Patents

Literature

57results about How to "Increase intake flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

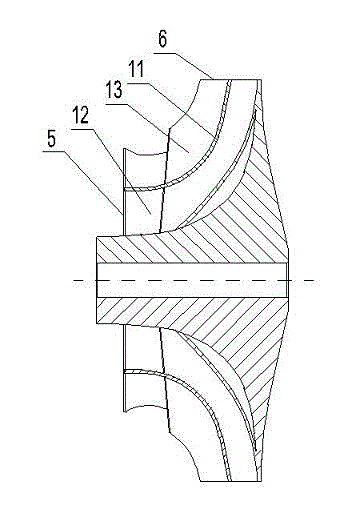

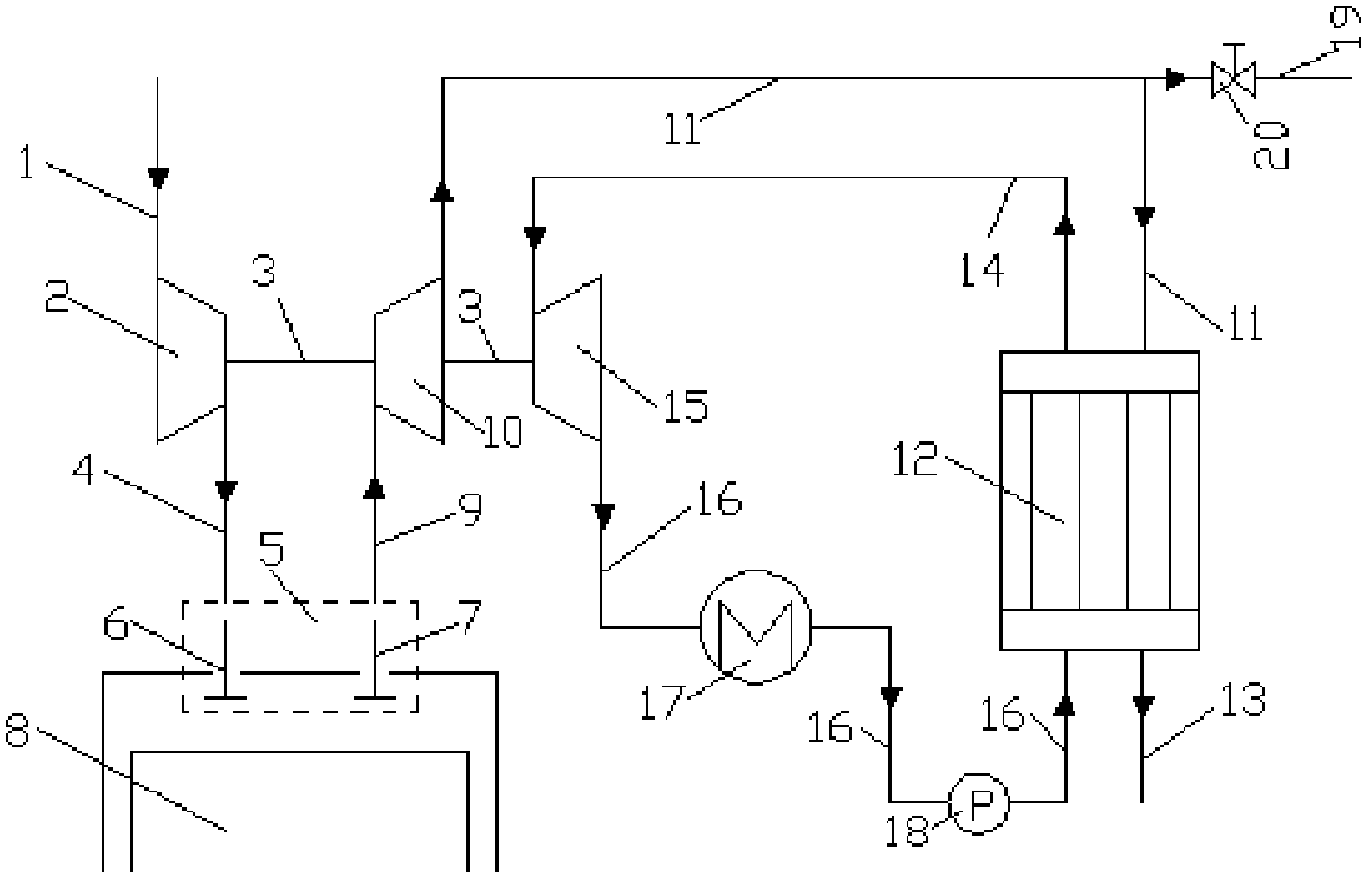

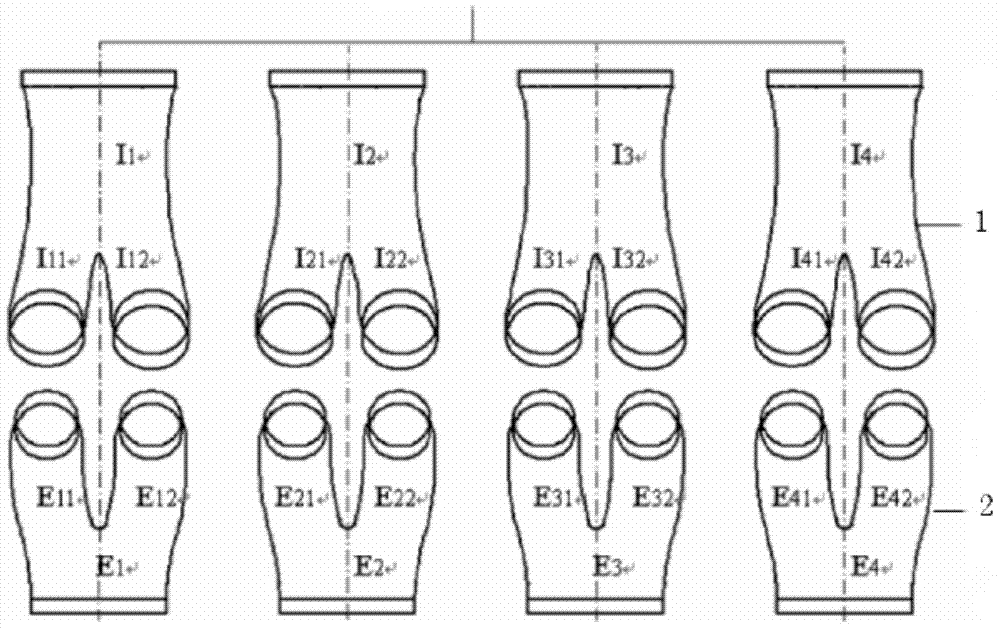

Turbofan engine

ActiveUS20090304518A1Increase flow rateSame flow rateEngine manufacturePump componentsLeading edgeEngineering

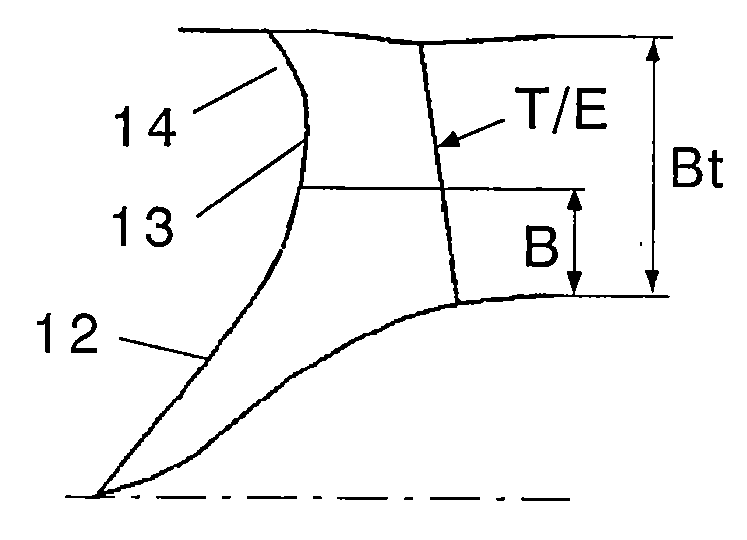

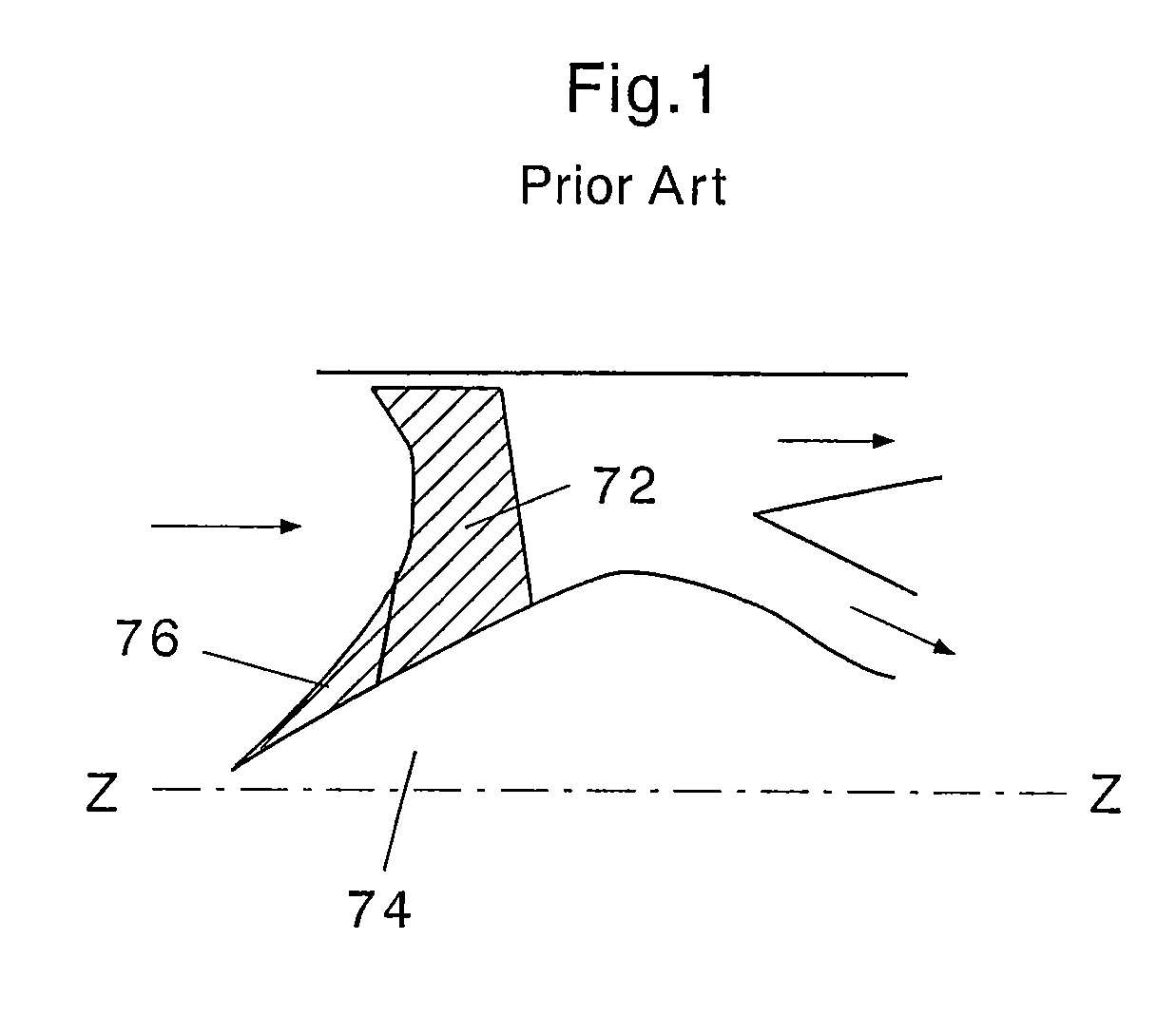

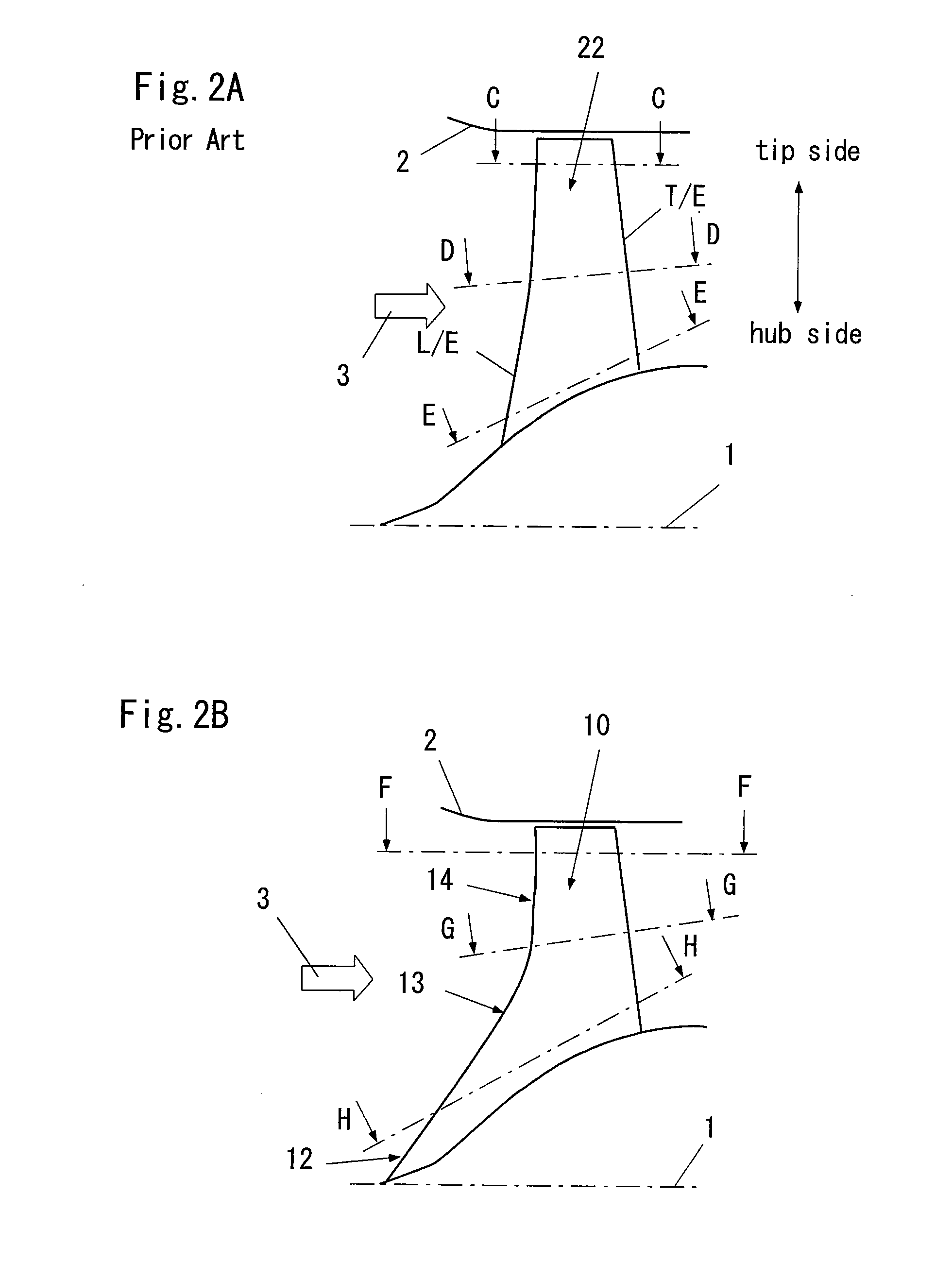

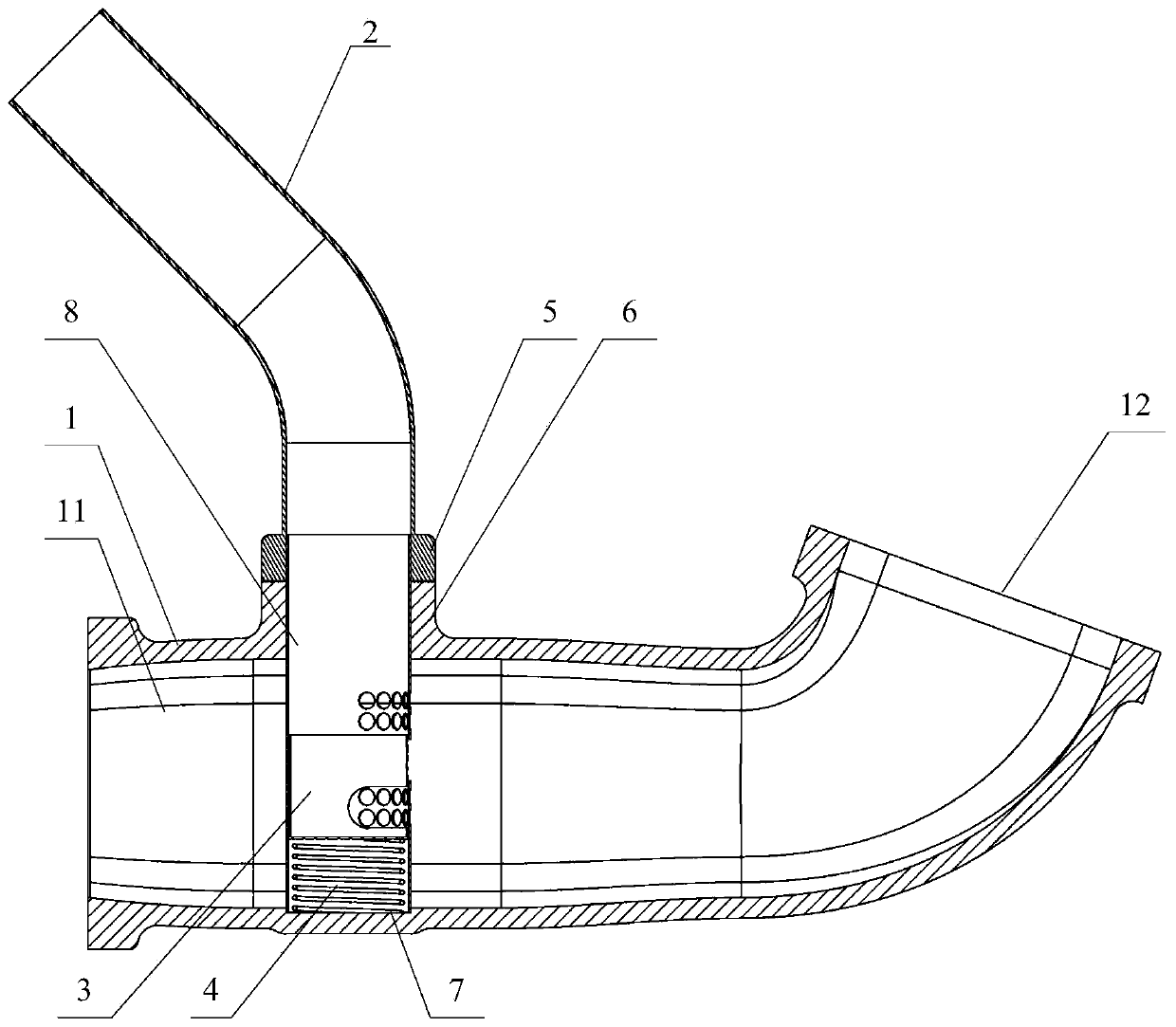

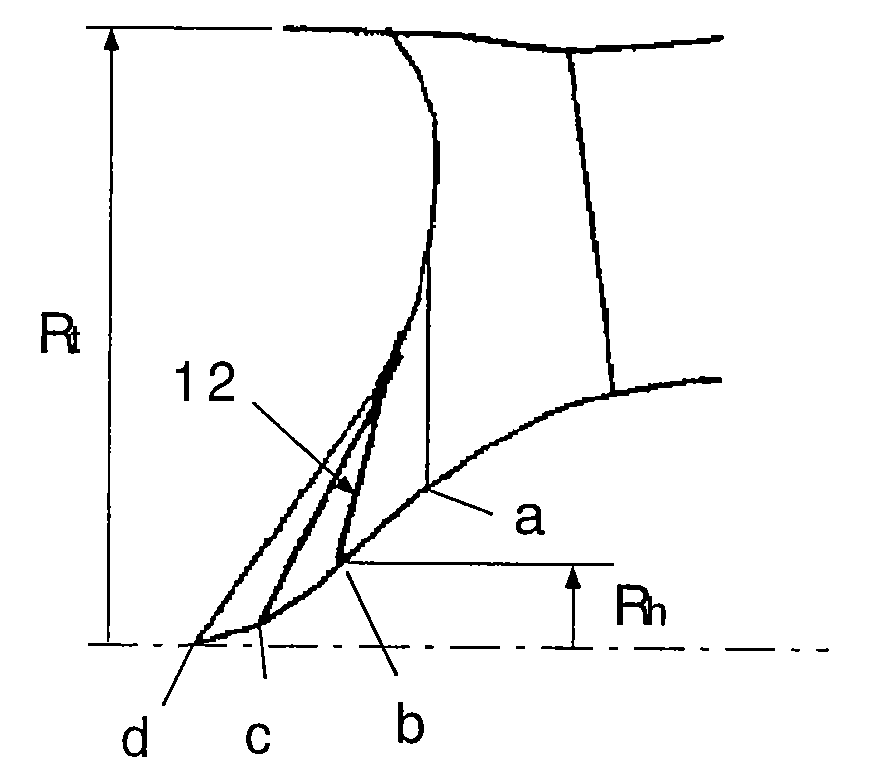

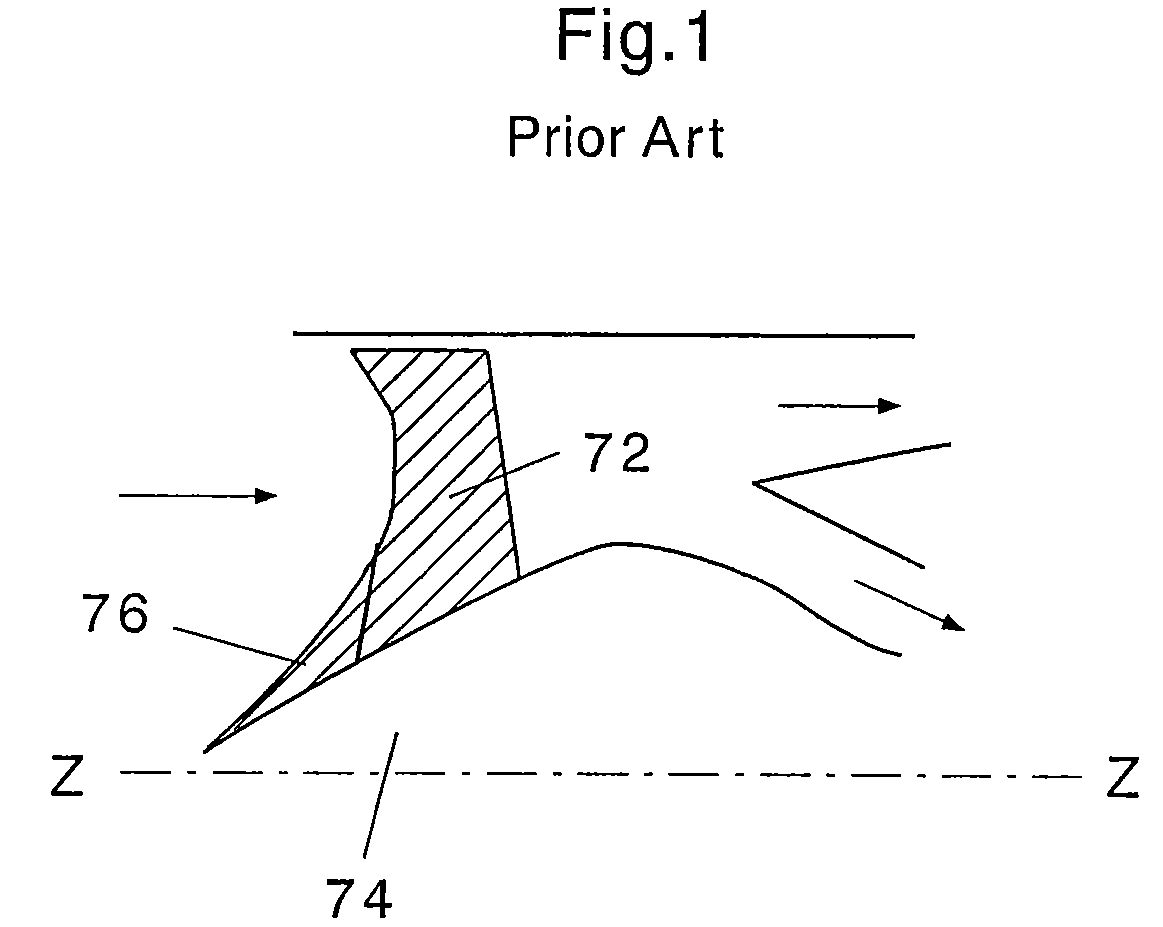

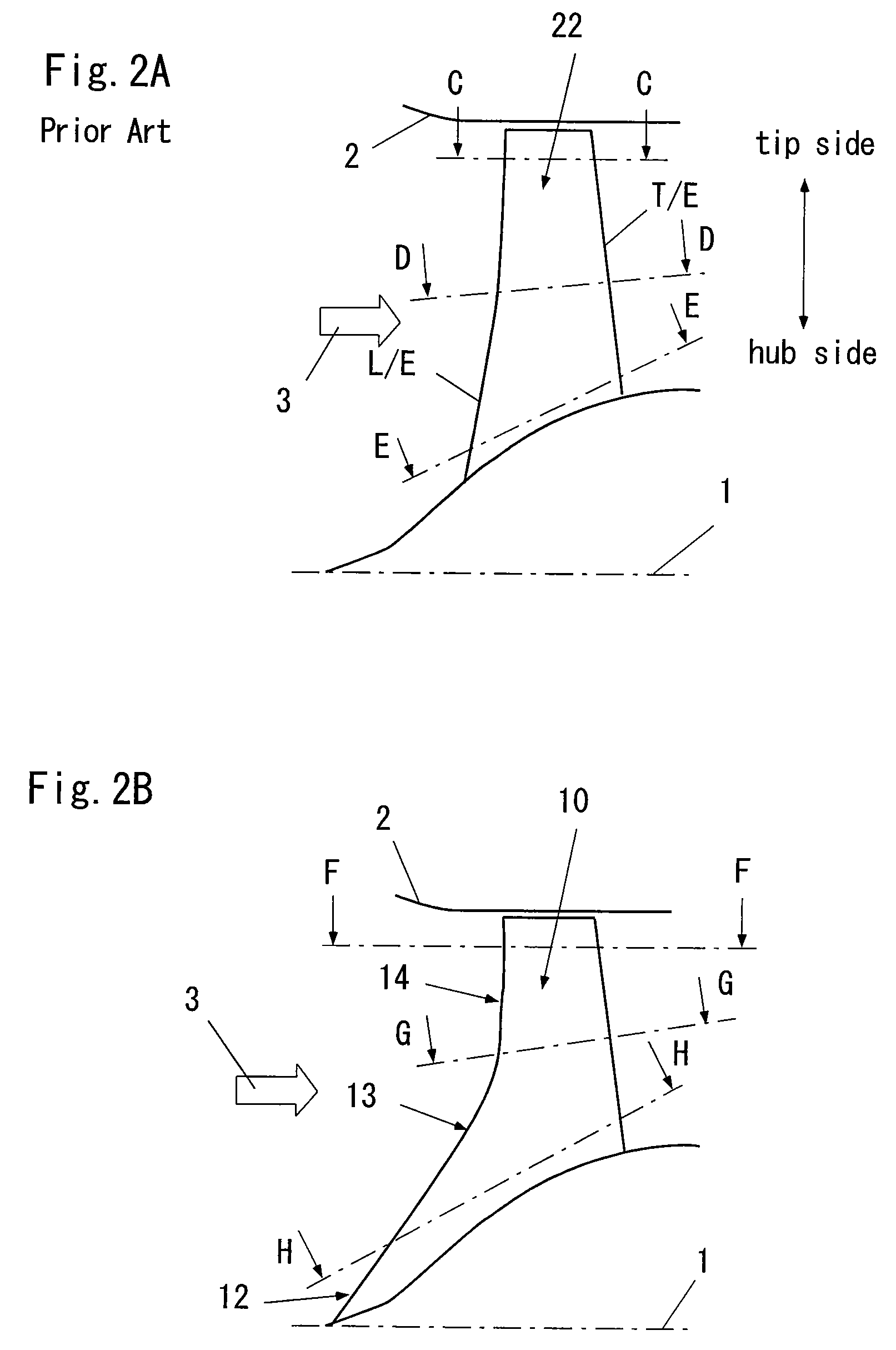

A hub-side leading edge part of a fan first-stage rotating blade 10 for taking an air thereinto more extends in a forward direction of an engine than a tip-side leading edge part and a mid-span leading edge part. The hub side of the fan first-stage rotating blade 10 is integrally connected as one with the tip side and the mid span while having a longer chord length than those of the tip side and the mid span. A radius at a root of the hub-side leading edge part is set in a boss ratio of 0 to 0.4.

