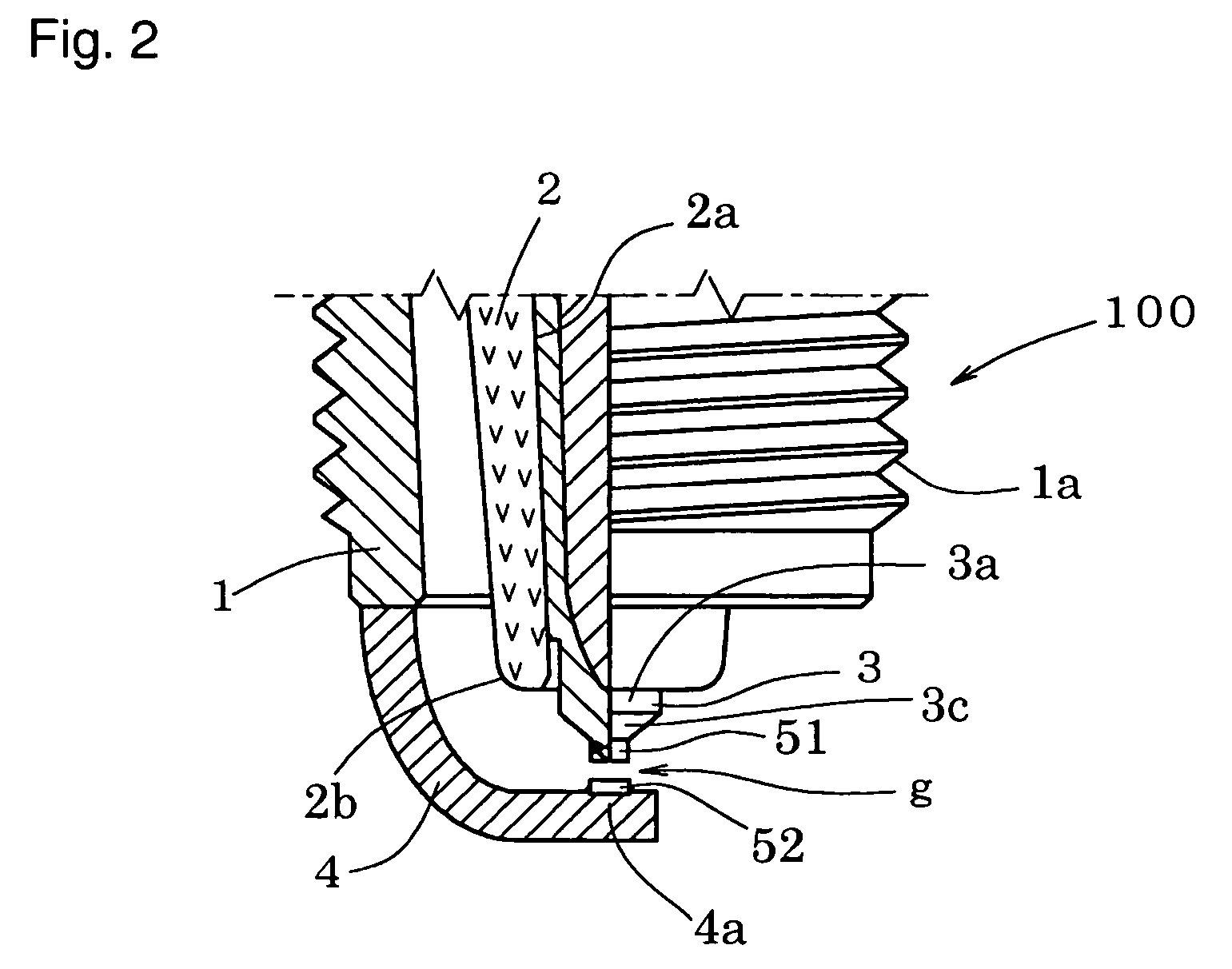

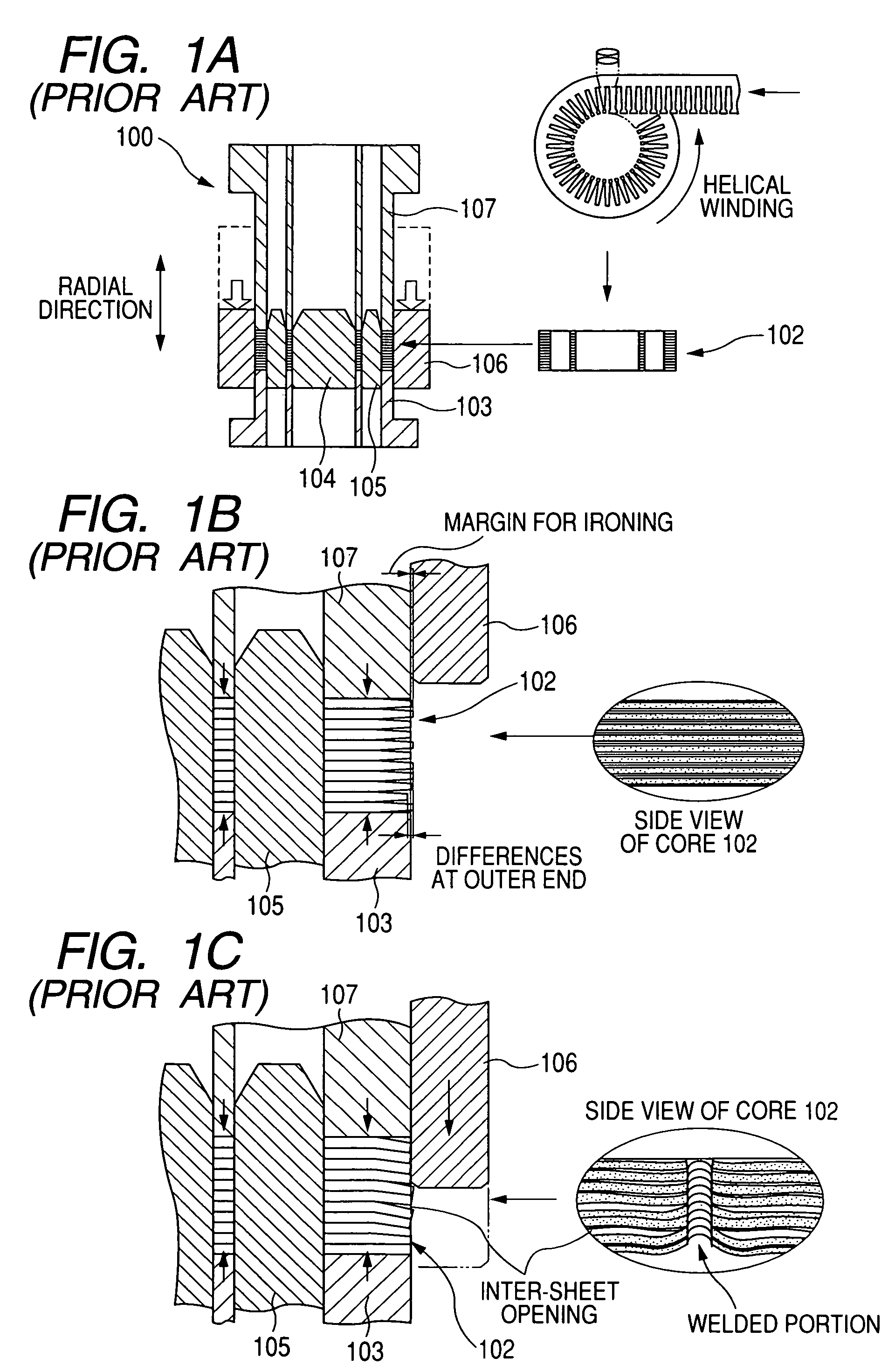

Method for manufacturing noble metal electric discharge chips for spark plugs

ActiveUS7131191B2Suppress oxidation volatilityRemarkable effectContact member manufacturingSpark gapsIridiumPlatinum

In a wire drawing process for forming a wire rod containing iridium as a main component and which further contains nickel and at least one of platinum, rhodium and ruthenium, and having a cross-sectional area of not smaller than 0.05 mm2 and not larger than 1.2 mm2. The worked material is continuously heated red hot and / or white hot in a heating region 103 extending up to 60 mm from the work inserting surface 101a of a die 101 in a direction opposite that in which the work 102 moves, the work being heated to a temperature of 1000 to 1150° C. at a temperature measuring position 105 which is removed from the work inserting surface 101a by 20 mm. Furthermore, the temperature in the region 106 extending from the temperature measuring position 105 to the work inserting surface 101a is set to not lower than 1000° C., and the wire drawing rate is set to 300 to 1600 mm / min.

Owner:NGK SPARK PLUG CO LTD

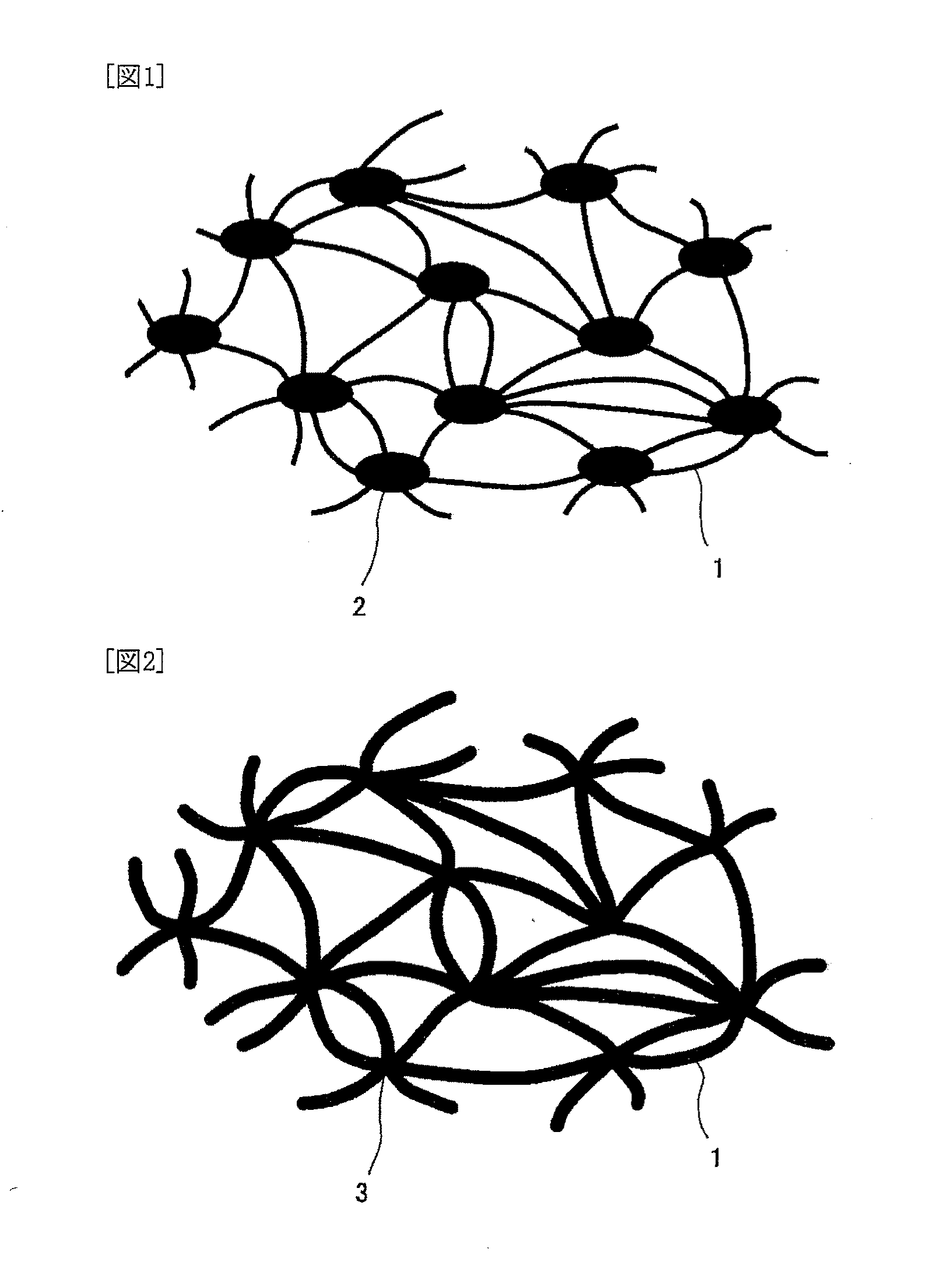

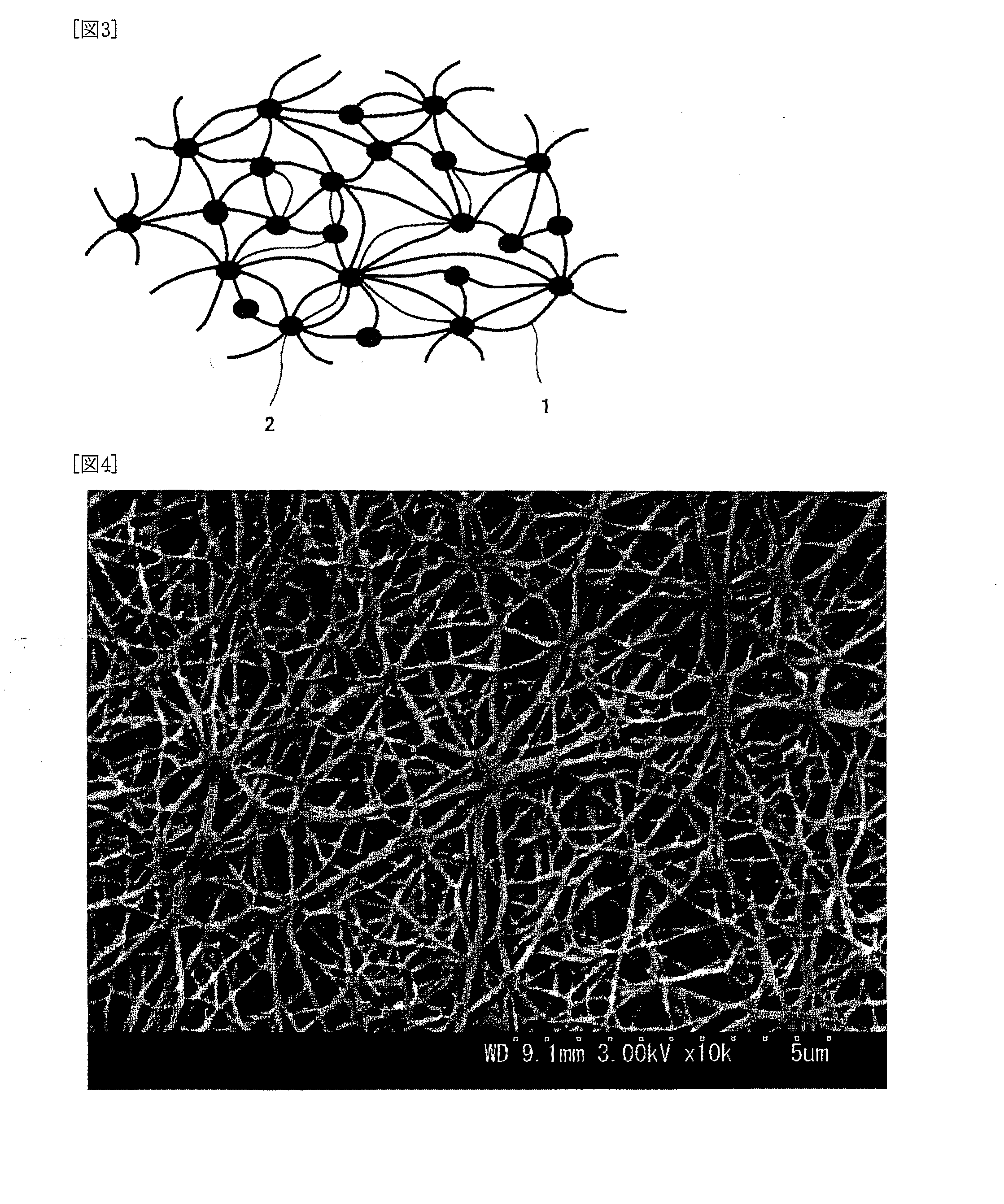

Expanded Porous Polytetrafluoroethylene Film-Laminated Sheet, and Gasket Composed of Said Sheet

ActiveUS20100283214A1Improve creep resistanceImprove adhesionBaby linensAdhesivesTetrafluoroethyleneVolumetric Mass Density

The laminated sheet of this invention is a sheet including expanded porous polytetrafluoroethylene films laminated by thermal compression bonding, wherein the sheet has a specific surface area of 9.0 m2 / g or larger and a density of from 0.4 g / cm3 to lower than 0.75 g / cm3, thereby making it possible to improve both the creep resistance and the adhesiveness between the films of the expanded porous PTFE film-laminated sheet.

