Webbing take-up device

A technology for coiling devices and safety belts, which is applied to safety belts in vehicles, combined with energy-absorbing devices, belt tighteners, etc., can solve problems such as increasing the amount of gas generated, reducing the force of rotation, and increasing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

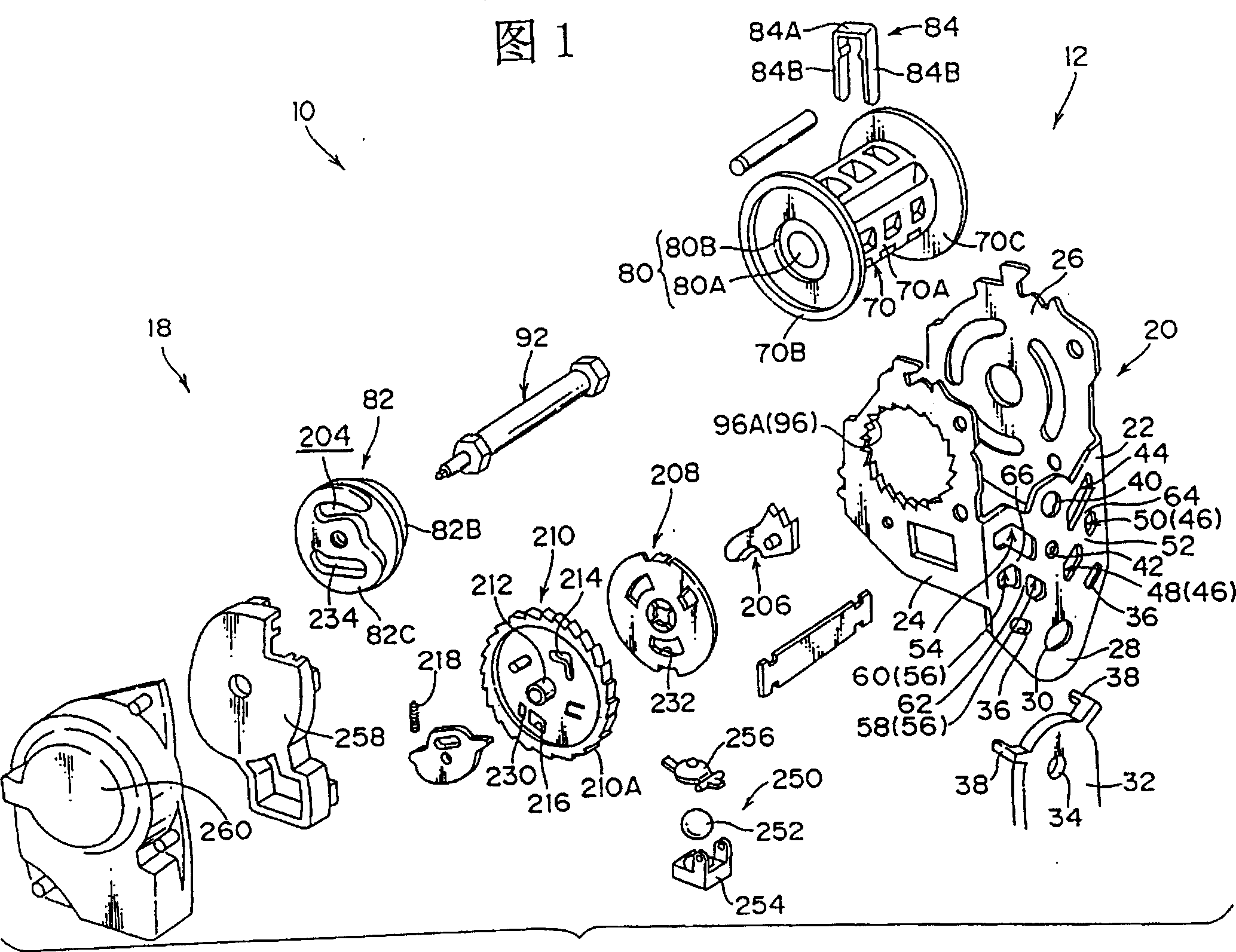

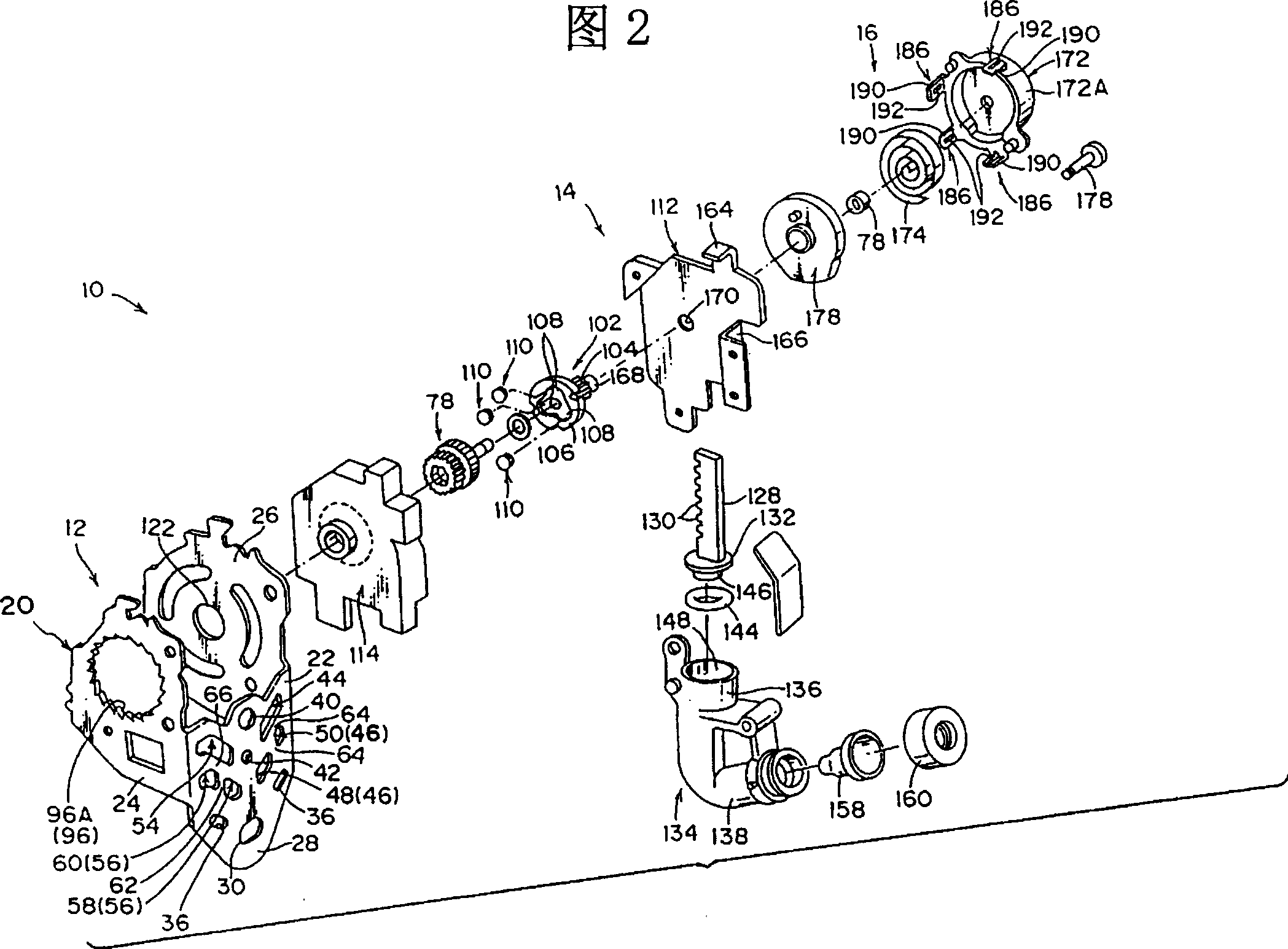

[0104] 1 and 2 show exploded perspective views of a seat belt take-up device 10 according to an embodiment of the invention. As shown in these figures, the seat belt take-up device 10 is composed of a device body 12 , a pretensioner 14 , an elastic force applying portion 16 , and a lock device 18 .