Owner:IHI CORP

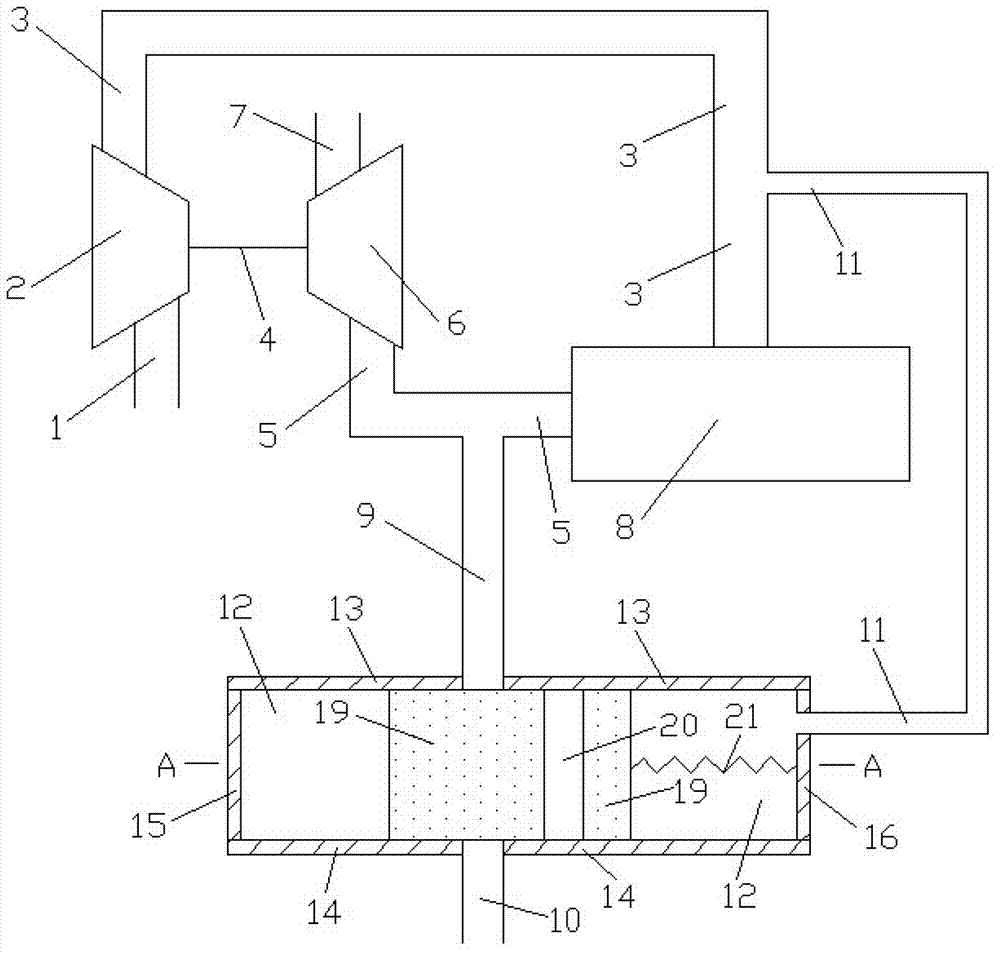

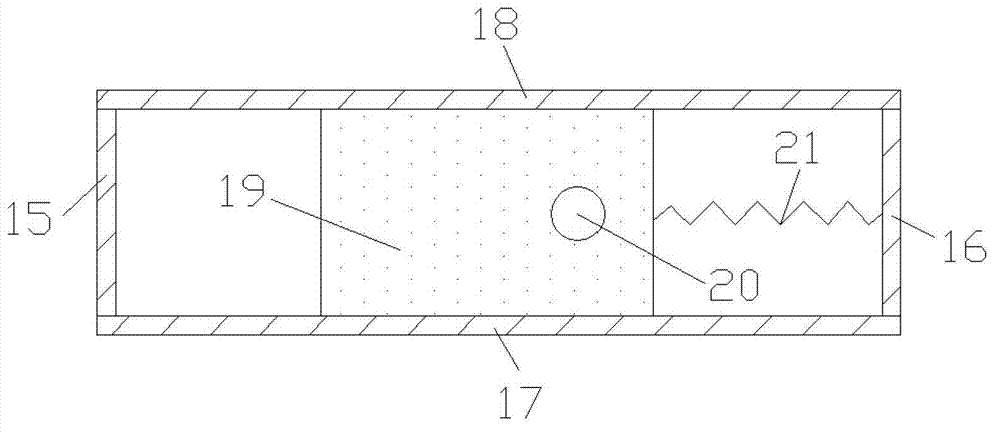

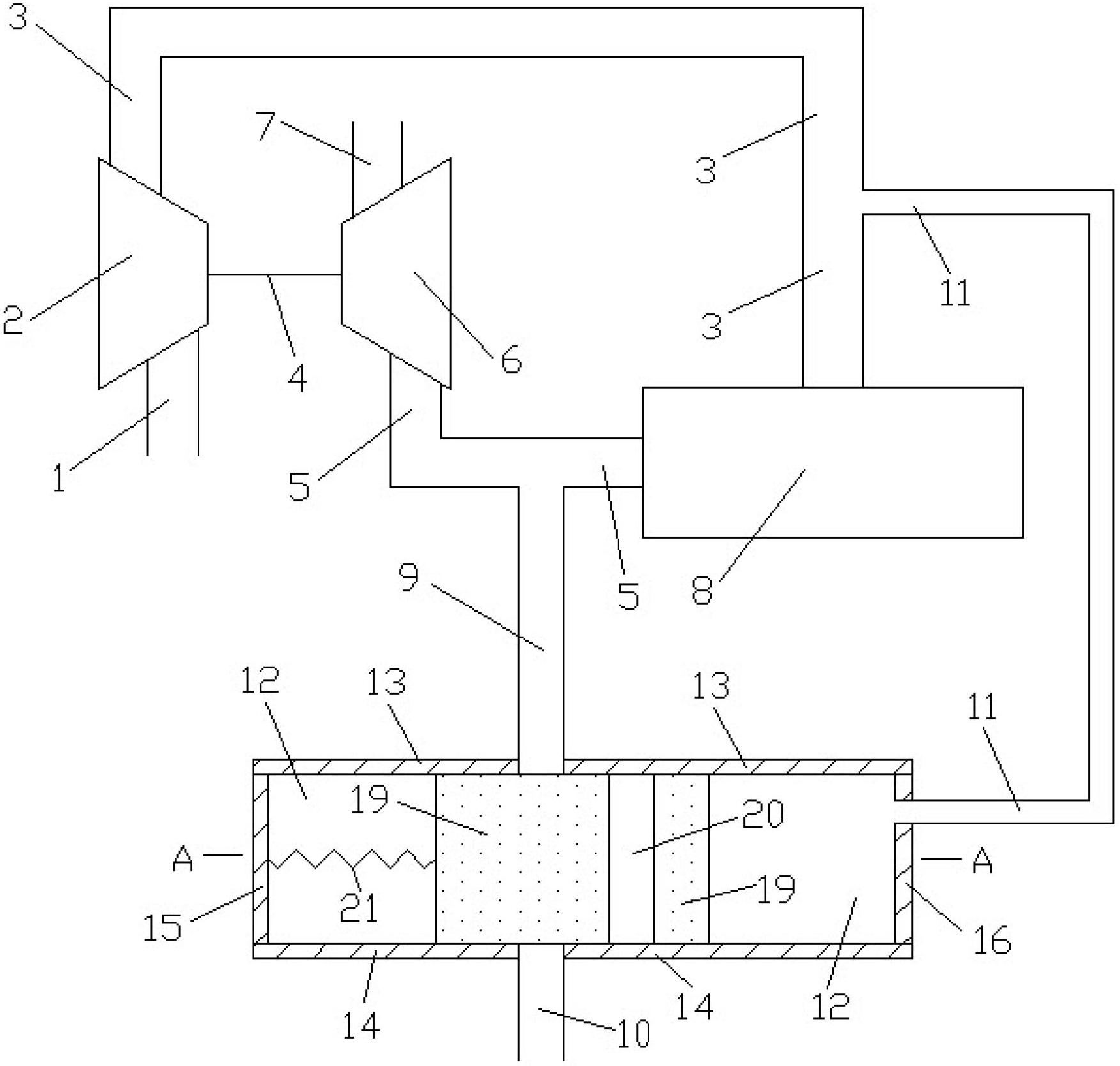

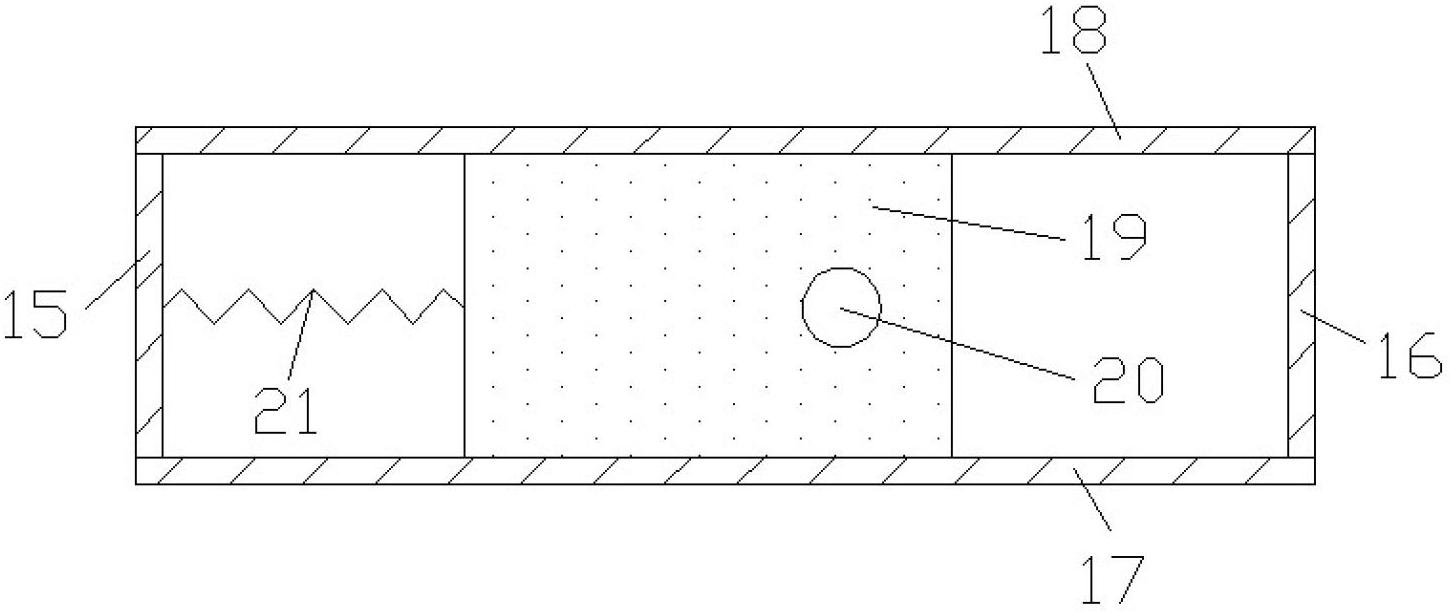

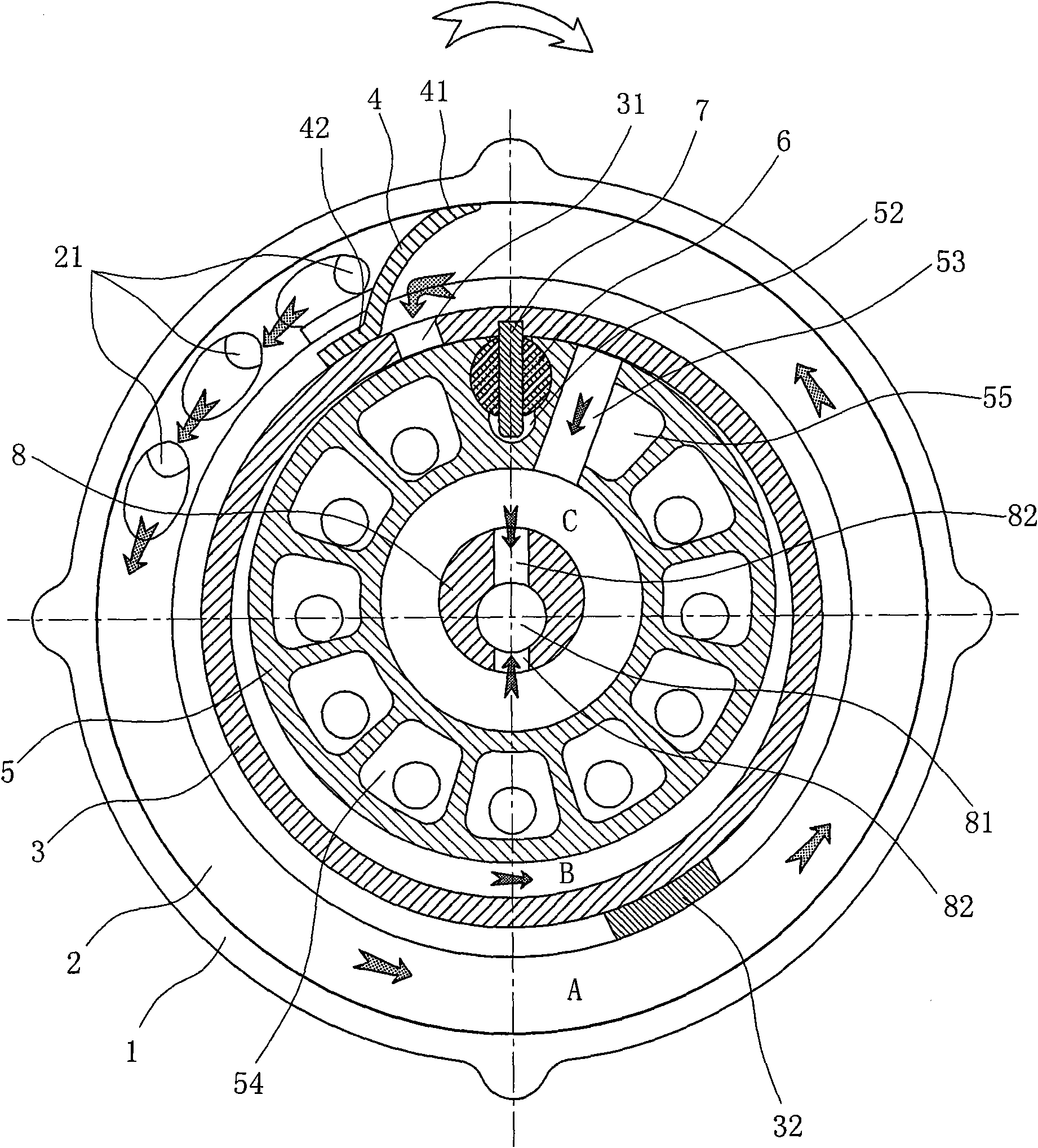

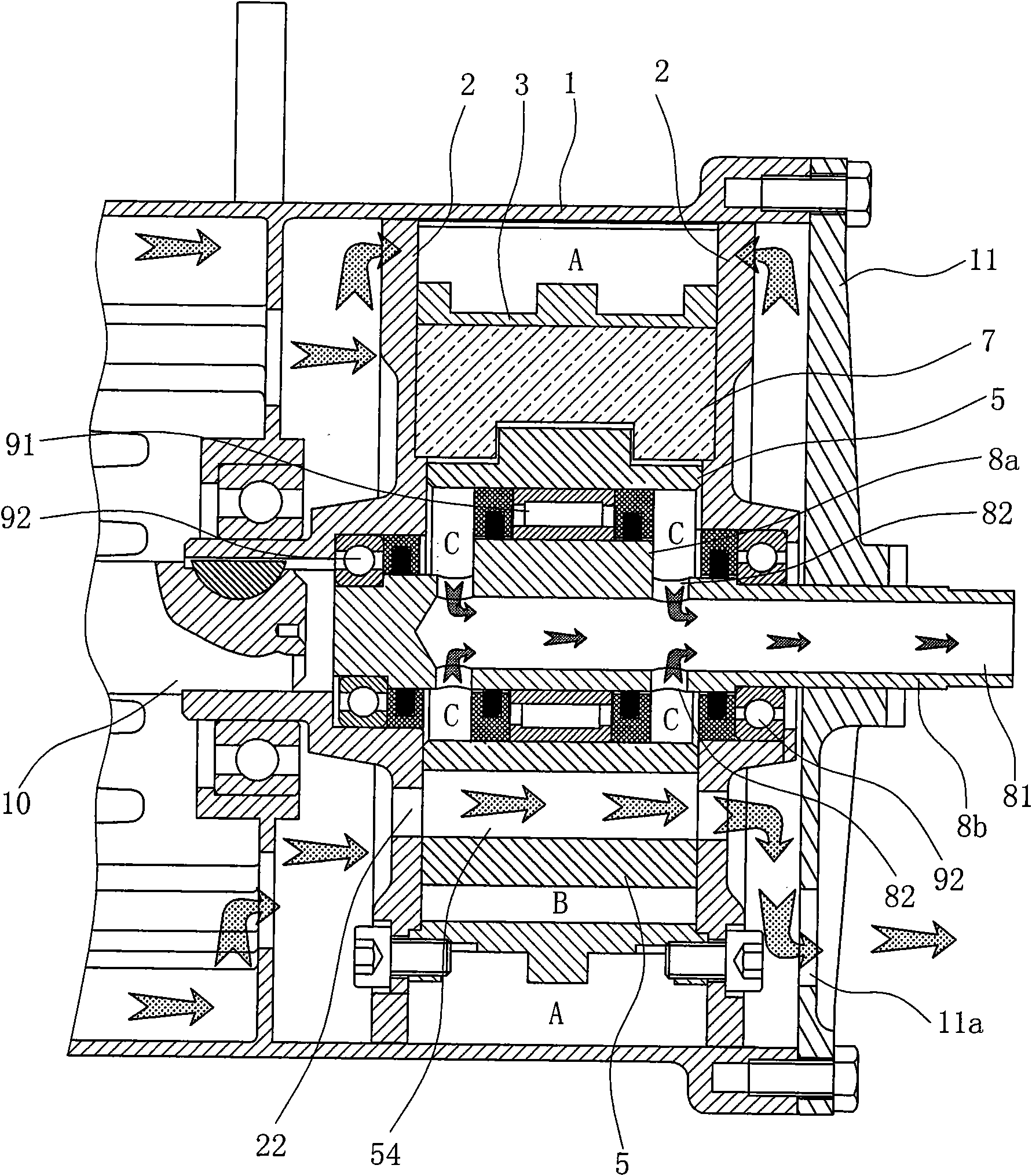

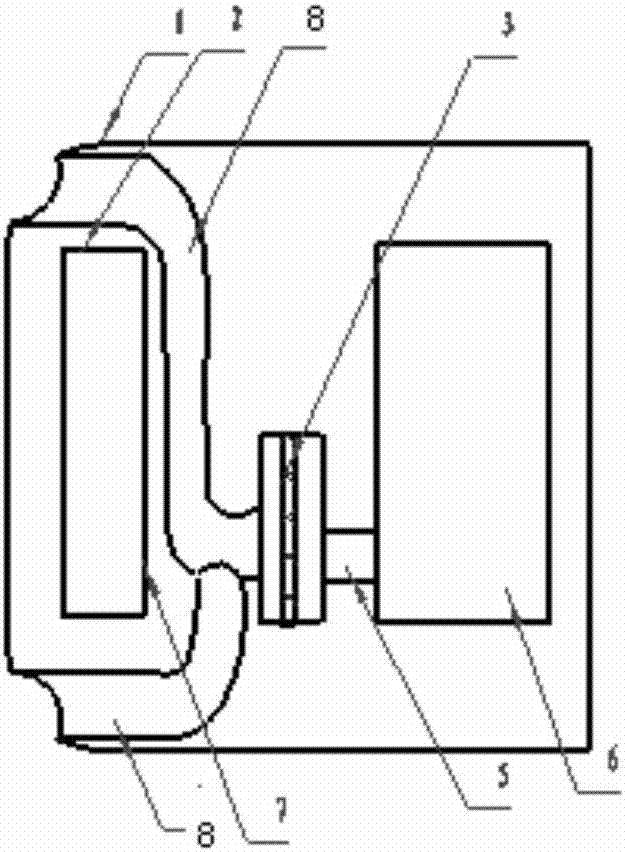

Double-driving parallel sequential supercharging compressor

ActiveCN102720692AIncrease intake flowImprove performanceEngine manufacturePump componentsImpellerLow speed

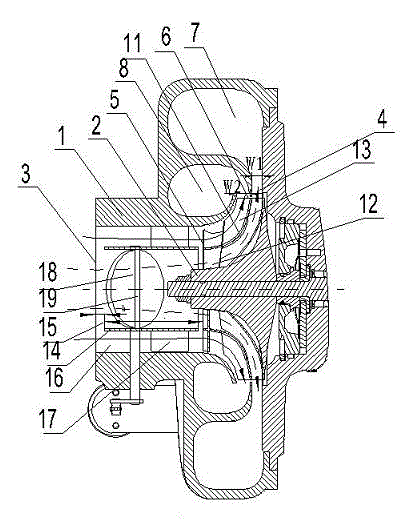

The invention discloses a double-driving parallel sequential supercharging compressor which comprises a compressor casing and a compressor impeller installed in the compressor casing. A compressor flow path is arranged in the compressor casing, and a compressor air inlet and a compressor air outlet which both communicate with the compressor flow path are arranged on the compressor casing. The compressor impeller is provided with an impeller air inlet flow path which communicates with the compressor air inlet and the compressor flow path. The double-driving parallel sequential supercharging compressor of the invention can effectively improve the compressor surge when the compressor is under a low speed condition, and effectively expand intake air flow when the compressor is under a middle or high speed condition and improve engine performance. The compressor casing and the compressor impeller of the double-driving parallel sequential supercharging compressor of the invention has good structural inheritance, and engineering is easy to be realized rapidly.