Owner:W L GORE & ASSOC GK

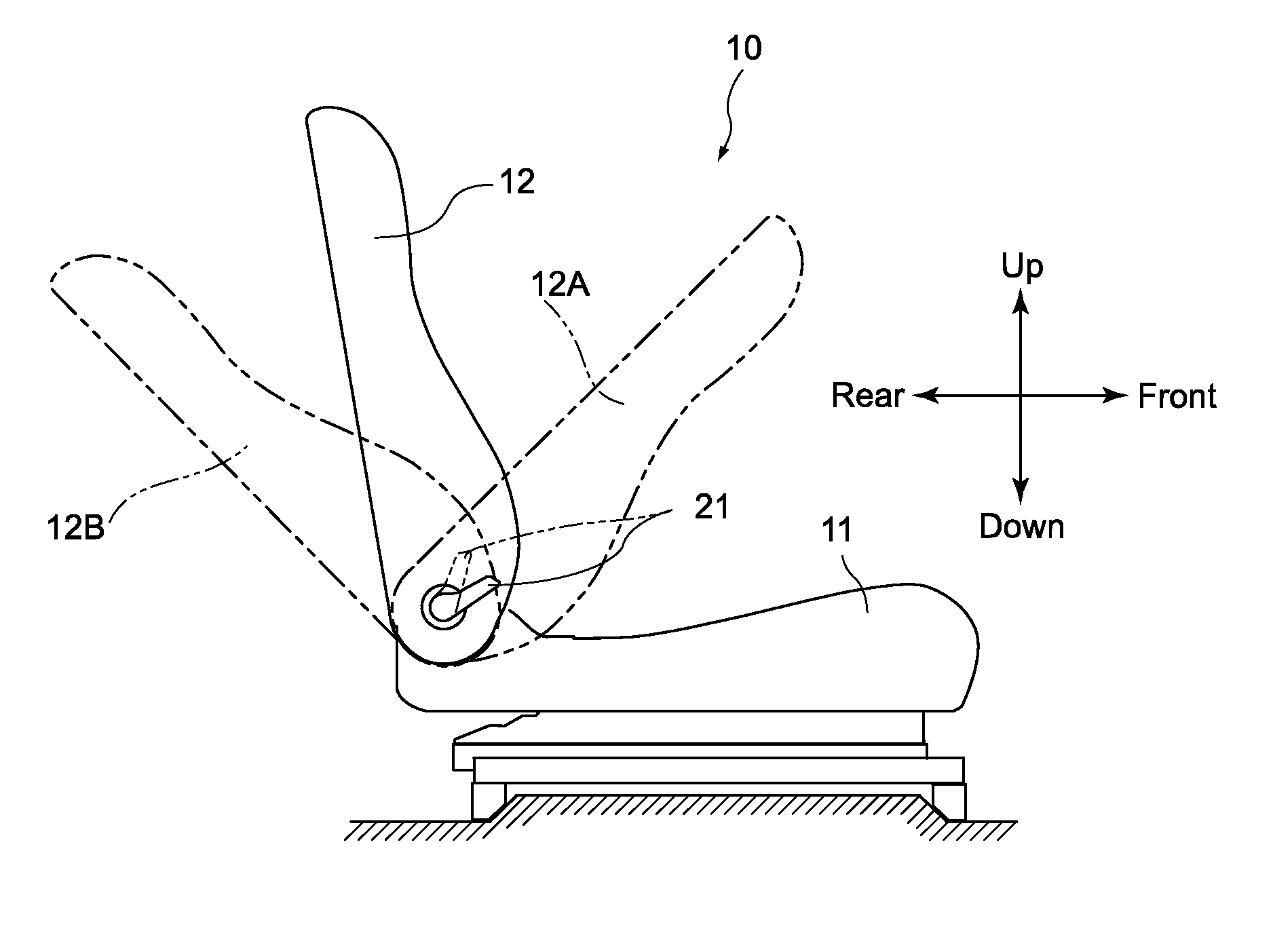

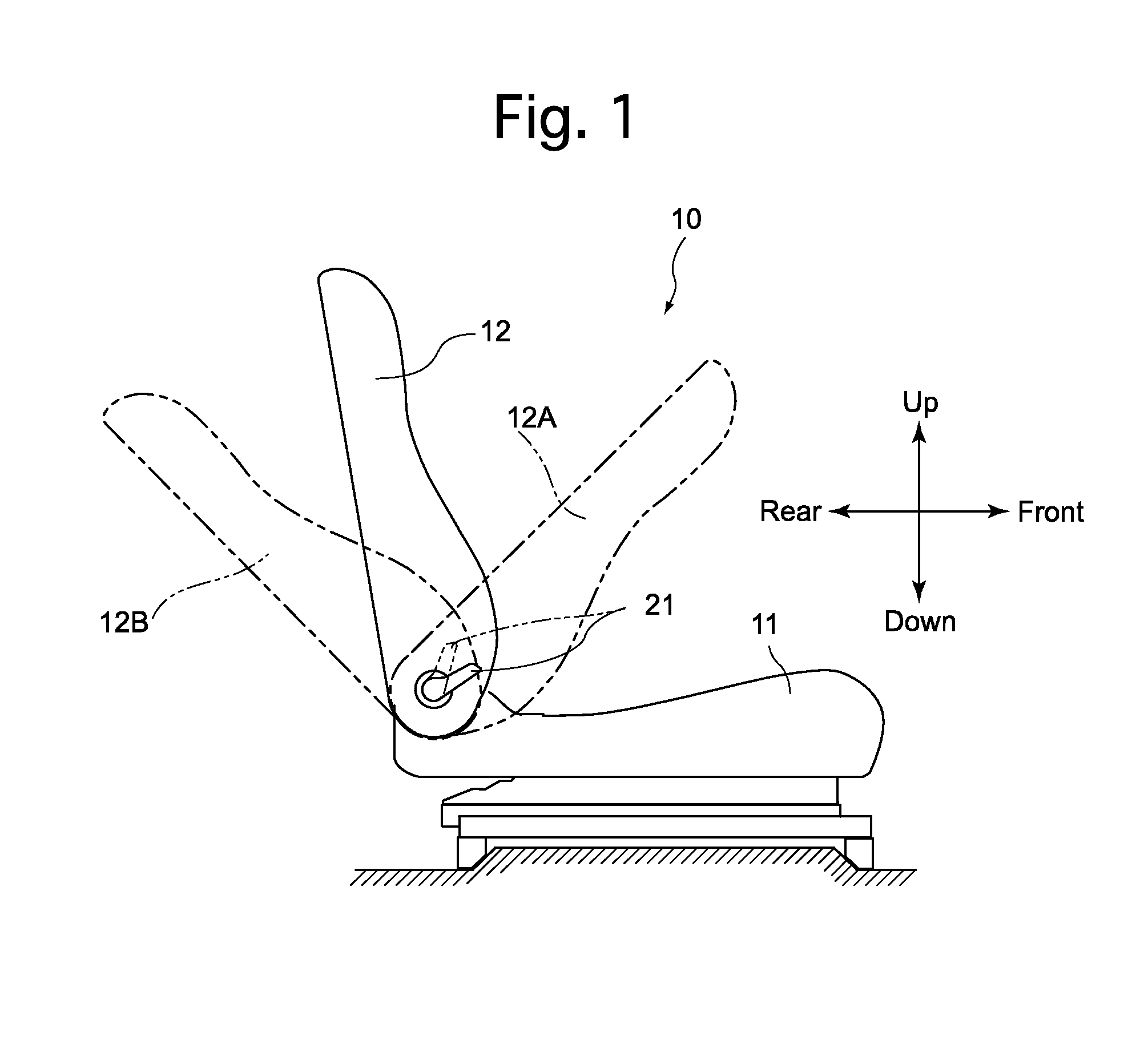

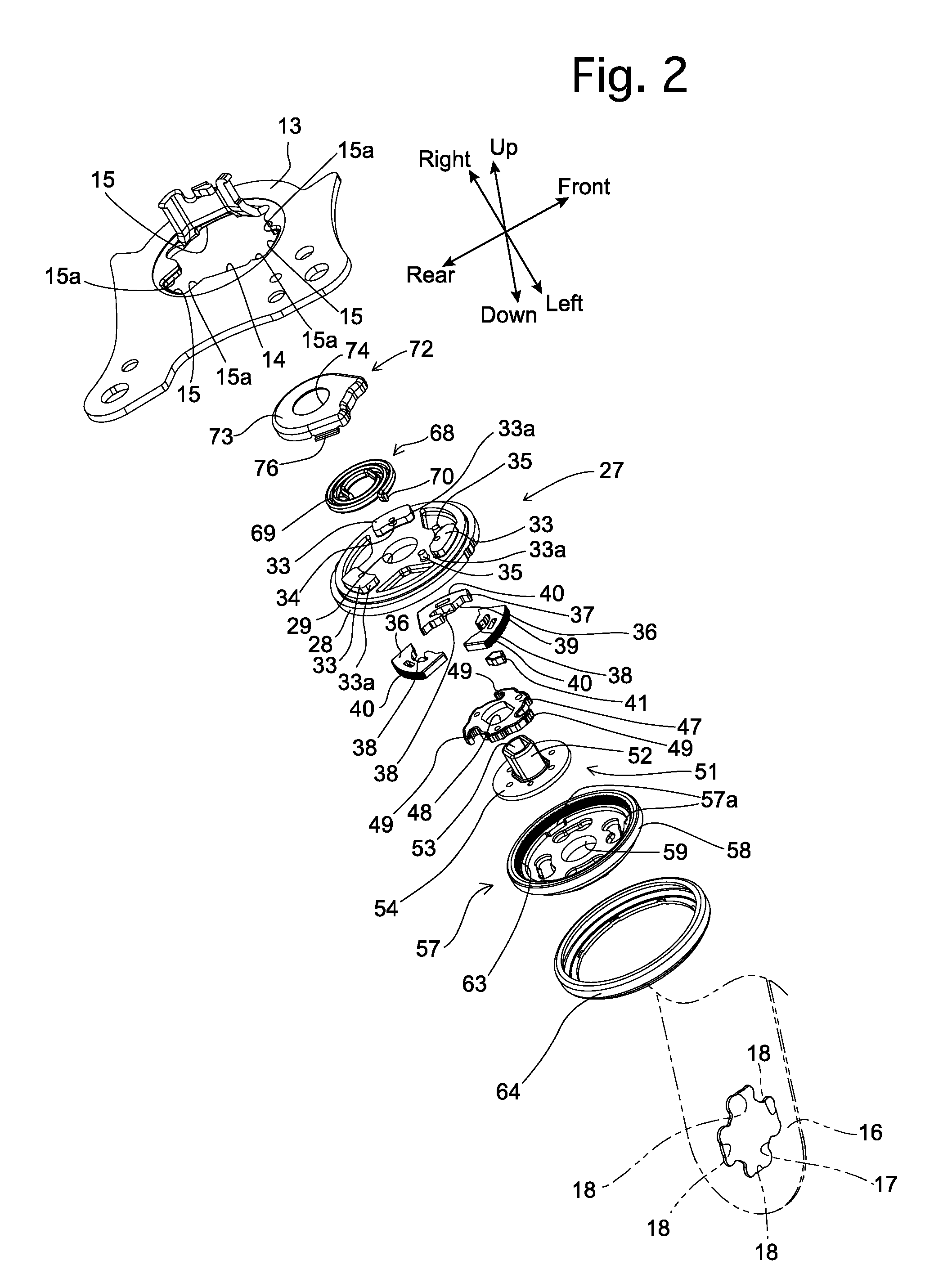

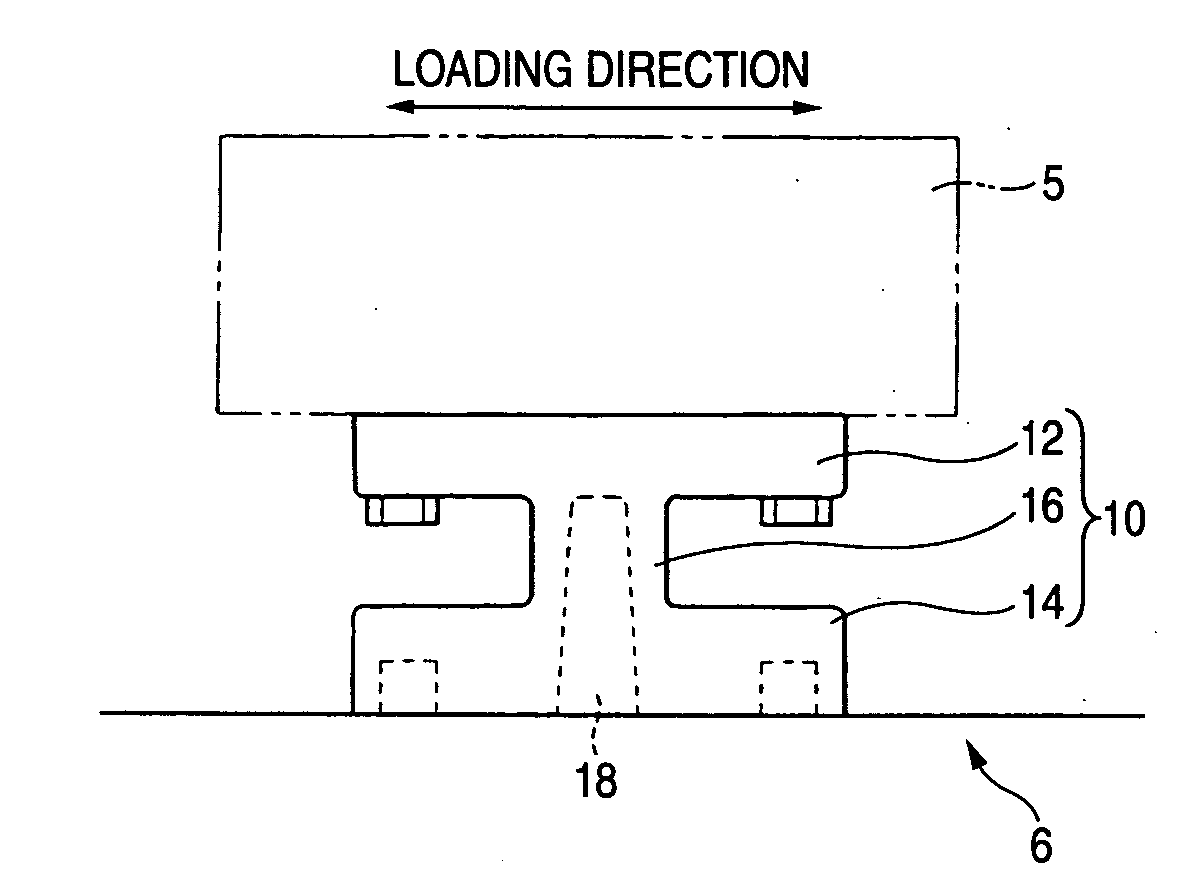

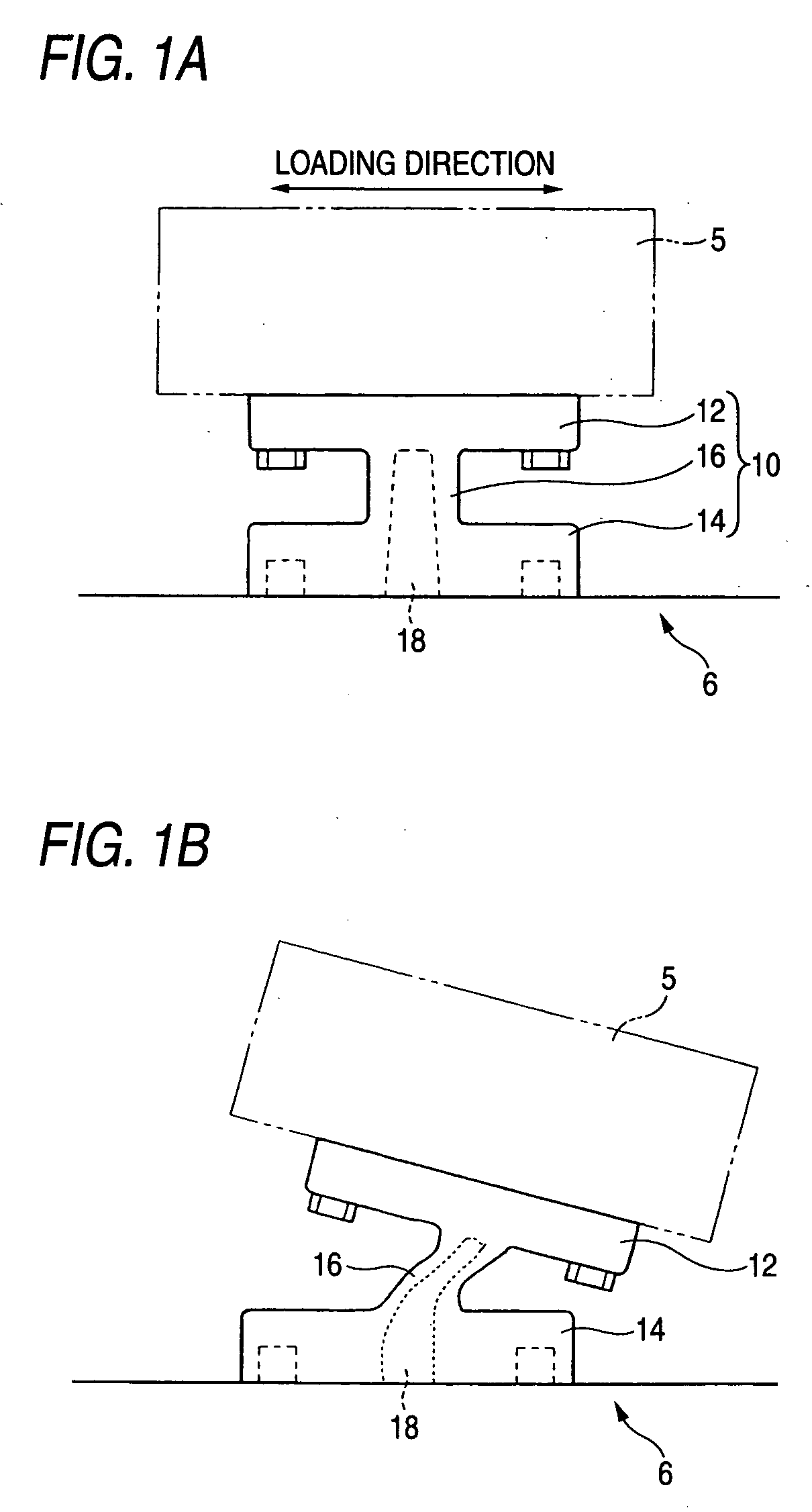

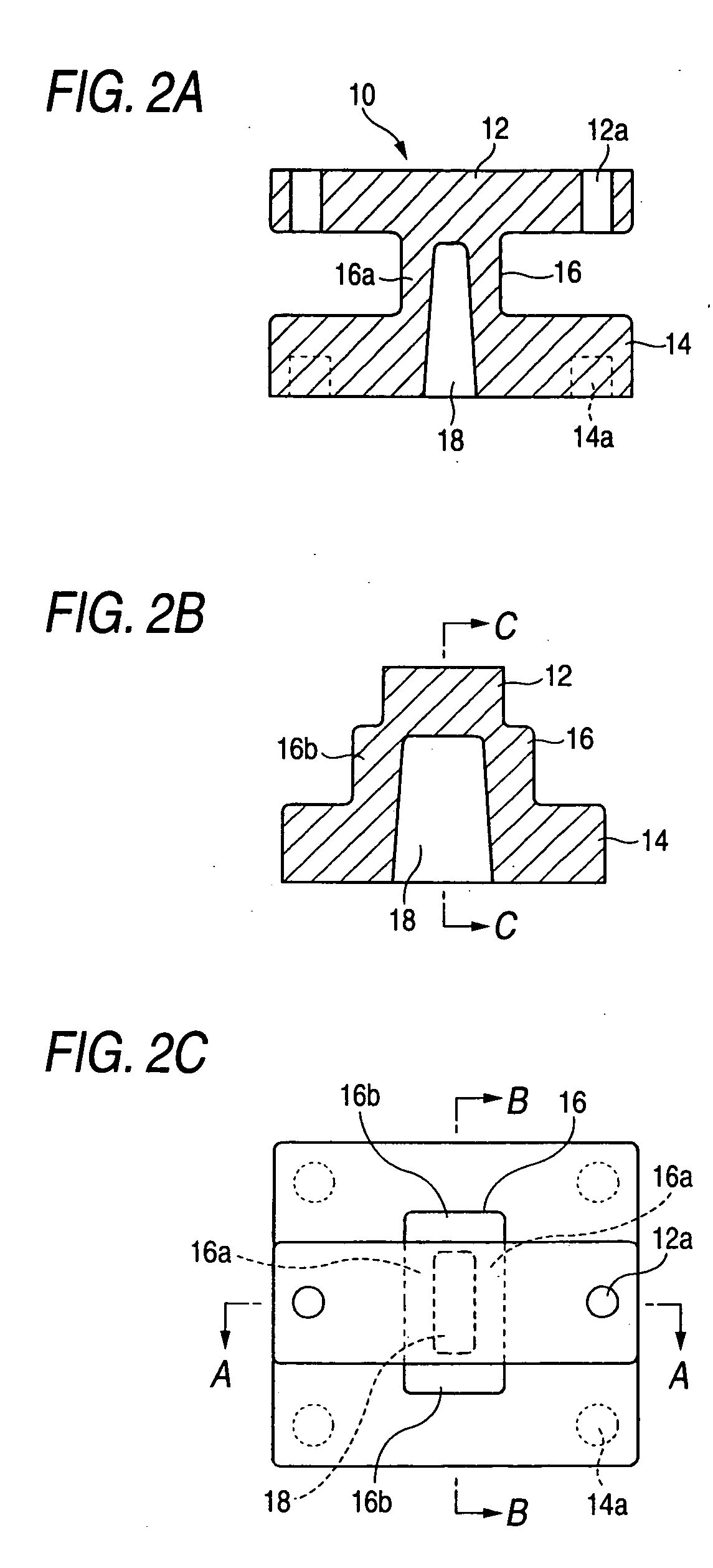

Seat reclining apparatus

ActiveUS20140077537A1Easy plastic deformationReduce the possibilityVehicle seatsPedestrian/occupant safety arrangementCamMechanical engineering

A seat reclining apparatus includes a base plate, a ratchet plate, a lock member guided by a guide groove of the base plate between engaged and disengaged positions, a first cam between the base plate and the ratchet plate, and a second cam which moves toward and presses the lock member to an engaged position by the first cam when the first cam rotates from the unlocked to locked positions. The second cam includes a surface contact portion which comes in surface contact with a guide surface in the guide groove, an engaging portion which is pressed by the first cam, and a pressing portion which presses a pressed portion of the lock member. One and the other of the pressing portion and the pressed portion respectively includes a flat surface and a curved surface that is convex toward the flat surface.