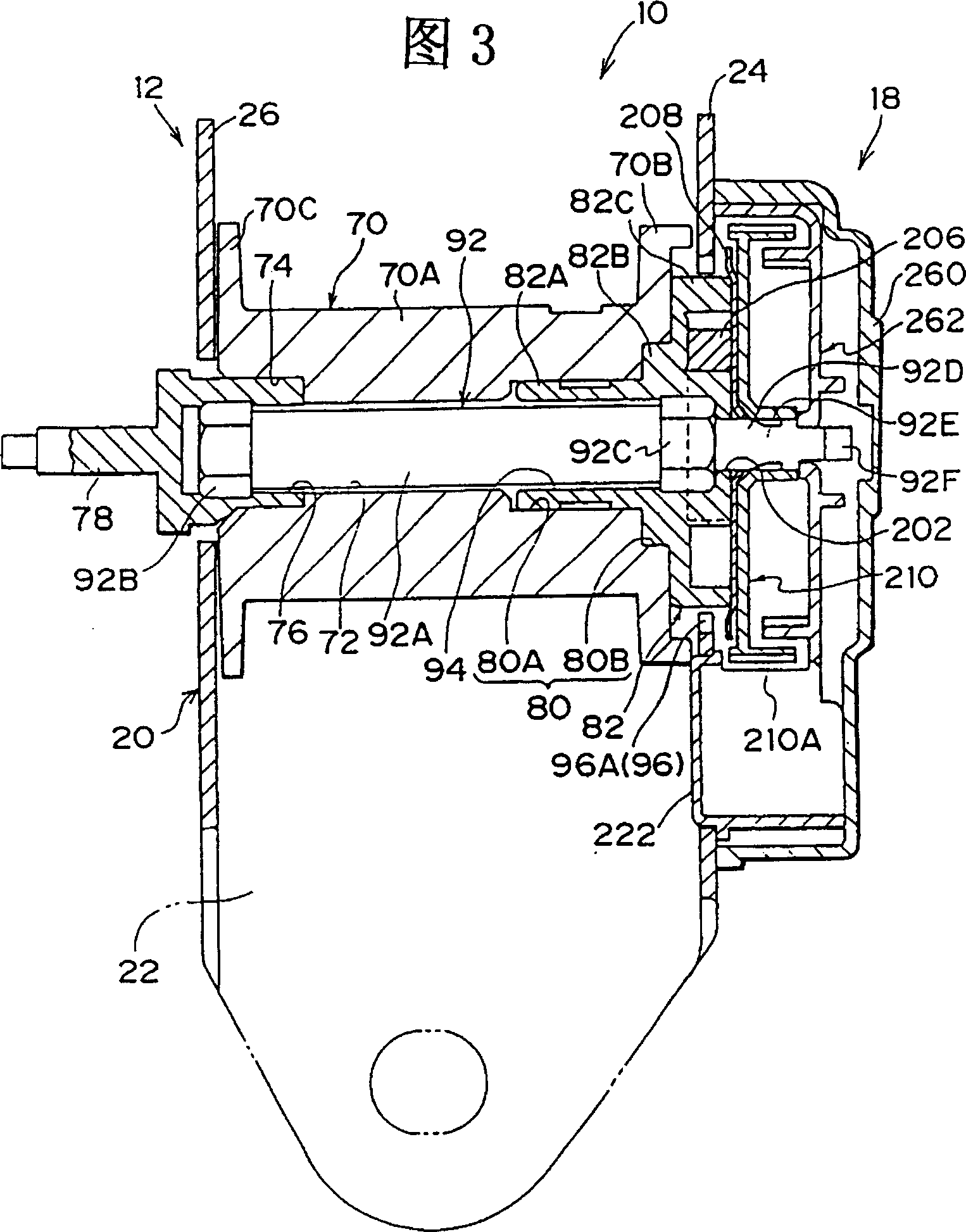

[0105] As shown in FIG. 1 , FIG. 2 , and FIG. 3 , the device body 12 has a bracket 20 . The bracket 20 is composed of a flat base 22 and a pair of leg plates 24 and 26 protruding in parallel from both ends in the width direction of the base 22 in this direction, and is formed so as to face one side in the thickness direction of the base 22 as a whole in a plan view. Opening in the shape of the word 匚.

[0106] (Detailed description of bracket 20)

[0107] FIG. 4 shows a front view of the bracket 20 . As shown in this figure, at the base 22 of the bracket 20, the lower side of the connecting portion with the foot plates 24, 26 forms a substantially triangular fixing portion 28 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com