Owner:康跃科技(山东)有限公司

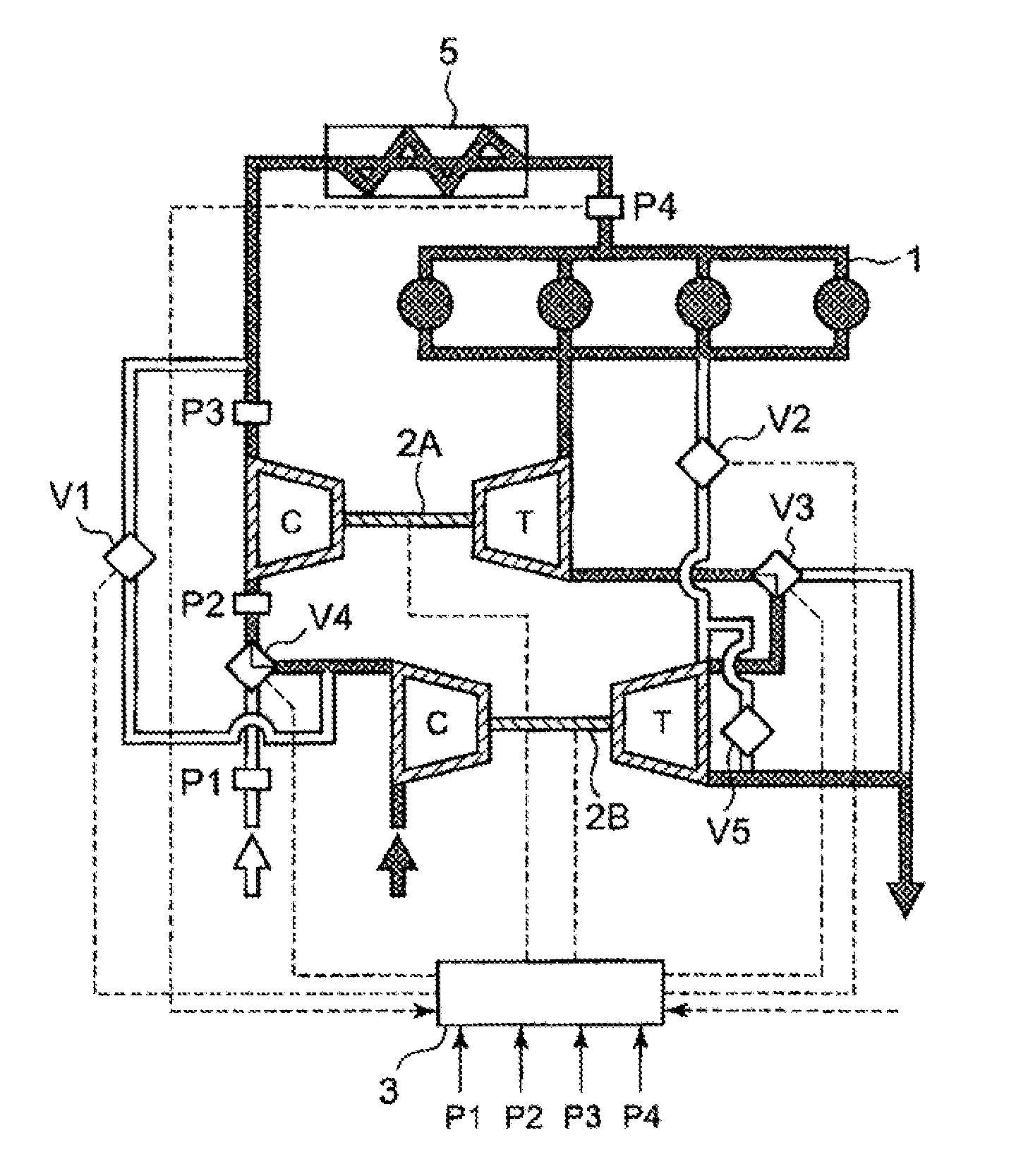

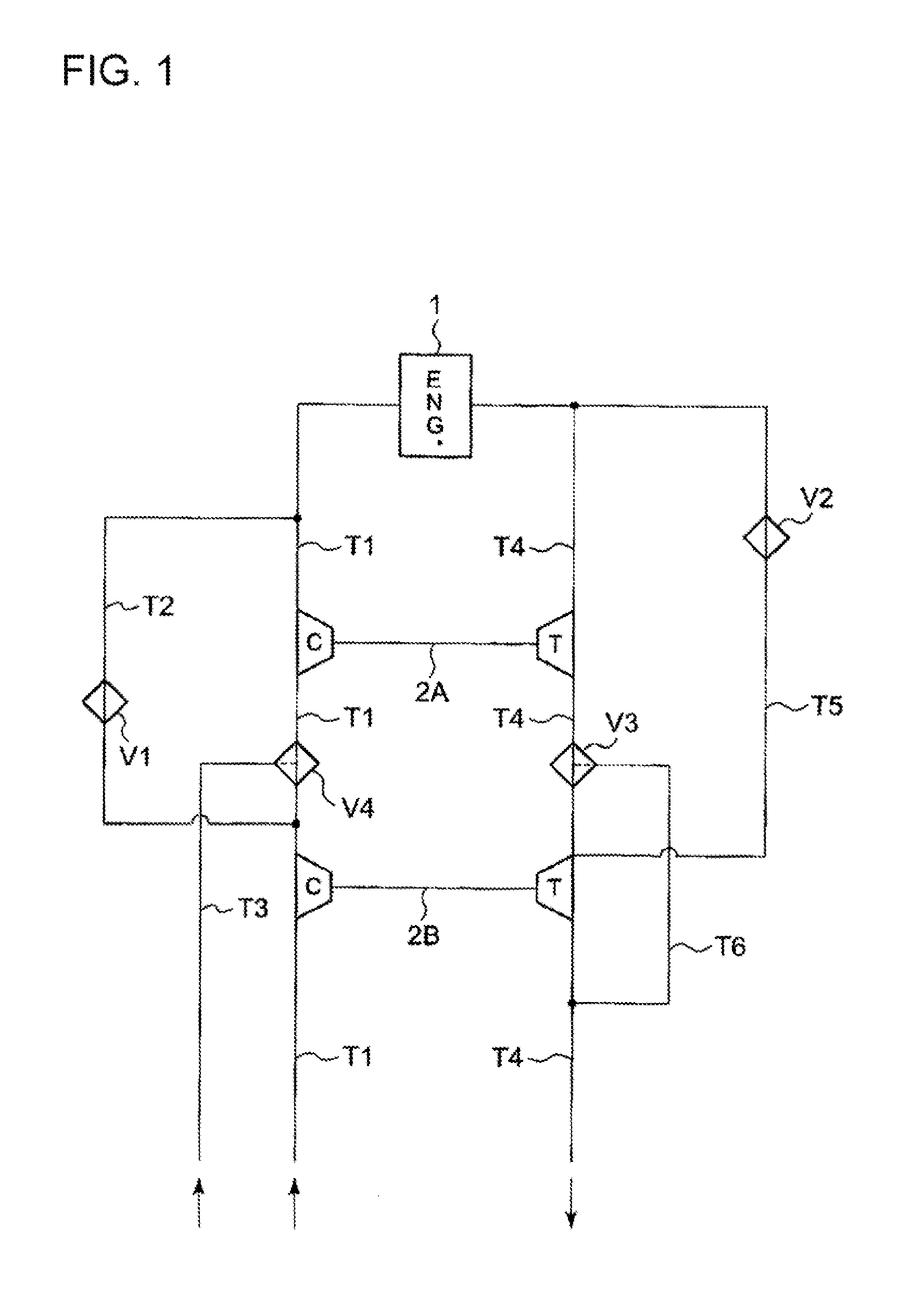

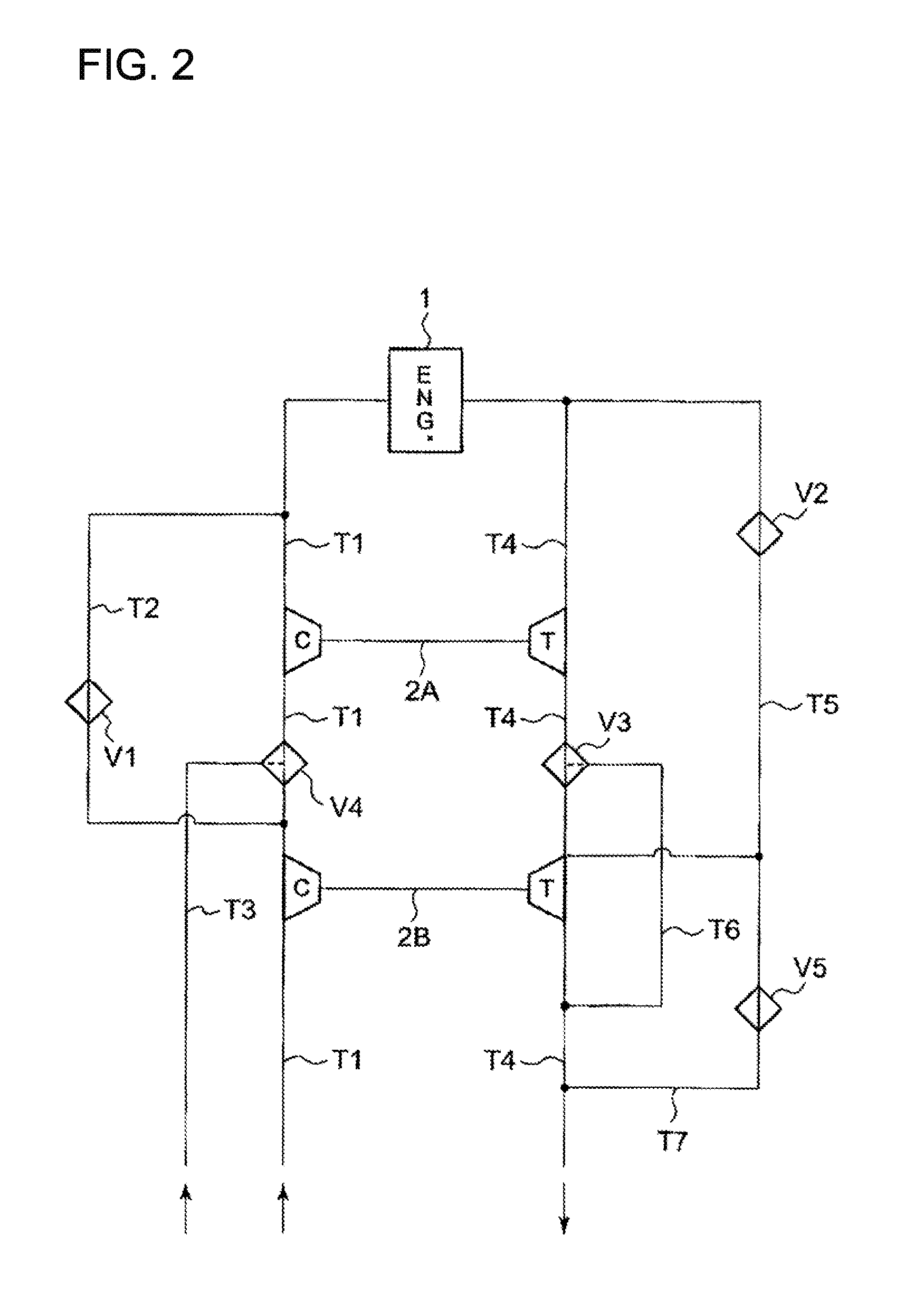

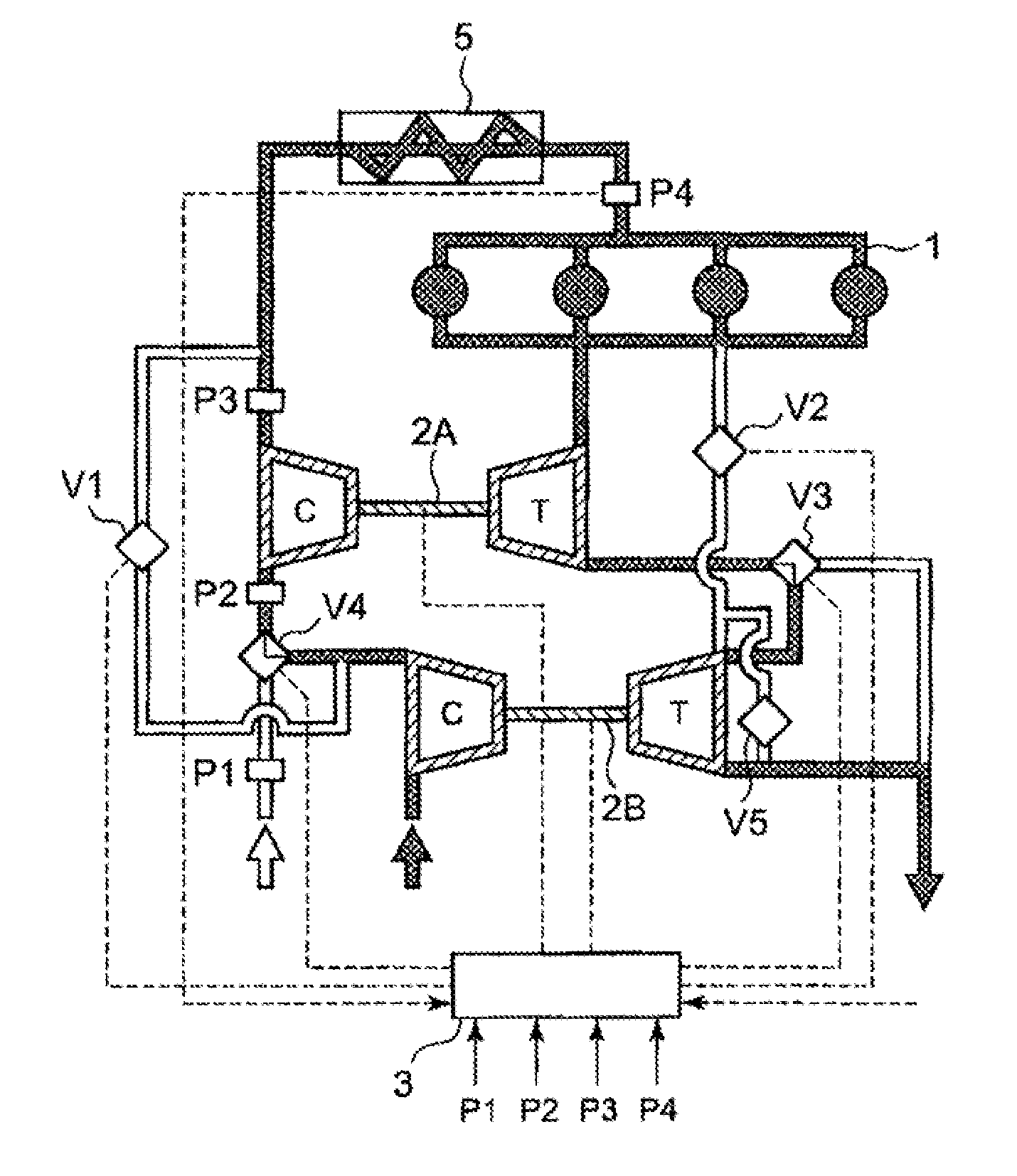

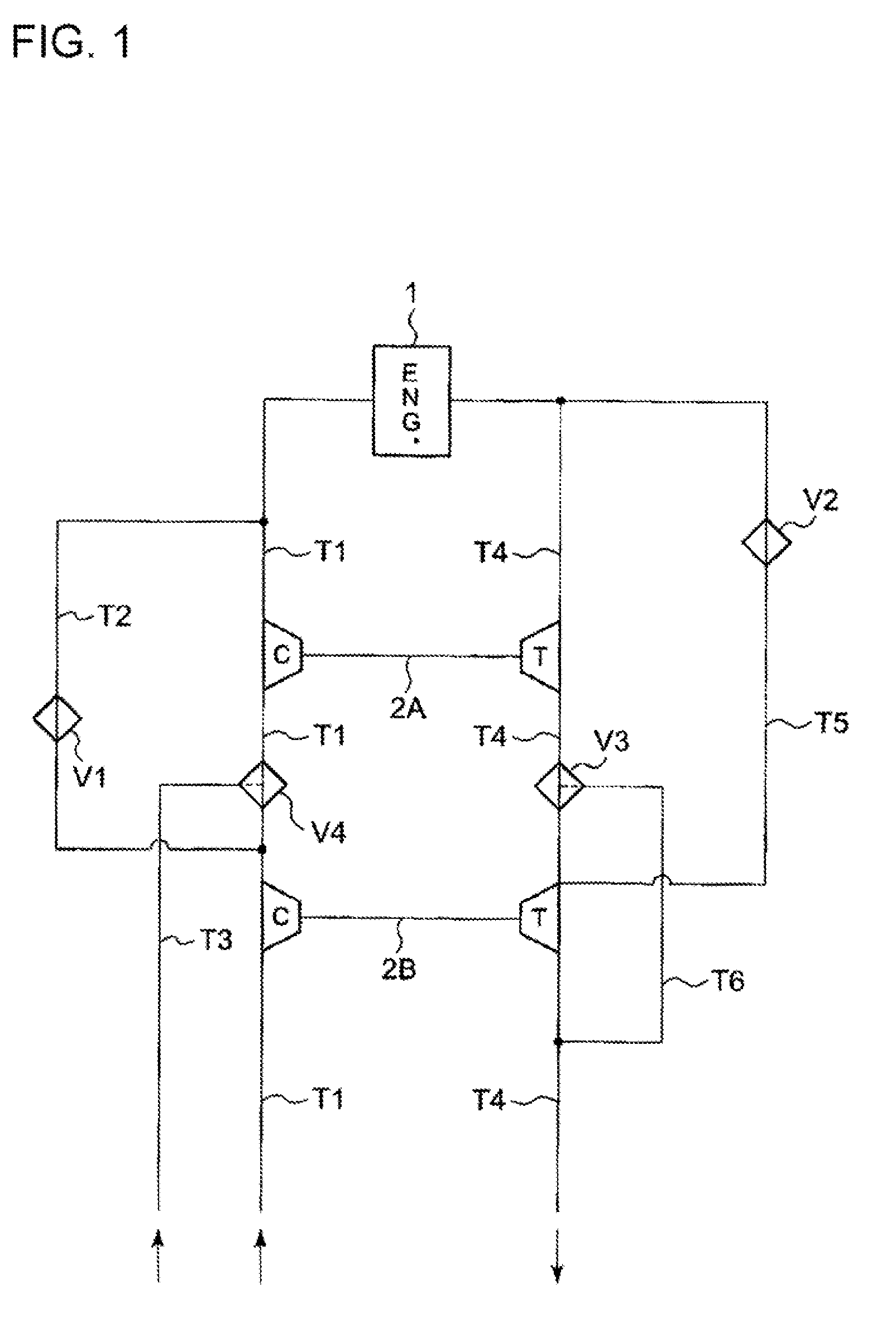

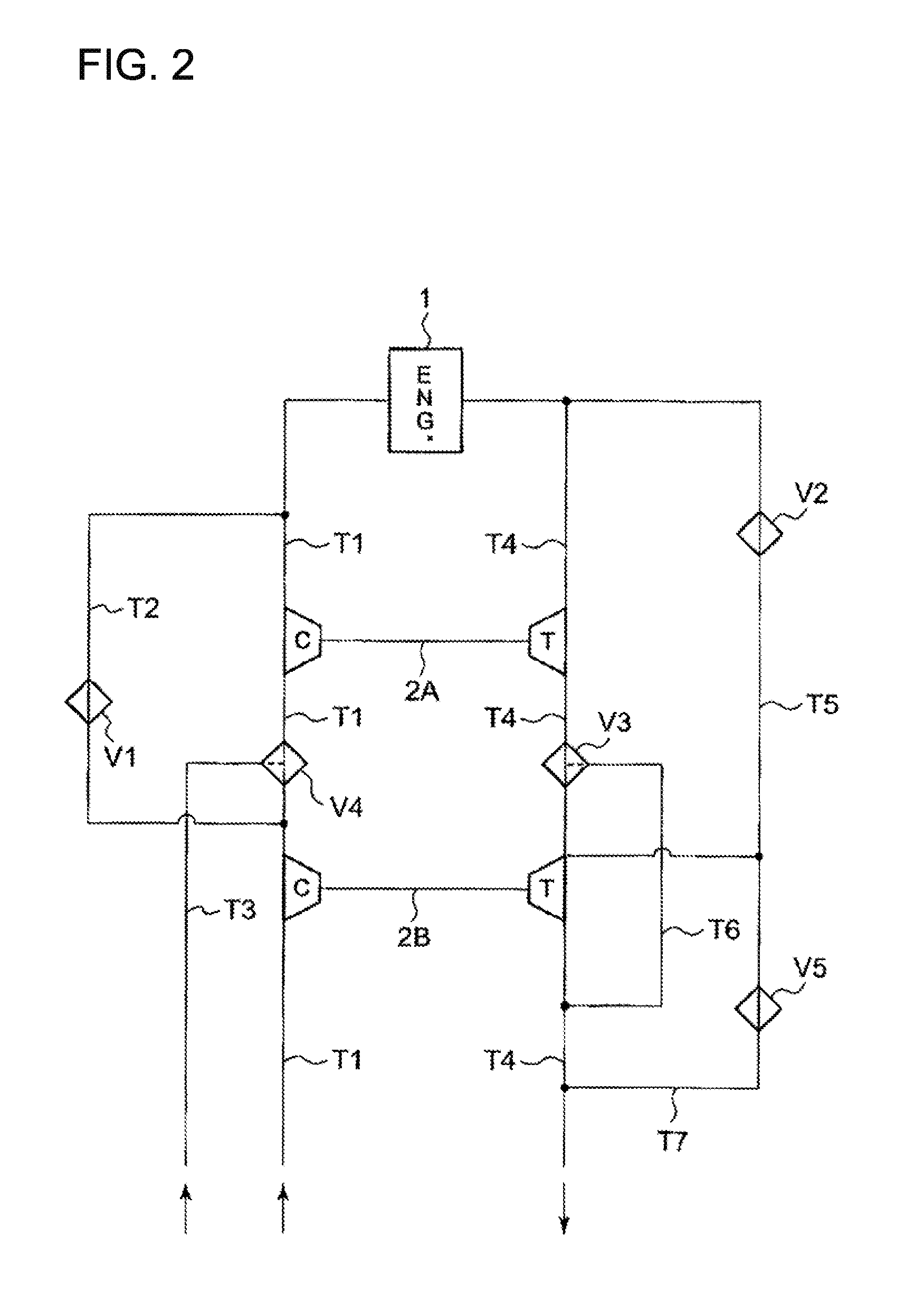

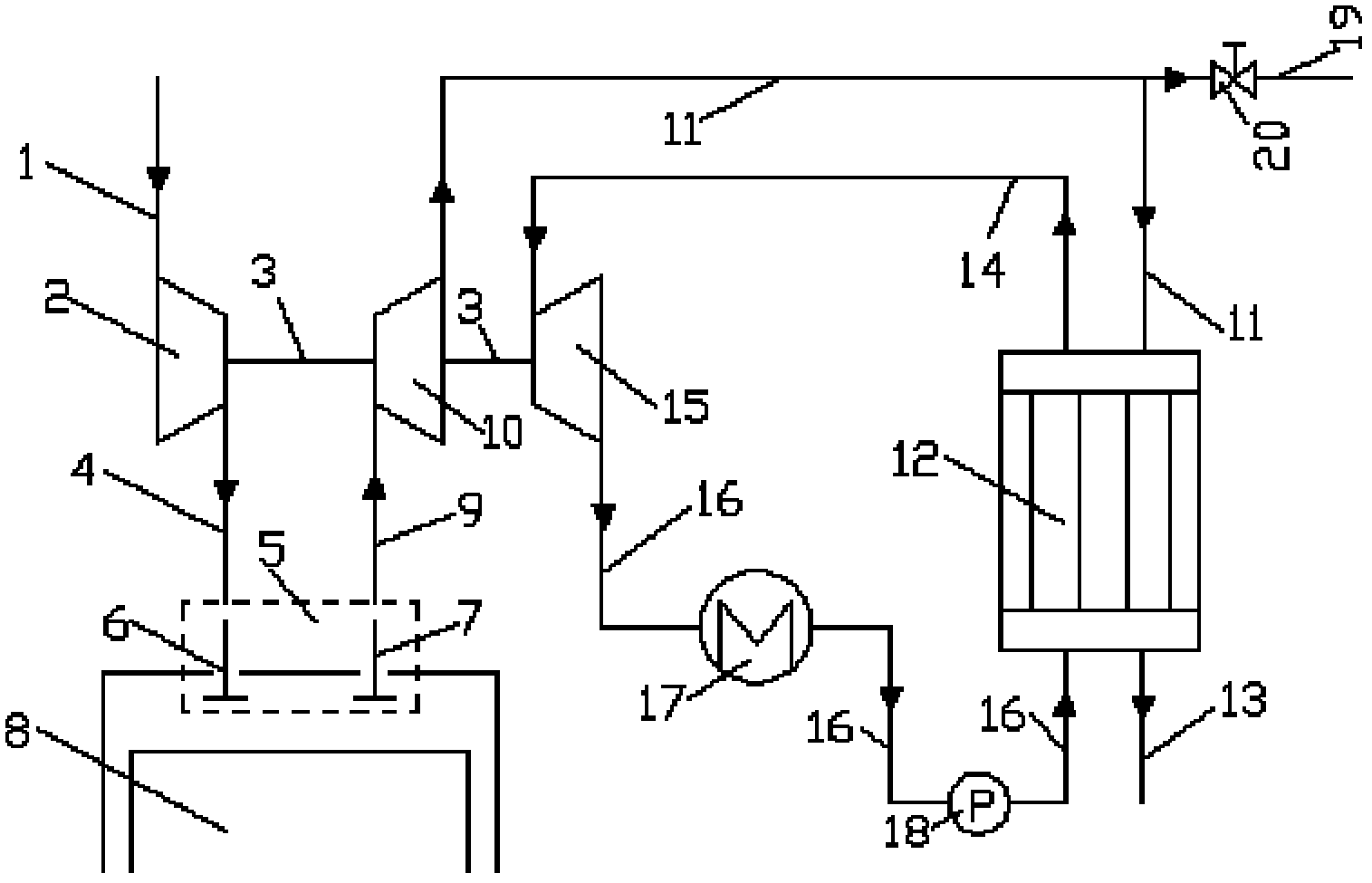

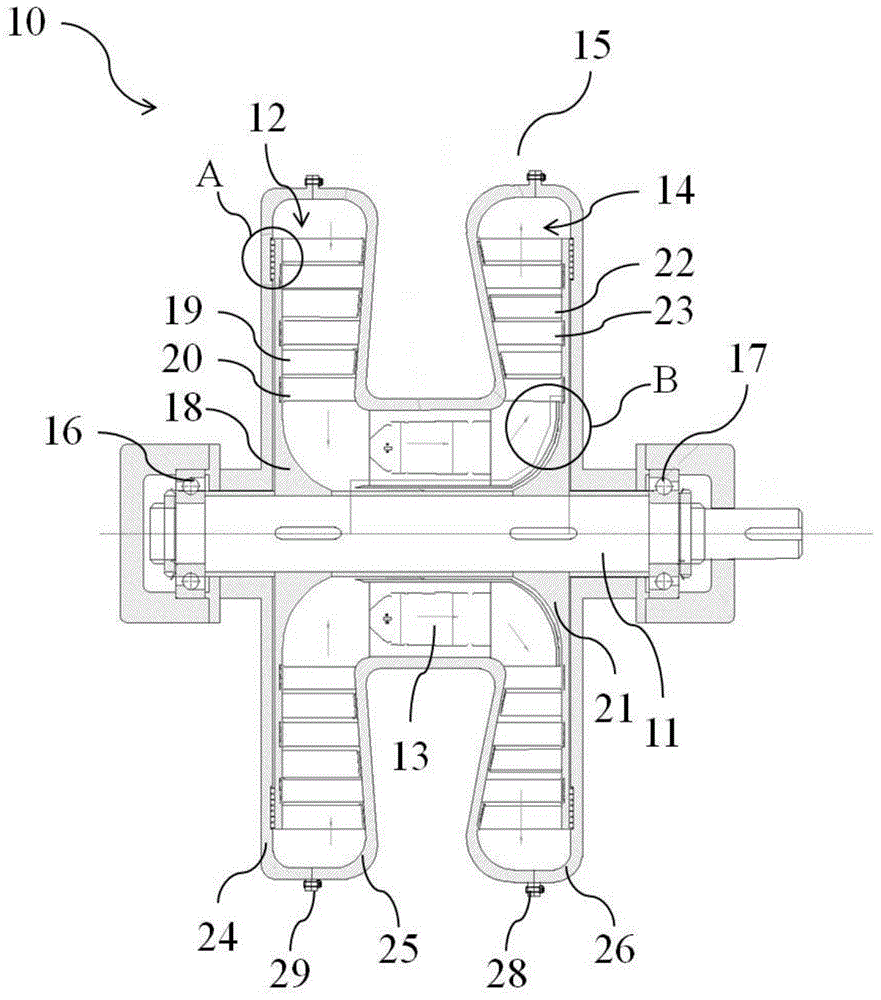

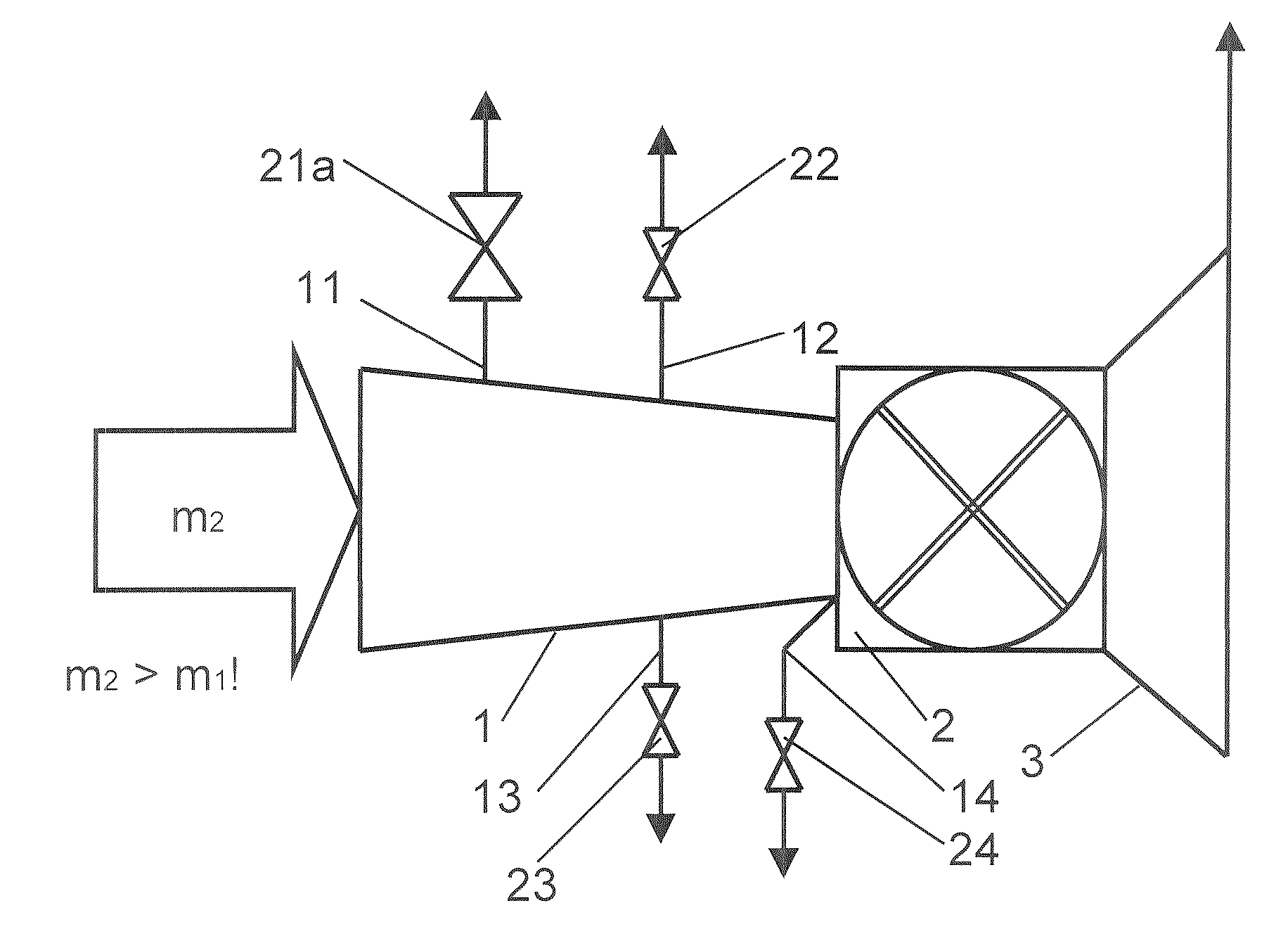

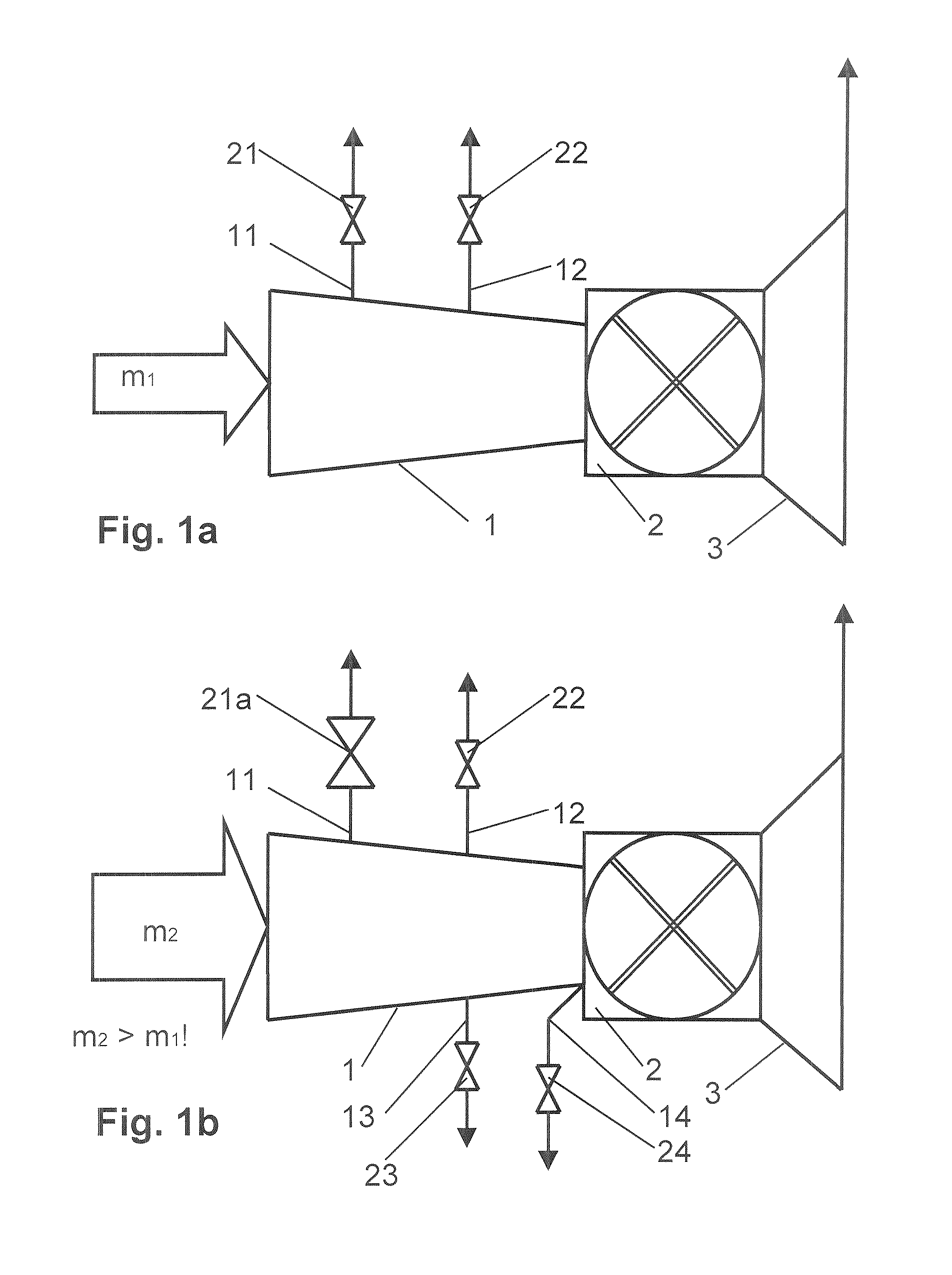

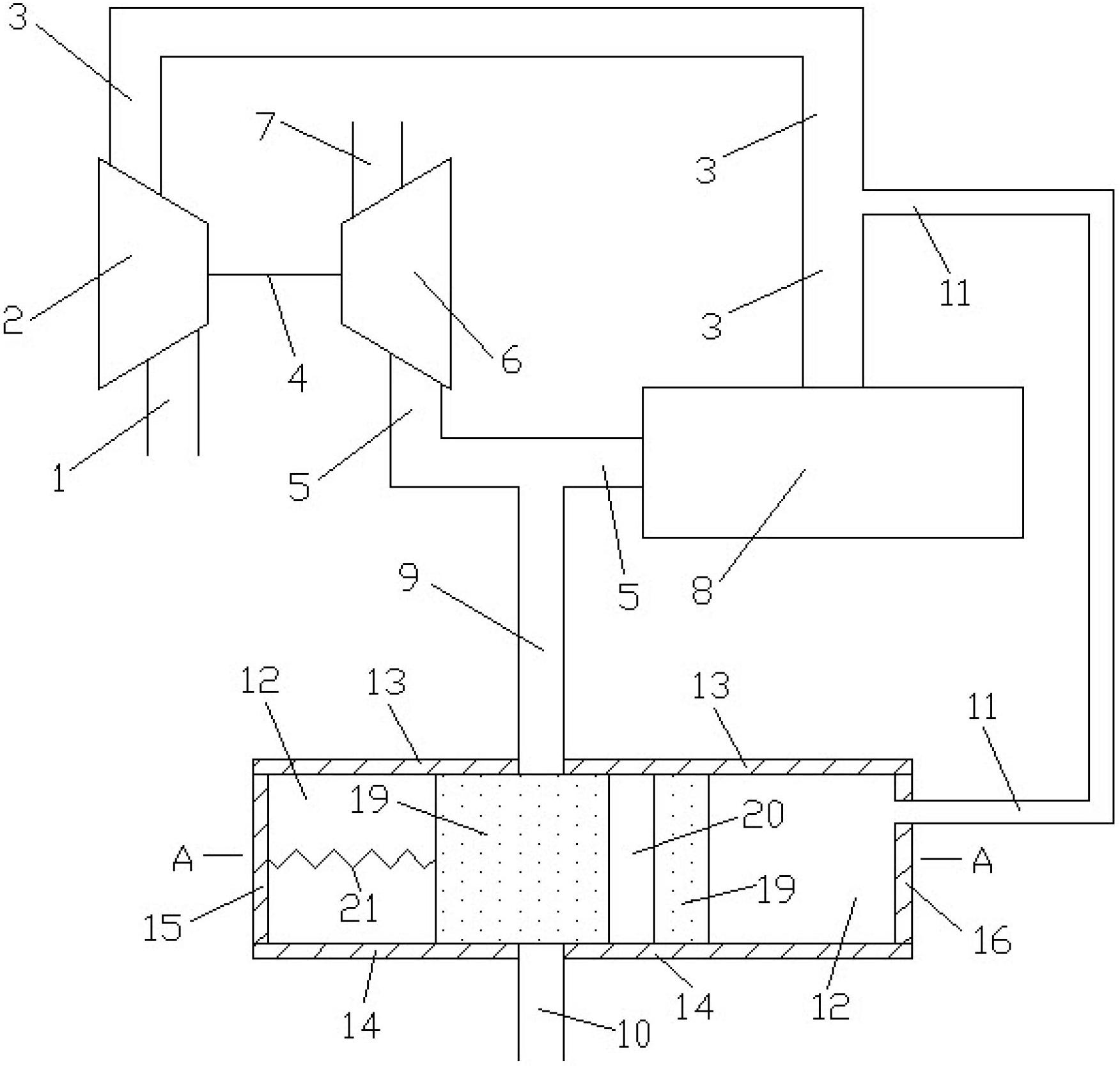

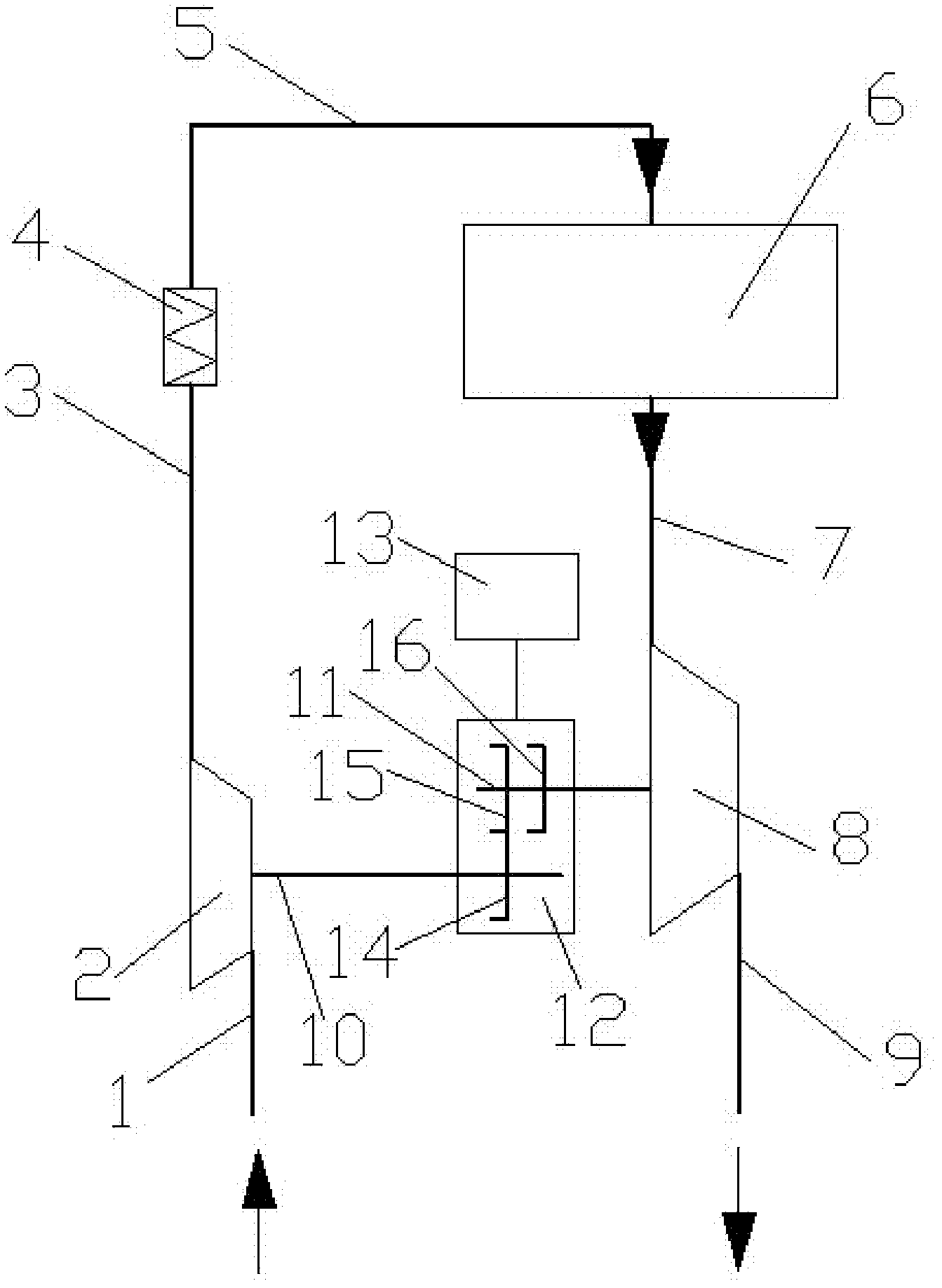

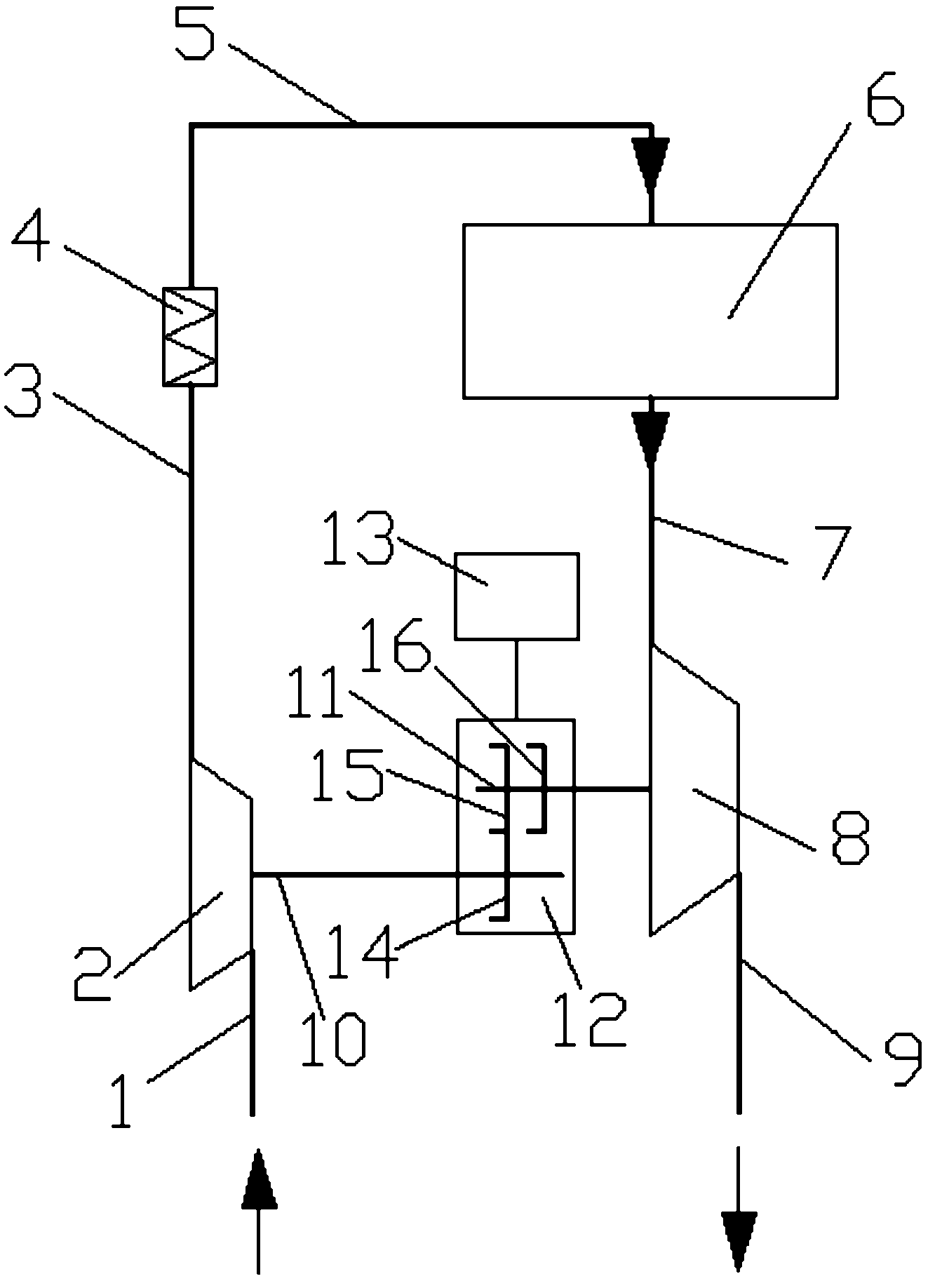

Turbocharging system for internal combustion engine

ActiveUS20110296828A1Improve responsivenessIncrease intake flowInternal combustion piston enginesEngine controllersTurbochargerControl valves

A two-stage turbo system using small-sized turbo-superchargers and simply configured. A two-stage turbo system provided with an internal combustion engine (1), two turbo-superchargers (2A, 2B) driven by exhaust gas from the internal combustion engine (1), control valves (V1-V5) for switching between the flow path of intake gas sucked into the internal combustion engine (1) and the flow path of exhaust gas from the internal combustion engine (1), and a control device for controlling the control valves (V1-V5) and the turbo-superchargers (2A, 2B). The two turbo-superchargers (2A, 2B) have the same turbine capacity, function respectively as the high-pressure side turbo-supercharger (2A) on the exhaust path upstream side and the low-pressure side turbo-supercharger (2B) on the exhaust path downstream side, and have, by switching between the flow paths by using the control valves (V1-V5), a series mode in which the two turbo-superchargers (2A, 2B) are serially connected to each other, a one-stage supercharging mode in which gas flows only to the high-pressure-side turbo-supercharger (2A) or only to the low-pressure-side turbo-supercharger (2B), and a parallel mode in which the two turbo-superchargers (2A, 2B) are connected in parallel to each other.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Turbocharging system for internal combustion engine

ActiveUS8635869B2Improve responsivenessIncrease intake flowInternal combustion piston enginesEngine controllersTurbochargerEngineering