Owner:SHIROKI KOGYO CO LTD

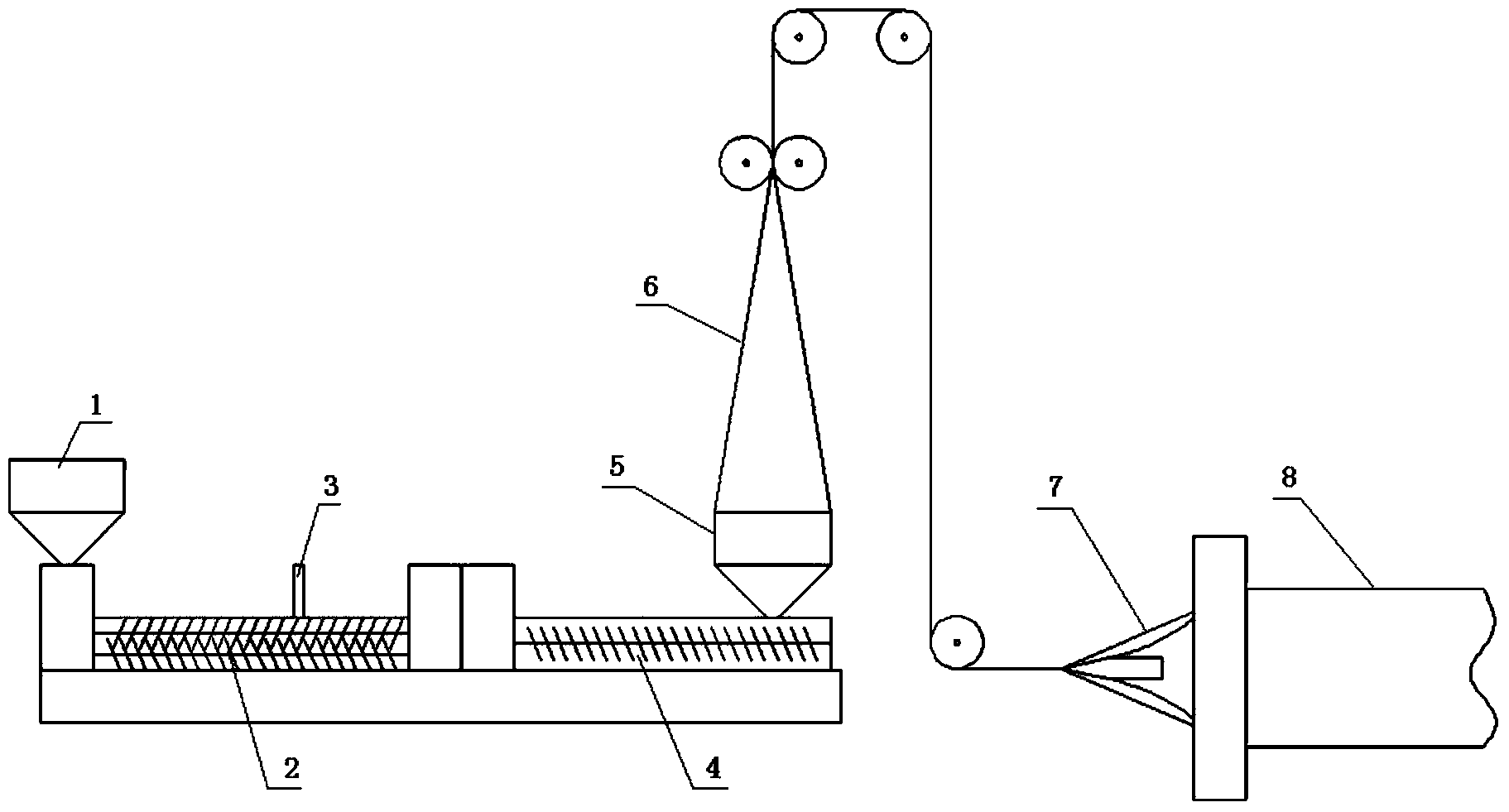

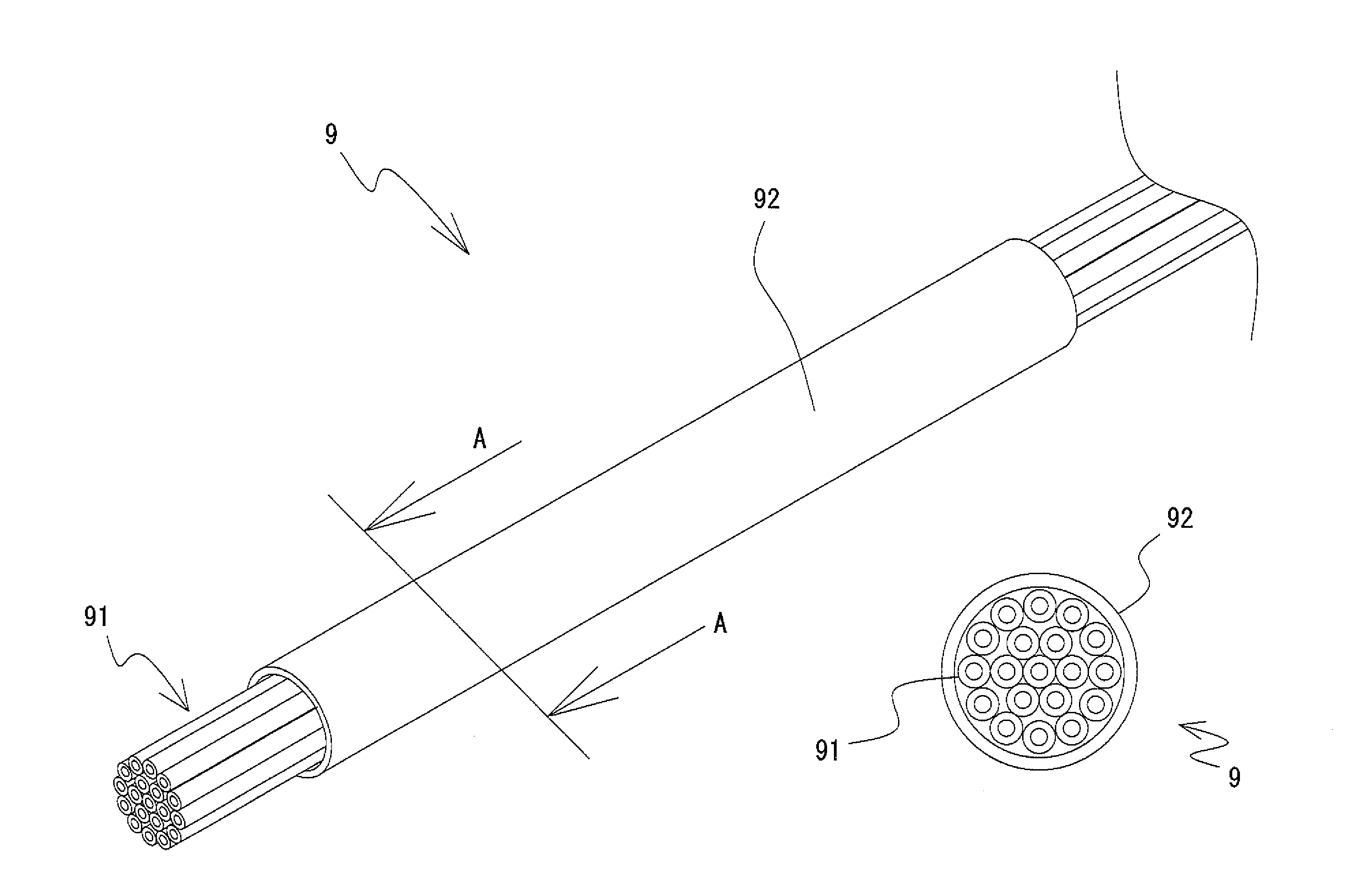

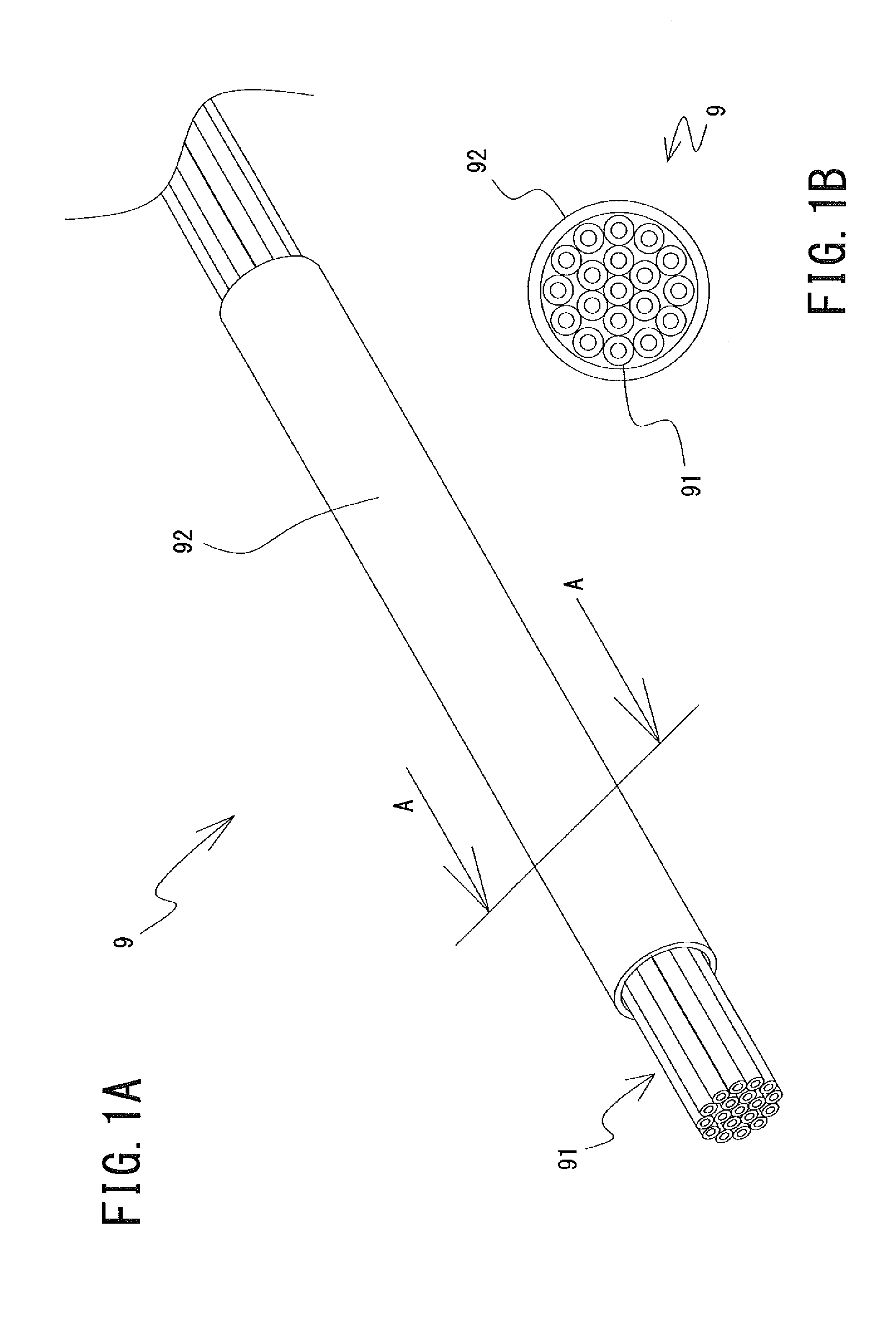

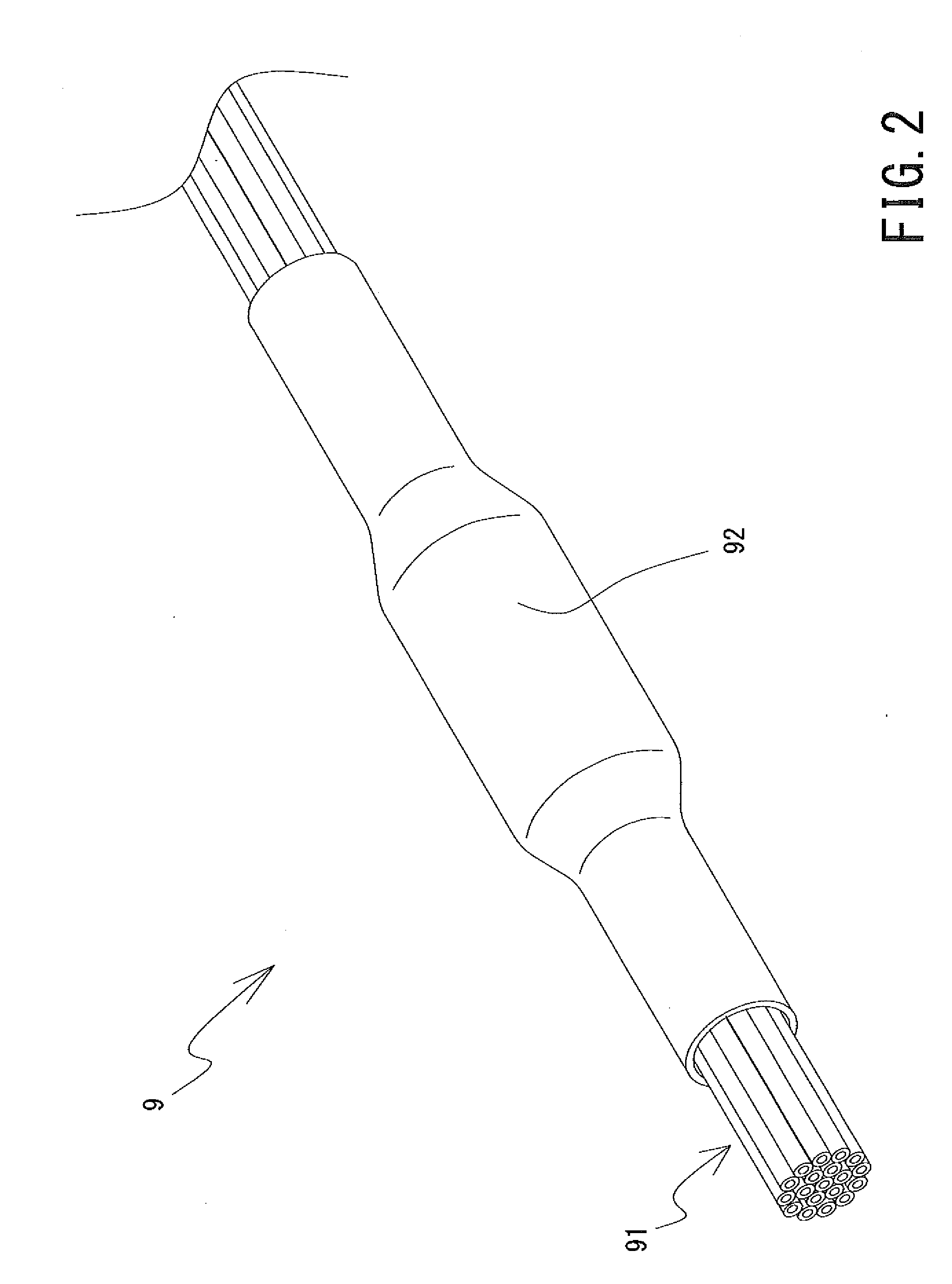

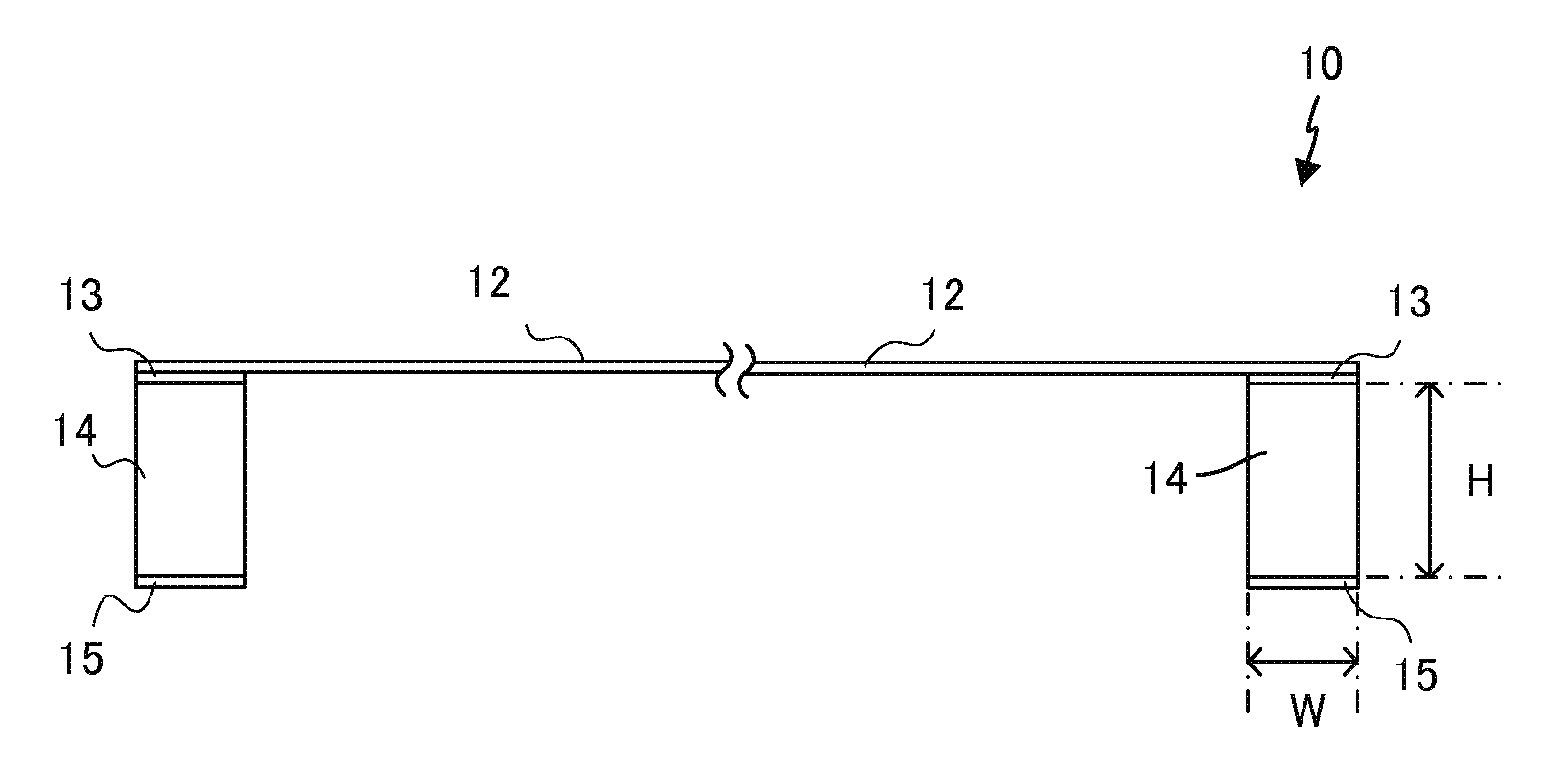

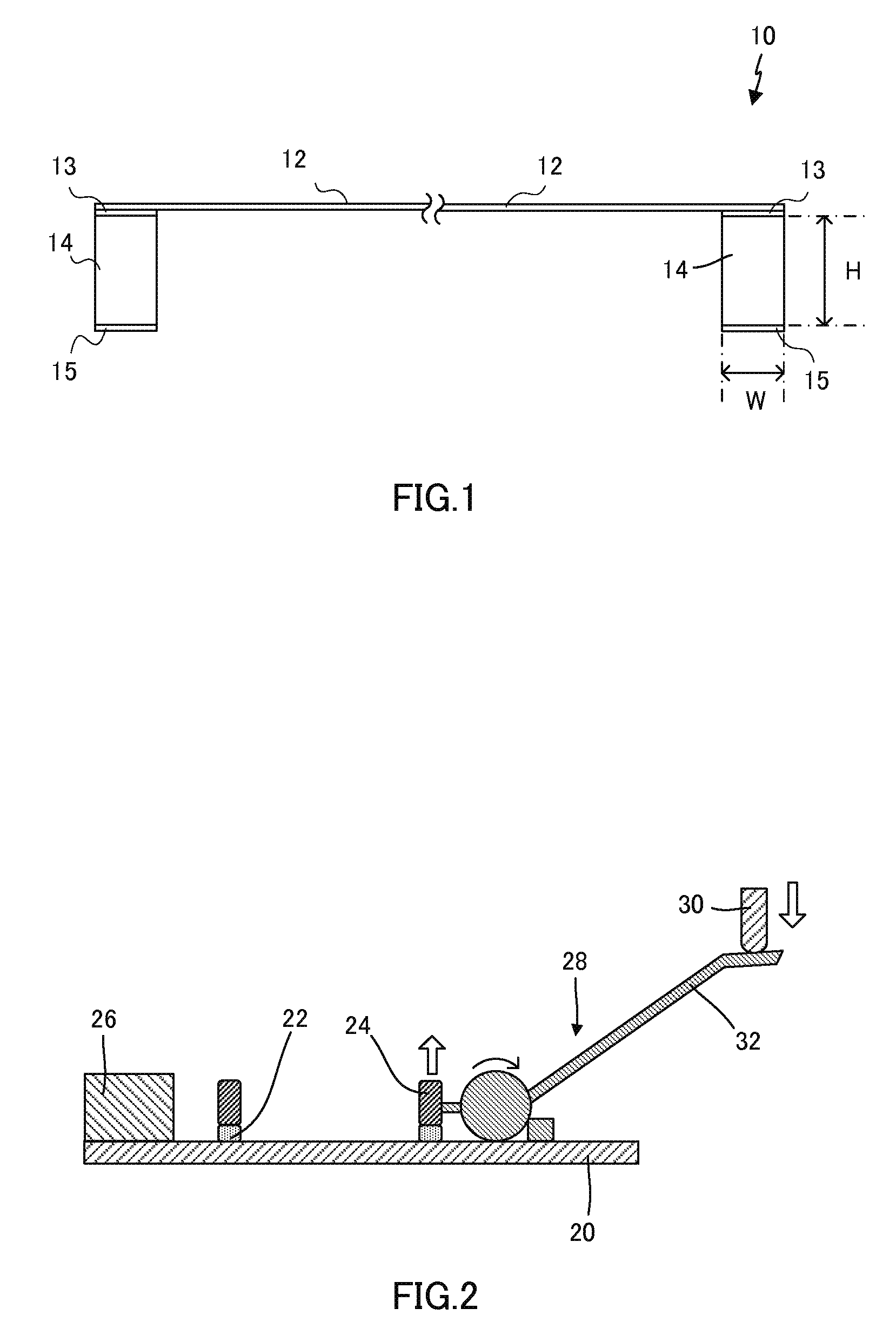

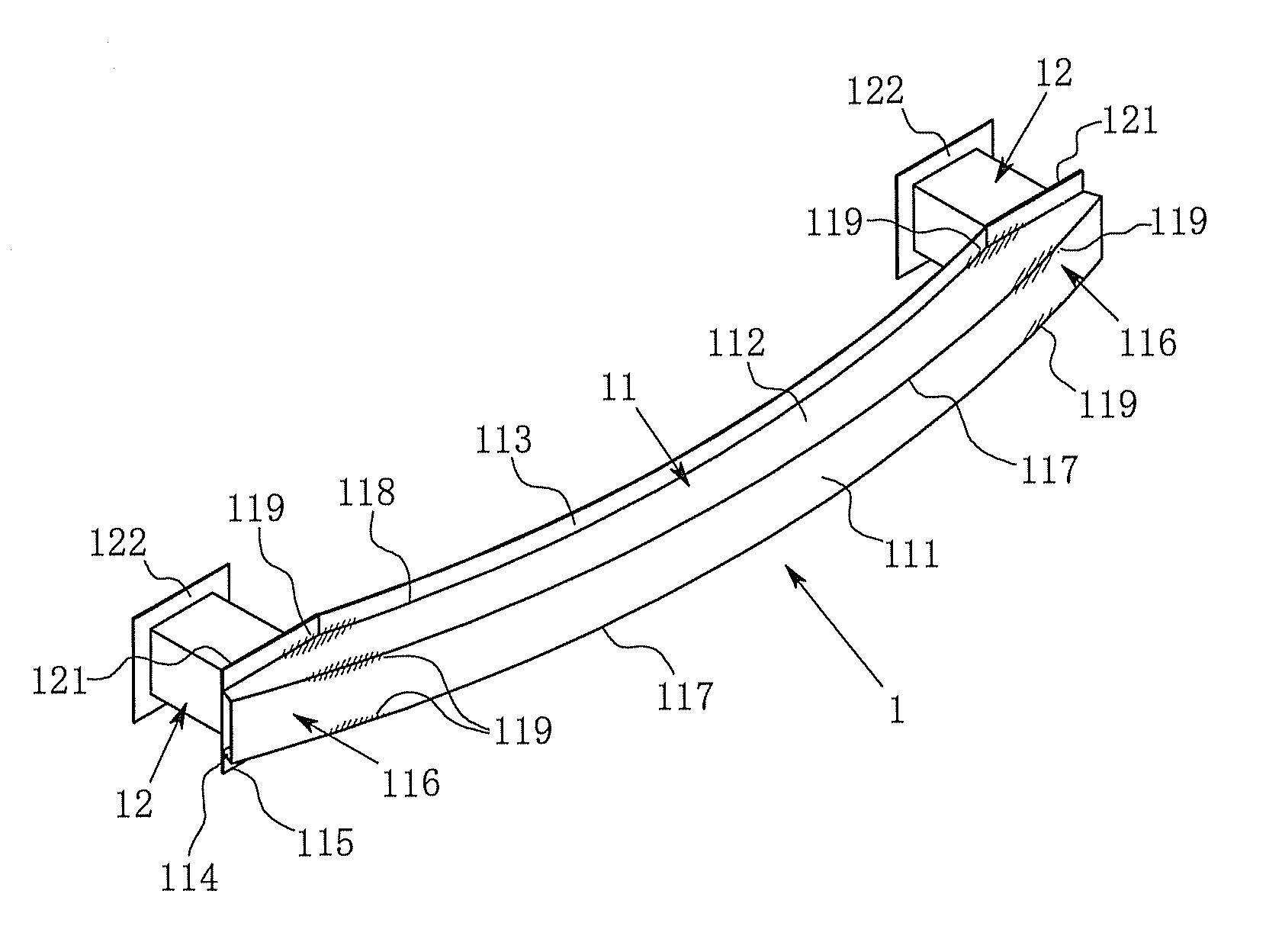

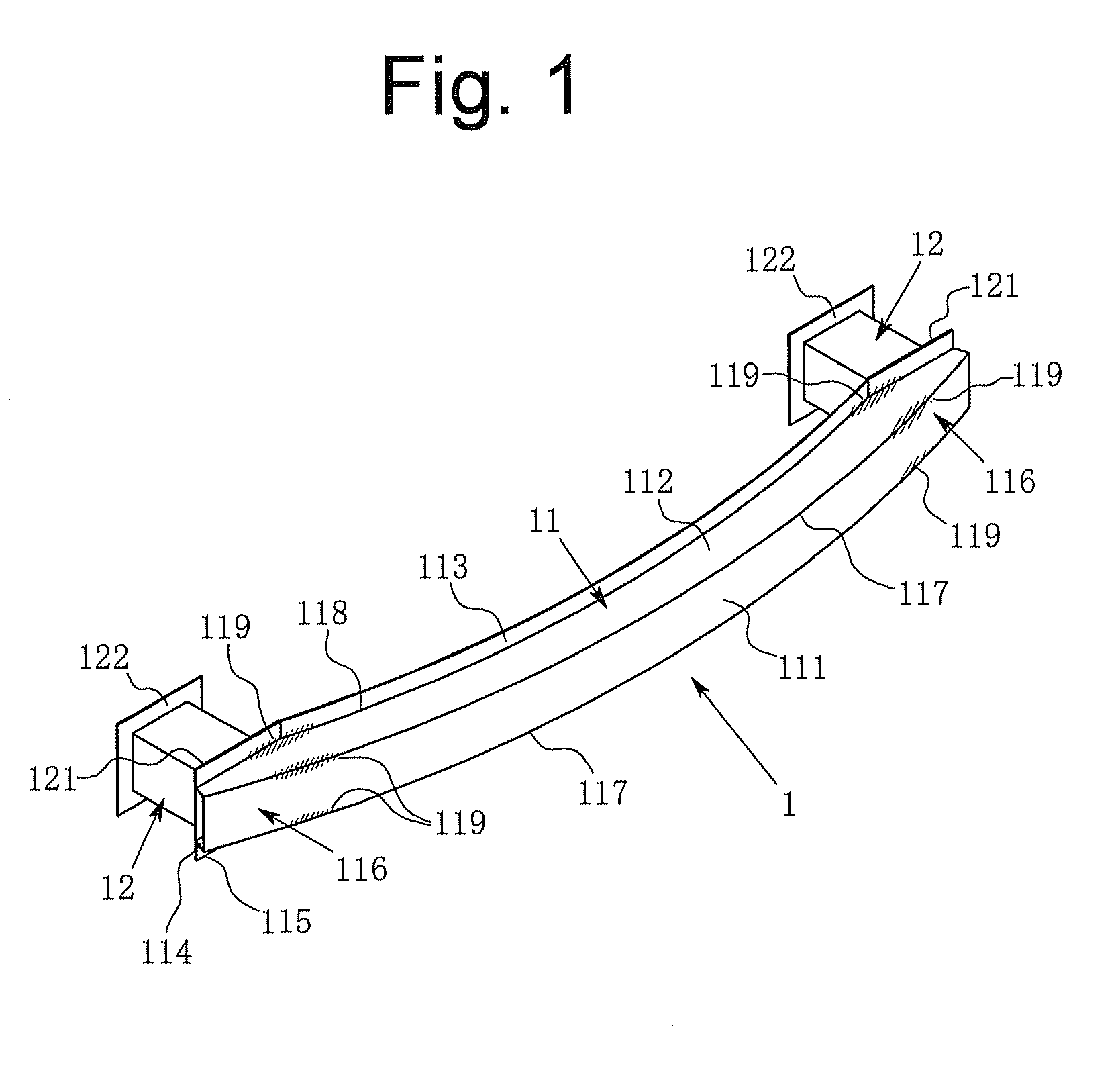

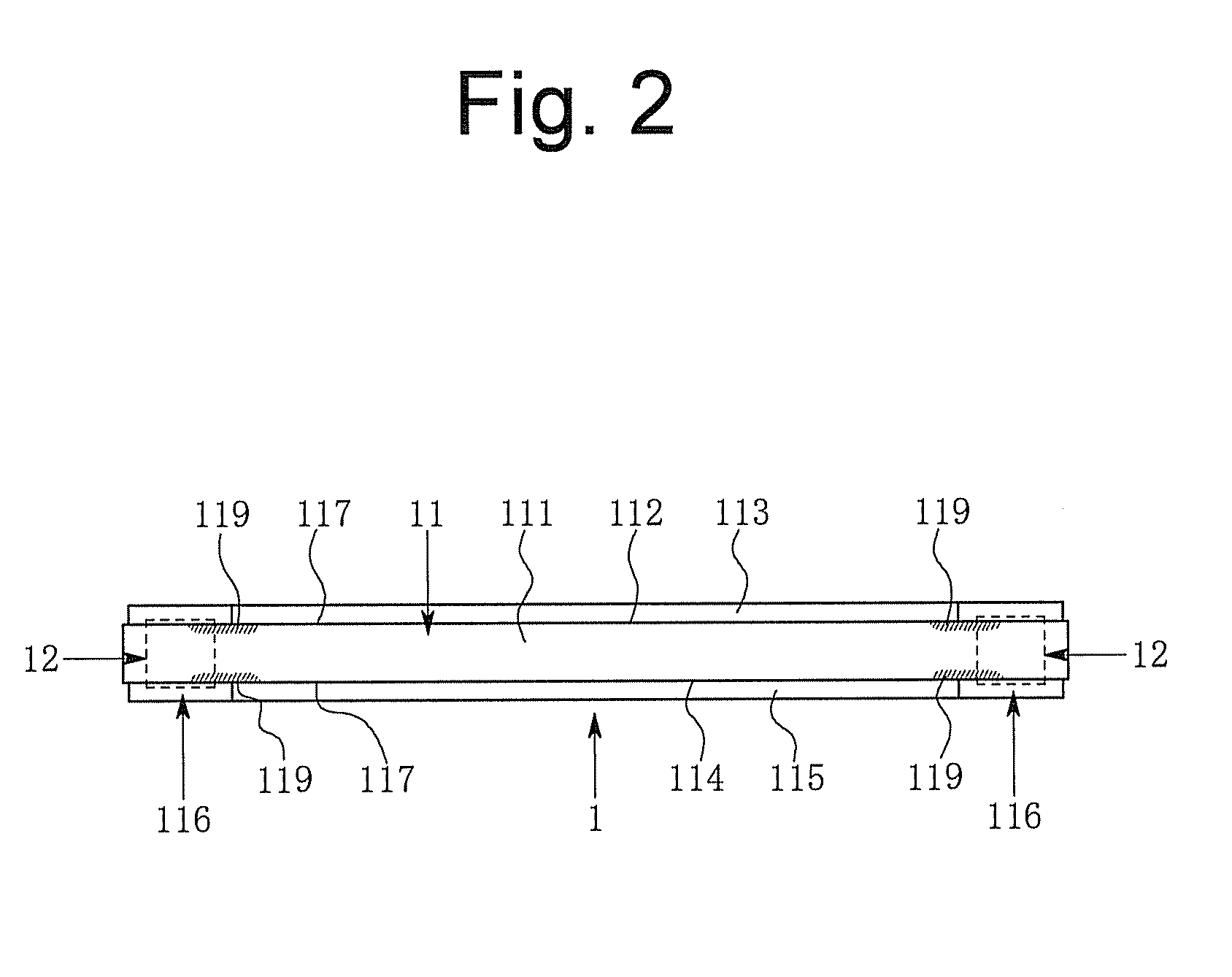

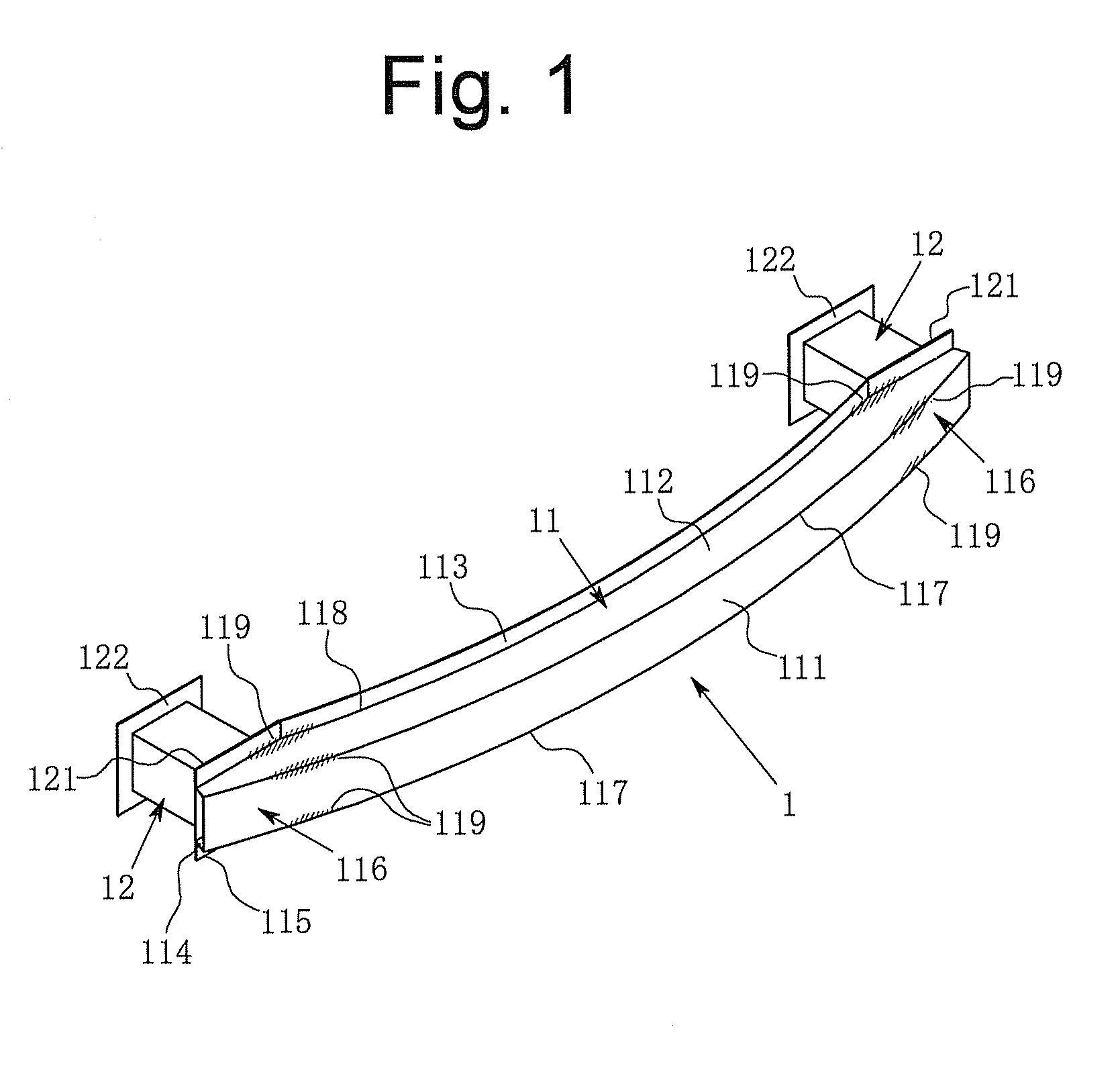

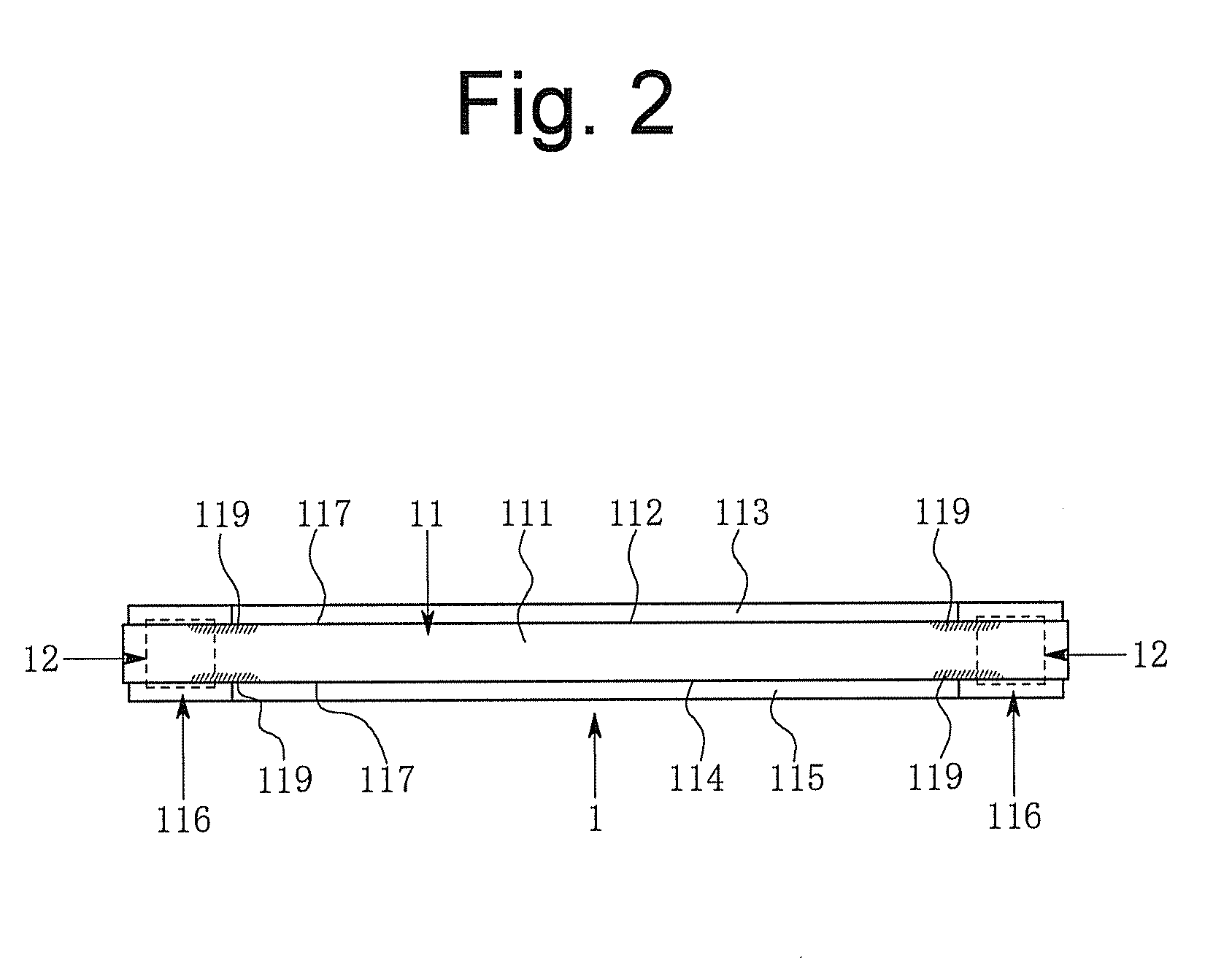

Wire harness, wire harness manufacturing method and wire harness manufacturing apparatus

InactiveUS20130306370A1Reduce manufacturing costReduce in quantityInsulated cablesCoatingsEngineeringElectric wire

A wire harness manufacturing method prevents inadvertent deformation of thermoplastic material and separation of thermoplastic material. A predetermined part of an electric wire 91 is accommodated in a through hole of a tubular body formed by connection between a first and second nest members (123, 124) of a nozzle (12), by integrally connecting first and second case body members (121, 122) of the nozzle (12), with the predetermined part of the electric wire 91 therebetween. An approximately tubular covering member (92) covering the predetermined part of the electric wire (91) is molded integrally with the thermoplastic material, by discharging thermoplastic material plasticized by a material plasticizing unit (11) from thermoplastic material discharge orifices (1213) and (1223) in the nozzle (12) to the outer periphery of the electric wire (91), while moving the electric wire (91) and the nozzle (12) relatively to each other.

Owner:AUTONETWORKS TECH LTD +2

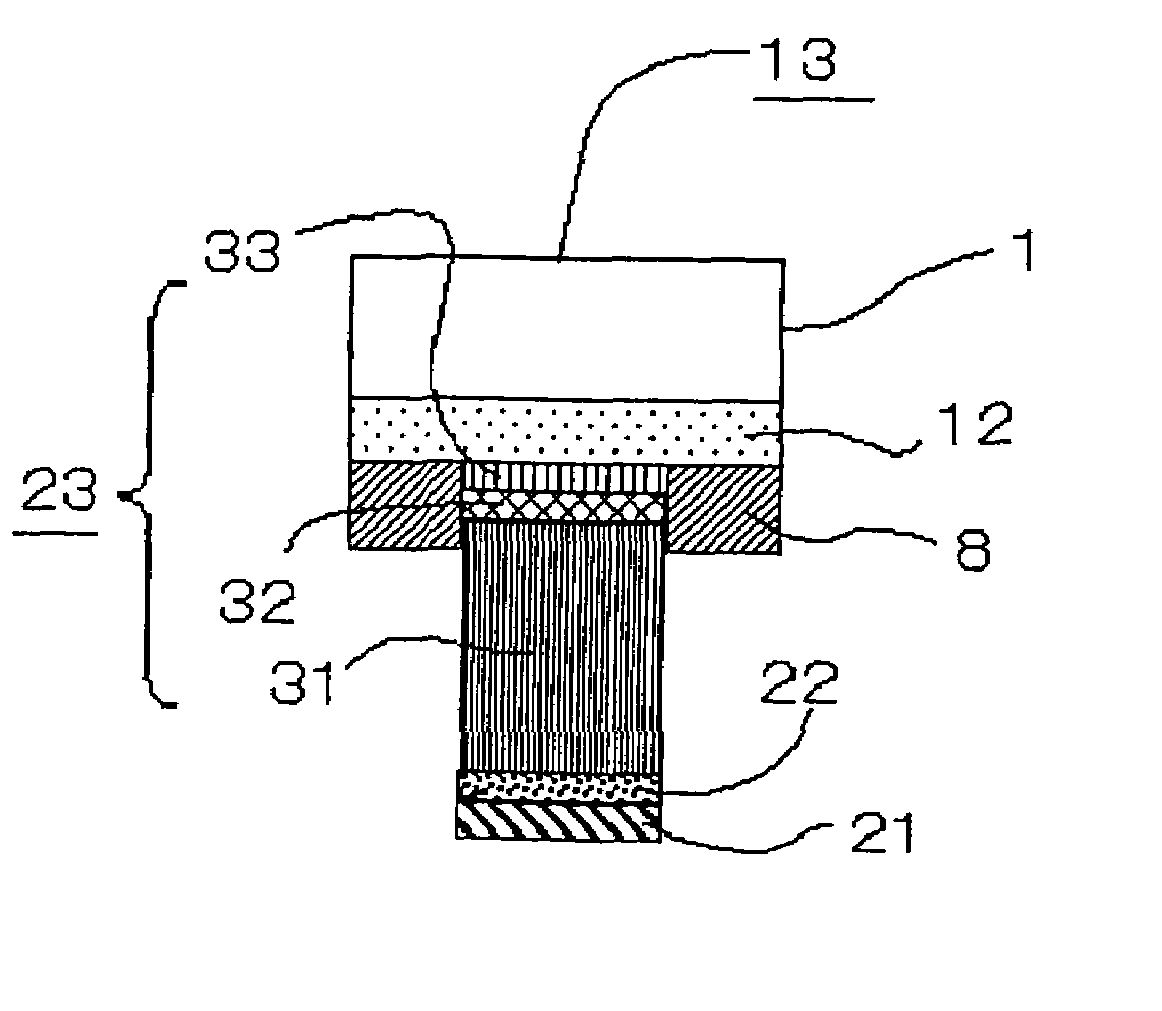

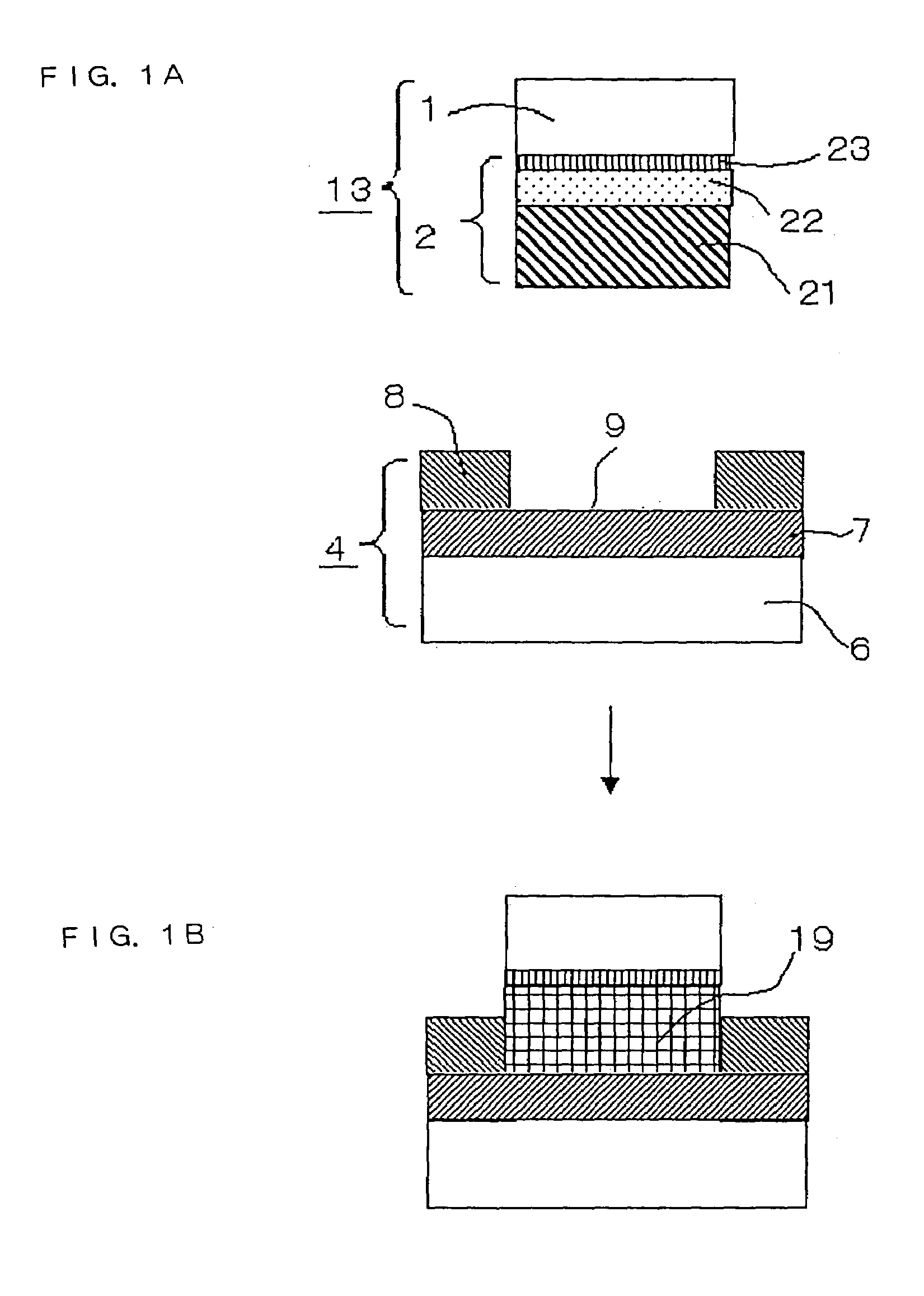

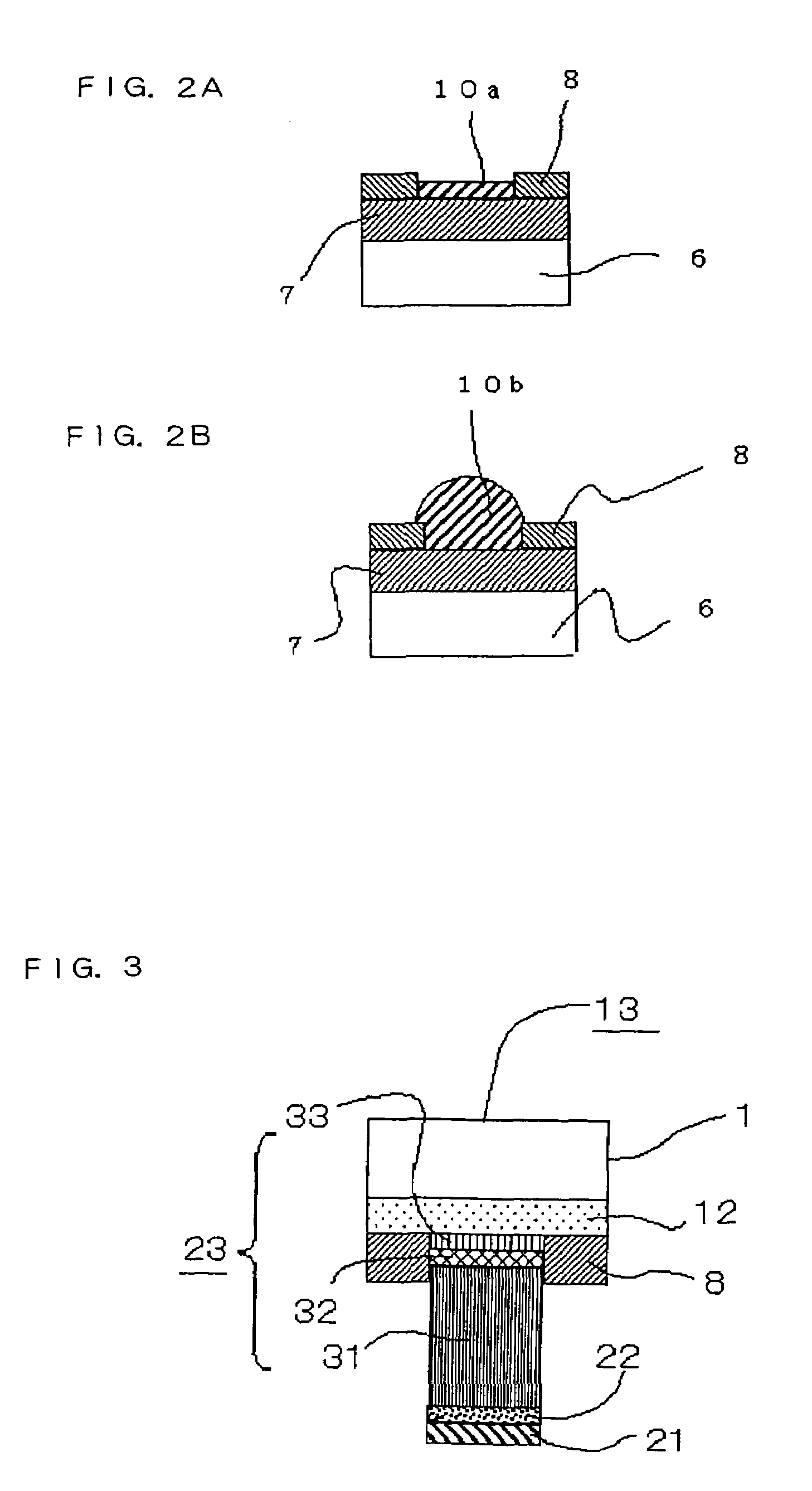

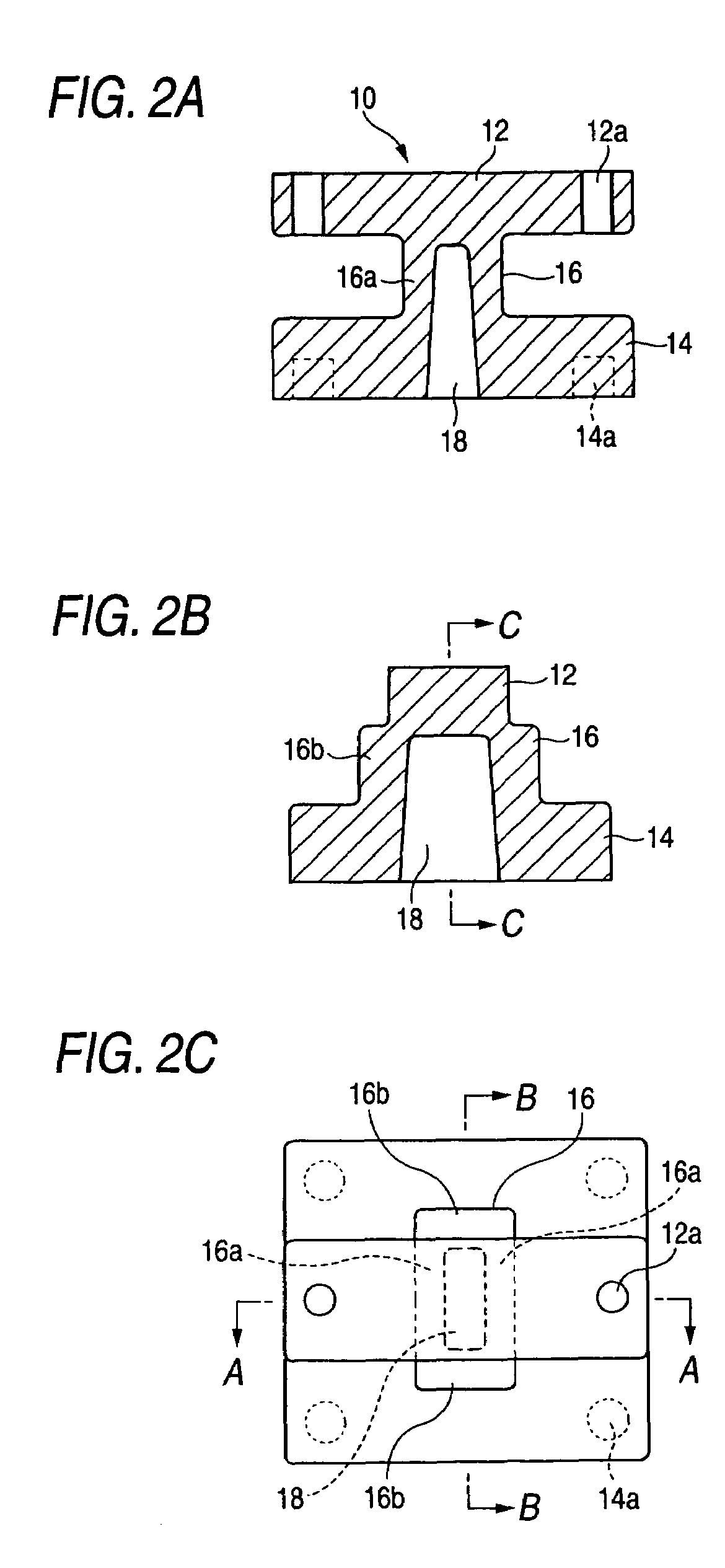

Metal electrode and bonding method using the metal electrode

InactiveUS7078330B2Easy plastic deformationReduce loadPrinted circuit assemblingSemiconductor/solid-state device detailsMetal electrodesMaterials science

A metal electrode is formed on a substrate. The metal electrode includes a first layer, a second layer, and a third layer lying, from an outermost surface of the metal electrode toward the substrate, in this order. The first layer contains tin as a principal constituent and the second layer contains a metallic element which produces an eutectic reaction with tin, wherein the melting point of the first layer is higher than the melting point of the second layer. The third layer is an underlying metallic layer for the first and second layers.

Owner:MITSUBISHI ELECTRIC CORP

Pellicle and mask adhesive agent for use in same

ActiveUS8945799B2Easy plastic deformationEasy to operateVinyl aromatic copolymer adhesivesOriginals for photomechanical treatmentElastomerPolymer science

A pellicle which has a mask adhesive layer that can be plastic-deformed readily particularly at a temperature at which exposure to light is carried out, rarely provides a residue of an adhesive agent upon the removal of the mask adhesive layer from a mask and has good handling properties, and which can prevent the position gap of a pattern. The pellicle comprises a pellicle frame, a pellicle membrane and a mask adhesive layer containing a mask adhesive agent. The mask adhesive agent comprises 100 parts by mass of a thermoplastic elastomer (A) having a tan δ peak temperature of −20 to 30 DEG C and 20 to 150 parts by mass of an adhesiveness-imparting resin (B).

Owner:MITSUI CHEM INC

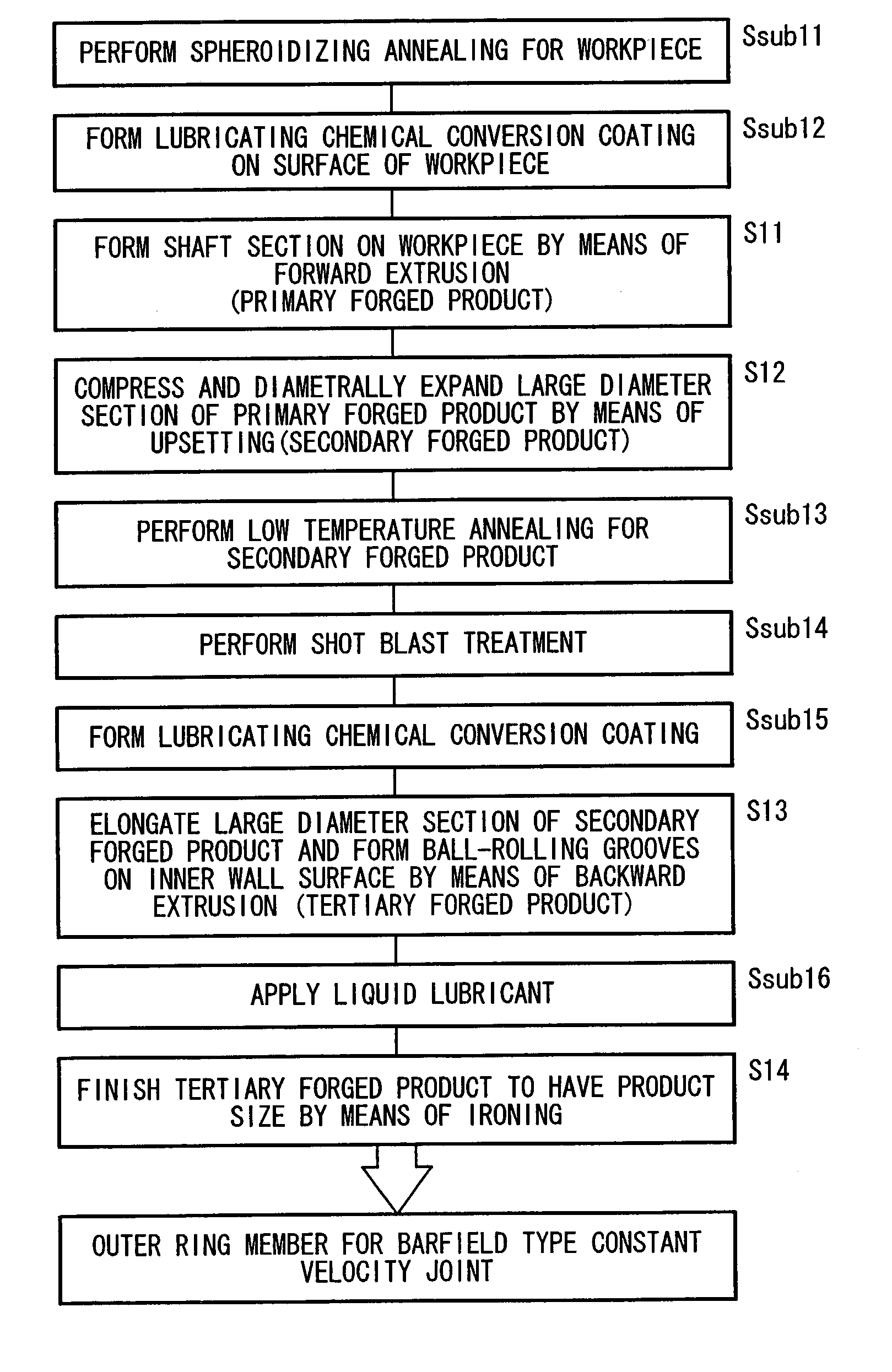

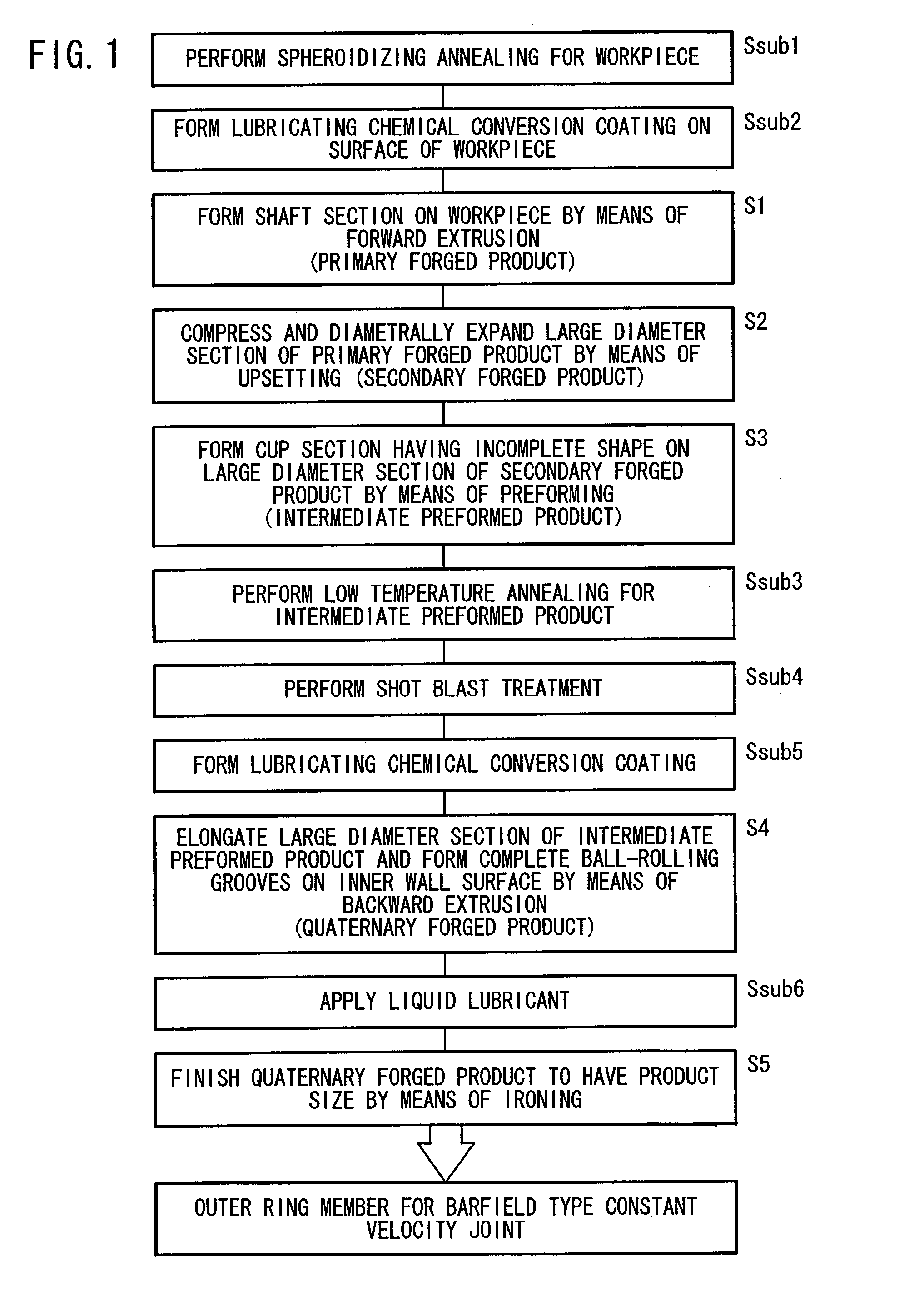

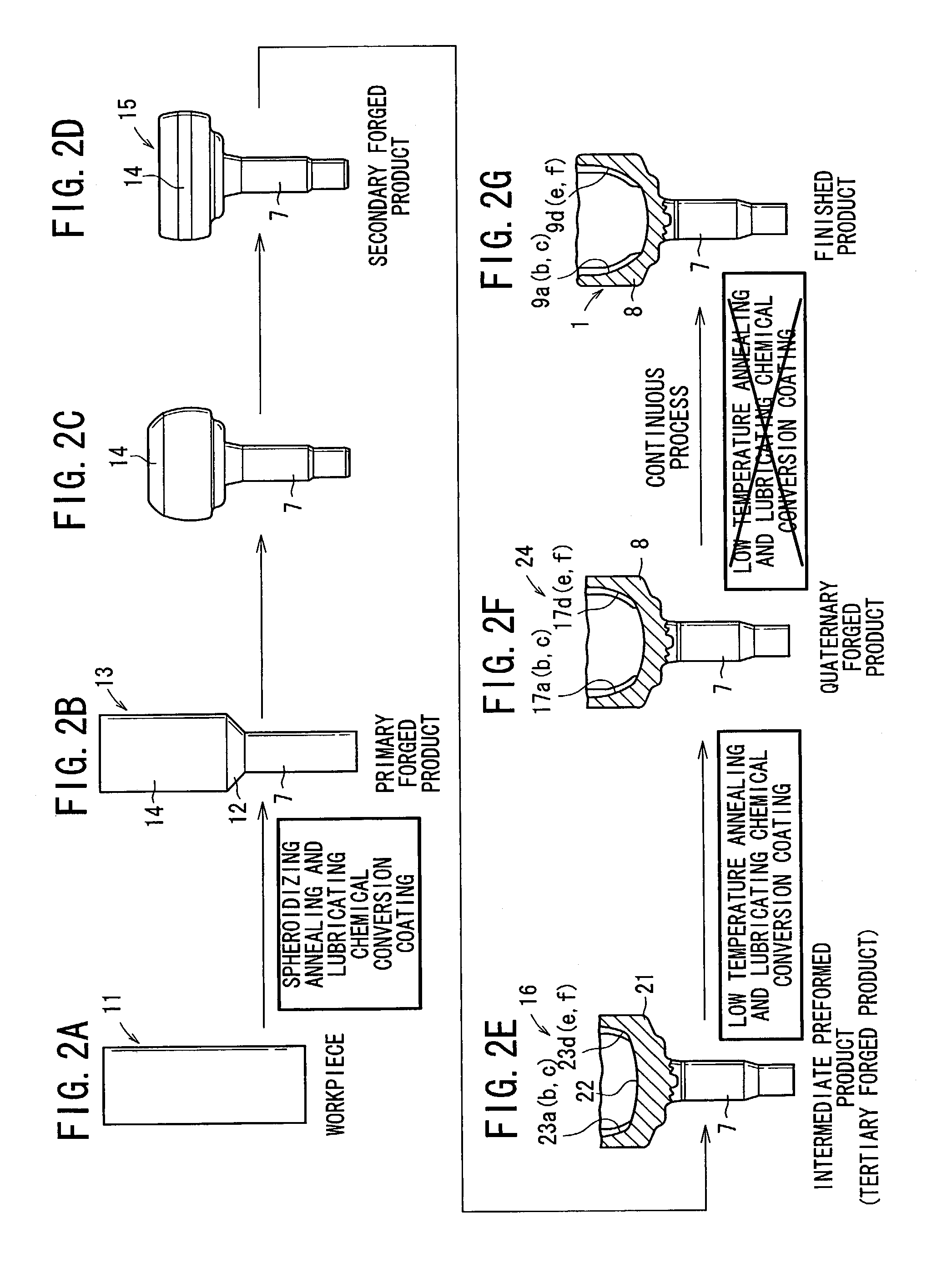

Outer ring member for constant velocity joint and method of manufacturing the member

InactiveUS7090729B2Improve production accuracyImprove production stabilityYielding couplingSolid state diffusion coatingProduct formationChemical conversion

An outer ring member for a constant velocity joint is manufactured. An intermediate preformed product having a cup section with an incomplete shape is formed by pressing a large diameter section without applying a low temperature annealing treatment and a lubricating chemical conversion coating treatment. Then, applying a low temperature annealing treatment and a lubricating chemical conversion coating treatment to the intermediate preformed product, thereafter a formed product having a cup section provided with ball-rolling grooves is formed by backward extrusion to the intermediate preformed product. Subsequently, the product is ironed before hardening, without applying a low temperature annealing treatment and a lubricating chemical conversion coating treatment to the formed product.