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

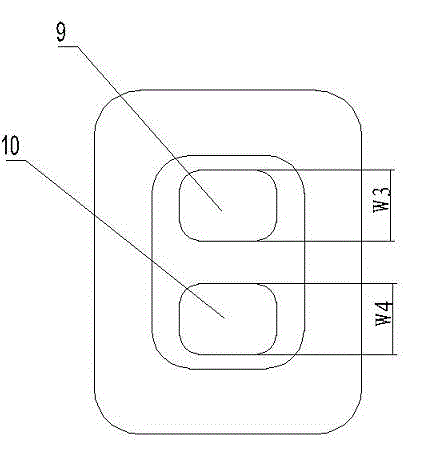

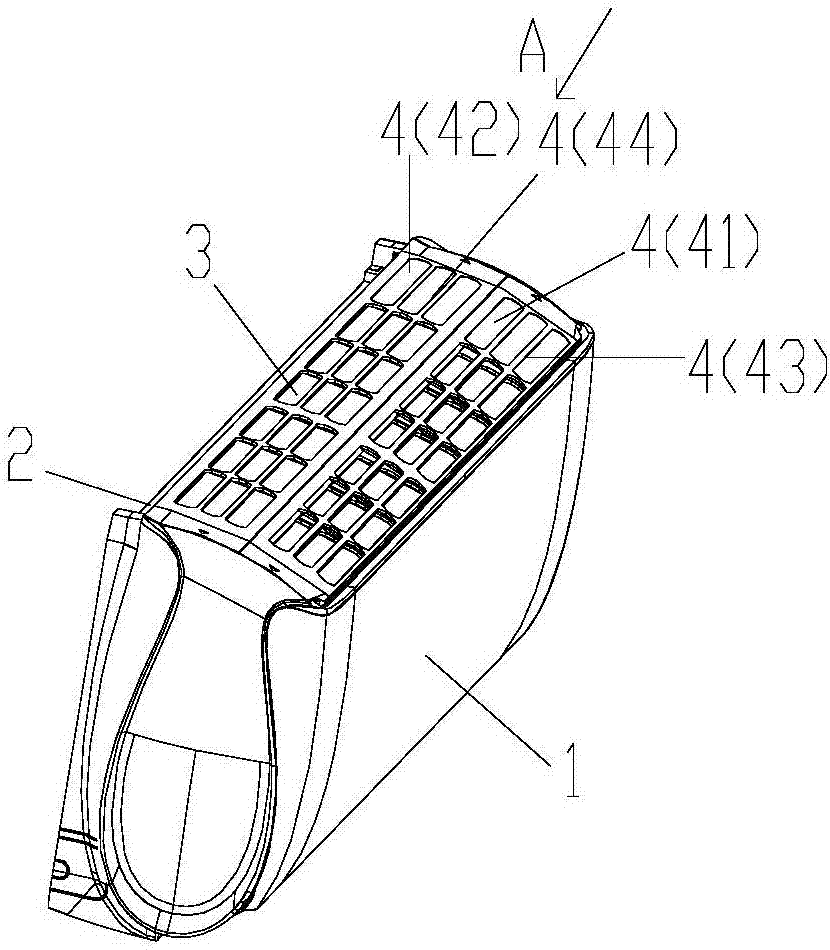

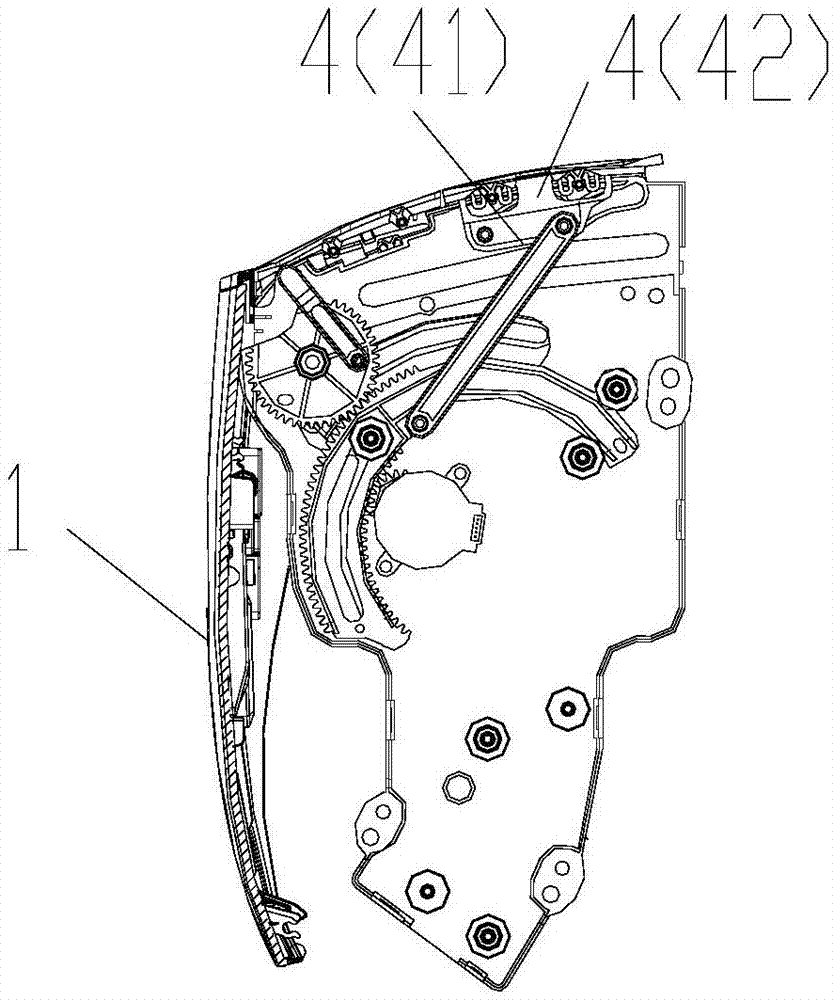

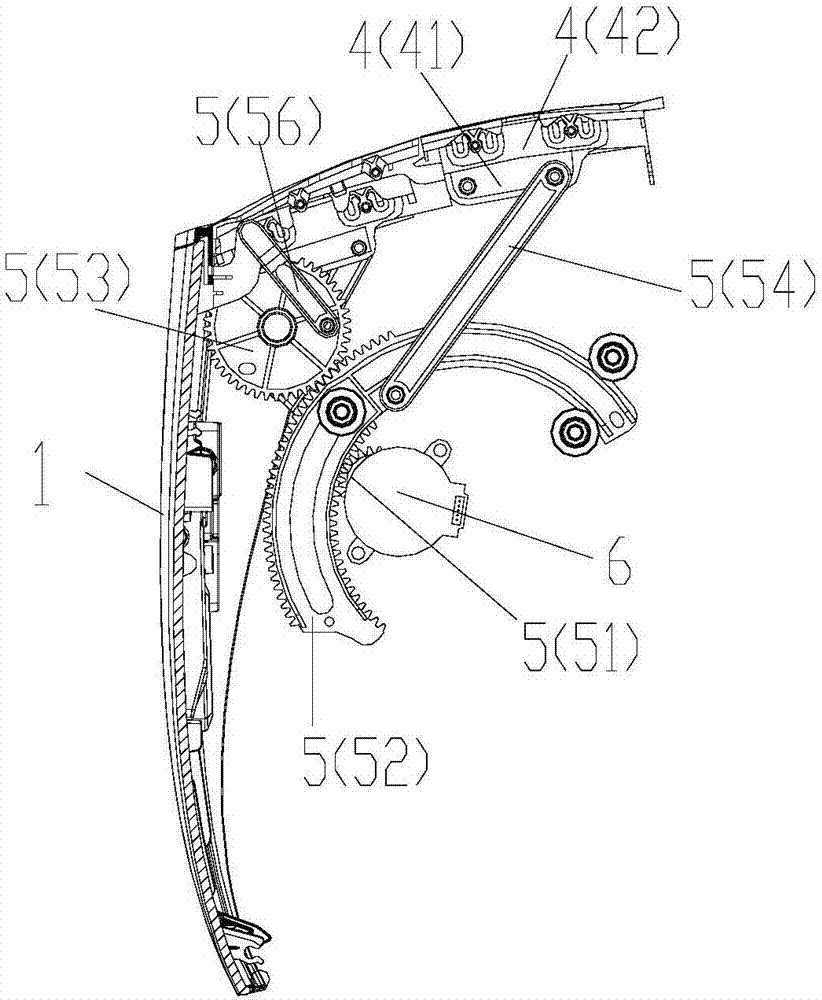

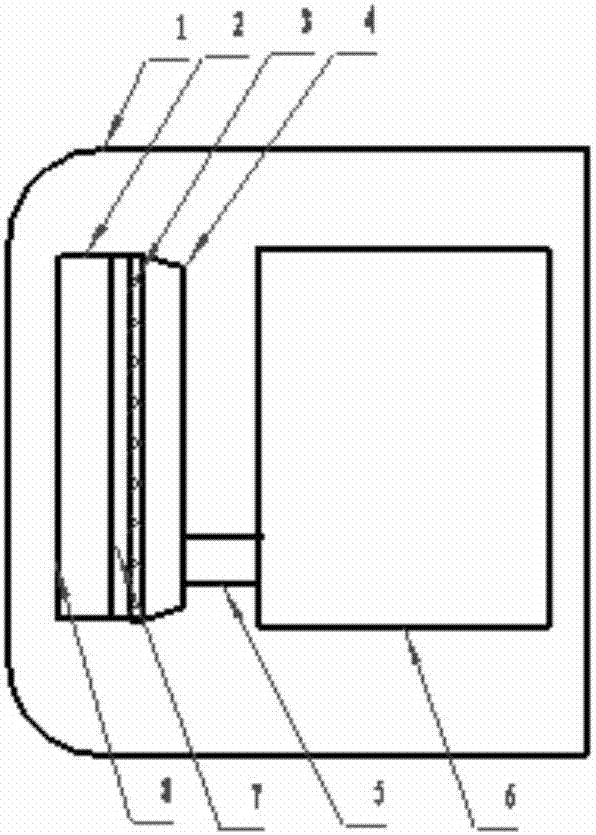

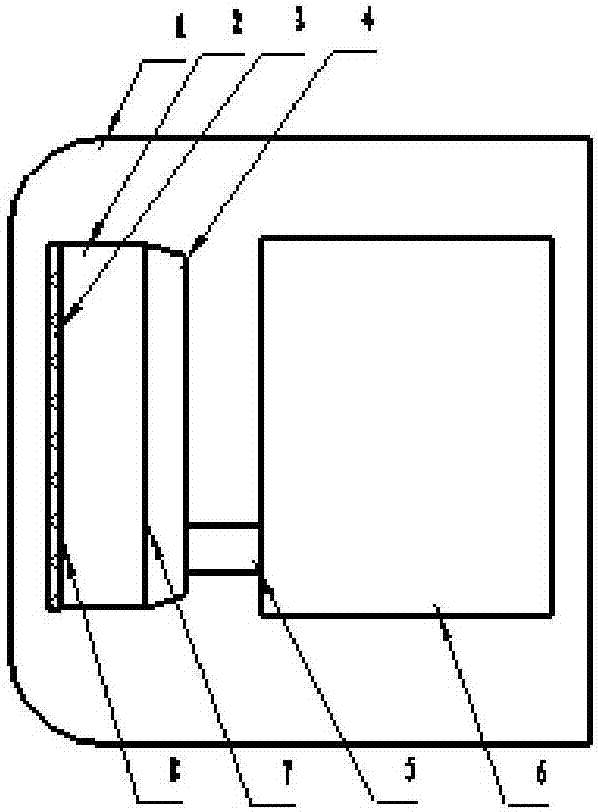

Air conditioner indoor unit, air conditioner and control method of air conditioner indoor unit

ActiveCN107300250AImprove heat transfer effectIncrease intake flowLighting and heating apparatusEfficient regulation technologiesEngineeringAir purification

The invention provides an air conditioner indoor unit, an air conditioner and a control method of the air conditioner indoor unit. The air conditioner indoor unit comprises a panel (1), a shell (2), an air inlet (3), an air purification device (4) and a driving device (5). The air inlet (3) is formed in the shell (2). The air purification device (4) is arranged on the air inlet (3). The driving device (5) can drive the air purification device to move to open the air inlet (3) and meanwhile drive the panel to move to open an air inflow region covered with the panel. The air purification device comprises a first filtering part and a second filtering part. The first filtering part independently moves relative to the second filtering part. The air inflow region covered with the panel can be opened by opening the panel, the air inflow area is further increased, the air inflow flow is increased, the heat exchange efficiency is improved, and the heat exchange effect of the air conditioner indoor unit is improved without filtering.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

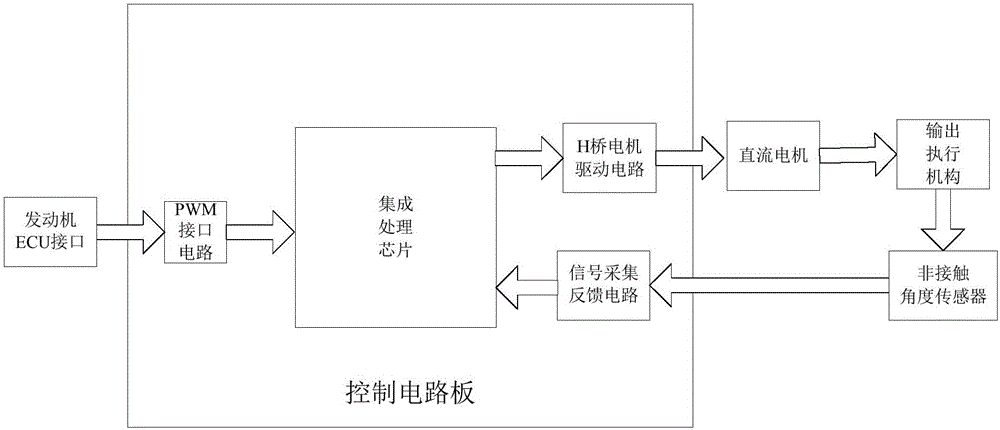

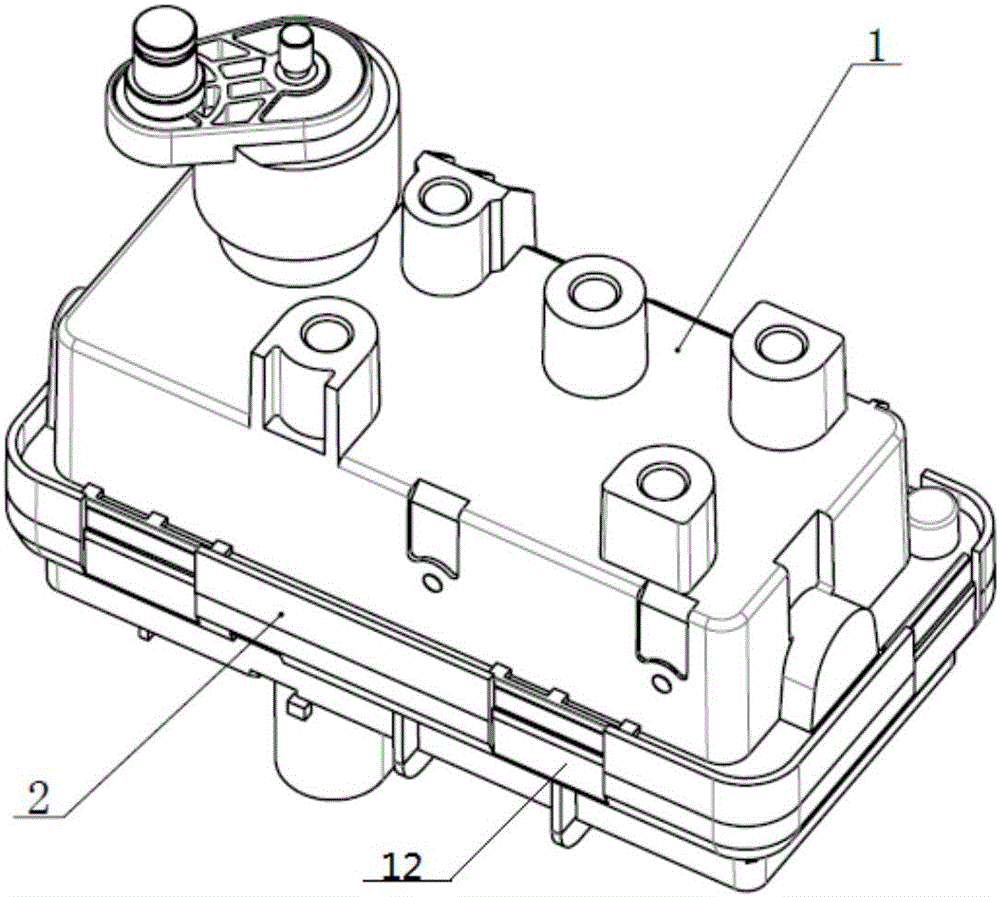

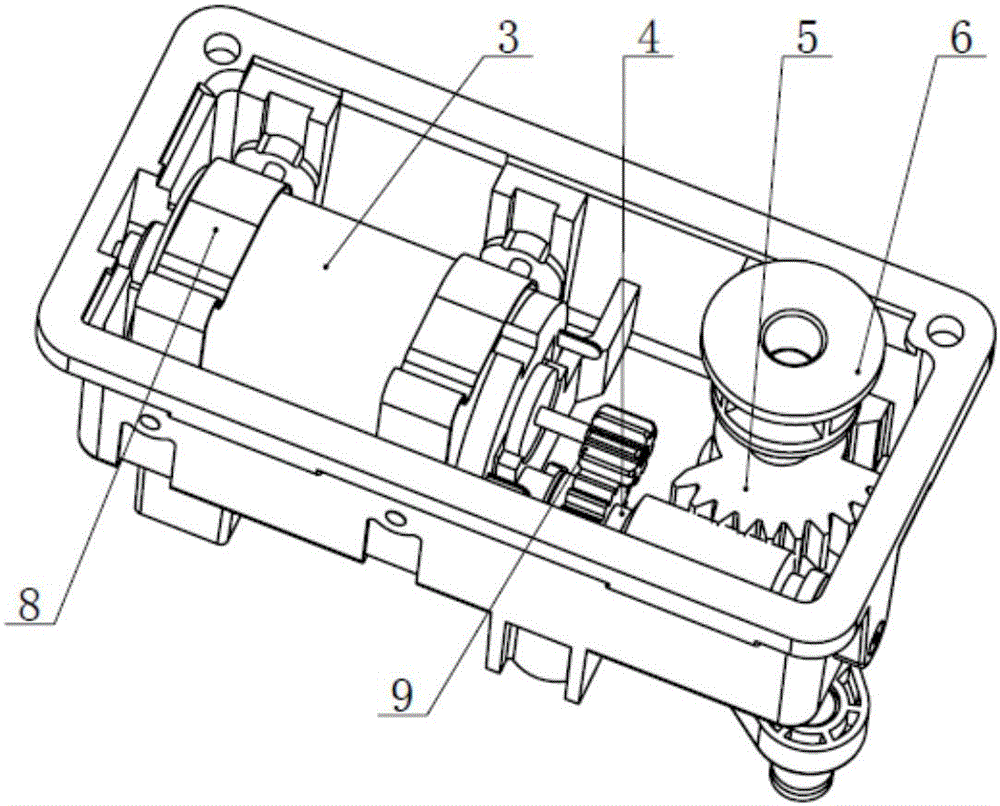

Electric control actuator for variable-geometry turbocharging

InactiveCN106640351AImprove economyReduce the flow cross-sectional areaInternal combustion piston enginesEngine componentsElectric controlActuator

The invention discloses an electric control actuator for variable-geometry turbocharging. The electric control actuator for variable-geometry turbocharging comprises a bottom casing, a plastic cover plate, a DC motor, a worm gear and worm unit, an output shaft, a non-contact high-precision position sensor and an integrated processing circuit PCB, wherein the DC motor is fixed in the bottom casing through a spring press piece, and a pinion is mounted at the shaft tail end of the DC motor and meshed and connected with the worm gear and worm unit; a rotor of the non-contact inductive sensor is prepared from a stamping part conducting material made of a closed wire in specific geometry and is fixed at the top end of the output shaft through a positioning hole, and a helical gear is mounted in the middle of the output shaft and meshed with the worm gear and worm unit for actuation output; and the integrated processing circuit PCB is inlaid in the plastic cover plate. Motor control is driven by angle signals acquired by an engine ECU to change the flow sectional area (nozzle opening) of a turbine nozzle, a supercharger and an engine are matched optimally, and the electric control actuator has the advantages of high real-timeness, high control precision, large torque and the like.

Owner:上海电控研究所有限公司

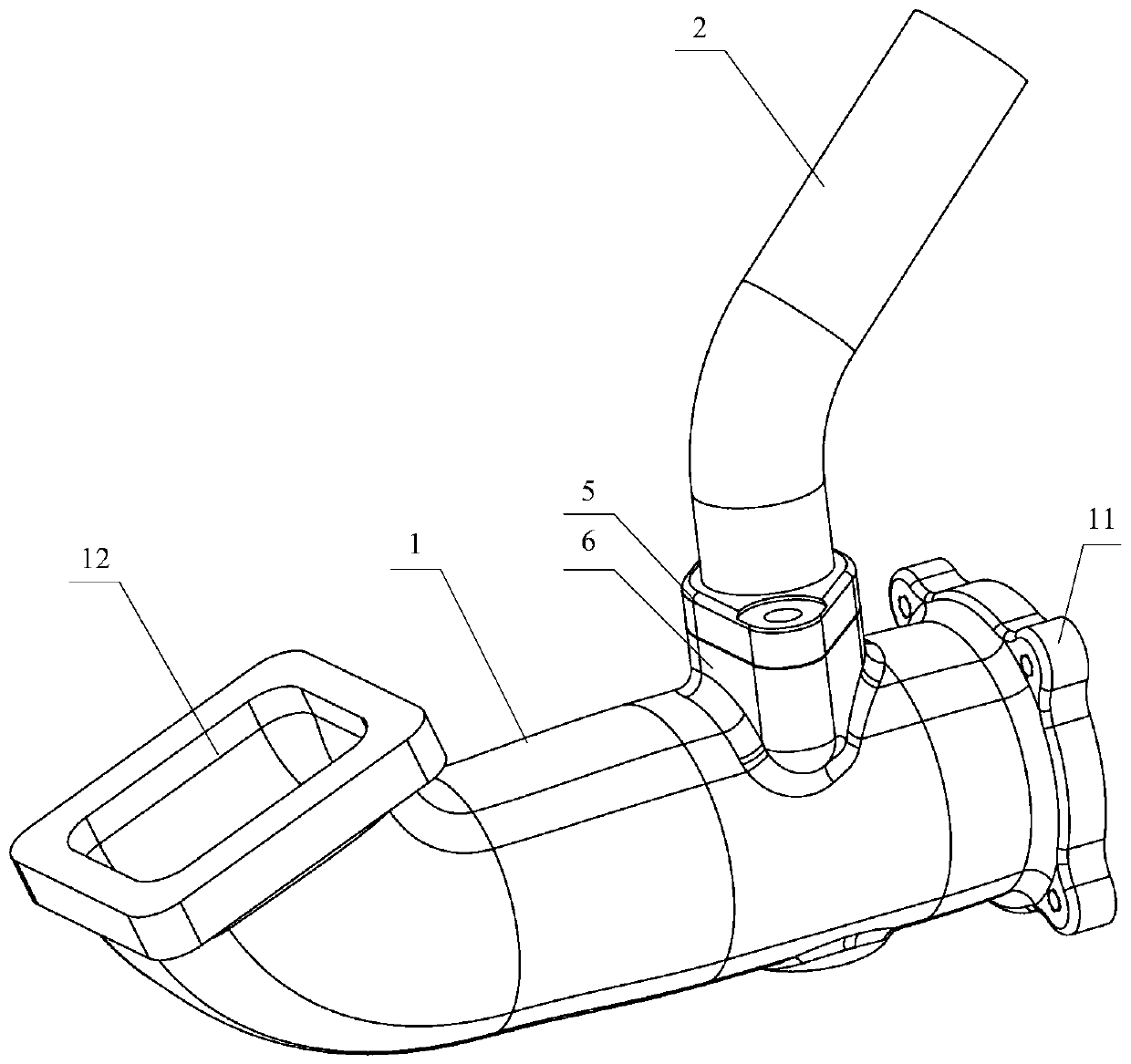

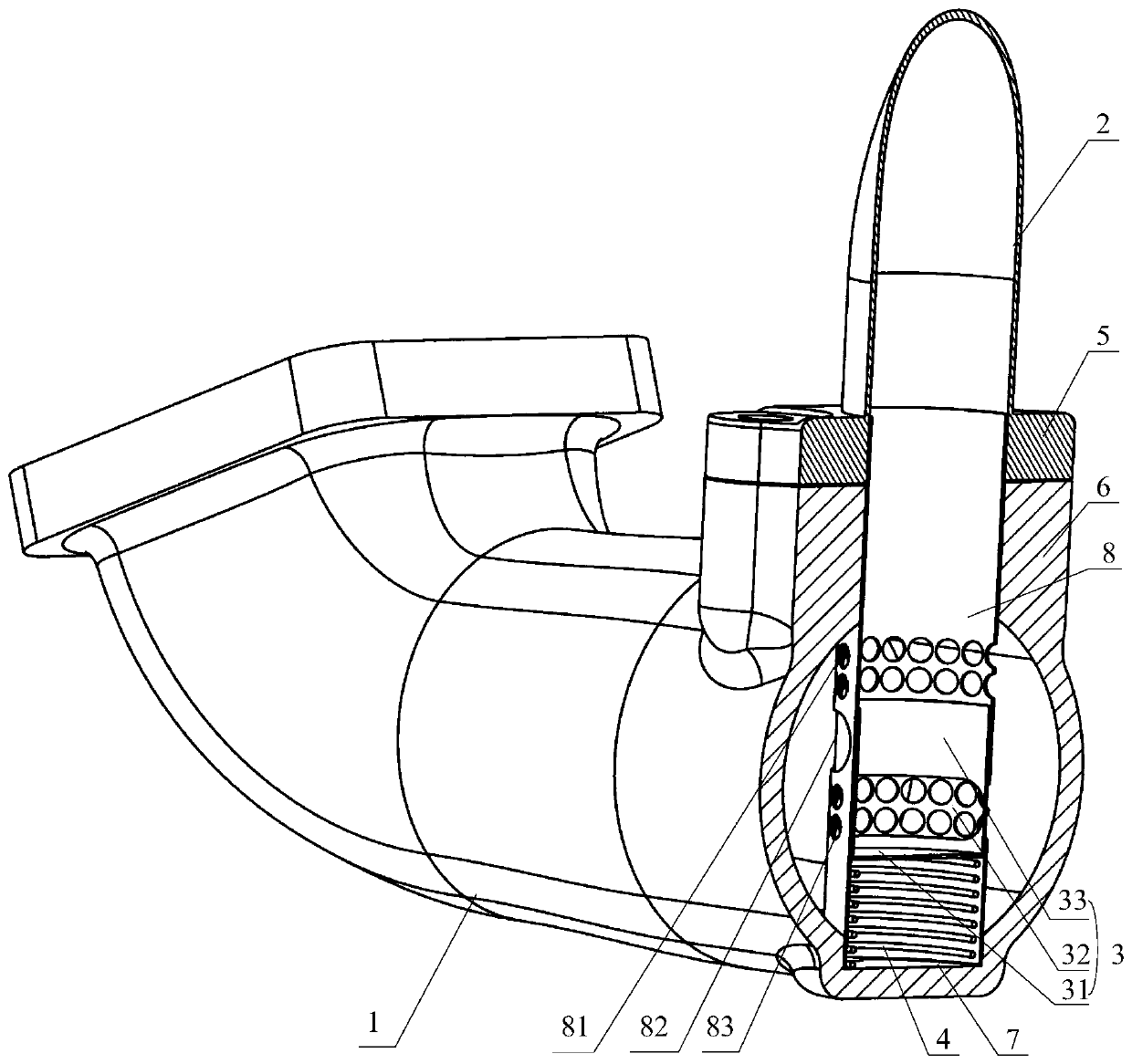

EGR mixer and engine with same

PendingCN109798205AReduce throttling lossIncrease intake flowExhaust gas recirculationMachines/enginesMixing effectIntake pressure

The invention discloses an EGR mixer and an engine with the same. The EGR mixer comprises a mixer shell and an EGR pipeline; the EGR pipeline comprises an EGR exhaust pipe section, an exhaust port adjusting device and an elastic device, wherein the EGR exhaust pipe section extends into the mixer shell; an exhaust port is formed in the EGR exhaust pipe section; the exhaust port adjusting device isarranged on the EGR exhaust pipe section, and is used for adjusting the exhaust area of the exhaust port; the elastic device is used for adjusting the exhaust port adjusting device relative to the position of the EGR exhaust pipe section; when the intake pressure of the EGR pipeline is increased, the exhaust port adjusting device overcomes elastic force of the elastic device to move relative to the EGR exhaust pipe section, and the exhaust area of the exhaust port is increased; and when the intake pressure of the EGR pipeline is reduced, the exhaust port adjusting device moves relative to theEGR exhaust pipe section under the effect of elastic recovery force of the elastic device, and the exhaust area of the exhaust port is reduced. The EGR mixer achieves a better mixing effect and lowerEGR pipeline throttling loss.