Owner:HONDA MOTOR CO LTD

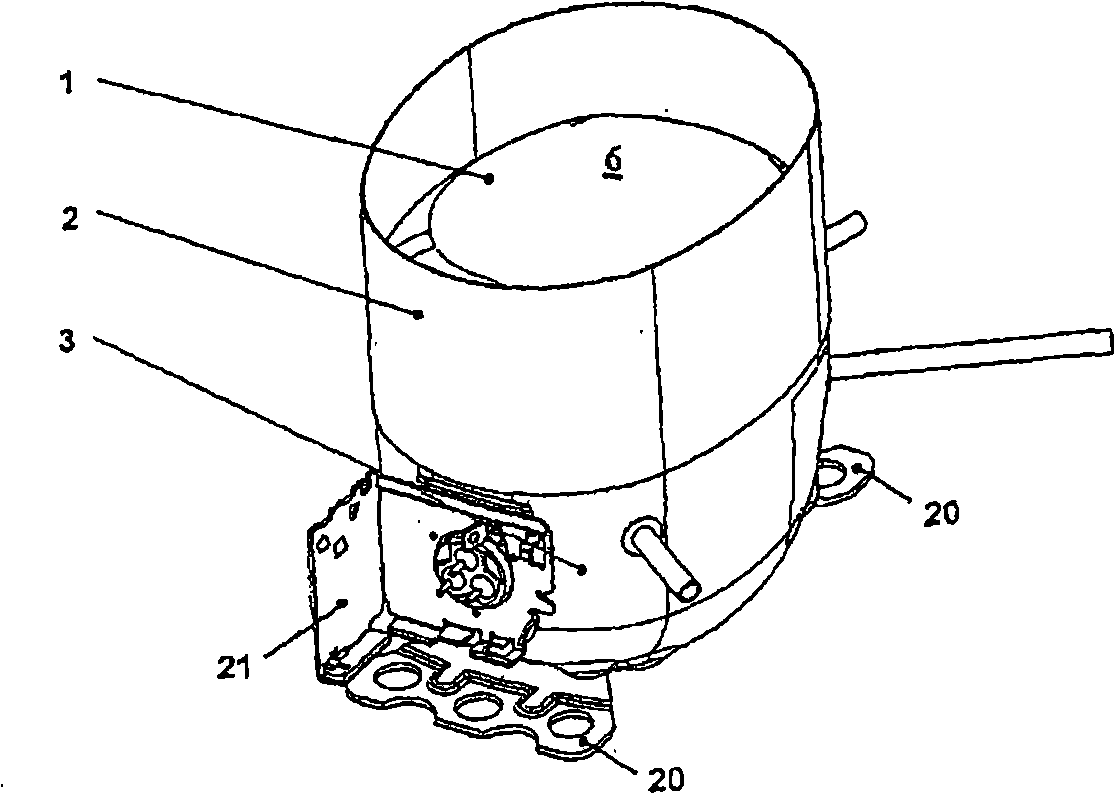

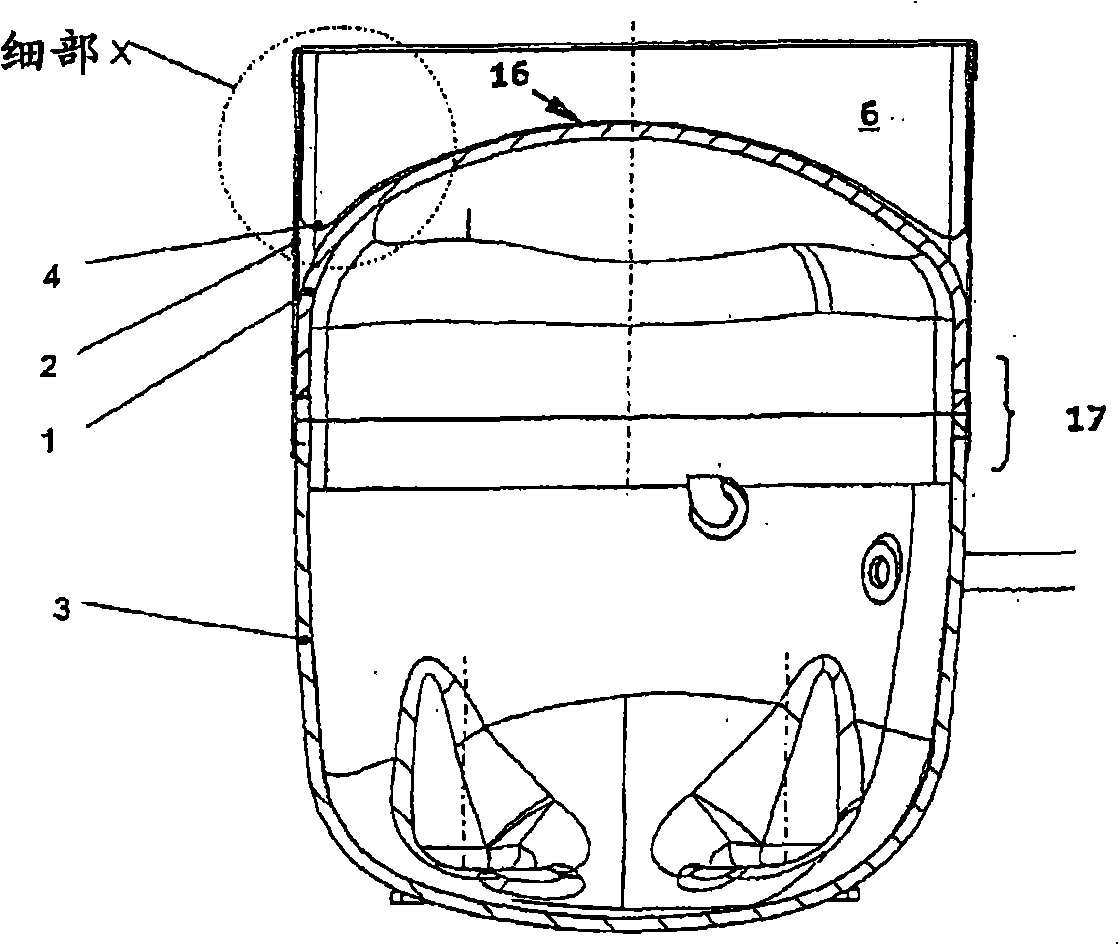

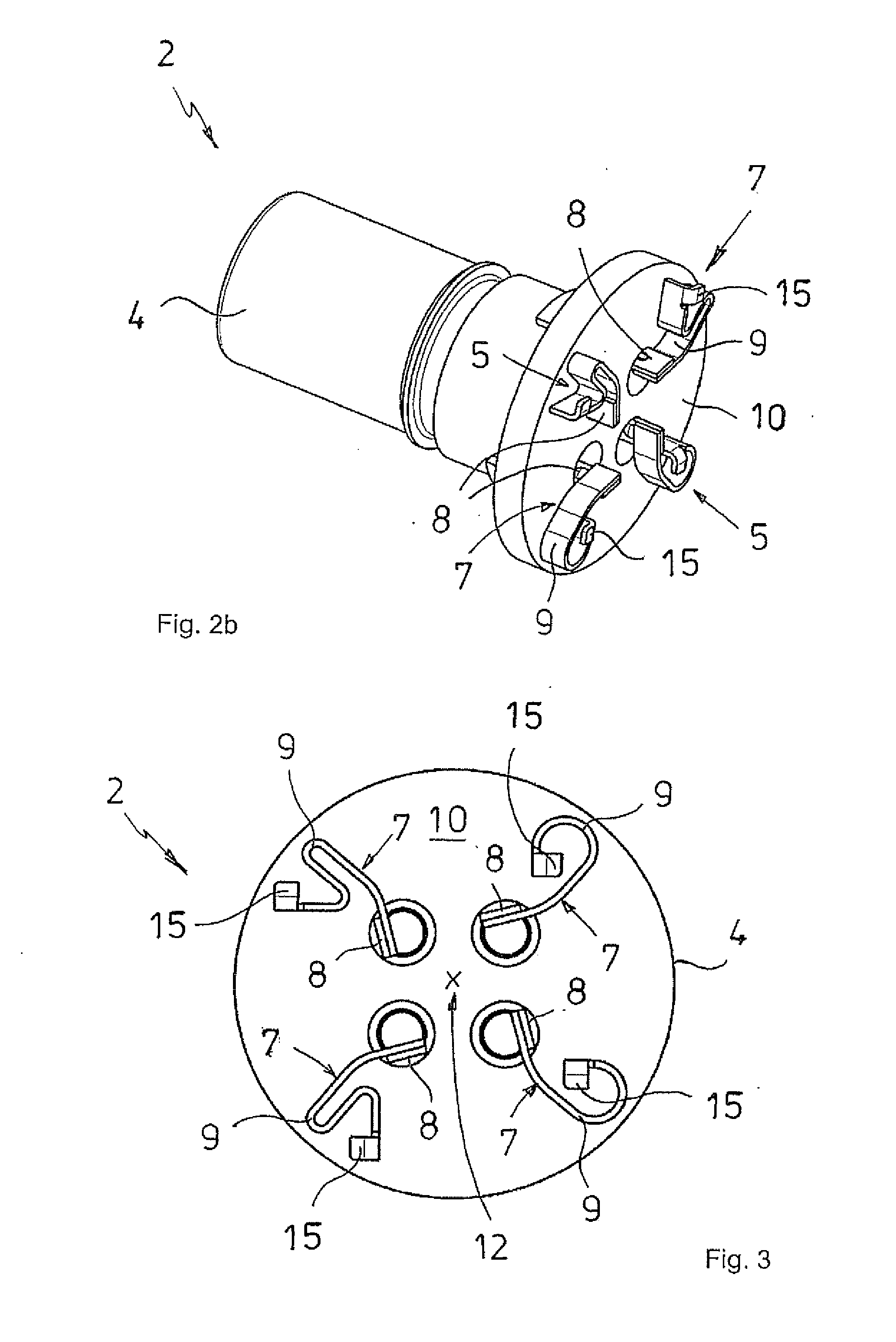

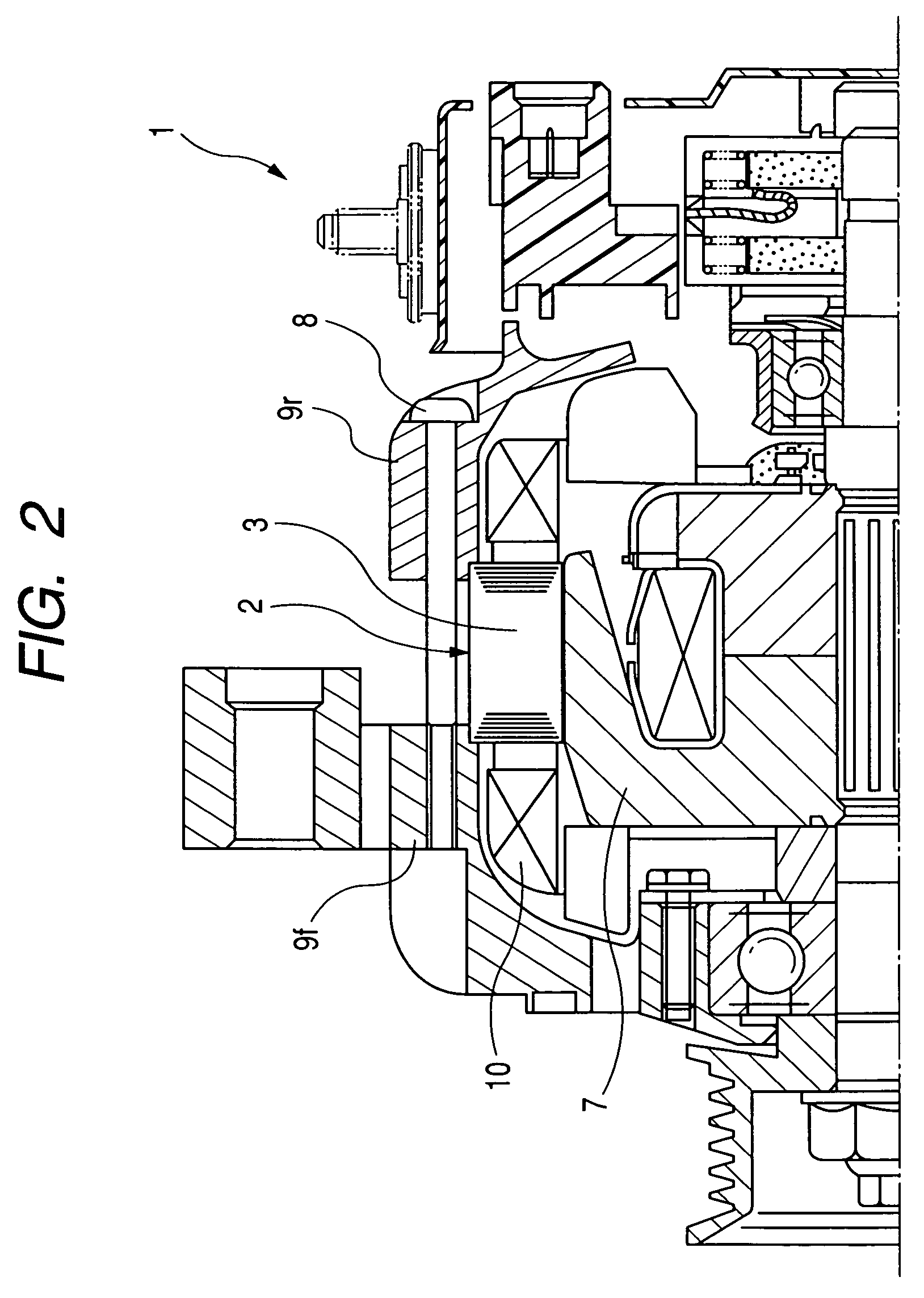

Refrigerant compressor

ActiveCN101341369AEasy plastic deformationAvoid air gapPositive displacement pump componentsLighting and heating apparatusEngineeringRefrigerant

The aim of the invention is to create a receptacle (4) which is used for evaporating condensed liquid on a small coolant compressor, allows the heat generated by the small coolant compressor to be utilized in an optimal way, and is easy and inexpensive to produce and mount on the compressor housing. Said aim is achieved by embodying the receptacle (4) as a plastic part that is deep-drawn in a receiving device (6) directly on the compressor housing. The plastic part perfectly matches the shape of the receiving device (6) such that the air gap that is usually formed between the compressor housing and the receptacle (4) can be eliminated altogether or reduced to a minimum. A holding element (2) that is arranged on the outer circumference of the cover part (1) ensures optimum support for the receptacle (4), thus dispensing with the need for expensive anti-corrosive measures while the evaporator power and the coefficient of performance (COP) of the small coolant compressor are optimized.

Owner:ACC AUSTRIA GMBH

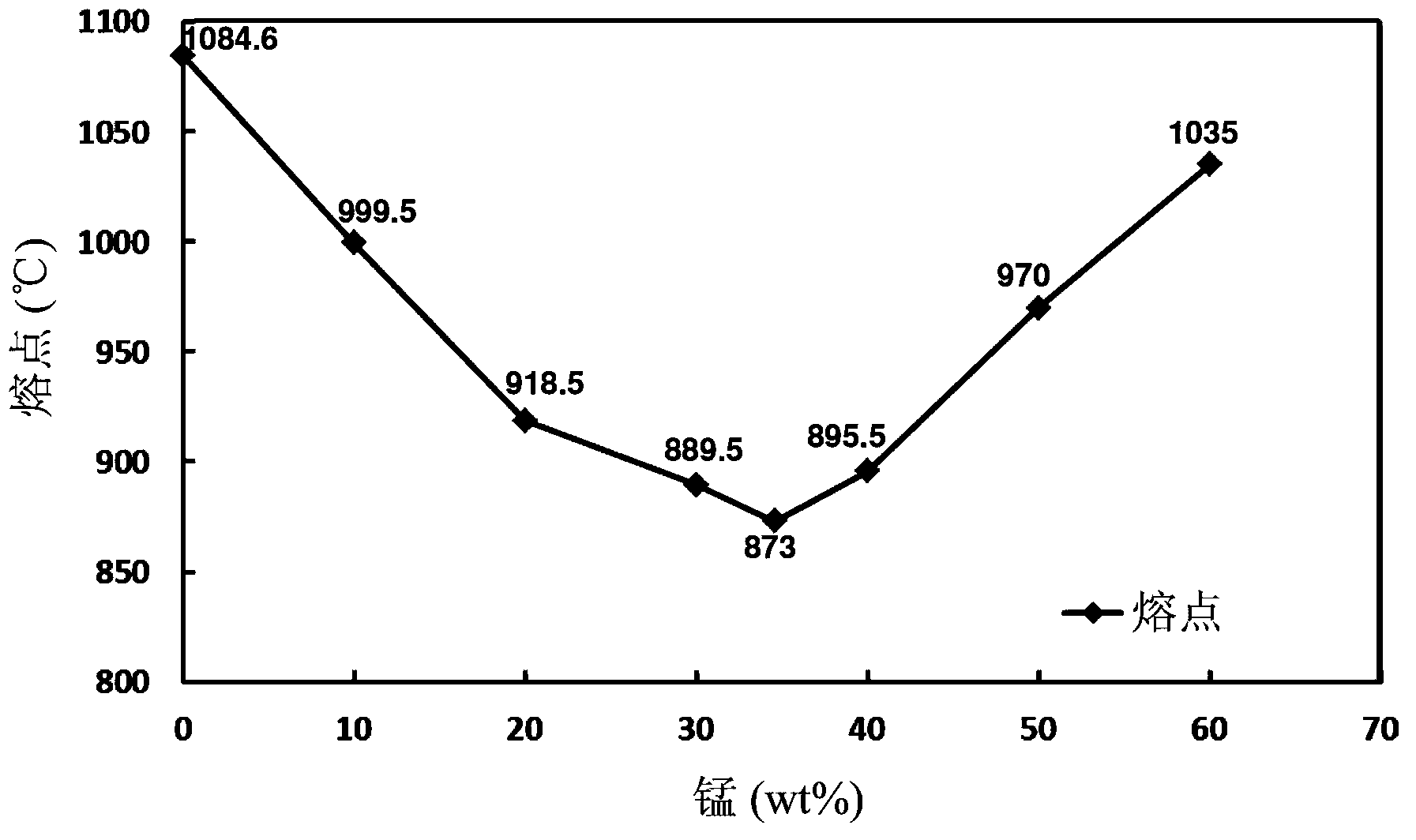

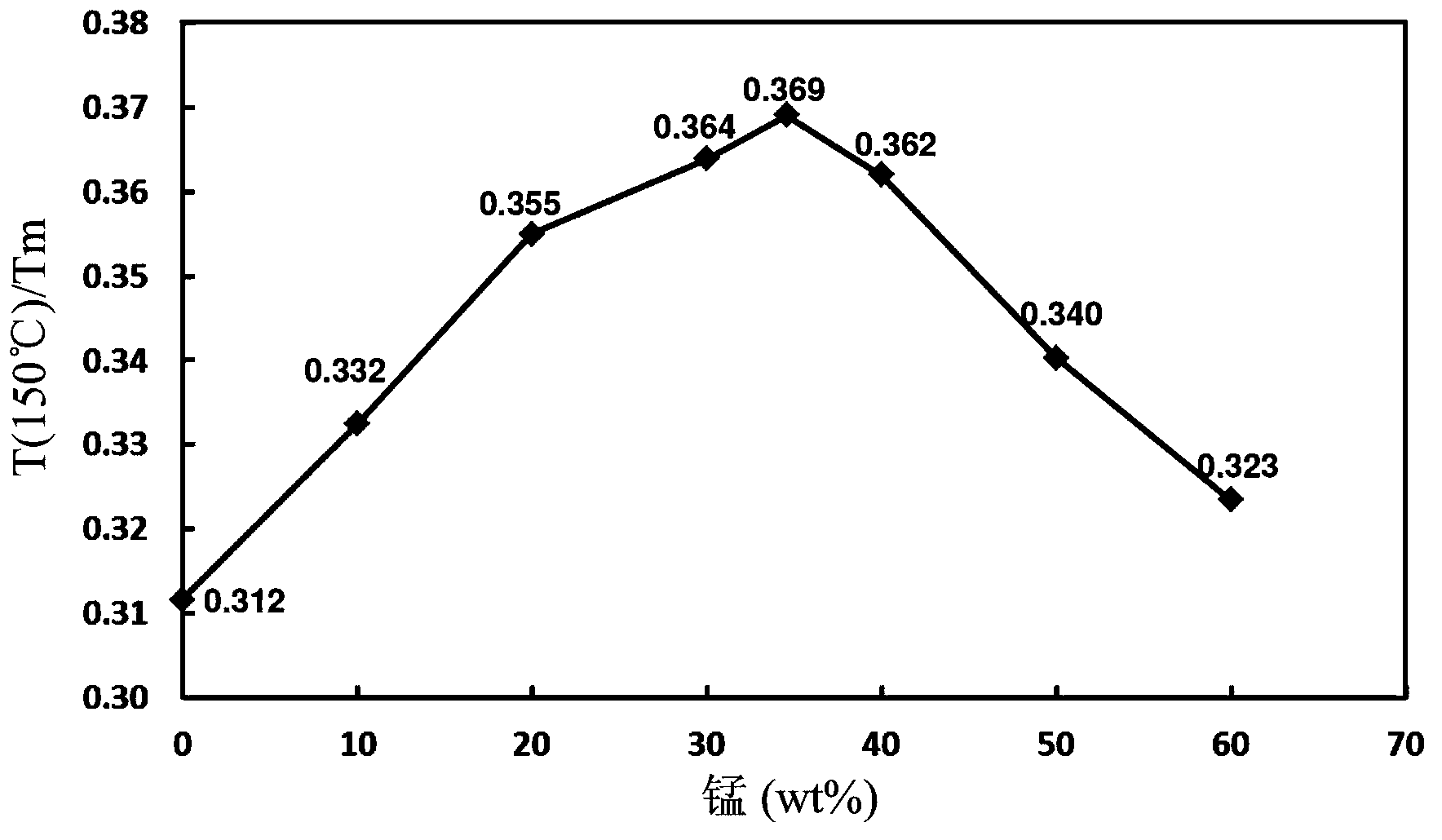

Copper alloy wire used for semiconductor devices

InactiveCN103849795AImprove physical and chemical propertiesImprove antioxidant capacityCopper wireManganese

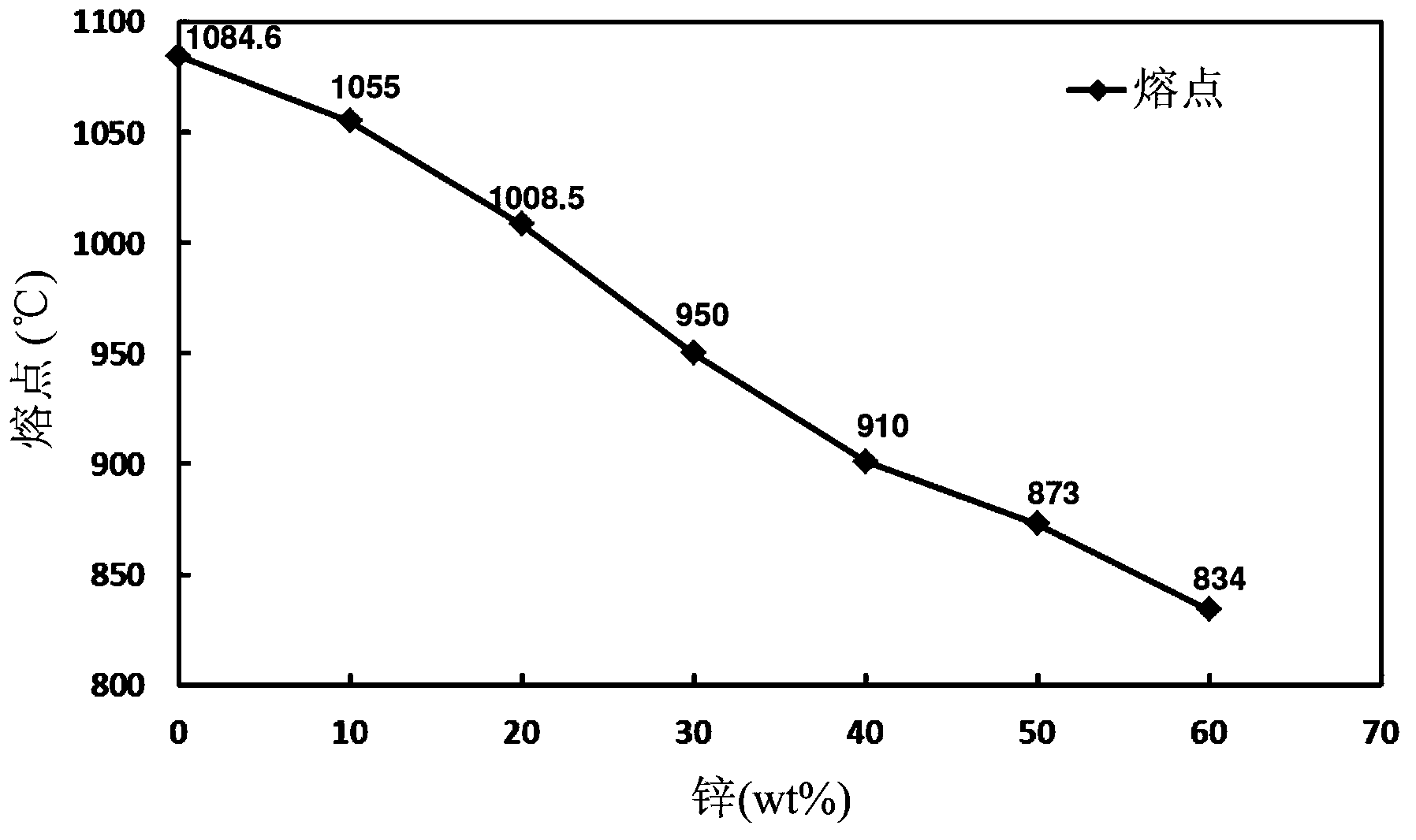

The invention discloses a copper alloy wire used for semiconductor devices. The copper alloy wire comprises, by weight, 20 to 40% of manganese, 20 to 30% of zinc, or 20 to 30% of zinc and manganese, and the balance copper. According to the copper alloy wire, relatively cheap manganese and / or zinc is added into copper base material according to the weight ratio so as to improve copper wire physico-chemical properties relating to wire bonding technology, wire melting point is reduced, wire oxidation resistance and corrosion resistance are improved, wire thermal softening degree at a working temperature is increased, and wire material cost is reduced; and in addition, oxidation resistance of the copper alloy wire is increased, so that reducing protective gas is not necessary in wire bonding processes, using of nitrogen is enough, and accidents are avoided.

Owner:ADVANCED SEMICON ENG INC

Prismatic battery having electrolyte injection-hole capable of excellent sealing-disposition

ActiveUS7479347B2Improve sealingEasy plastic deformationCell lids/coversCell sealing materialsCouplingEngineering

Owner:LG ENERGY SOLUTION LTD

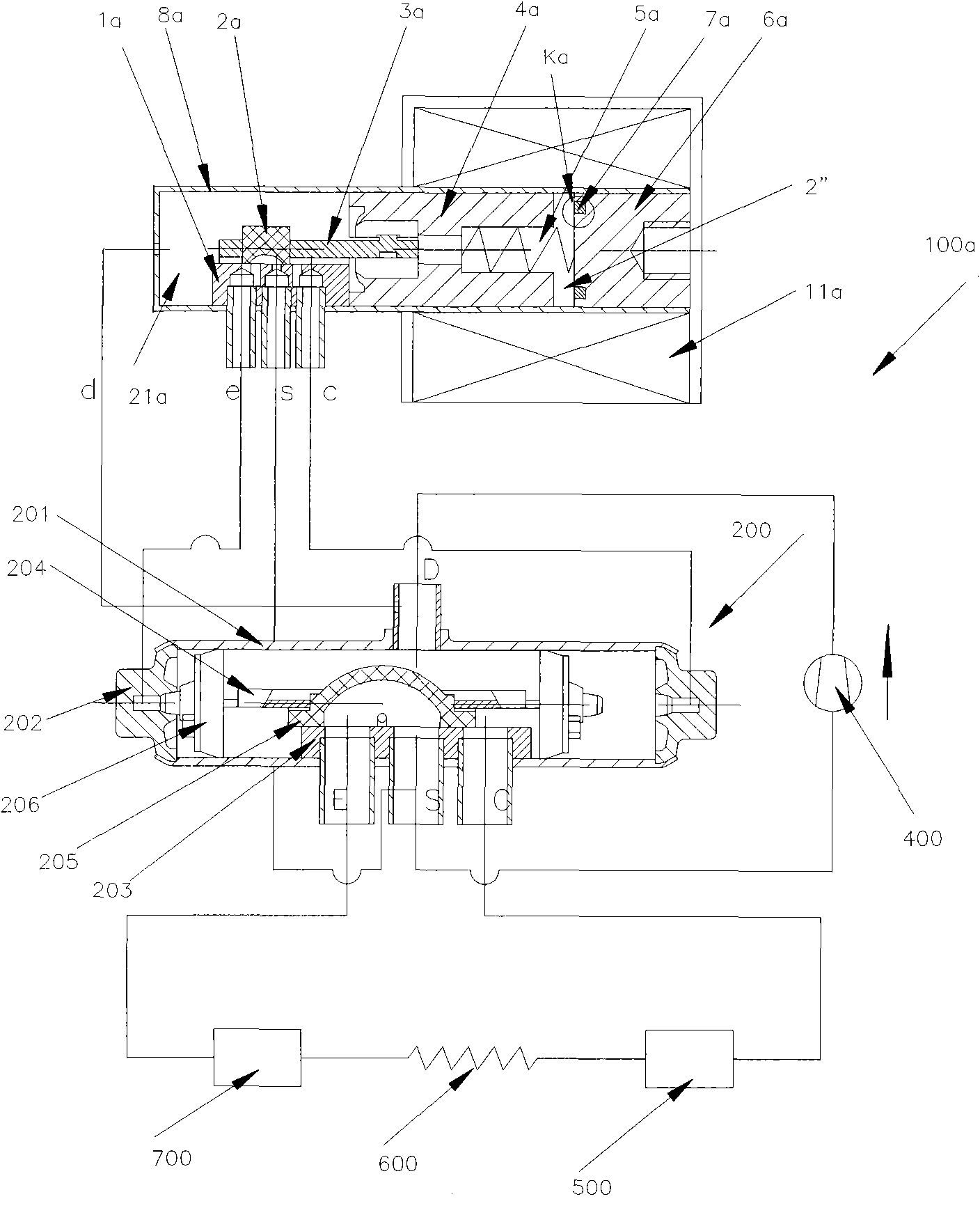

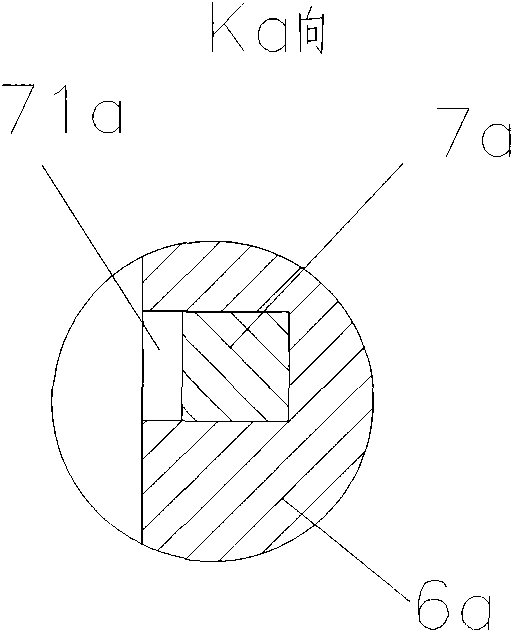

Alternating current electromagnetic valve

InactiveCN101592250AImprove conductivityEasy plastic deformationOperating means/releasing devices for valvesMultiple way valvesEngineeringAlternating current

The invention relates to an alternating current electromagnetic valve comprising a movable iron core, a stationary iron core and an electromagnetic coil. The movable iron core is arranged in a magnetic sleeve and slides under the action of magnetic force to open and close a valve pathway; the stationary iron core attracts the movable iron core and blocks the movable iron core to slide; the electromagnetic coil is arranged outside the magnetic sleeve; the end of the stationary iron core facing to the movable iron core is provided with an annular groove; and a shading ring is arranged in the annular groove. The alternating current electromagnetic valve is characterized in that the shading ring is made of soft aluminum material, and the annular groove is in a ladder-shaped structure which is gradually widened from an opening to the inside in the direction of the cross section. The shading ring made of the soft aluminum material is arranged in the groove after being deformed by external force in the installation process, therefore, the structure ensures that the shading ring can not easily fall off, is suitable for normally working in a vibration environment and ensures the reliability of a product.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

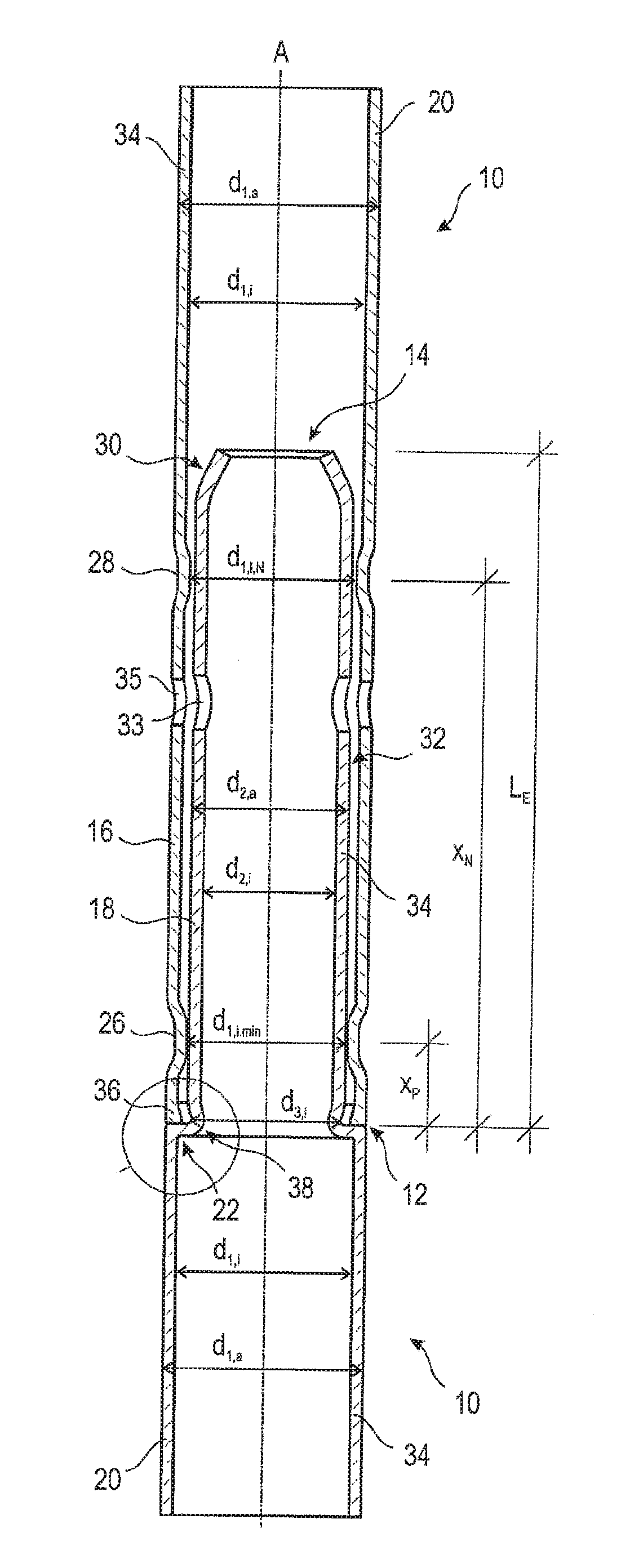

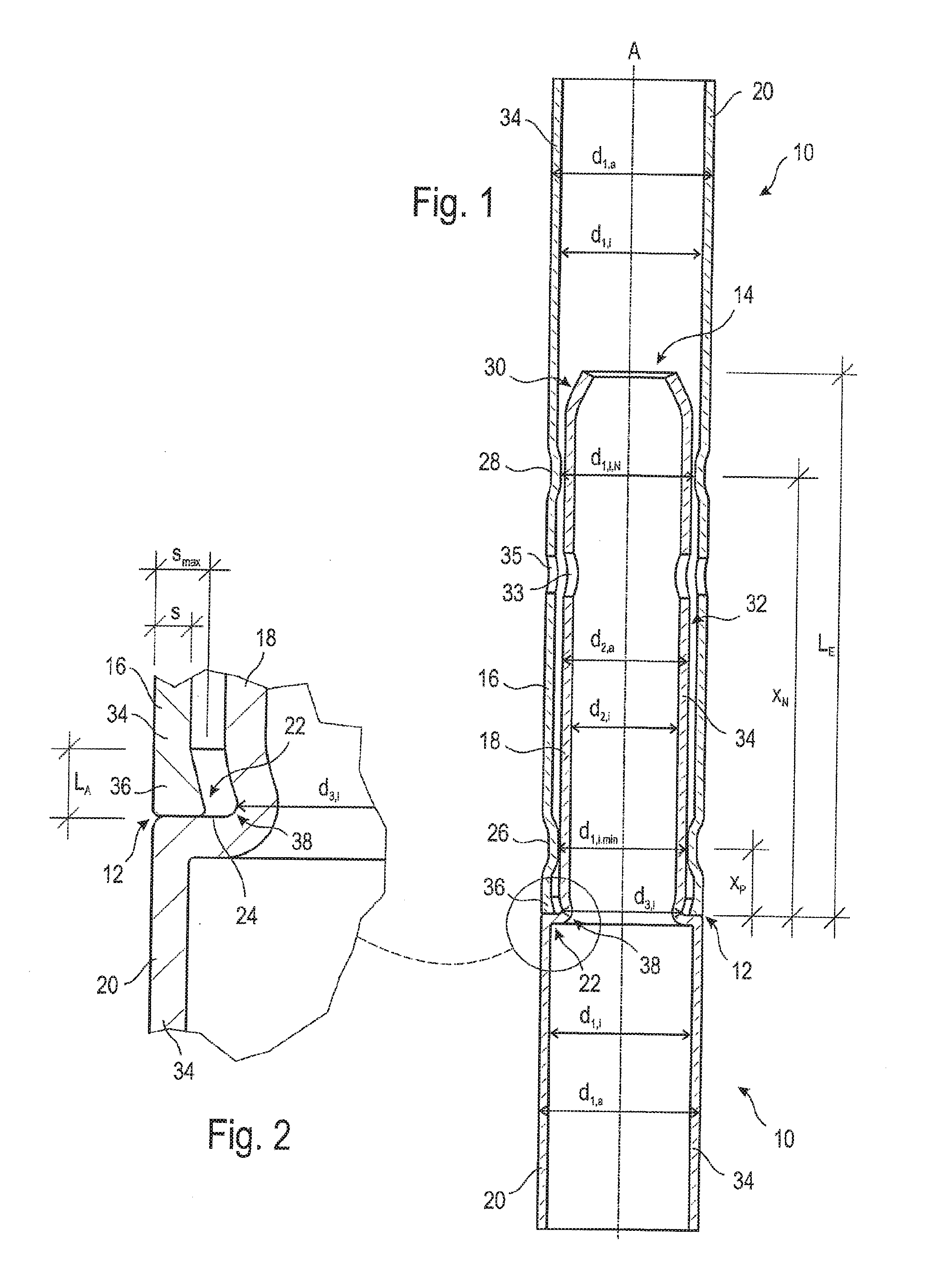

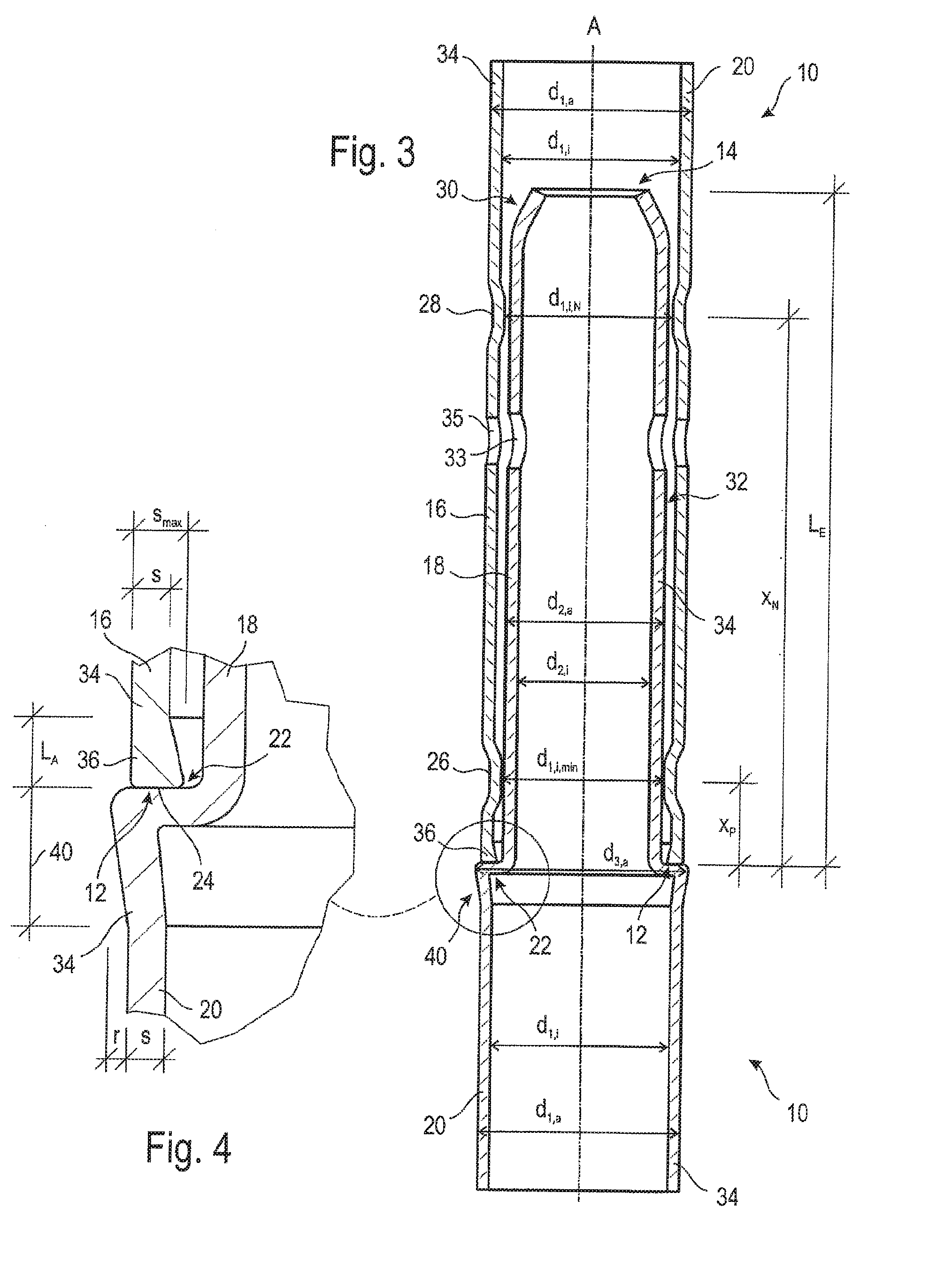

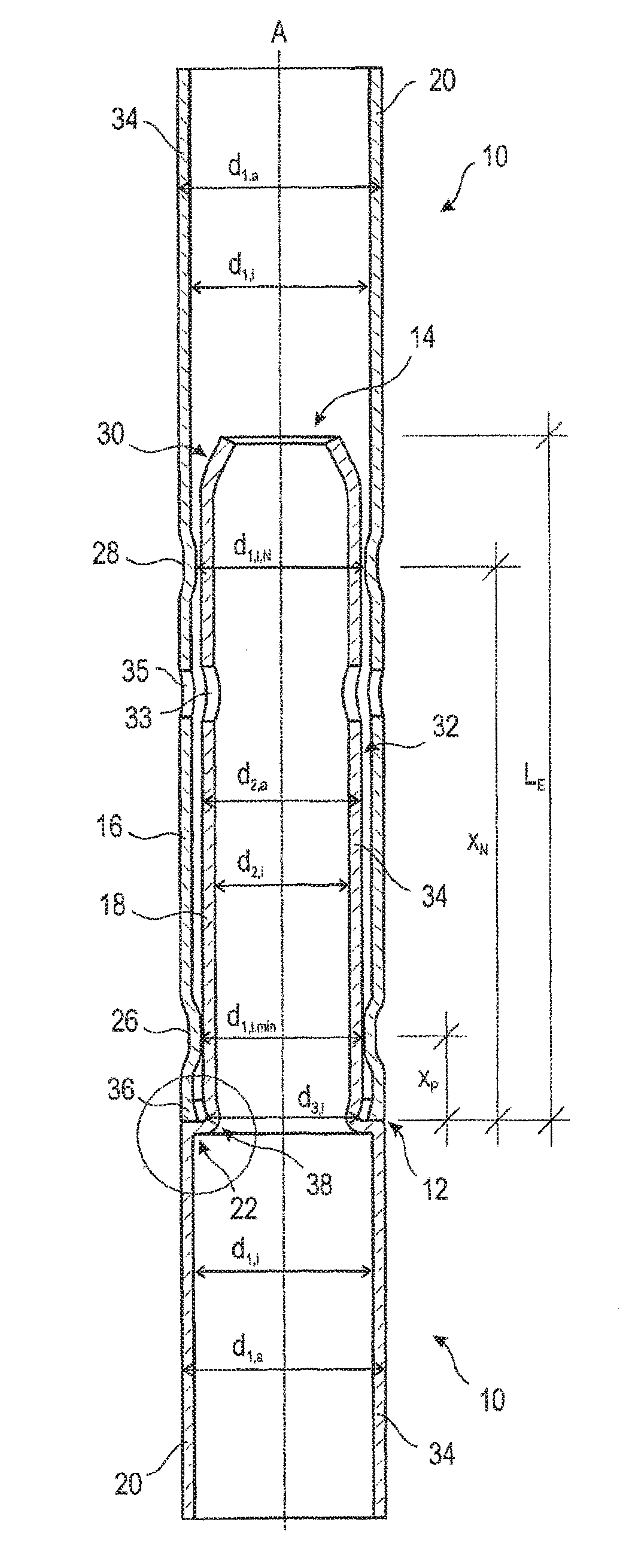

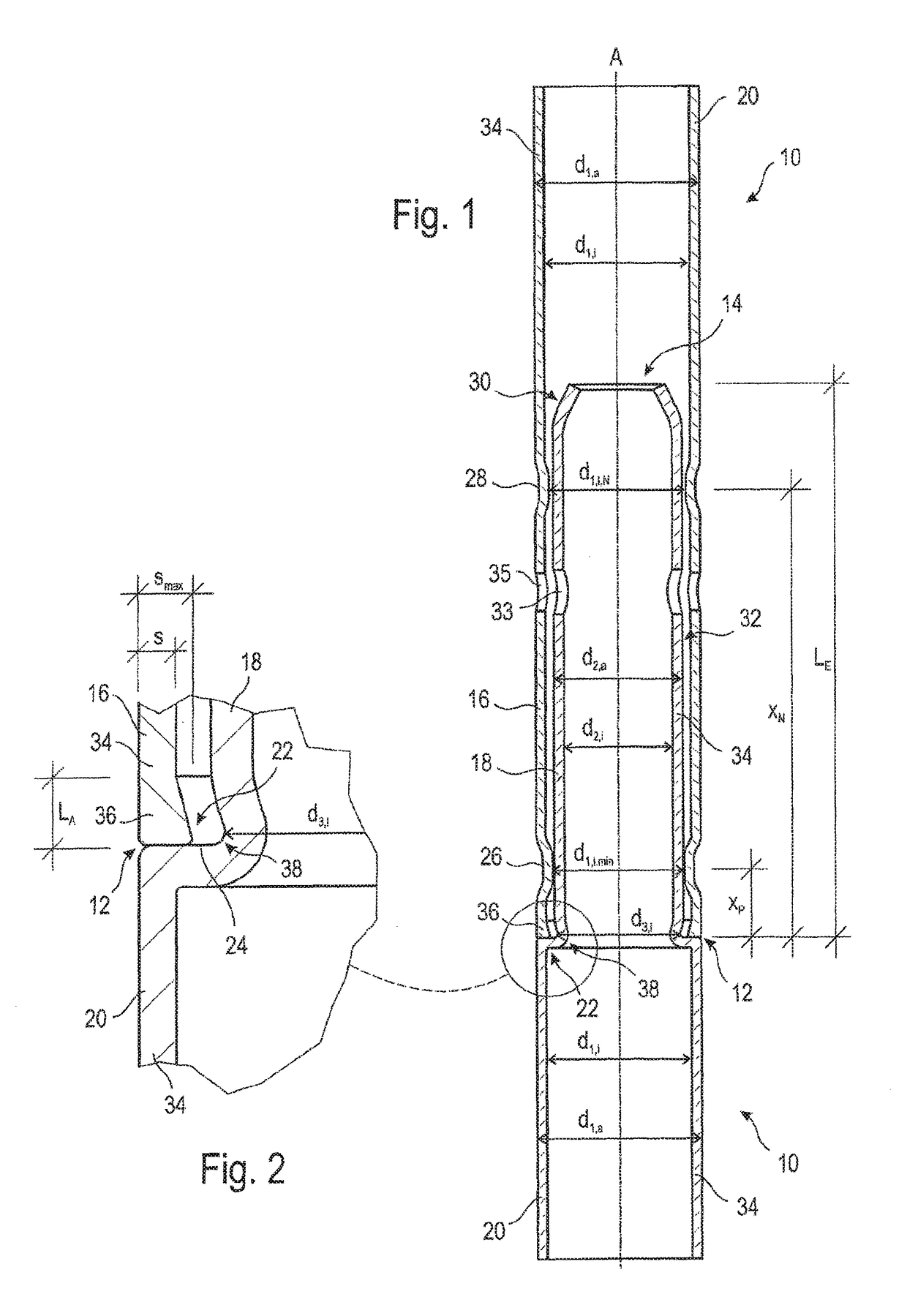

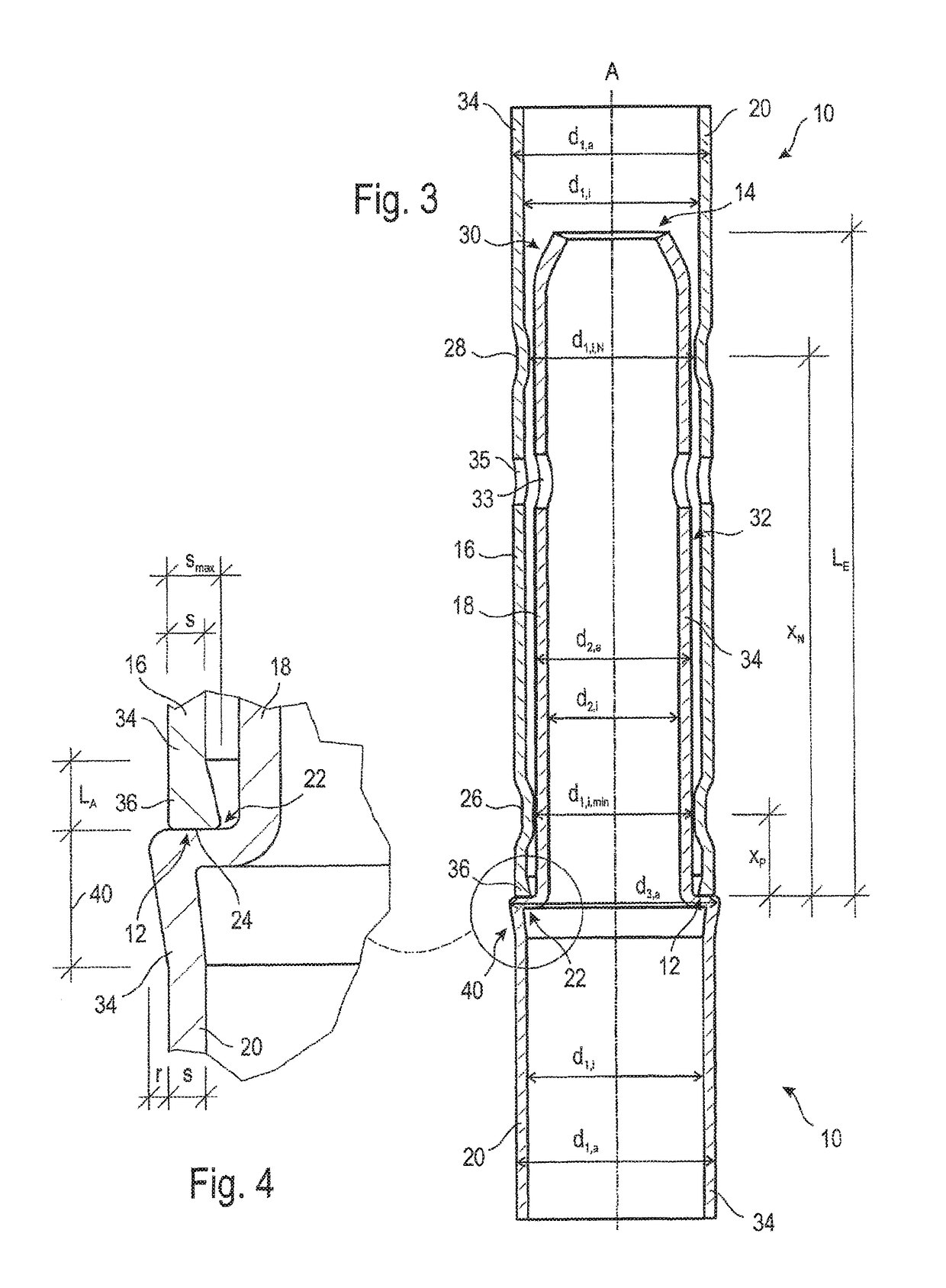

Scaffolding pipe of a structural scaffolding system and scaffolding element

ActiveUS20160153205A1Easy to insertGood effectScaffold connectionsJoints with sealing surfacesBiomedical engineering

A scaffolding pipe of a structural scaffolding system extends from a first axial pipe end to an opposing second axial pipe end. A receiving portion is provided on the first axial pipe end and an insertion portion is provided on the second axial pipe end. The insertion portion has a reduced cross-section compared with the receiving portion and terminates with a radial shoulder which forms a support face. The receiving portion inner diameter is greater than the insertion portion outer diameter. The receiving portion at the first axial pipe end has one positioning groove which is interrupted or continuous in a peripheral direction which reduces the inner diameter of the receiving portion and which defines the minimum inner diameter of the receiving portion. A pipe wall of the scaffolding pipe has at the first axial pipe end a maximum wall thickness greater than the otherwise smaller wall thickness.

Owner:PERI GMBH

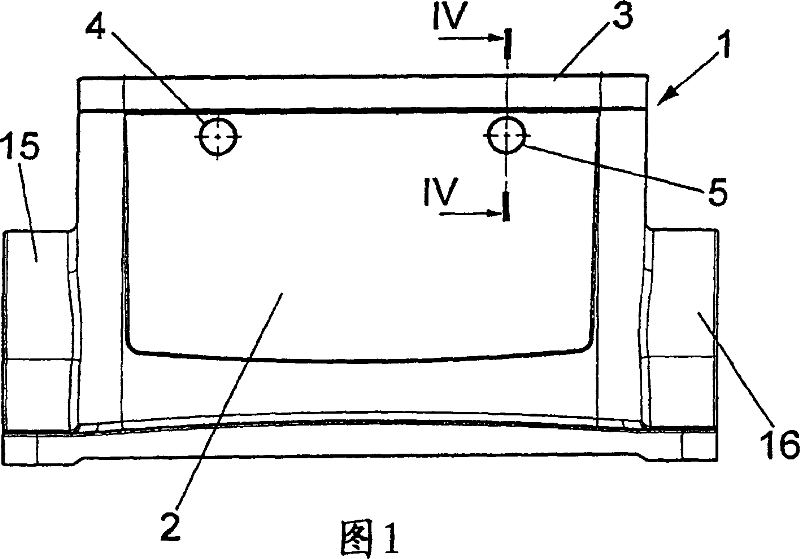

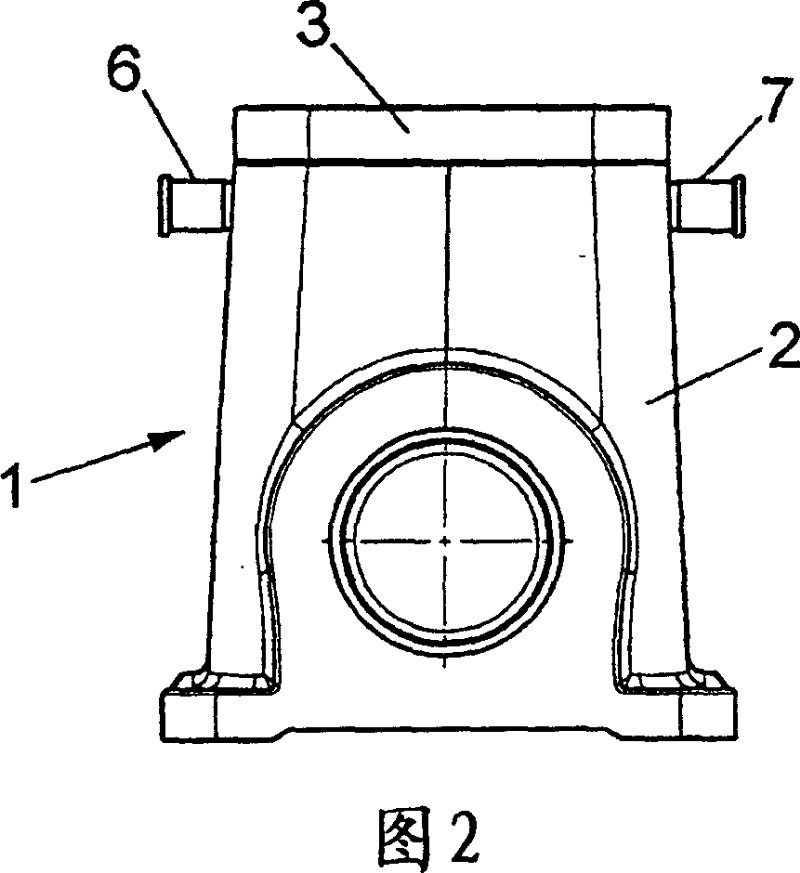

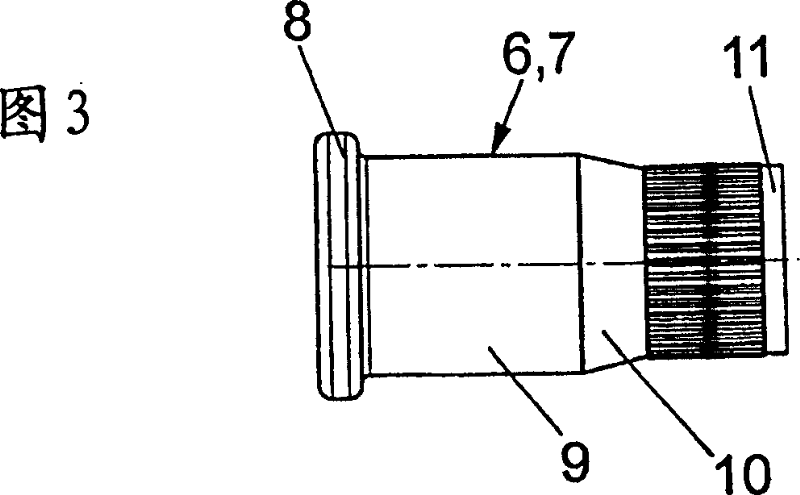

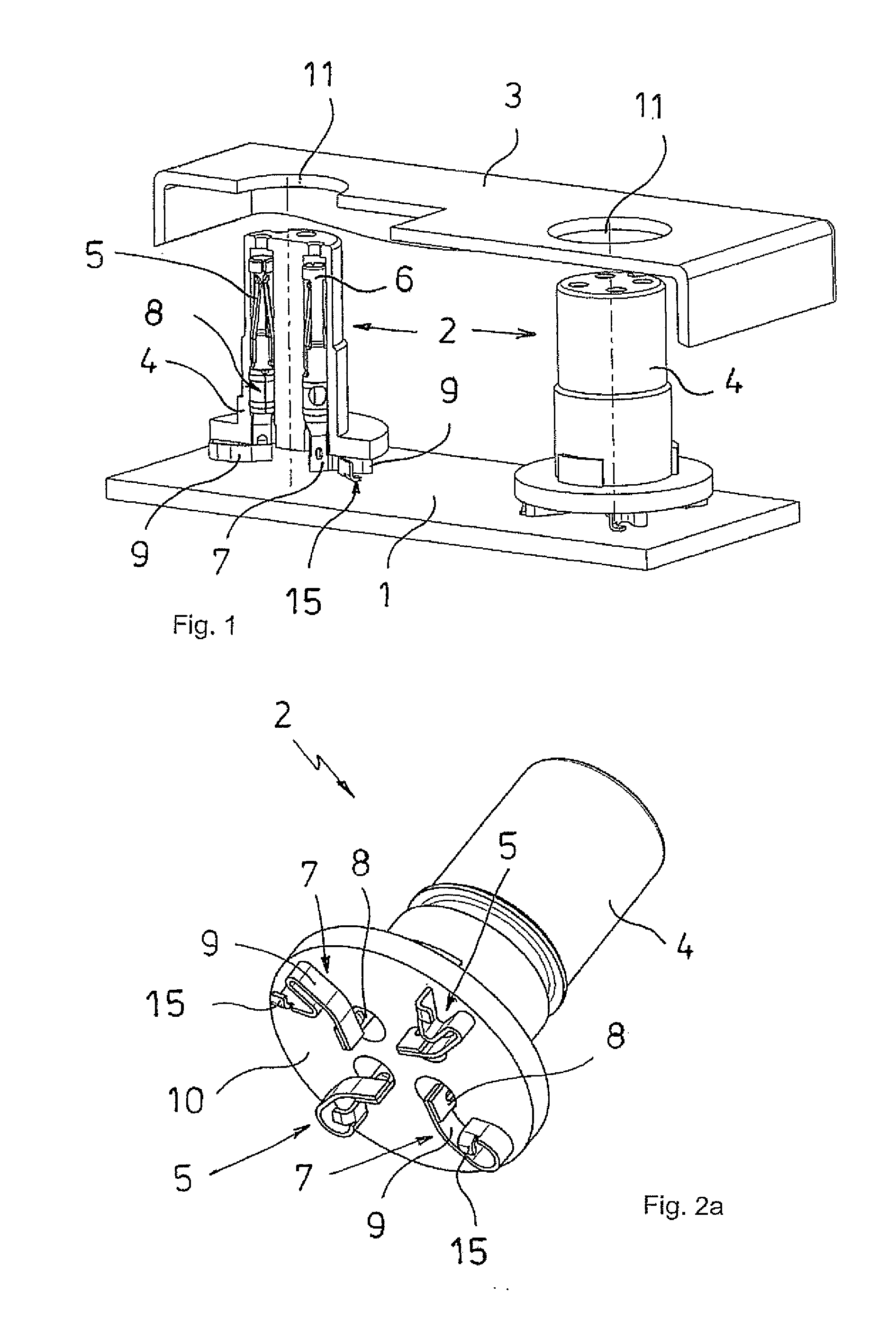

Casing

The invention provides a housing (1), especially a plug connector housing which is made of metal, wherein at least a housing wall is provided with a via hole (4, 5), an inserting region (11) of an end side of a pin (6, 7) is arranged in the via hole in a manner that cann't be rotated, wherein cooperation between each of the via holes (4, 5) of the housing wall and the inserting region (11) of the pin (6, 7) is pressing-cooperation.