Owner:WEICHAI POWER CO LTD

Turbofan engine

ActiveUS8579592B2Increase intake flowImproves the turbofan enginePropellersEngine manufactureLeading edgeEngineering

A hub-side leading edge part of a fan first-stage rotating blade 10 for taking an air thereinto more extends in a forward direction of an engine than a tip-side leading edge part and a mid-span leading edge part. The hub side of the fan first-stage rotating blade 10 is integrally connected as one with the tip side and the mid span while having a longer chord length than those of the tip side and the mid span. A radius at a root of the hub-side leading edge part is set in a boss ratio of 0 to 0.4.

Owner:IHI CORP

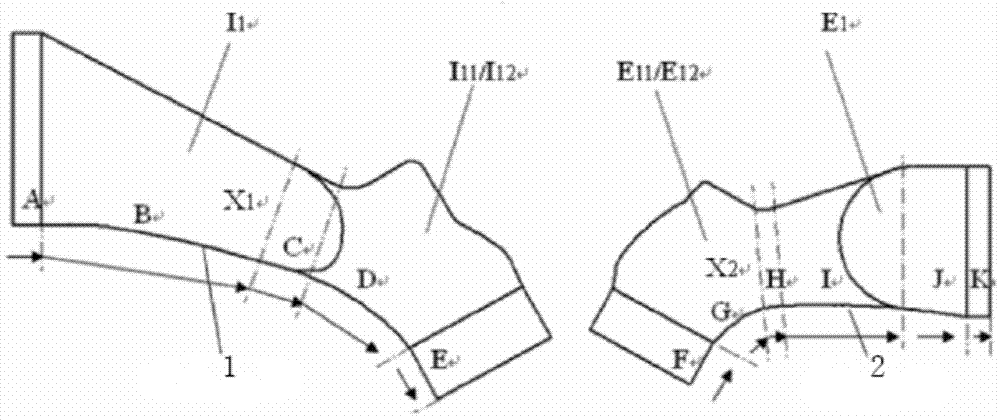

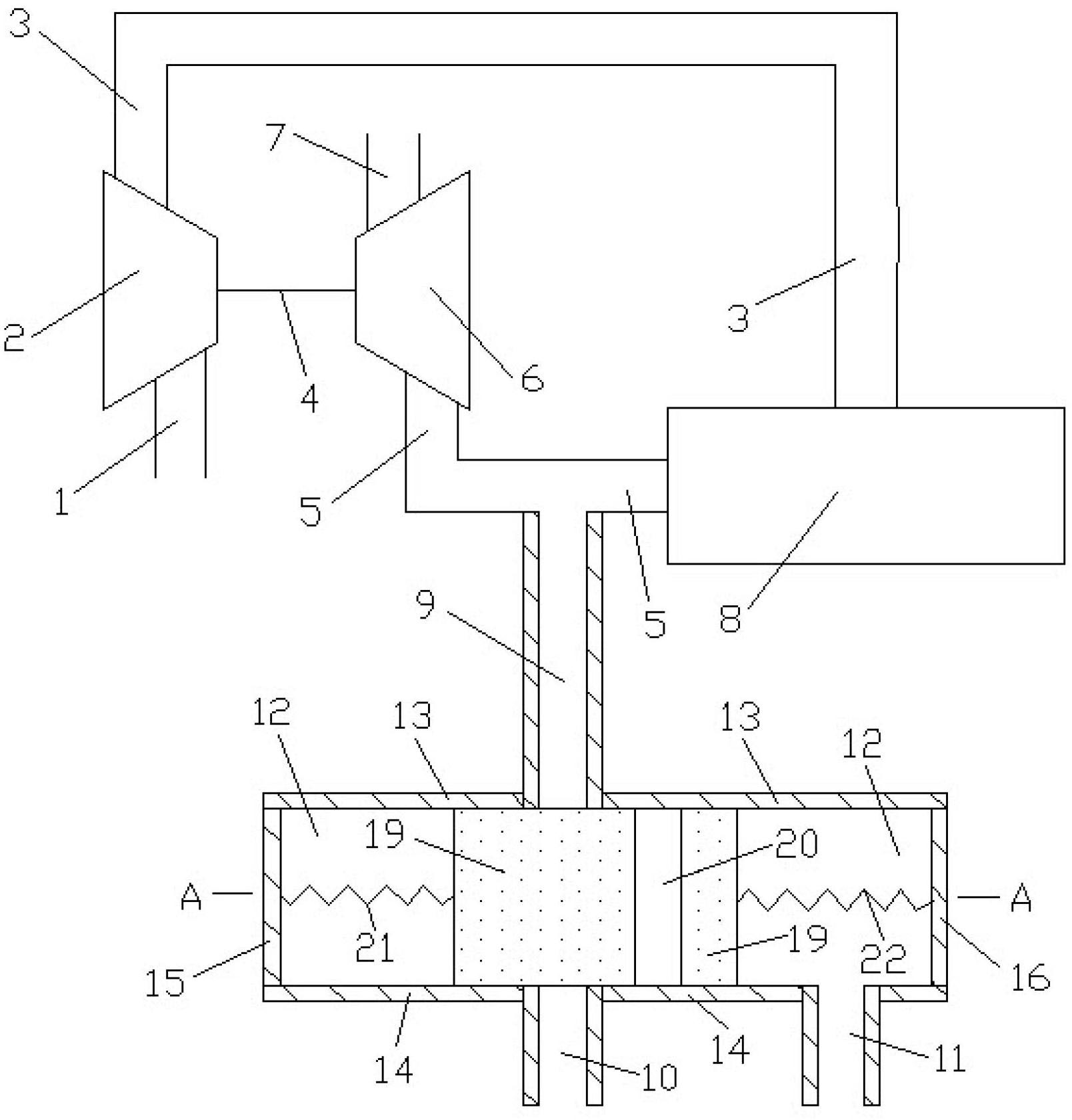

Engine exhaust gas energy recovery system

InactiveCN102661194AIncrease intake flowIncrease output powerValve arrangementsInternal combustion piston enginesExhaust gasRecuperator

The invention provides an engine exhaust gas energy recovery system in the technical field of internal combustion engines, which comprises an engine cylinder, a gas compressor, turbines, a heat exchanger, a condenser and a booster pump, wherein the gas compressor, a first turbine and a second turbine are coaxially connected through connecting shafts; a gas outlet of a gas outlet pipe of the first turbine, a gas inlet of an exhaust pipe of the first turbine, a gas inlet of a gas inlet pipe of the second turbine and a gas outlet of a gas outlet pipe of the second turbine are all connected with the heat exchanger; and the condenser and the booster pump are sequentially mounted in the gas outlet pipe of the second turbine along the fluid flow direction. In the working process of an engine, flow media flowing through the second turbine are heated by engine exhaust gas flowing out of the first turbine in the heat exchanger and are enabled to expand and do work in the second turbine, so that more available energy can be obtained by the gas compressor, the gas inlet flux of the engine is increased and the output power is improved. The engine exhaust gas energy recovery system is reasonable in design and simple in structure, and is suitable for a turbocharging system in which the gas compressor is coaxially connected with the two turbines.

Owner:SHANGHAI JIAO TONG UNIV

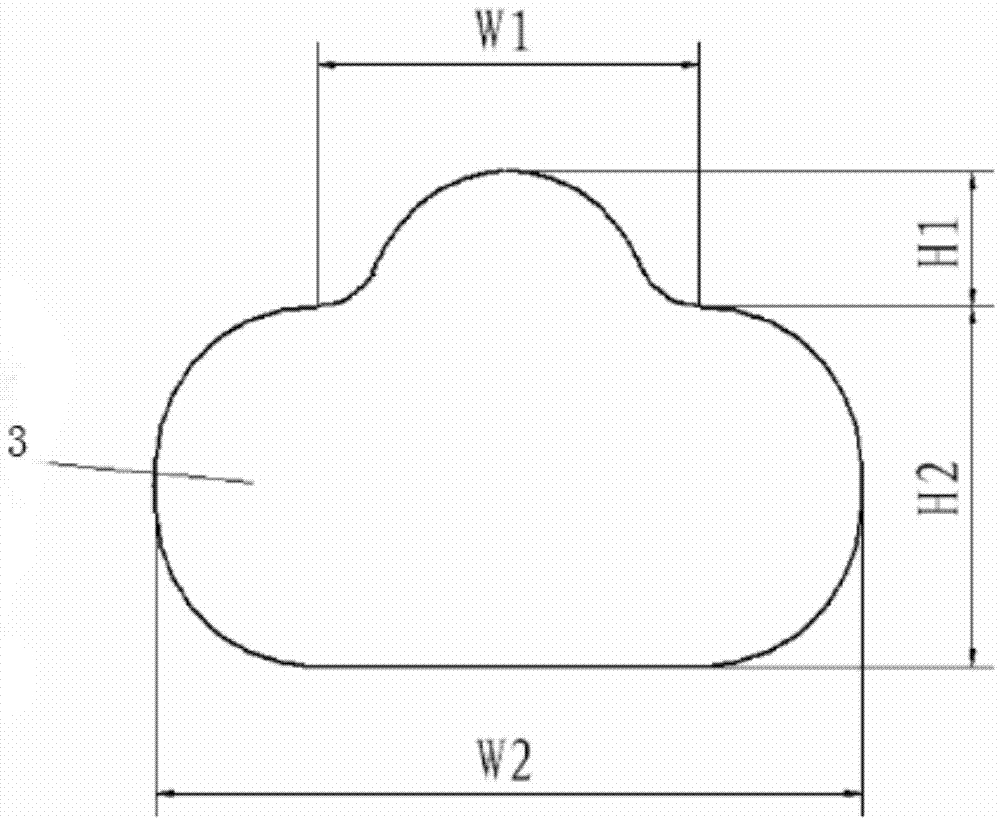

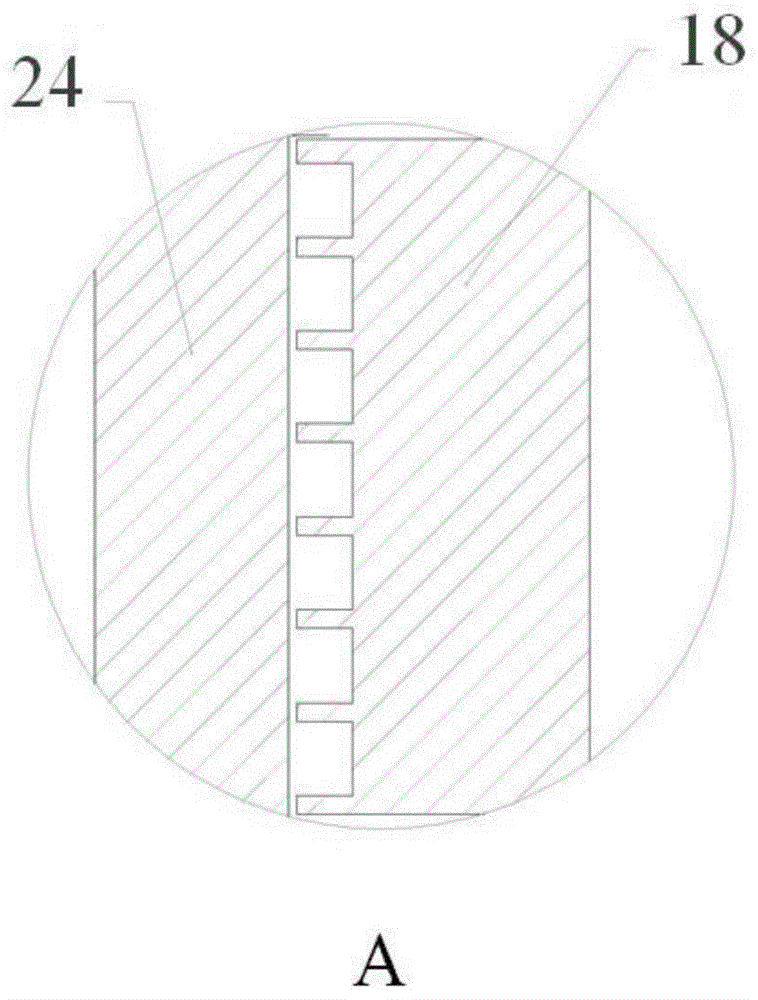

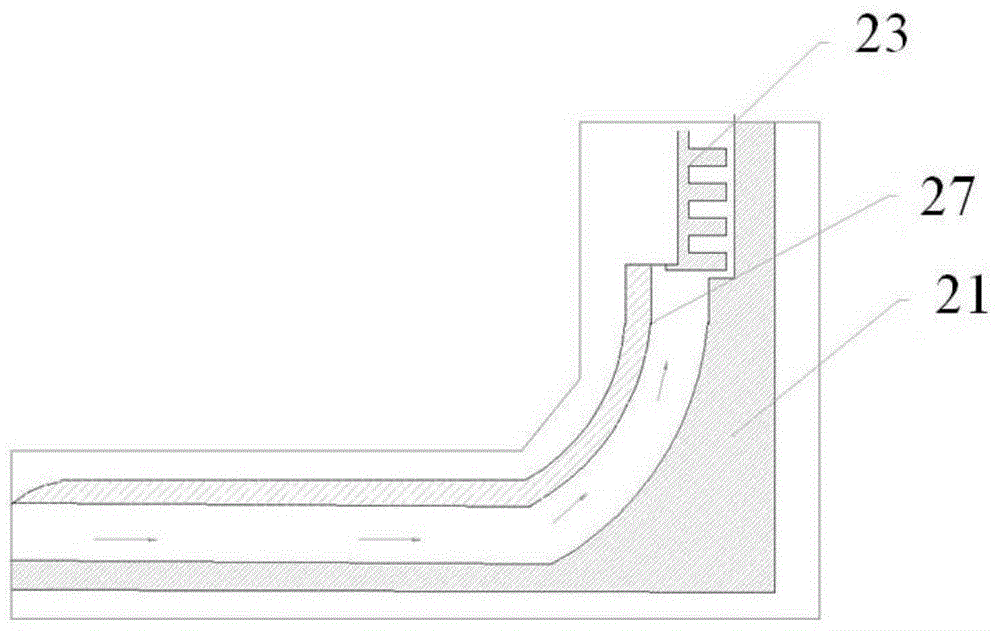

Engine cylinder cover air channel structure

The invention relates to an engine cylinder cover air channel structure. The engine cylinder cover air channel structure corresponding to a quadruple-cylinder engine consists of four groups of same air channels, wherein each group of air channels comprises one air inlet channel and an exhaust channel. Each air inlet channel consists of one main air inlet channel located on the outer side of a cylinder cover and two air inlet branch channels. Each exhaust channel consists of a main exhaust channel located on the outer side of the cylinder cover and two exhaust branch channels. An inlet of the main air inlet channel is similar-calabash-shaped. An outlet of the main exhaust channel is similarly oval. The two air inlet branch channels and the two exhaust branch channels are symmetrically distributed on two sides of a central plane of the air channels.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

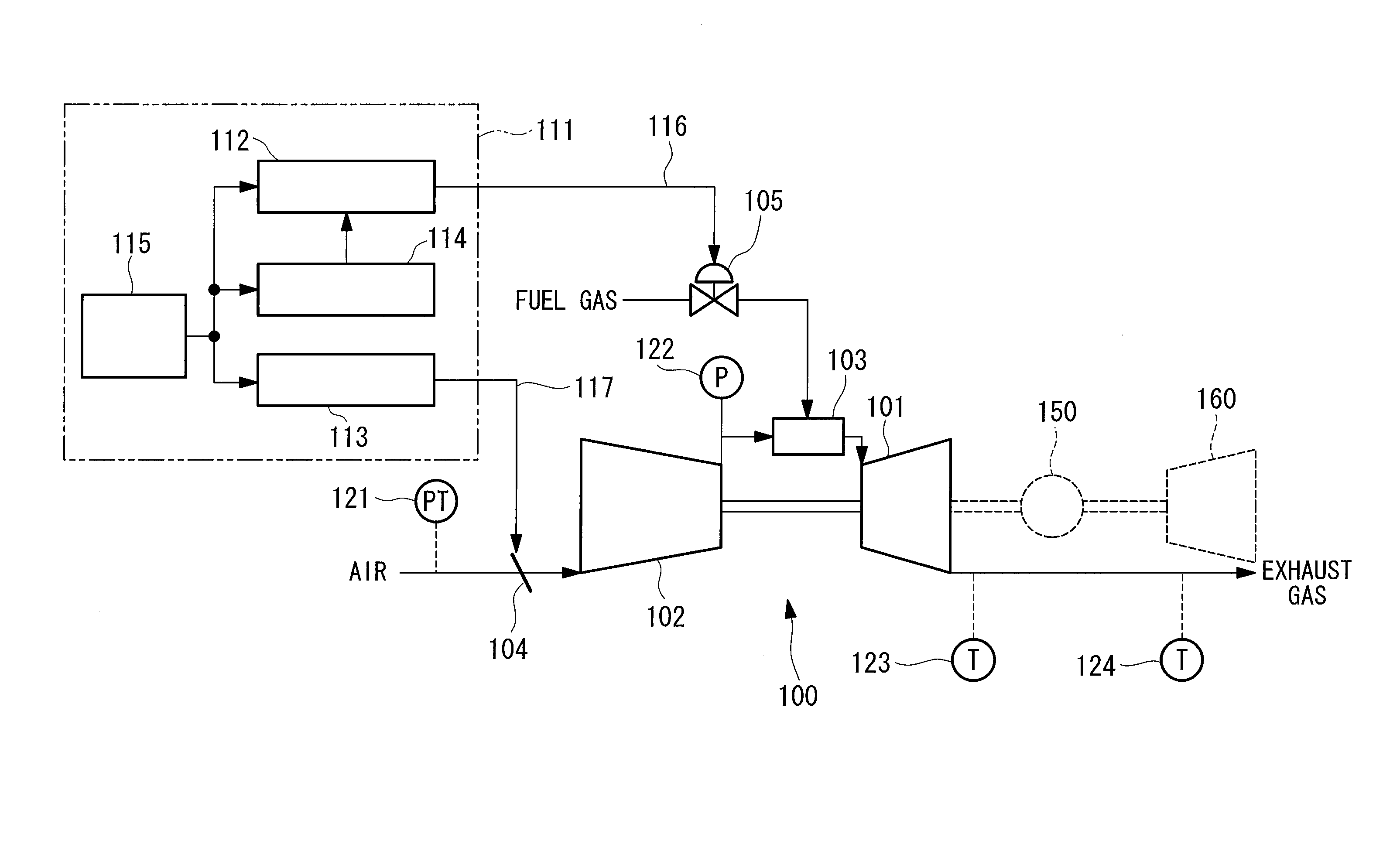

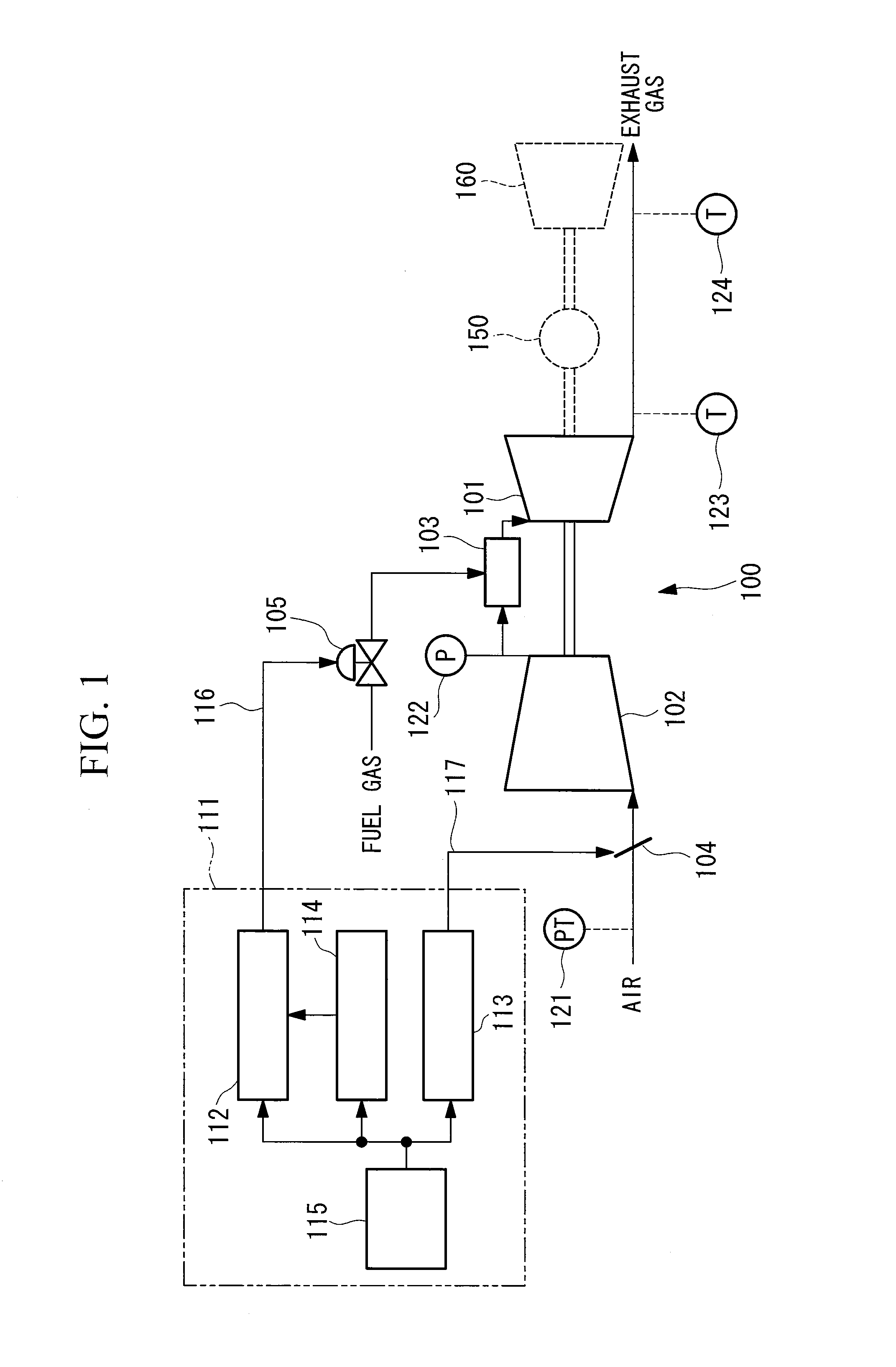

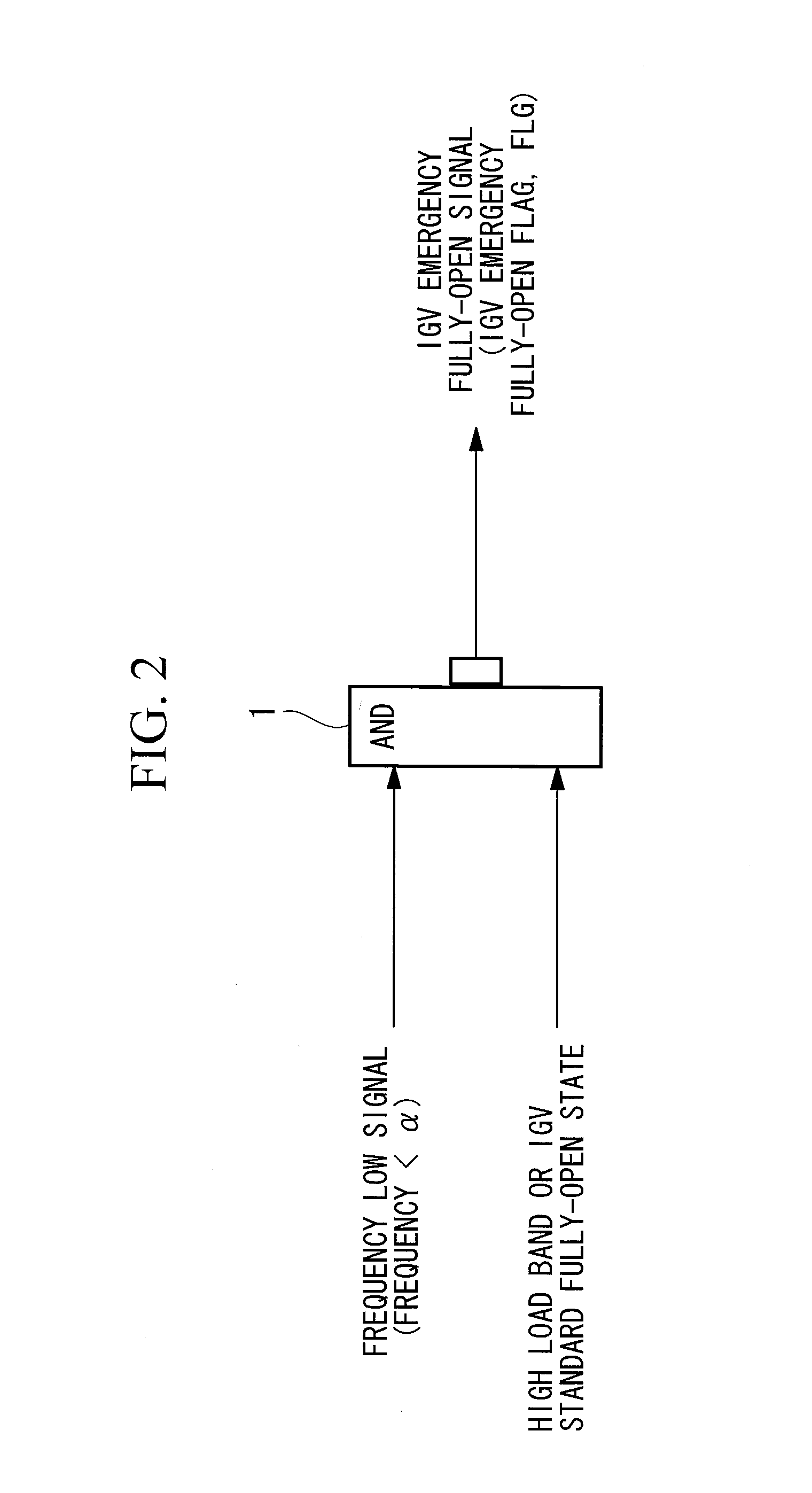

Gas turbine operation control device and operation control method

ActiveUS8694170B2Speed up the air flowImprove load responsivenessMechanical power/torque controlLevel controlCombustorEngineering

Provided is a gas turbine operation control device and operation control method that are capable of suppressing turbine inlet temperature and of satisfying the demand response for shaft output. An IGV emergency fully-open flag is activated when the output of a generator is in a high load band at or above a predetermined value, and the like. When the IGV emergency fully-open flag is activated, the degree of opening of an inlet guide vane is set to a predetermined degree of opening, a temperature adjustment setting is set by switching in accordance with the degree of opening of the inlet guide vane, and an exhaust gas temperature setting value or a blade path temperature setting value of a turbine, for controlling the fuel supply amount for a combustor, is generated based on the temperature adjustment setting.