Owner:WEIDMULLER INTERFACE GMBH & CO KG

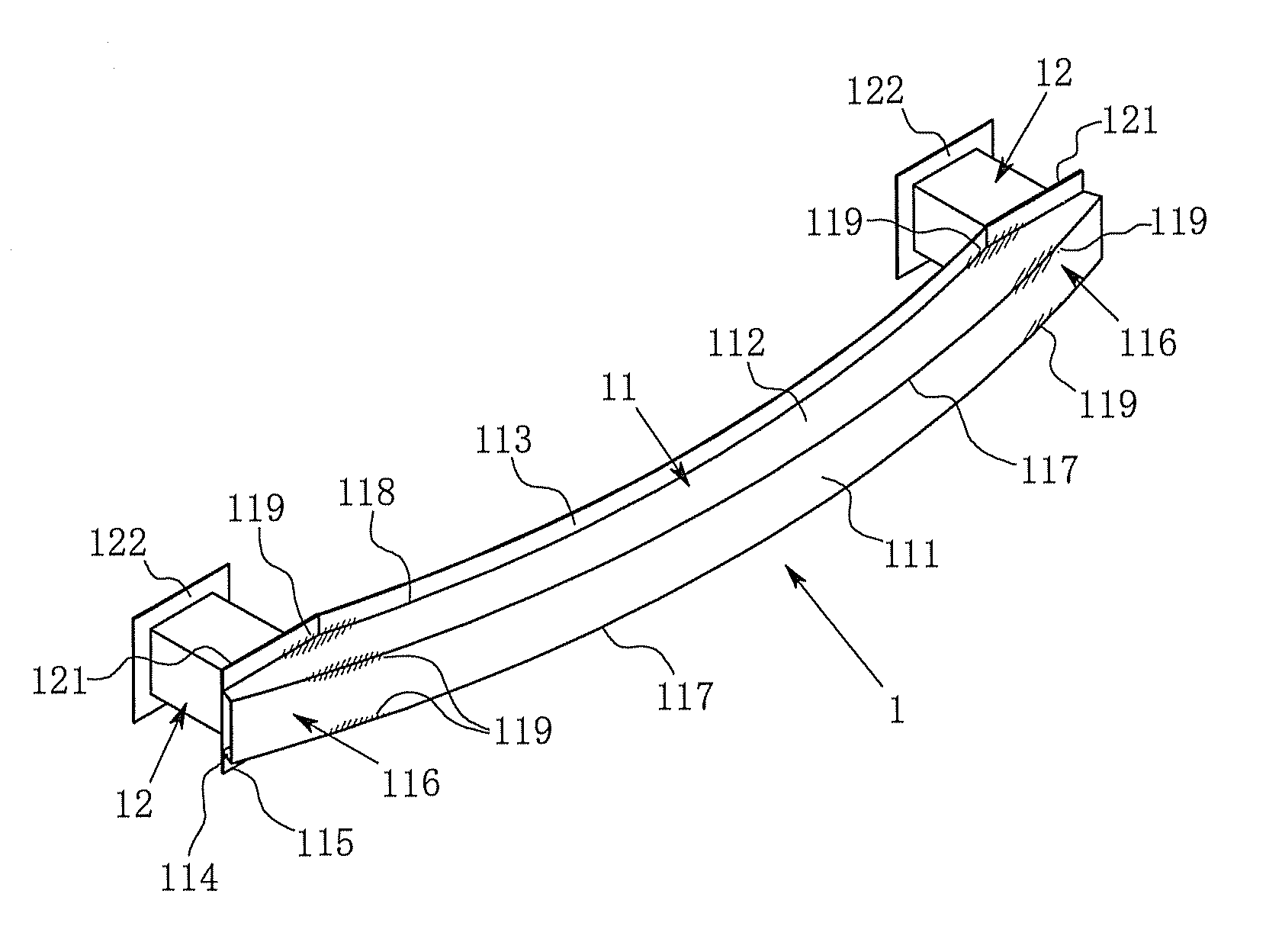

Bumper

Providing a bumper absorbing large amount of impact energy with respect to both a light collision and a heavy collision, and preventing the reinforcement beam from bending and protruding backward at a portion where an obstacle collides and from displacing backward in this protruding state. Provided is a bumper for vehicles including a reinforcement beam made of metal and a pair of support members having a hollow cross section, protruding from a vehicle frame, and supporting the reinforcement beam therebetween. A quenched region is provide over a portion including a middle of the reinforcement beam. Unquenched portions are provided on the pair of connecting portions or a pair of adjacent portions inside the pair of connecting portions.

Owner:ASTEER

Scaffolding pipe of a structural scaffolding system and scaffolding element

ActiveUS9920541B2Solve large capacityEasy plastic deformationScaffold connectionsJoints with sealing surfacesFalseworkEngineering

A scaffolding pipe of a structural scaffolding system extends from a first axial pipe end to an opposing second axial pipe end. A receiving portion is provided on the first axial pipe end and an insertion portion is provided on the second axial pipe end. The insertion portion has a reduced cross-section compared with the receiving portion and terminates with a radial shoulder which forms a support face. The receiving portion inner diameter is greater than the insertion portion outer diameter. The receiving portion at the first axial pipe end has one positioning groove which is interrupted or continuous in a peripheral direction which reduces the inner diameter of the receiving portion and which defines the minimum inner diameter of the receiving portion. A pipe wall of the scaffolding pipe has at the first axial pipe end a maximum wall thickness greater than the otherwise smaller wall thickness.

Owner:PERI GMBH

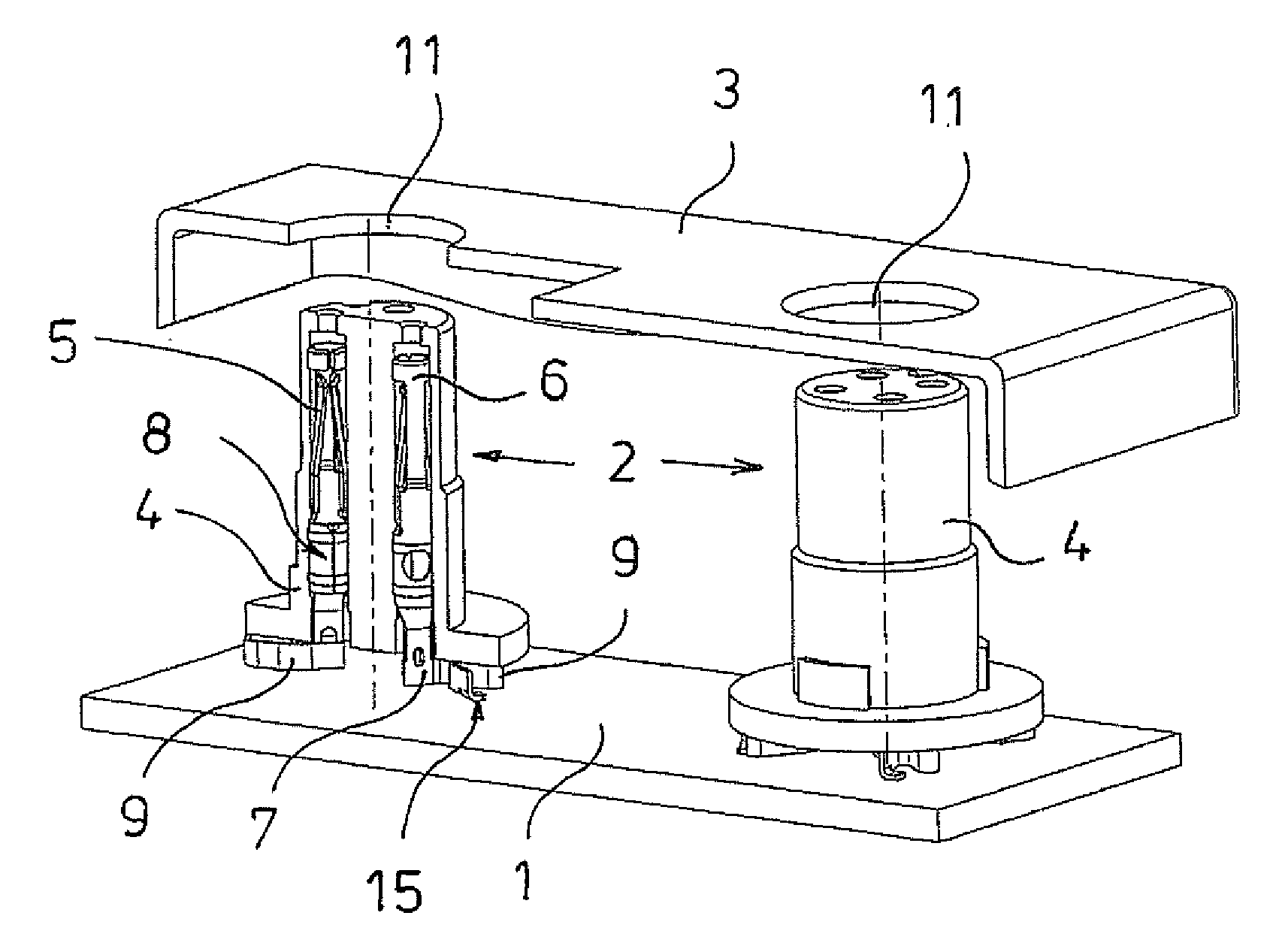

Electrical plug connector with tolerance compensation

ActiveUS20130237070A1Easy plastic deformationAvoid using forceContact member manufacturingIncorrect coupling preventionEngineeringElectrical and Electronics engineering

An electrical plug connector with an insulating body that holds at least one metallic plug part that comprises at least one solder connection element that can be soldered to a circuit board, and at least one plug connection element for a matching plug part, both of which are connected with each other via a central piece of the plug connection element. The solder connection element may be connected via a tolerance compensation part with the central piece of the plug part, or directly with the plug connection element, in such a way that, relative to the position of the solder connection element—with the solder connection element soldered to the circuit board—the position of the plug connection element can be changed in any direction, parallel to the plane of the circuit board. In addition, the invention relates to a plug connector assembly.

Owner:CONINVERS

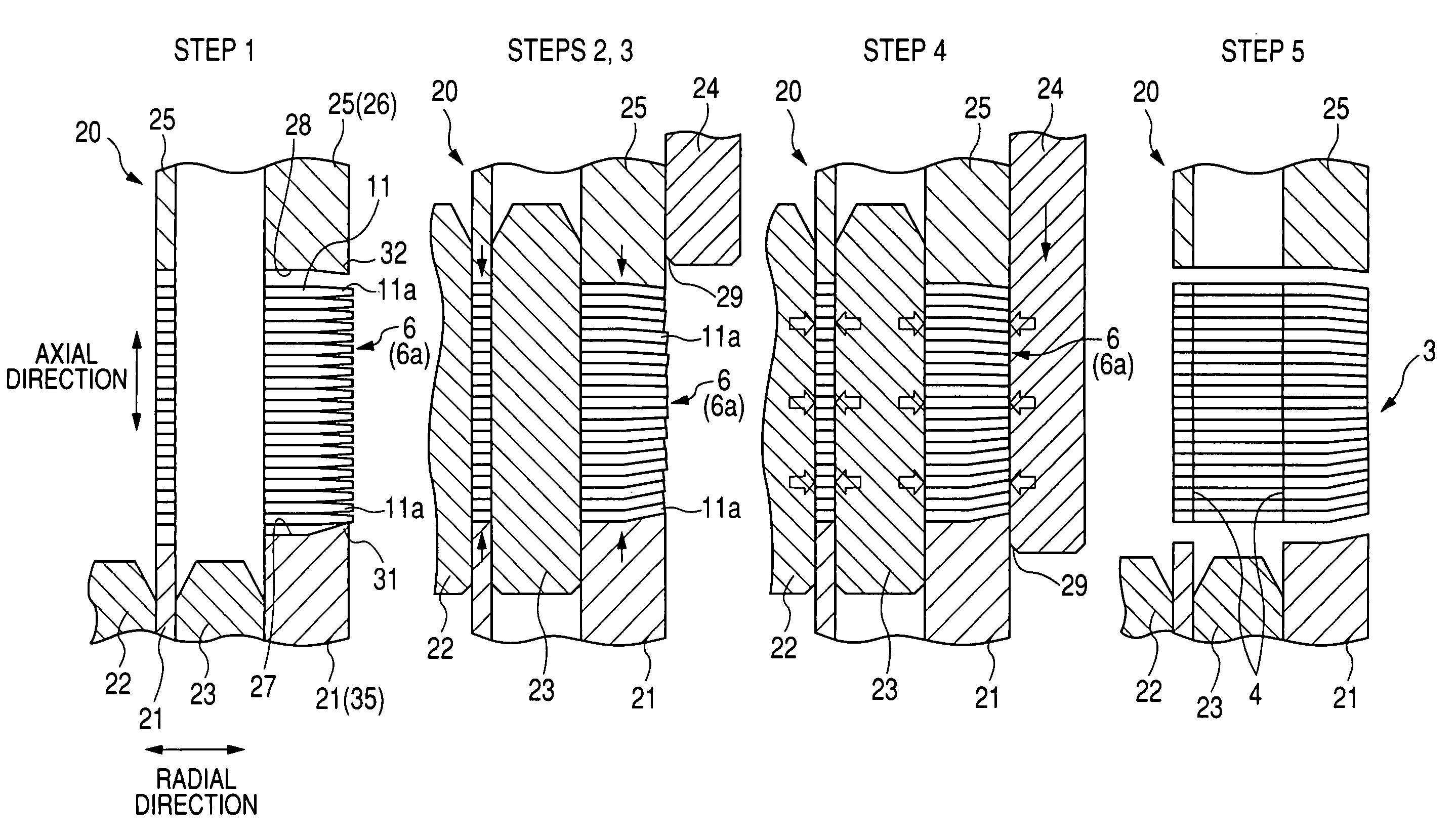

Method of manufacturing stator core of electric rotating machine

InactiveUS8061015B2Easy to adjustInhibition formationManufacturing dynamo-electric machinesElectromagnetsElectric machineMagnetic poles

In a method of manufacturing a stator core of an electric rotating machine, a cylindrical laminated core is formed by thinning a side portion of a steel plate with magnetic pole teeth and helically winding the steel sheet, and the stator core is manufactured by performing ironing for the laminated core. This laminated core has steel sheets aligned along the axial direction thereof, and the sheets have respective thinned outer end portions spaced apart from one another on the outer side of the laminated core. In the ironing, the thinned outer end portions of the steel sheets are brought into contact with one another in a forming apparatus, and an ironing load is given to the thinned outer end portions to shorten lengths of the thinned outer end portions in the radial direction of the laminated core at a predetermined value.

Owner:DENSO CORP

Manufacturing method of supporting structure for vehicle

InactiveUS20070107970A1Precise absorptionReduce manufacturing costPlural diverse prime-mover propulsion mountingSpecial foundation layoutEngineeringMechanical engineering

A manufacturing method of a supporting structure for vehicle has steps of preparing a casting mold having: a first and a second casting mold, which are matched to each other at casting, and has forming faces which form at least sides of first and second fixing portions and the connecting portion and a third casting mold having a forming face which forms a fixing face of the second fixing portion and a protruding body which forms a recess hole penetrating to an interior of the connecting portion from the fixing face of the second fixing portion; matching the third casting mold together with the first and the second casting mold so as to form a cavity for integrally forming the first fixing portion, the second fixing portion and the connecting portion in the casting mold; and pouring molten metal into the cavity so as to mold the supporting structure.

Owner:NISSIN KOGYO CO LTD

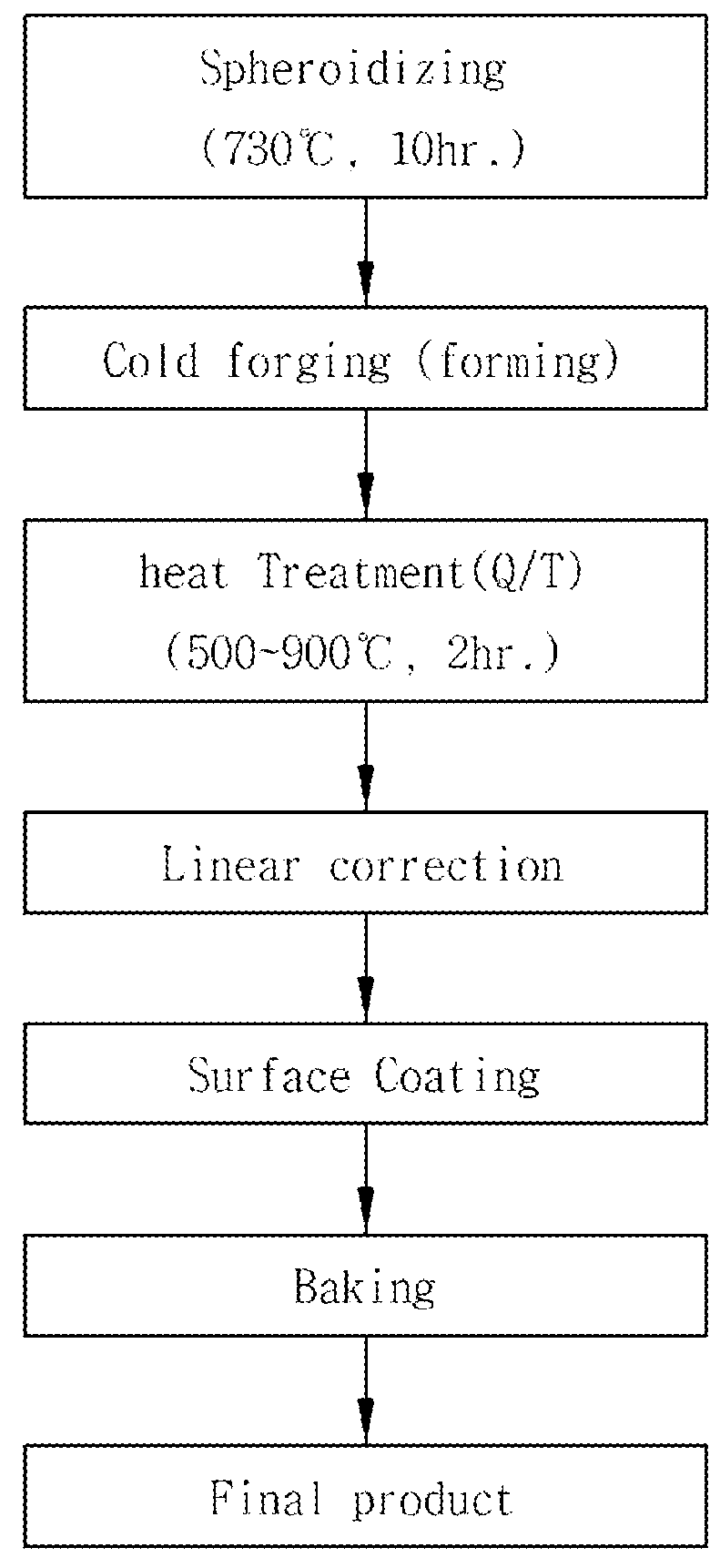

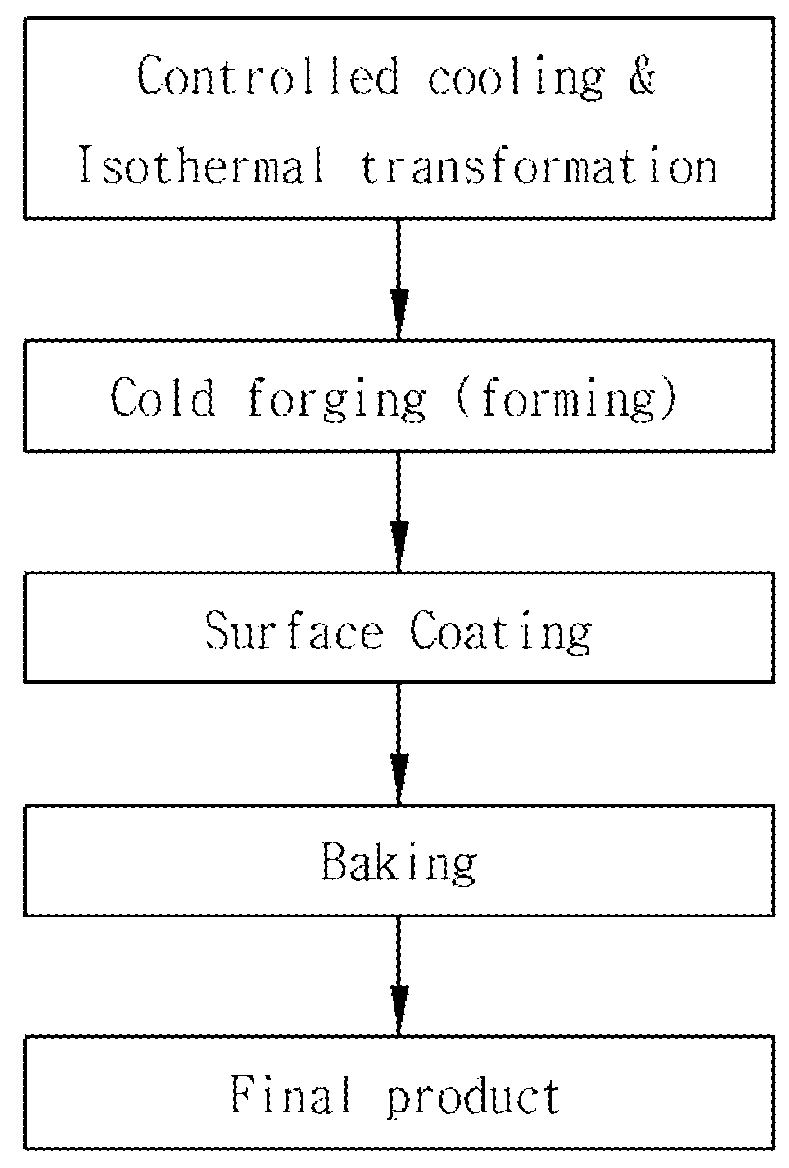

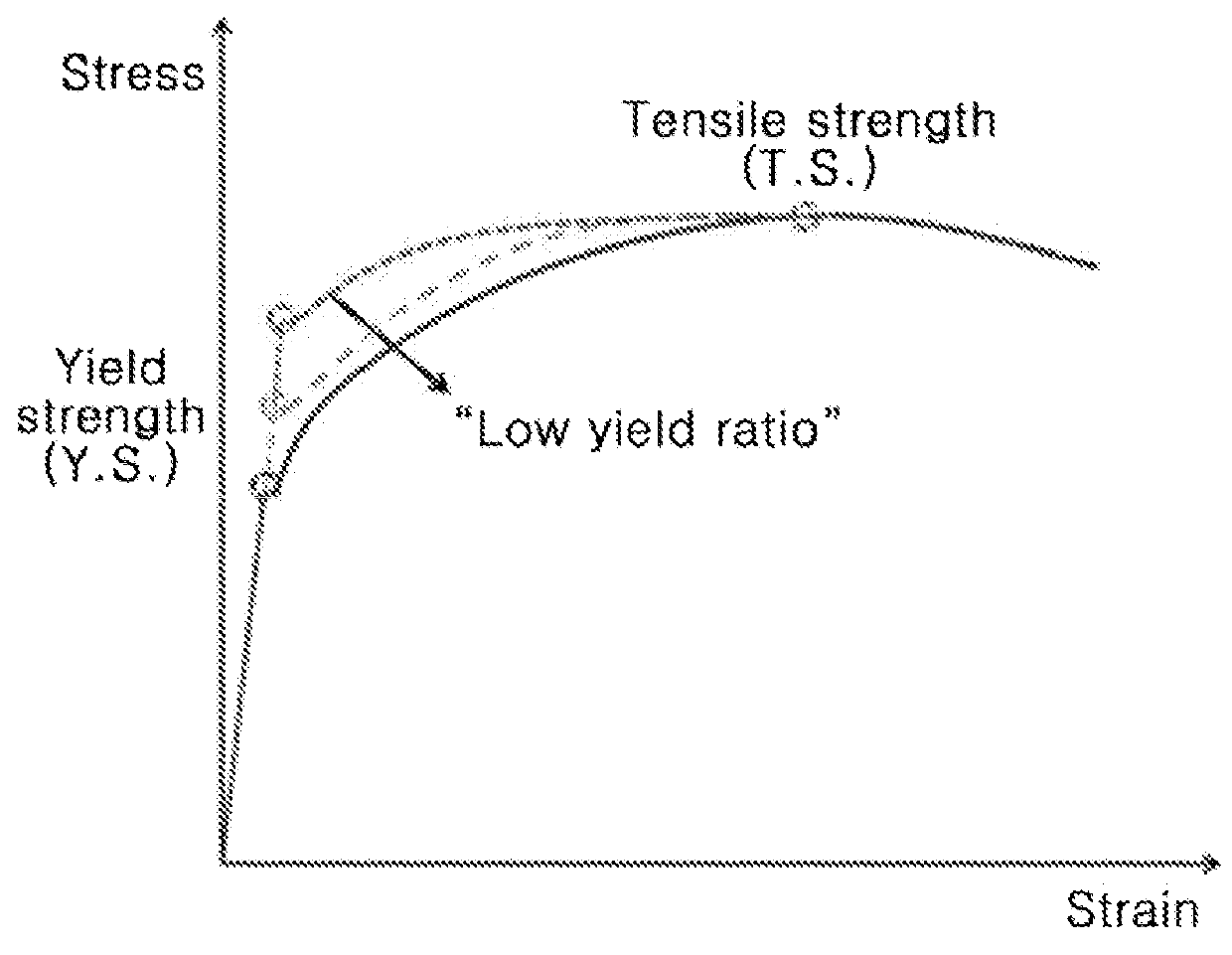

Work hardenable yield ratio-controlled steel and method of manufacturing the same

ActiveUS20160032417A1Low-yield-ratioEasy plastic deformationFurnace typesHeat treatment furnacesYield ratioMartensite

A method of manufacturing yield ratio-controlled steel, including the steps of subjecting alloy steel to rolling or wire drawing, thus obtaining a bar material; performing a first heat treatment, in which the material is heated and maintained for a predetermined period of time at a first temperature ranging from Ac1 to Ac3 based on Ac1 and Ac3 transformation temperatures; and cooling the material to a second temperature ranging from Mf to Ms based on a martensite start temperature (Ms) and a martensite finish temperature (Mf), and performing a second heat treatment, in which the material is maintained at the second temperature for a predetermined period of time.

Owner:KOREA INST OF MATERIALS SCI

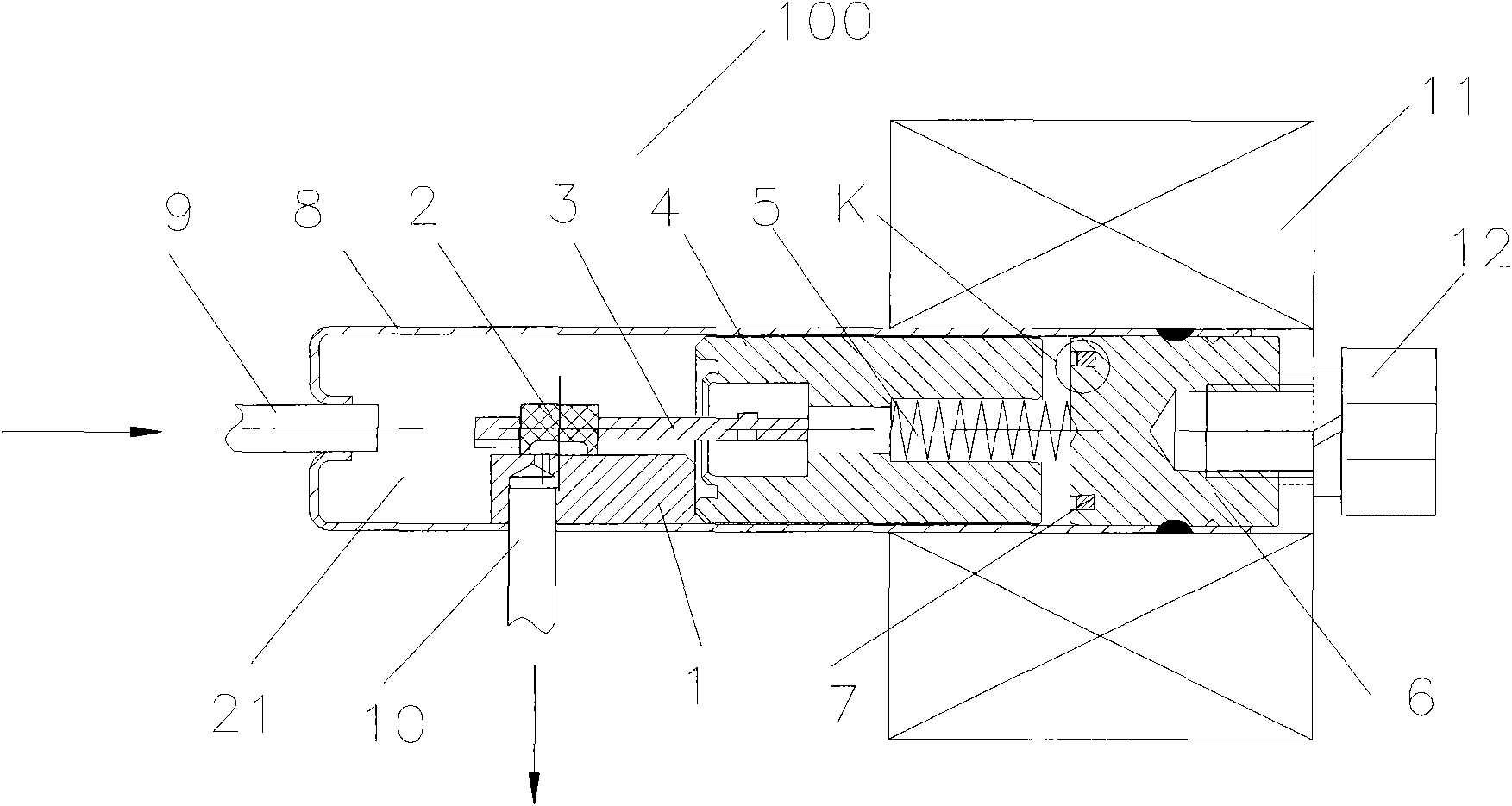

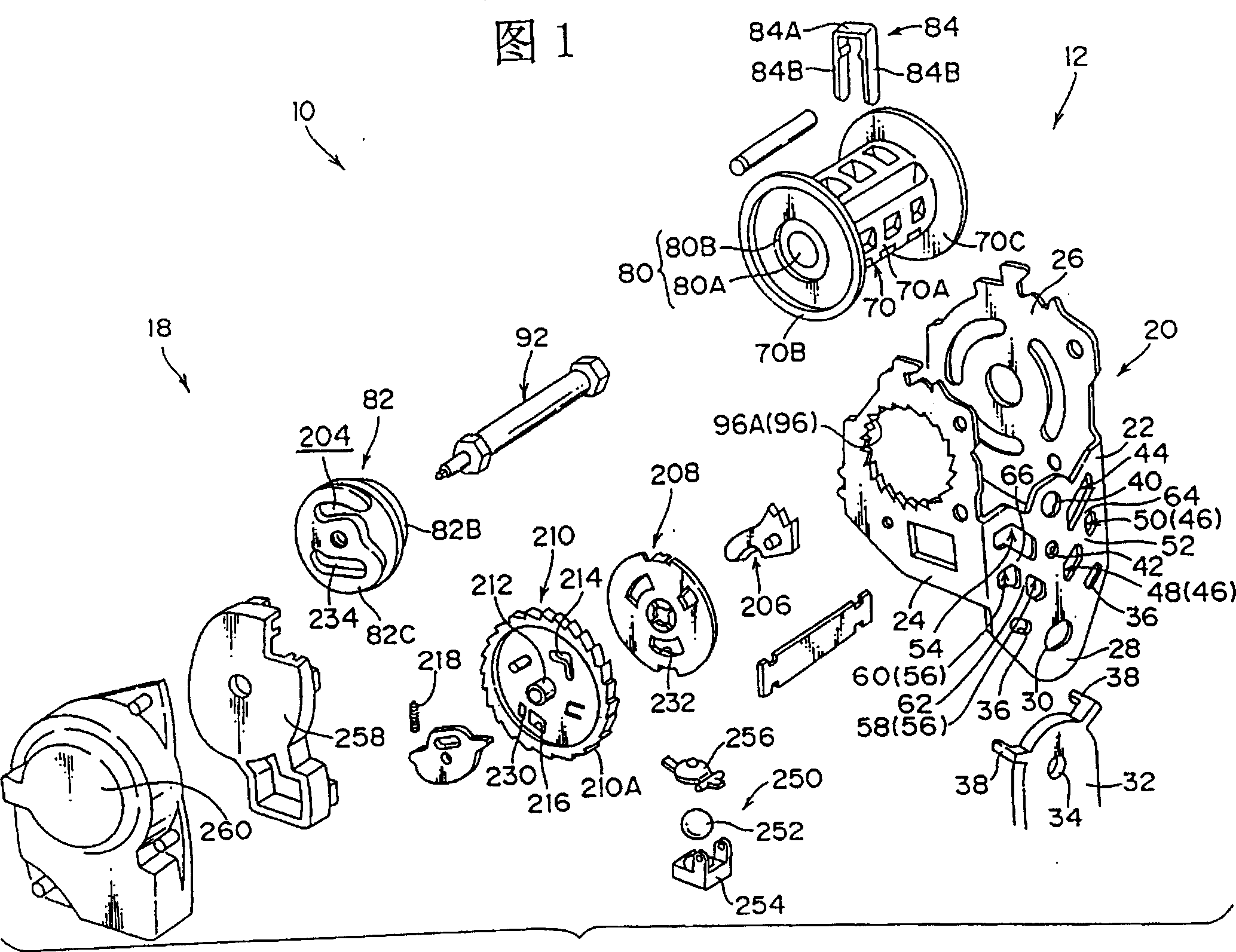

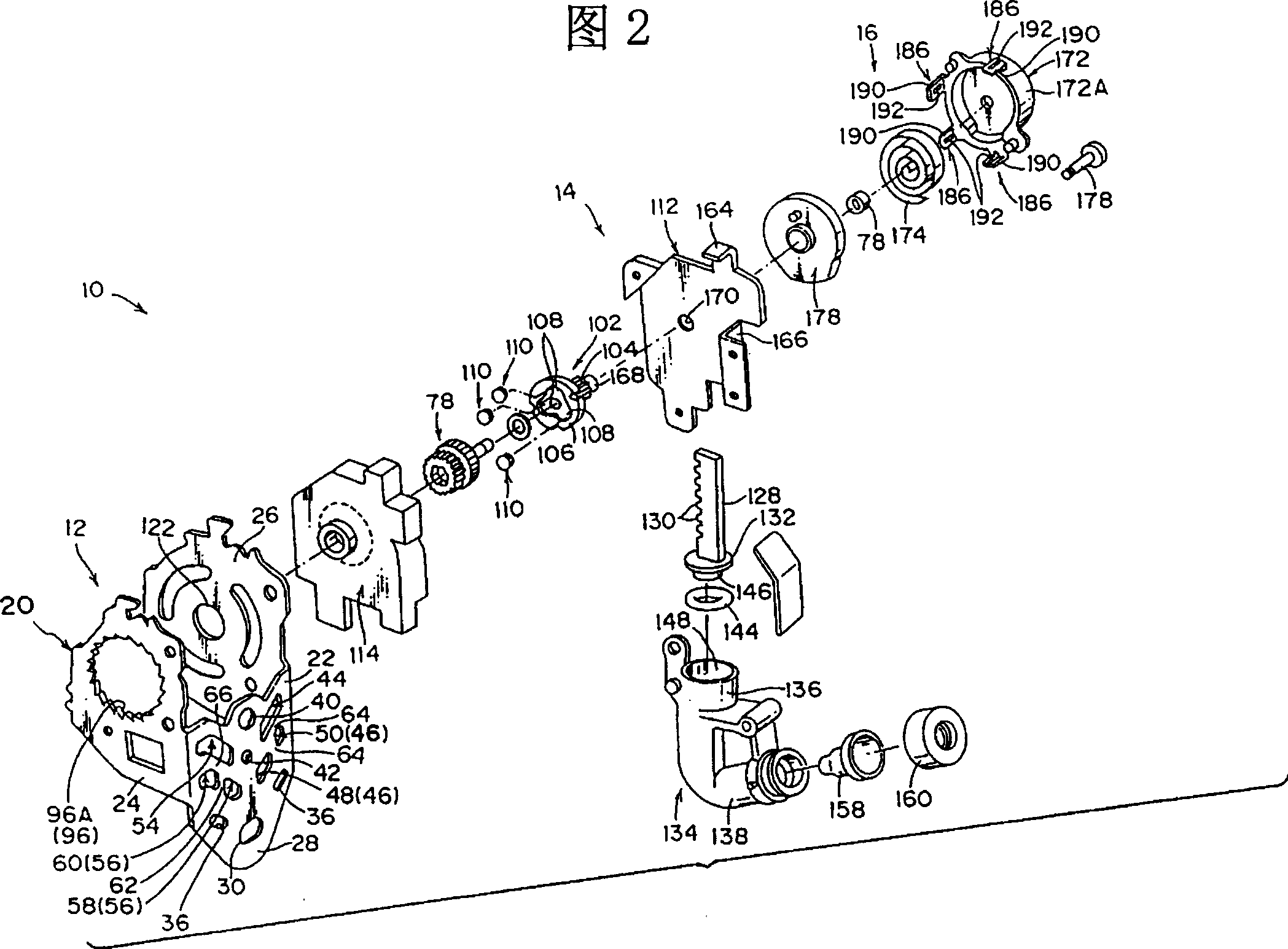

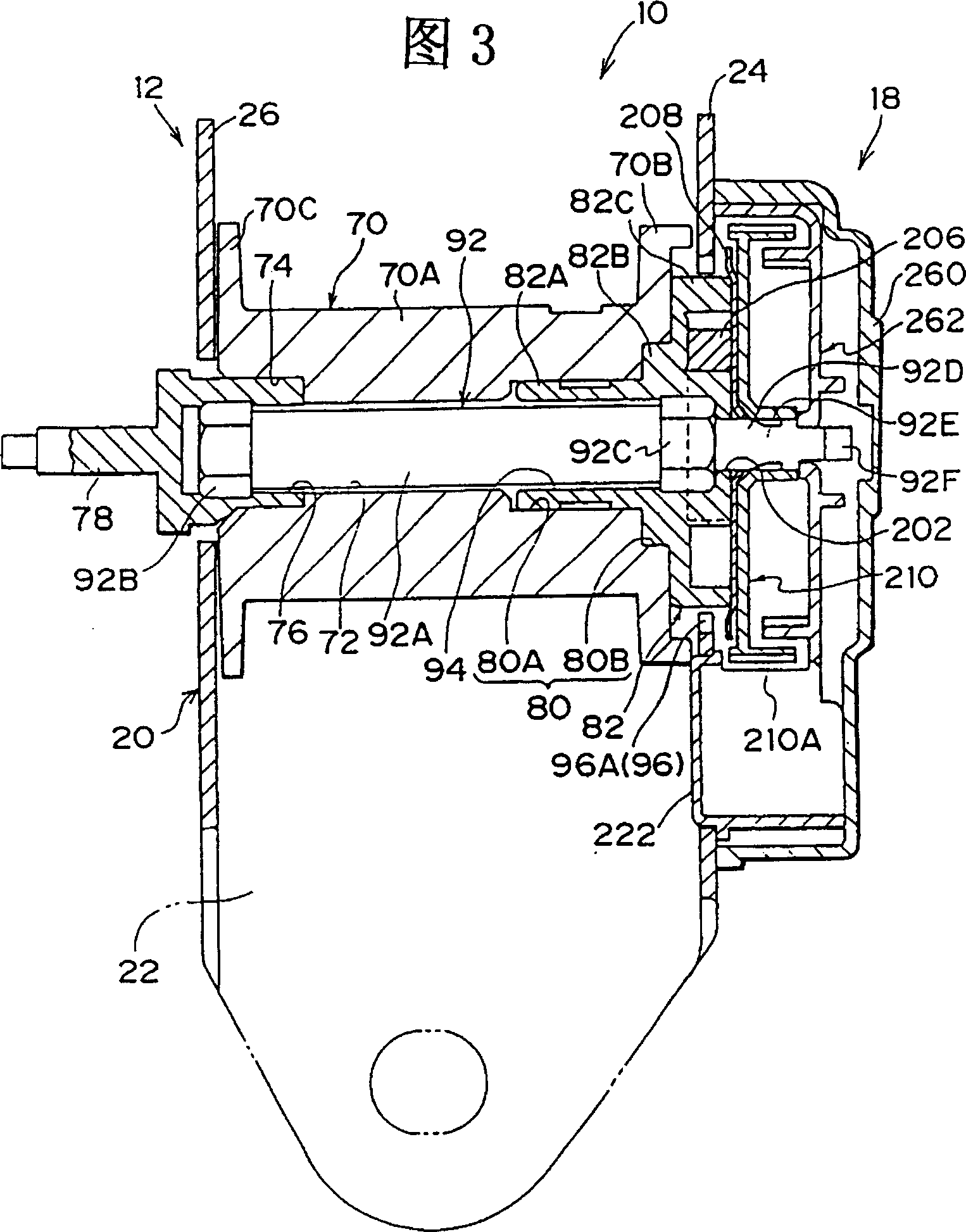

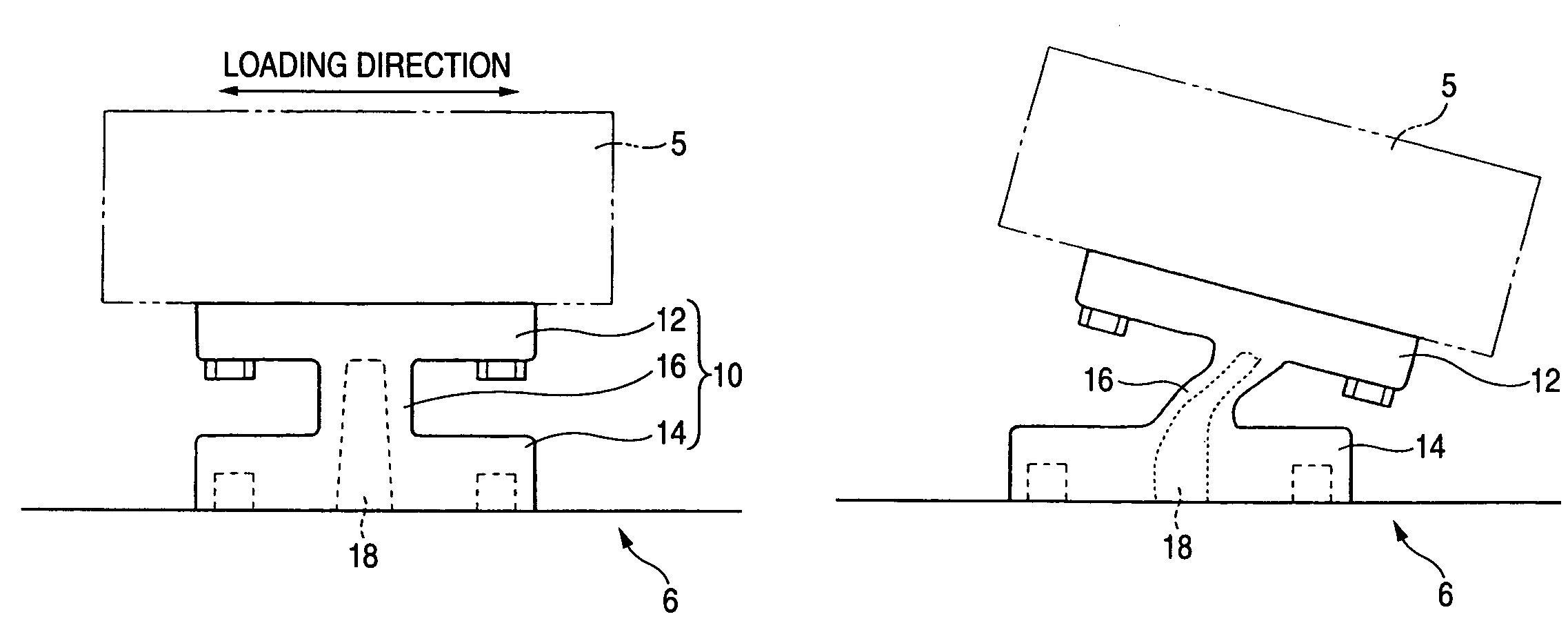

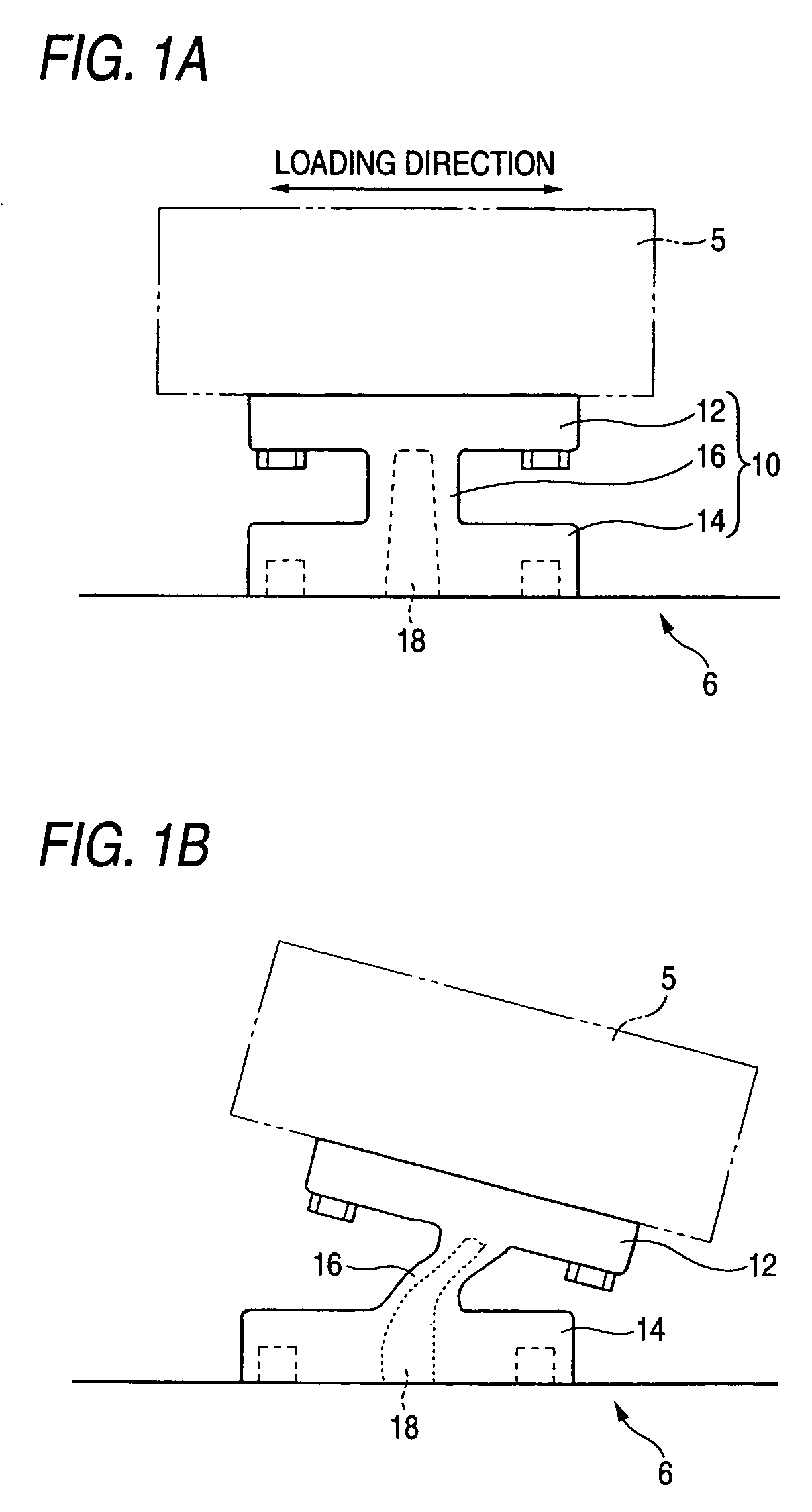

Webbing take-up device

InactiveCN1128078CConcentration of pushing forceEasy plastic deformationBelt retractorsEnergy-absorbing device incorporationMiniaturizationEngineering

A webbing take-up device reduced in cost by a reduction in size of a pre- tensioner and a lock device and a reduction in number of parts, wherein a plurality of projected parts (126) are formed on the inner peripheral part o f a bearing main body (124) pivotally supporting a clutch part (106) and are in linear contact with the outer peripheral part of the clutch part (106) so th at the bearing main body (124) pivotally supports the clutch part (106) indirectly through the projected parts (126), whereby, because the projected parts (126) are in linear contact with the clutch part (106), a contact area becomes extremely small and the projected parts (126) are easily deformed plastically by a frictional resistance between the projected parts (126) and the clutch part (106), and thus a resistance to prevent the clutch part (106) from rotating is reduced enough to supply a gas pressure efficiently for the rotation of a take-up shaft (20) and, as a result, those members which form the pre-tensioner (14) such as a gas generator (158) can be reduced in size and cost.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

Manufacturing method of supporting structure for vehicle

InactiveUS7478701B2Precise absorptionReduce manufacturing costPlural diverse prime-mover propulsion mountingMotor depositionForming faceCasting mold

A manufacturing method of a supporting structure for vehicle has steps of preparing a casting mold having: a first and a second casting mold, which are matched to each other at casting, and has forming faces which form at least sides of first and second fixing portions and the connecting portion and a third casting mold having a forming face which forms a fixing face of the second fixing portion and a protruding body which forms a recess hole penetrating to an interior of the connecting portion from the fixing face of the second fixing portion; matching the third casting mold together with the first and the second casting mold so as to form a cavity for integrally forming the first fixing portion, the second fixing portion and the connecting portion in the casting mold; and pouring molten metal into the cavity so as to mold the supporting structure.

Owner:NISSIN KOGYO CO LTD

Sliding bearing for internal combustion engine and sliding bearing device

InactiveUS8419285B2Increase stiffnessInhibition effectConnecting rod bearingsCrankshaft bearingsHigh stiffnessEngineering

Disclosed is a sliding bearing consisting of a pair of semi-cylindrical bearings for supporting a crankshaft or a crank pin in an internal combustion engine. The sliding bearing is incorporated in a split-type bearing housing. One of the semi-cylindrical bearings being incorporated in at least one of the pair of housing halves, which one housing half has a relatively higher stiffness, is provided with a number of circumferential grooves on an inner surface of the semi-cylindrical bearing so as to extend circumferentially along the inner surface of the semi-cylindrical bearing. The circumferential grooves existing at least one circumferential end region of the inner surface of the semi-cylindrical bearing have a depth of not less than 10 μm, the circumferential end region including a circumferential bearing end face orientating a direction opposite to the rotation direction of the shaft or pin.

Owner:DAIDO METAL CO LTD

Expanded porous polytetrafluoroethylene film-laminated sheet, and gasket composed of said sheet

ActiveUS8784983B2Improve creep resistanceImprove adhesionBaby linensAdhesivesThin slabThermal compression

The laminated sheet of this invention is a sheet including expanded porous polytetrafluoroethylene films laminated by thermal compression bonding, wherein the sheet has a specific surface area of 9.0 m2 / g or larger and a density of from 0.4 g / cm3 to lower than 0.75 g / cm3, thereby making it possible to improve both the creep resistance and the adhesiveness between the films of the expanded porous PTFE film-laminated sheet.

Owner:W L GORE & ASSOC GK

Bumper

ActiveUS20140062105A1Easy to manufacturePreventing temperature of targetedBumpersVehicle frameEngineering

Providing a bumper absorbing large amount of impact energy with respect to both a light collision and a heavy collision, and preventing the reinforcement beam from bending and protruding backward at a portion where an obstacle collides and from displacing backward in this protruding state. Provided is a bumper for vehicles including a reinforcement beam made of metal and a pair of support members having a hollow cross section, protruding from a vehicle frame, and supporting the reinforcement beam therebetween. A quenched region is provide over a portion including a middle of the reinforcement beam. Unquenched portions are provided on the pair of connecting portions or a pair of adjacent portions inside the pair of connecting portions.

Owner:ASTEER

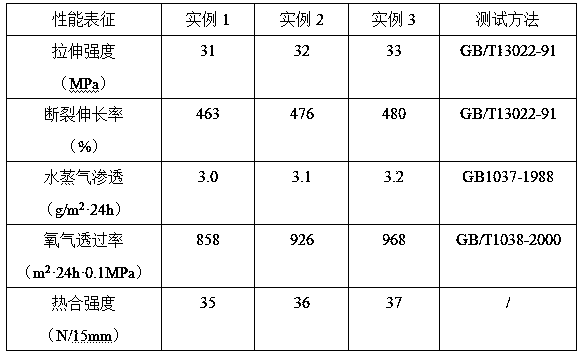

Preparation method for high-combination interface stable type medical transfusion film material

PendingCN110450303ALarge specific surface areaReduce clumpingSynthetic resin layered productsMedical devicesStress concentrationComposite film

The invention relates to a preparation method for a high-combination interface stable type medical transfusion film material and belongs to the technical field of medical materials. According to the technical scheme, silicon dioxide is adopted for modifying crystallization performance of a PET material, a nano silicon oxide material achieves a nucleation effect so that nanometer silicon balls canserve as crystallization crystal nuclei to improve substrate crystallization performance, meanwhile an EVA resin material serves as a bonding interface layer, and stress concentration phenomena generated when a three-phase composite film is subjected to an applied load are reduced with the improvement of interface bonding performance. When an applied load is applied, a flexible deformation layer on the surface of the PET can loosen prestress of an interface and can also transmit stress to the surface of the PET evenly, thus crack extension at the stress section of the film is restrained, tensile strength of the film is improved, and the mechanical property of the high-combination interface stable type medical transfusion film material is further improved.

Owner:刘军伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com