Owner:MITSUBISHI POWER LTD

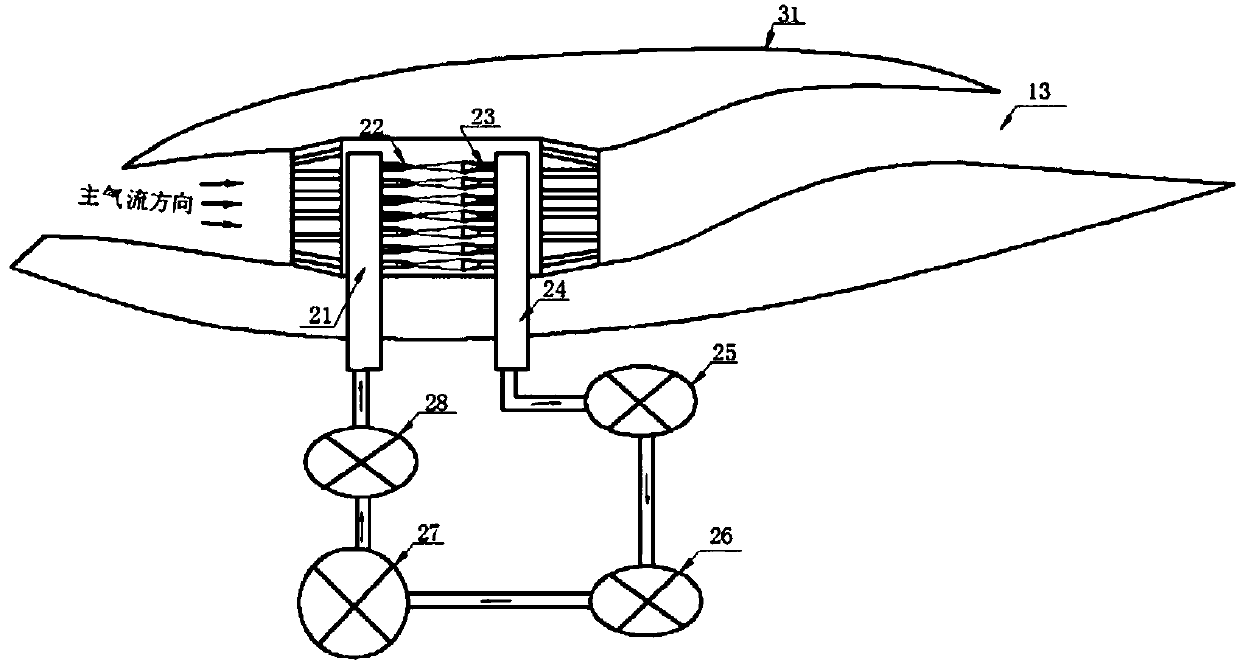

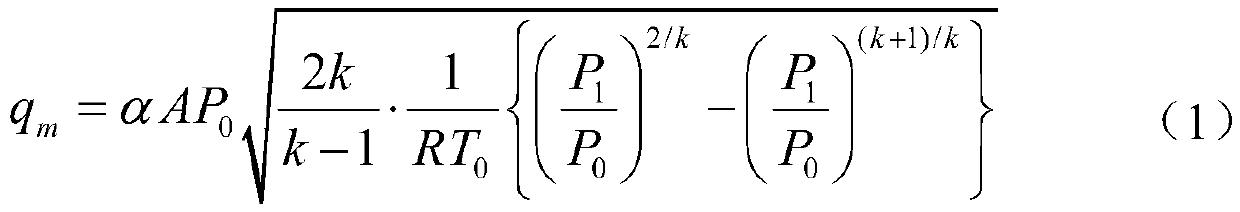

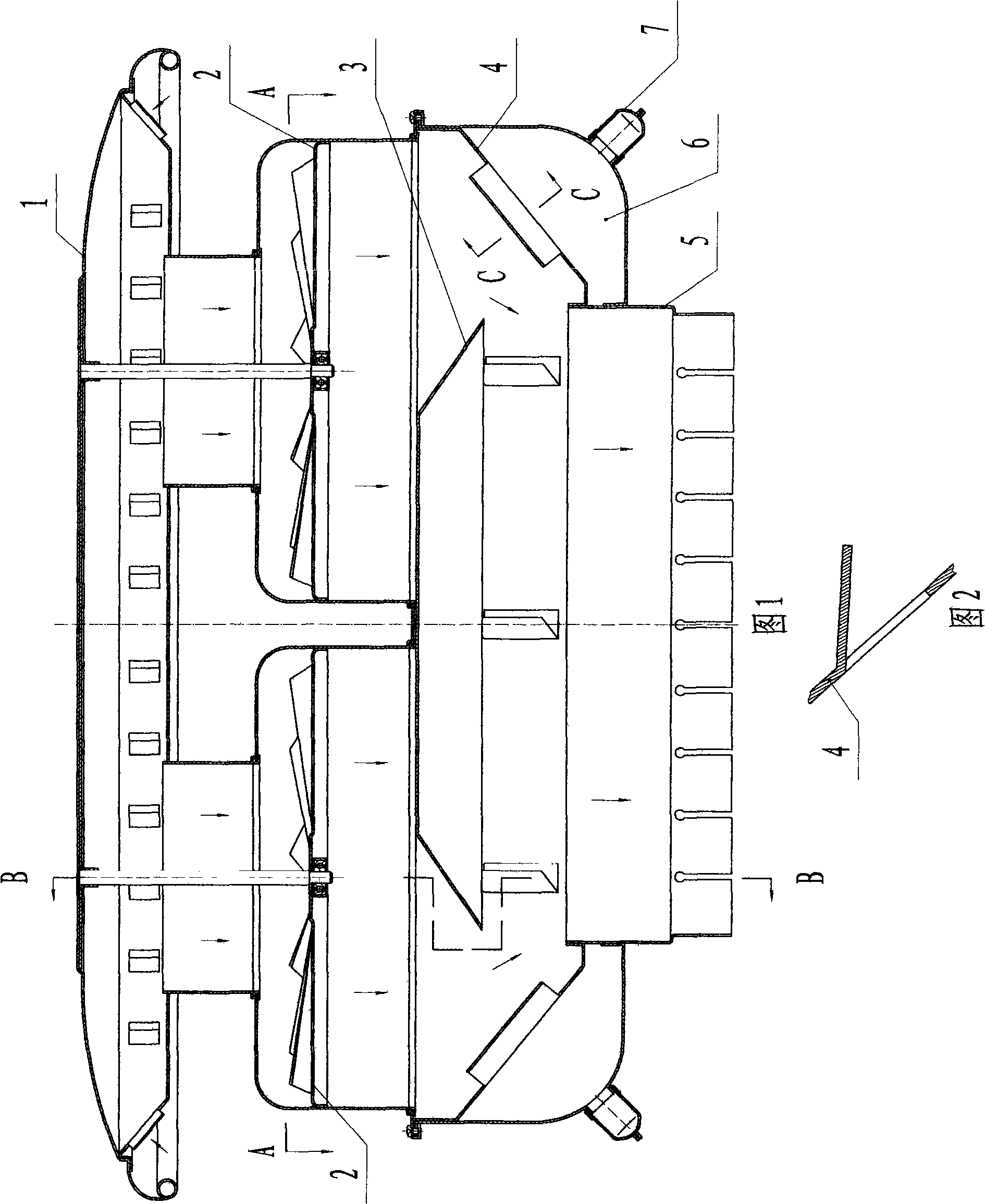

Flow control ejection system for aircraft model low-speed wind tunnel test

The invention discloses a flow control ejection system for an aircraft model low-speed wind tunnel test. When the aircraft model low-speed wind tunnel test is carried out, a high-pressure air intake nozzle recovers most of the high-pressure airflow sprayed by a high-pressure spray nozzle, the high-pressure airflow enters a recovery pressurization device for pressurization and returns to a high-pressure air tank through a one-way valve, and the main airflow and a small part of the high-pressure airflow are discharged through an outlet of a main air intake pipeline. Since most of the high-pressure airflow is recovered and does not flow through the outlet of the main air intake pipeline, the congestion of the outlet of the main air intake pipeline cannot be caused, the air intake flow of themain air intake pipeline is increased, the simulated flow of the main air intake pipeline in the aircraft model low-speed wind tunnel test can be increased to reach 100% of the design flow, and thus the real working condition can be more closely approximated, and the authenticity of the test can be improved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Adjustment system with post-pressure of air compressor as control pressure

InactiveCN102817703AImprove working abilityIncrease air intakeInternal combustion piston enginesLow speedGas compressor

The invention provides an adjustment system with the post-pressure of an air compressor as control pressure in the technical field of an internal combustion engine, comprising an air compressor, a turbo, an engine, connection pipes, a volume chamber, a moving body, a penetration pipe and an elastic part, wherein two ends of the first connection pipe are communicated with an exhaust pipe and the upper wall face of the volume chamber respectively; two ends of the third connection pipe are communicated with the right wall face of the volume chamber and the air inlet pipe of the engine respectively; and the penetration pipe penetrates through the upper wall and the lower wall of the moving body. During the working process of the engine, the moving body can move left and right in the volume chamber; under the low speed working condition, since the pressure on the right side of the moving body is lower, the moving body moves rightward; the first connection pipe and the second connection pipe cannot be communicated; the air inflow of the engine is relatively increased; and the power rises. Under the high speed working condition, since the pressure on the right side of the moving body is higher, the moving body moves leftward; the first connection pipe and the second connection pipe are communicated with each other; the air input of the engine is relatively decreased; and the explosive pressure of each cylinder is decreased. The adjustment system with the post-pressure of the air compressor as the control pressure is rational in design, simple in structure and applicable for a turbo charging system of the engine.

Owner:SHANGHAI JIAO TONG UNIV

Combustion gas turbine

InactiveCN104948300AReduce axial forceOverall small sizeGas turbine plantsCombustion chamberHigh pressure gas

The invention provides a combustion gas turbine. The combustion gas turbine is characterized by comprising a spindle, radial inflow compressors, combustion chambers, an outward flow turbine and a shell. The spindle outputs mechanical work through rotation, and the spindle is sleeved with the radial inflow compressors; air entering the radial inflow compressors in a radial manner is pressurized through rotation to form high-pressure gas, and then the high-pressure gas is exhausted in the axial direction; the spindle is sleeved with the combustion chambers, and the combustion chambers are communicated with the radial inflow compressors to enable the high-pressure gas to be mixed with fuel to be combusted, and high-temperature high-pressure fuel gas is formed; the spindle is sleeved with the outward flow turbine, and the outward flow turbine is communicated with the combustion chambers; the outward flow turbine is driven by the high-temperature high-pressure fuel gas to rotate so as to drive the spindle to rotate, and then, the high-temperature high-pressure fuel gas is exhausted in the radial direction; and the shell comprises compressor shell bodies, combustion chamber shell bodies and a turbine shell, the compressor shell bodies are provided with air inlets, the turbine shell is provided with an air outlet, and cooling devices are arranged below the combustion chambers and are used for cooling the spindle.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

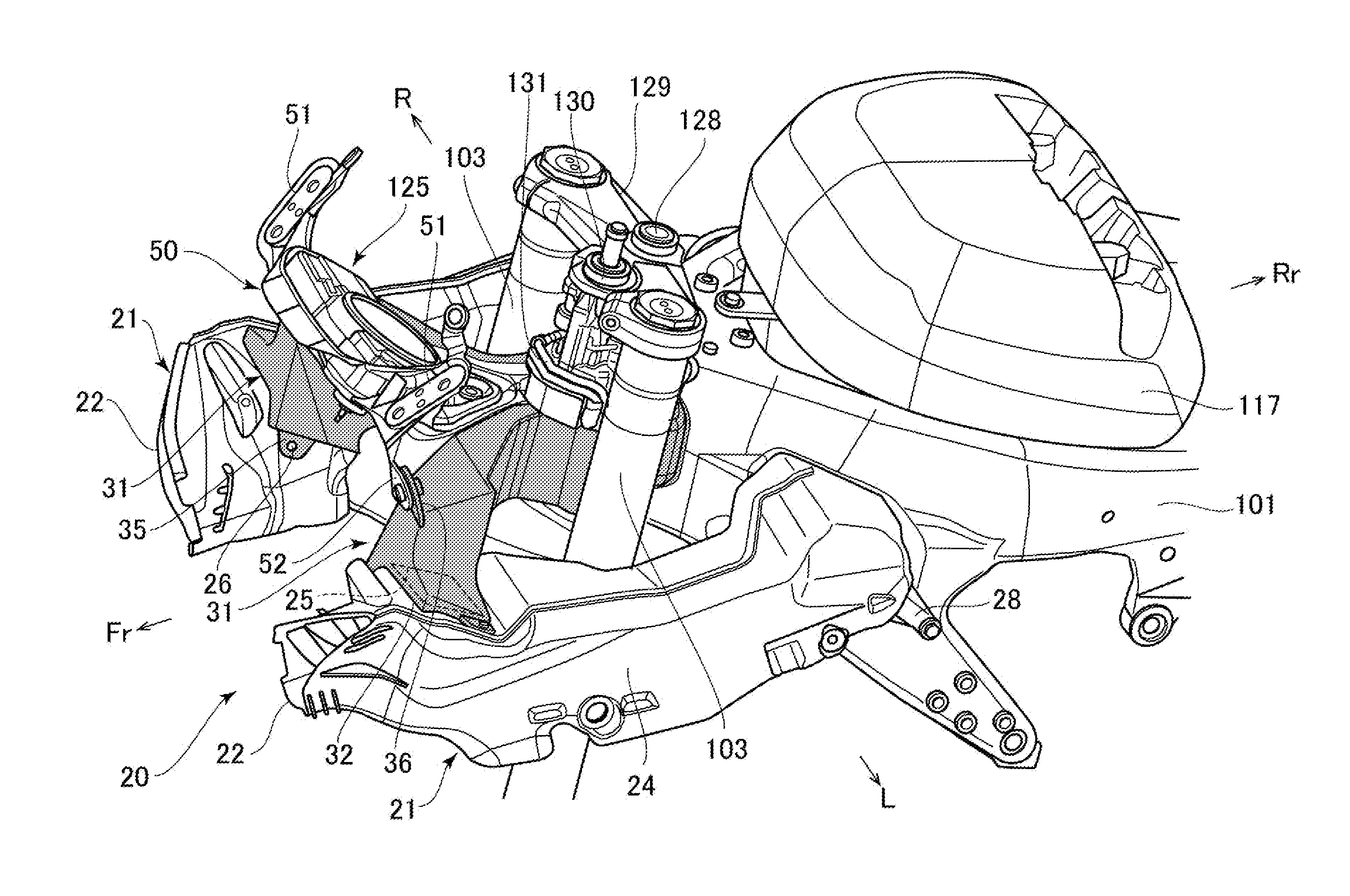

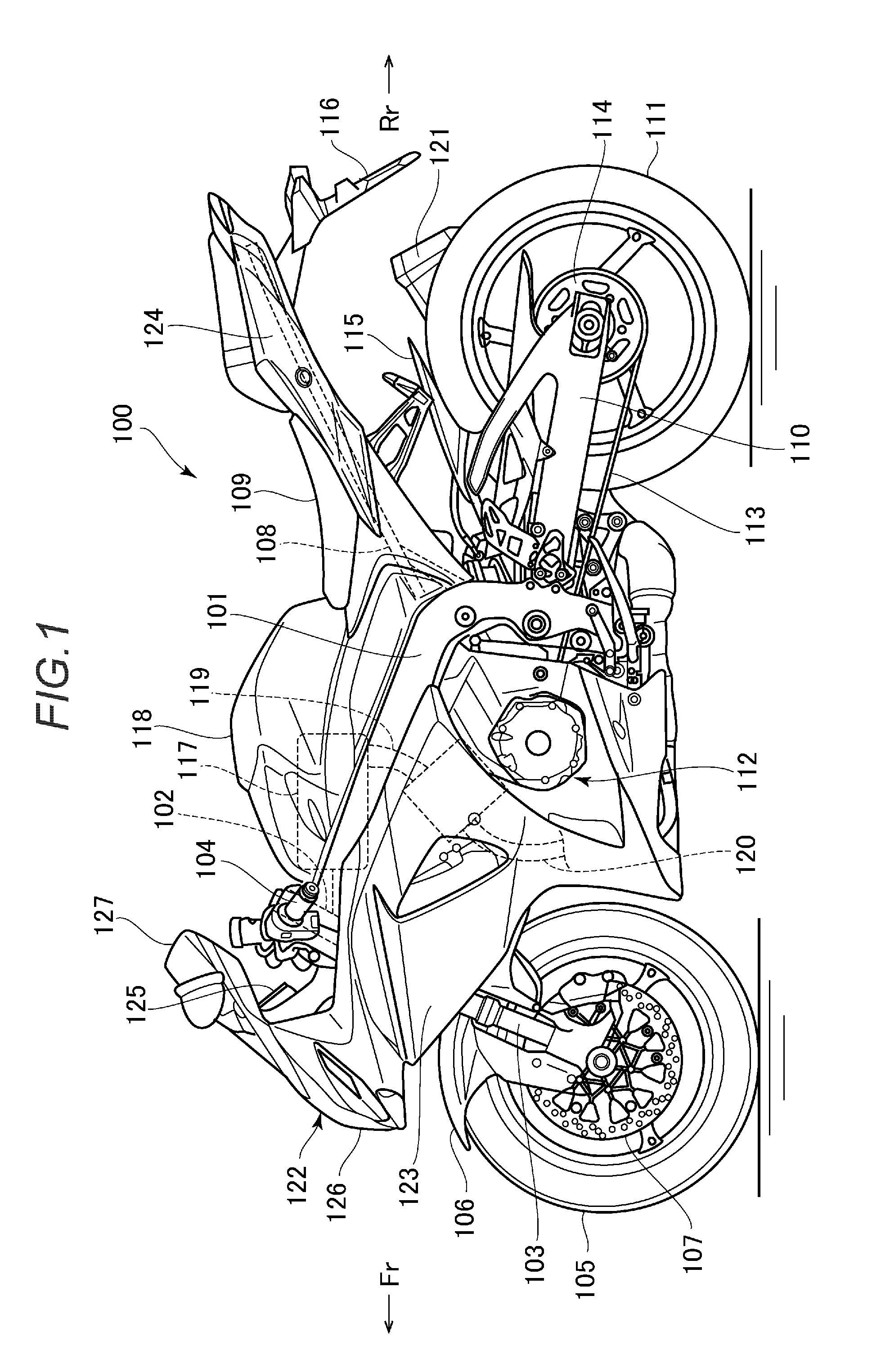

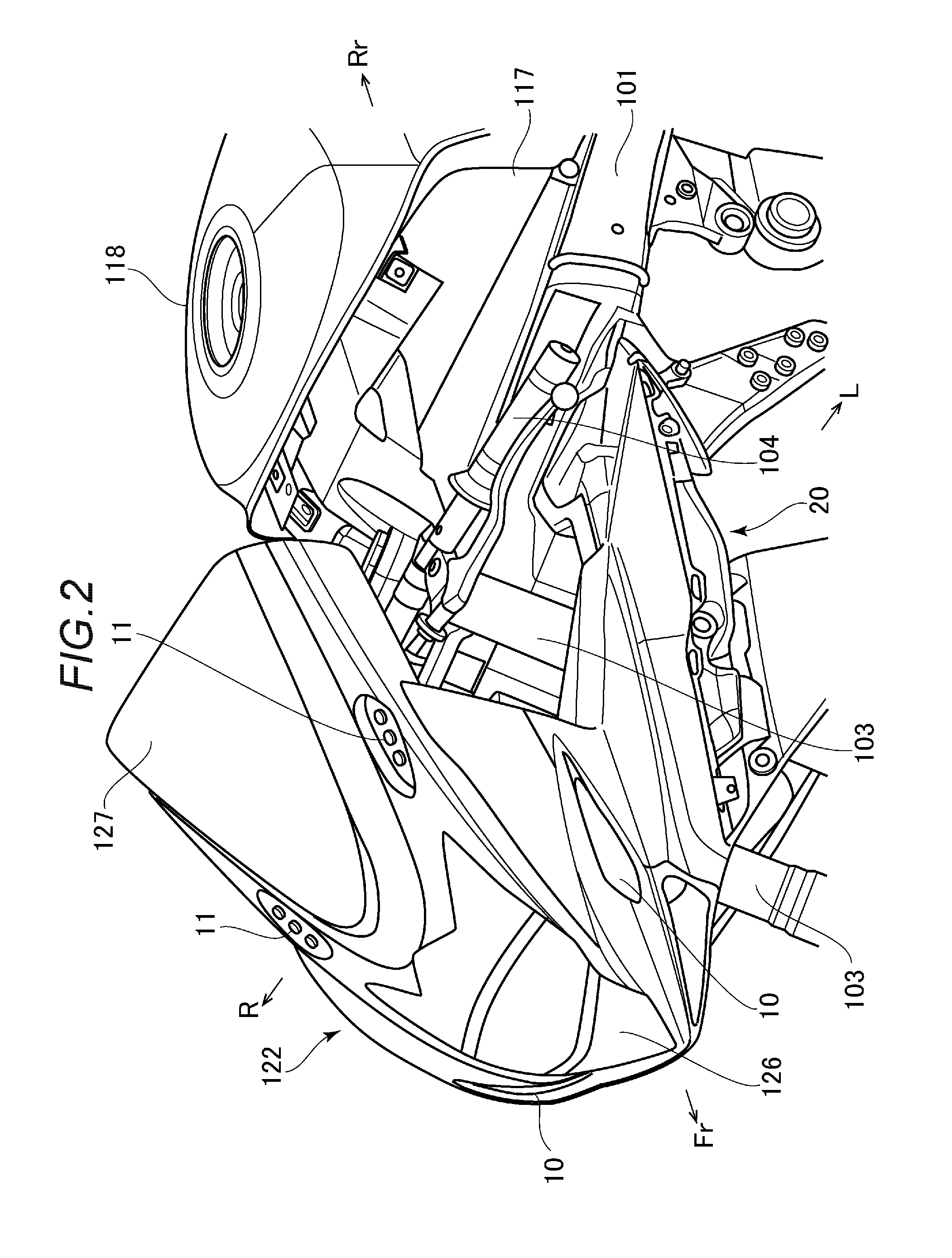

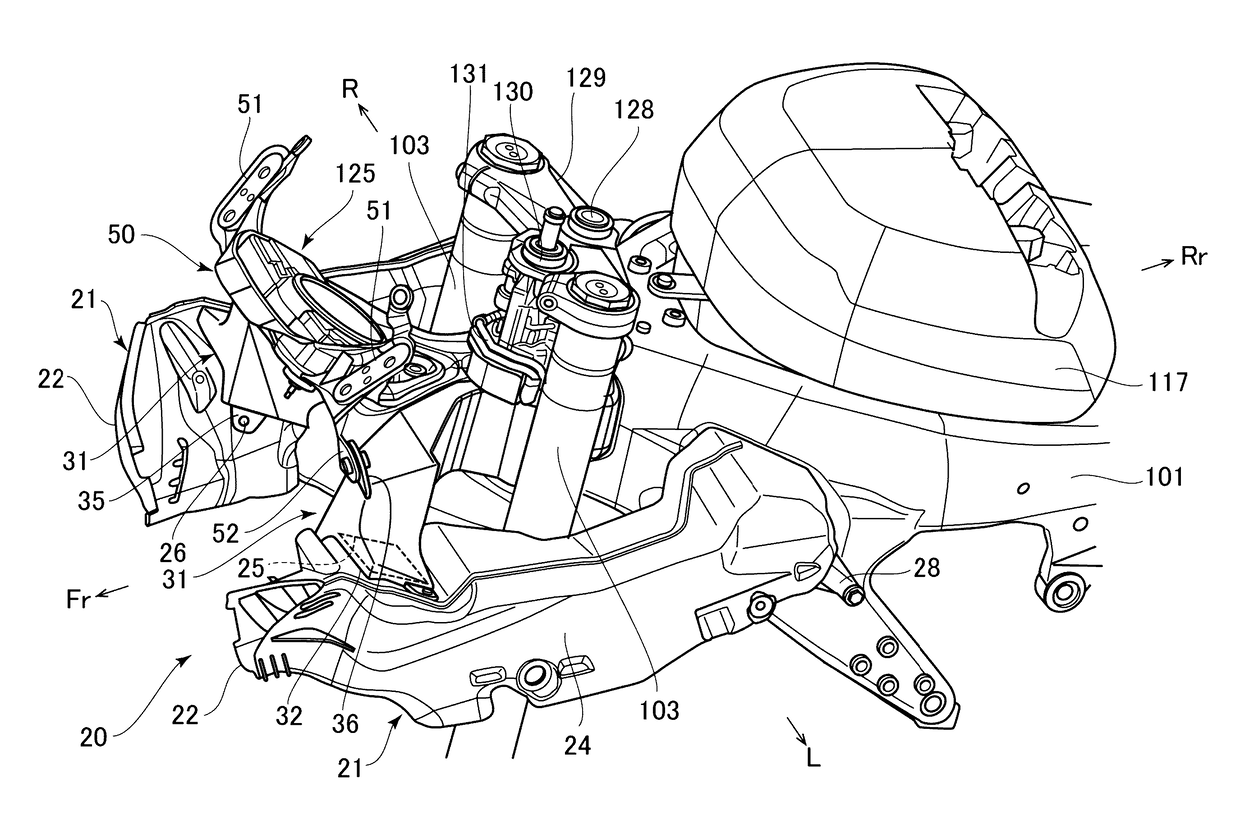

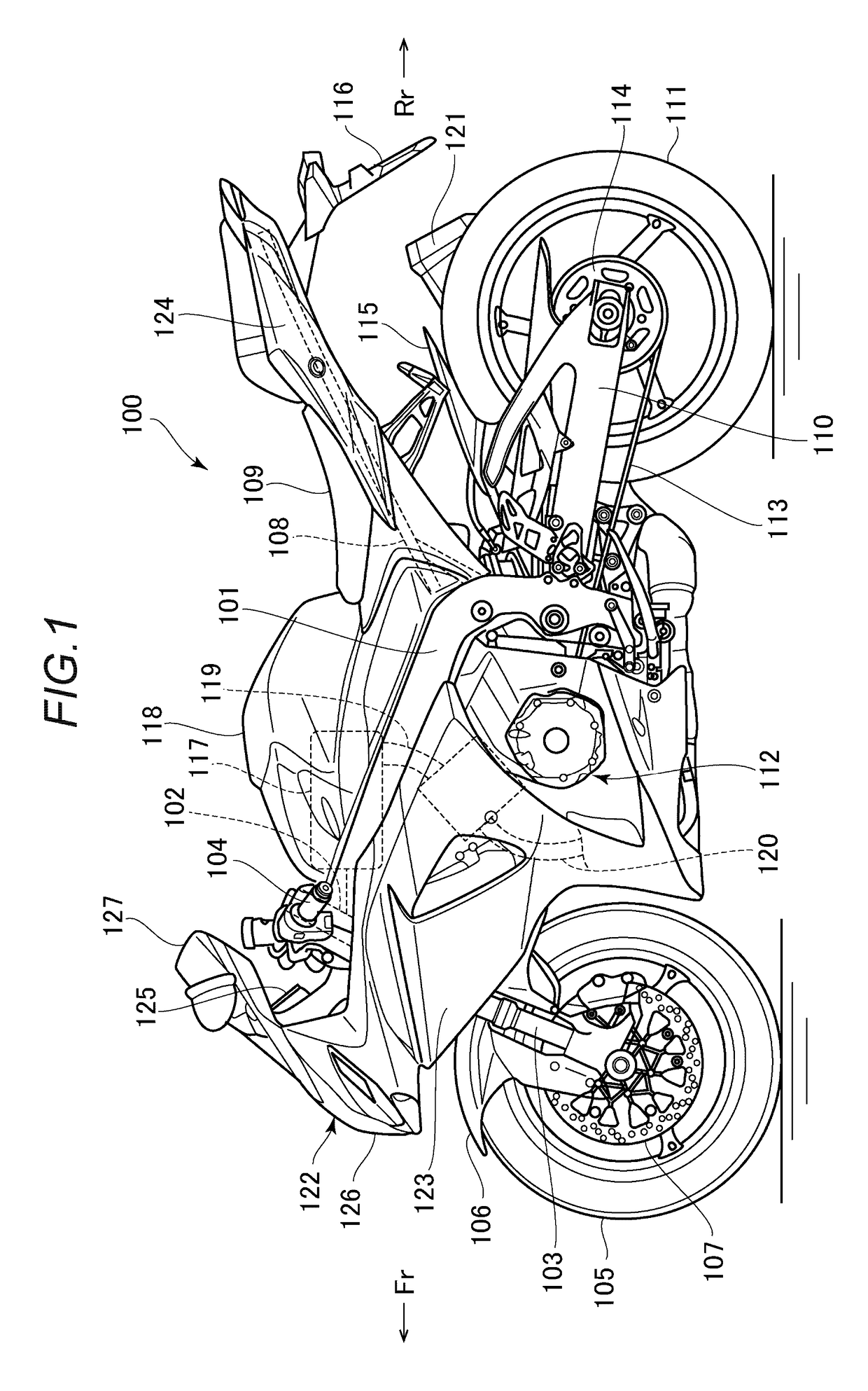

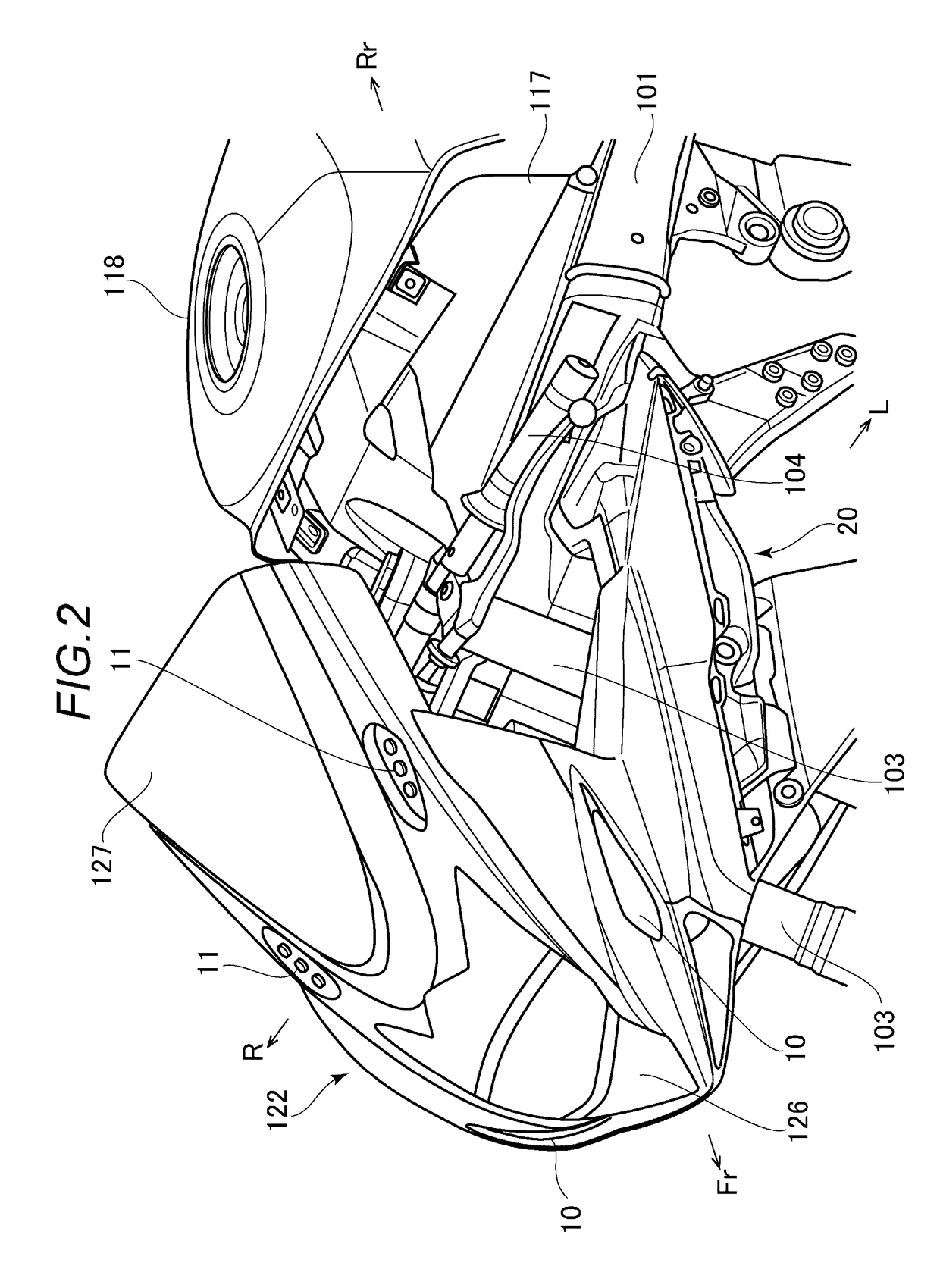

Air intake structure for saddle-ride type vehicle

ActiveUS20160368369A1Increase intake air flow rateIncrease intake flowSteering deviceMachines/enginesAir cleanersAerospace engineering

The air intake structure for a saddle-ride type vehicle includes a front cowl, a pair of right and left air duct portions, an air cleaner box, and a vehicle body frame. The front cowl includes a pair of right and left air intake ports. The pair of the right and left air duct portions guides air taken from the pair of the right and left air intake ports. The air cleaner box cleans the air guided by the pair of the right and left air duct portions. The vehicle body frame is branched backward from a steering head pipe disposed on a front side of a vehicle into a bifurcated shape with a pair of right and left. The vehicle body frame includes the air cleaner box between the branches of the bifurcated shape. The air duct portion includes a first air duct and a second air duct. The first air duct guides air to the air cleaner box from the air intake port through the vehicle body frame. The second air duct branches from the first air duct in a middle to guide air to the air cleaner box.

Owner:SUZUKI MOTOR CO LTD

Pressure control device and semiconductor equipment

ActiveCN110543194AReduce openingIncrease intake flowFluid pressure control using electric meansEngineeringElectric control

The invention discloses a pressure control device and semiconductor equipment. A reaction chamber is connected with a vacuum generator. The pressure control device comprises a pressure sensor used formeasuring the pressure P of the reaction chamber in real time, an electric control pressure regulating valve which is connected with a compressed air inlet end of the vacuum generator and used for regulating the air exhaust pressure of a negative pressure opening end of the vacuum generator, an opening degree regulating mechanism which is arranged on a pipeline for connecting the reaction chamberwith the negative pressure opening end of the vacuum generator and is used for regulating the exhaust flow of the reaction chamber, and a controller, wherein a pressure set value of the electric control pressure regulating valve is regulated according to a difference value between the pressure P and the target pressure P0, so the air exhaust pressure of the negative pressure opening end of the vacuum generator is regulated, the opening degree of the opening degree regulating mechanism is controlled according to the air inlet flow of the reaction chamber, the exhaust flow of the reaction chamber is regulated, and the pressure of the reaction chamber is further controlled. The pressure control device is advantaged in that pressure control can be achieved even when the intake air flow rate of the reaction chamber varies over a large range.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

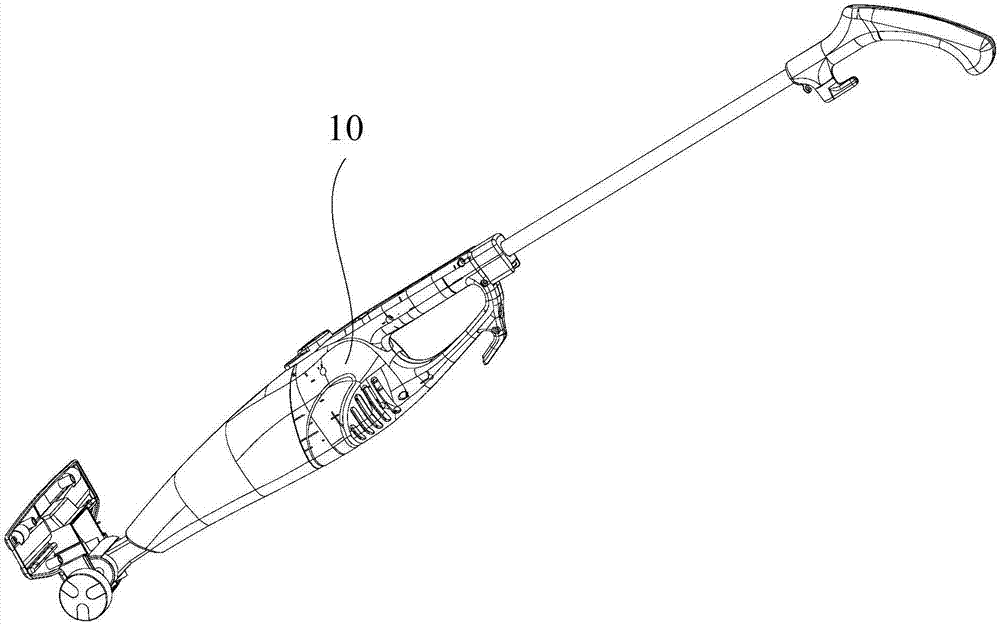

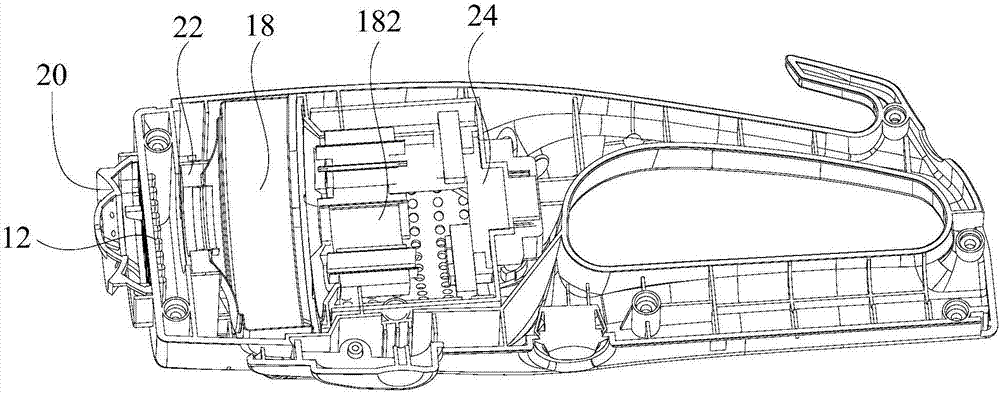

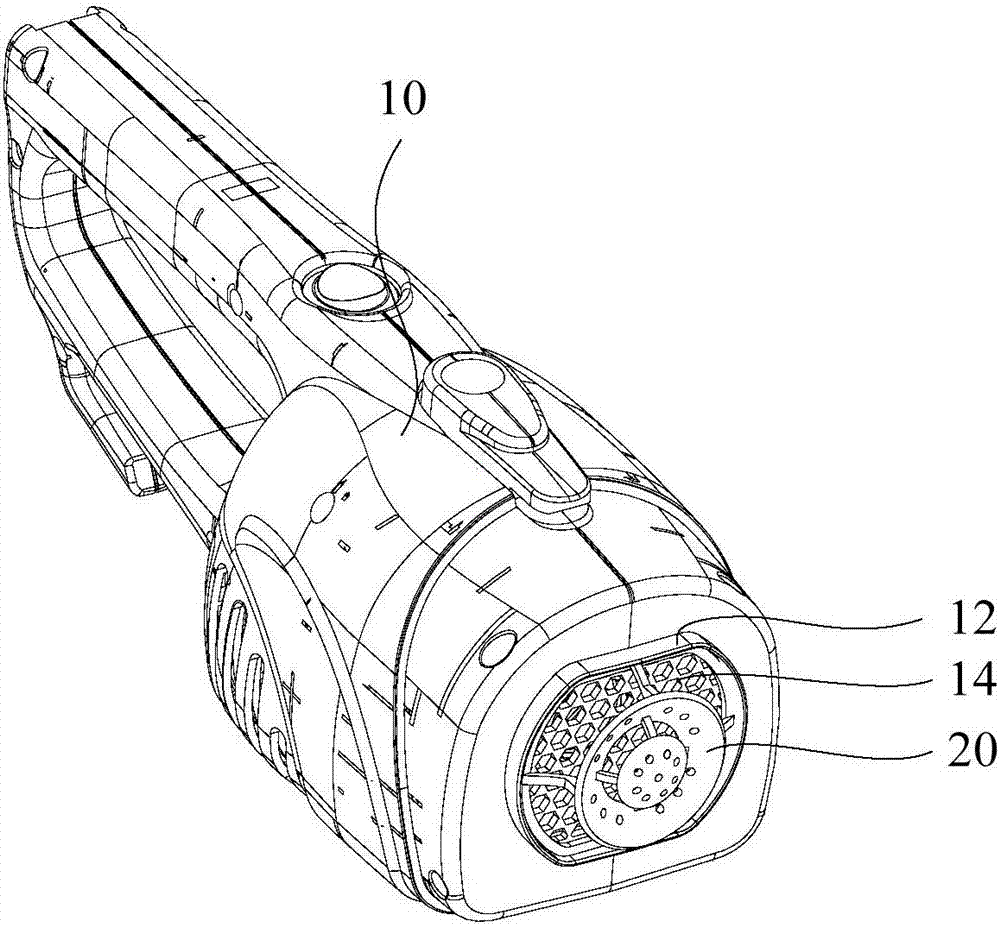

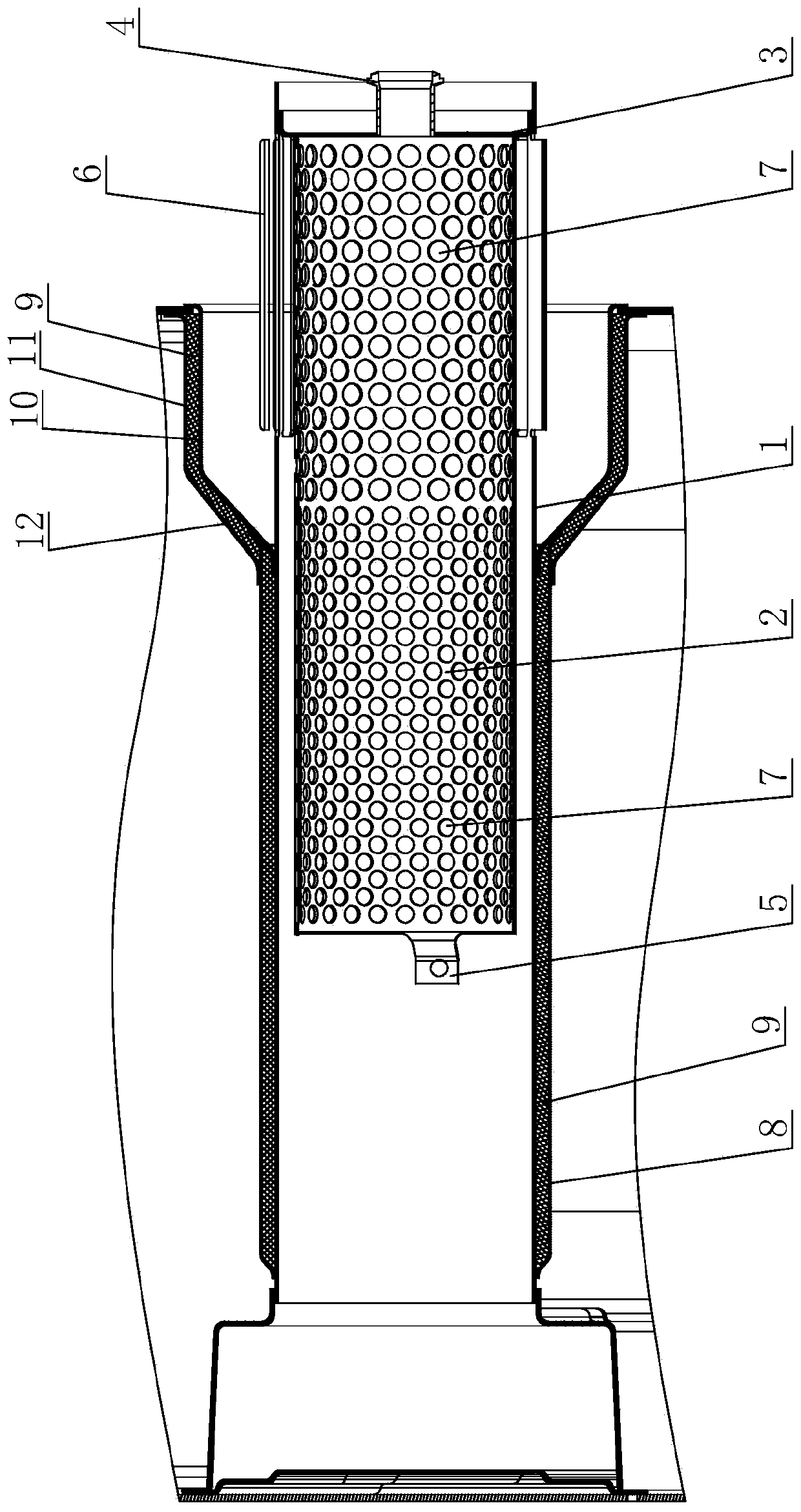

Dust collector

ActiveCN107184146AReduce shockImprove experienceHuman health protectionExhaust-air diffusionEngineeringDust collector

The invention provides a dust collector which comprises an enclosure, a dust cup and an air suction device, wherein the enclosure comprises an air inlet, an air inlet grille is disposed in the air inlet, the air inlet grille comprises multiple air inlets, and the multiple air inlets are distributed in a spiral or cellular or annular manner; the dust cup is disposed on the enclosure; and the air suction device is disposed in the enclosure and comprises a motor. According to the invention, the air inlet grille with the multiple air inlets distributed in the spiral or cellular or annular manner is applied, so that noise of the dust collector is reduced effectively. When the multiple air inlets are distributed in the spiral or annular manner, the noise generated from impact of air inlet vortexes on the air inlet grille can be reduced through effective cooperation with air inlet features brought by motor rotation of the dust collector; and when the multiple air inlets are distributed in a cellular manner, the vortex shape formed after airflows flow through the air inlet grille can be fully decomposed, so that impact noise brought by the airflows in the dust collector can be reduced, and users' experience can be improved.

Owner:MIDEA GRP CO LTD +1

Method of Modifying a Turbocompressor

InactiveUS20070128024A1Increase mass flowIncrease capacityWind motor controlPump componentsEngineeringMechanical engineering

In a method of modifying a turbocompressor, the compressor blades are replaced by new compressor blades in such a way that the delivered mass flow of the compressor increases. At the same time, the capacities for blowing off during the start-up are increased.

Owner:ANSALDO ENERGIA IP UK LTD

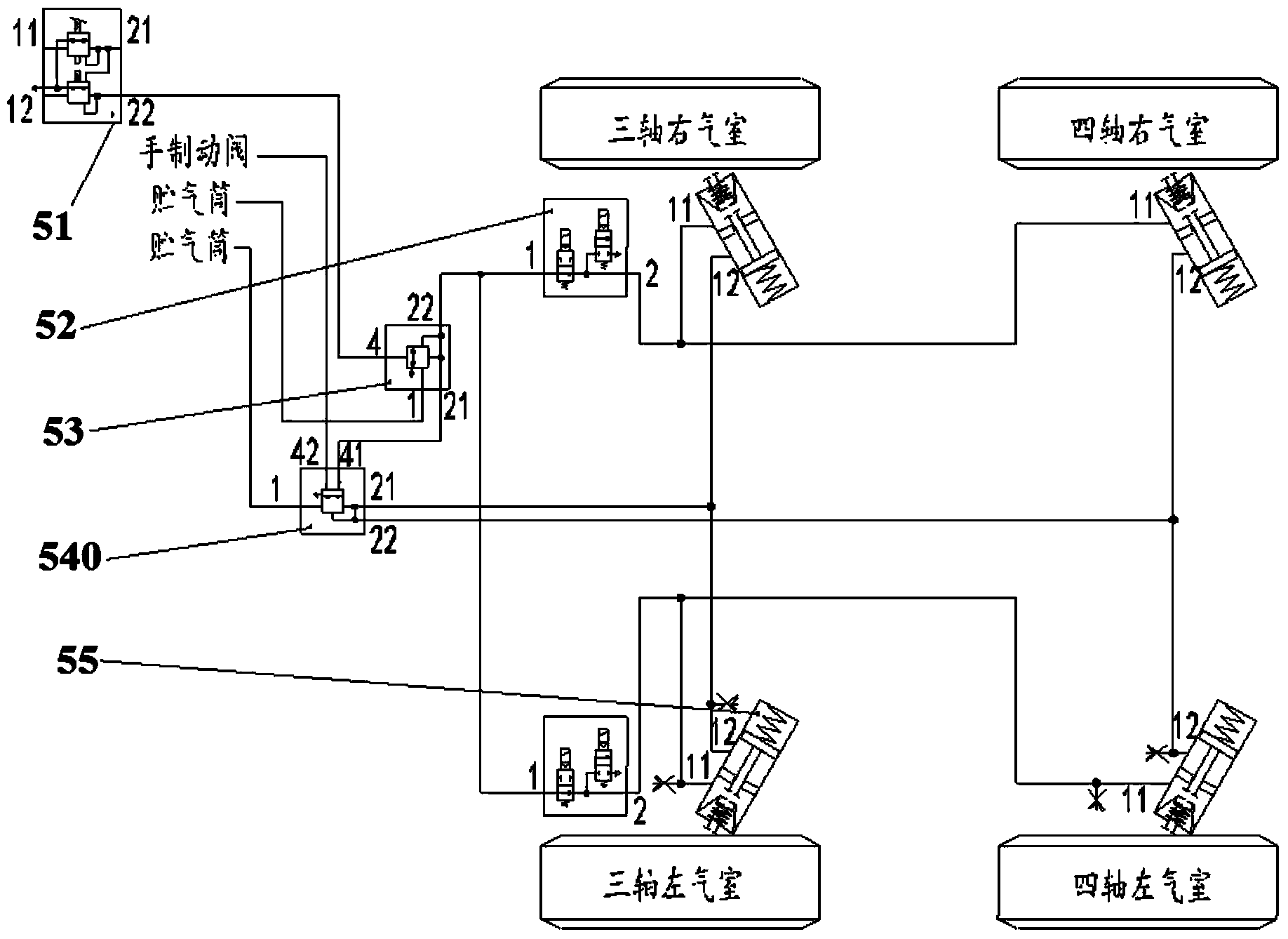

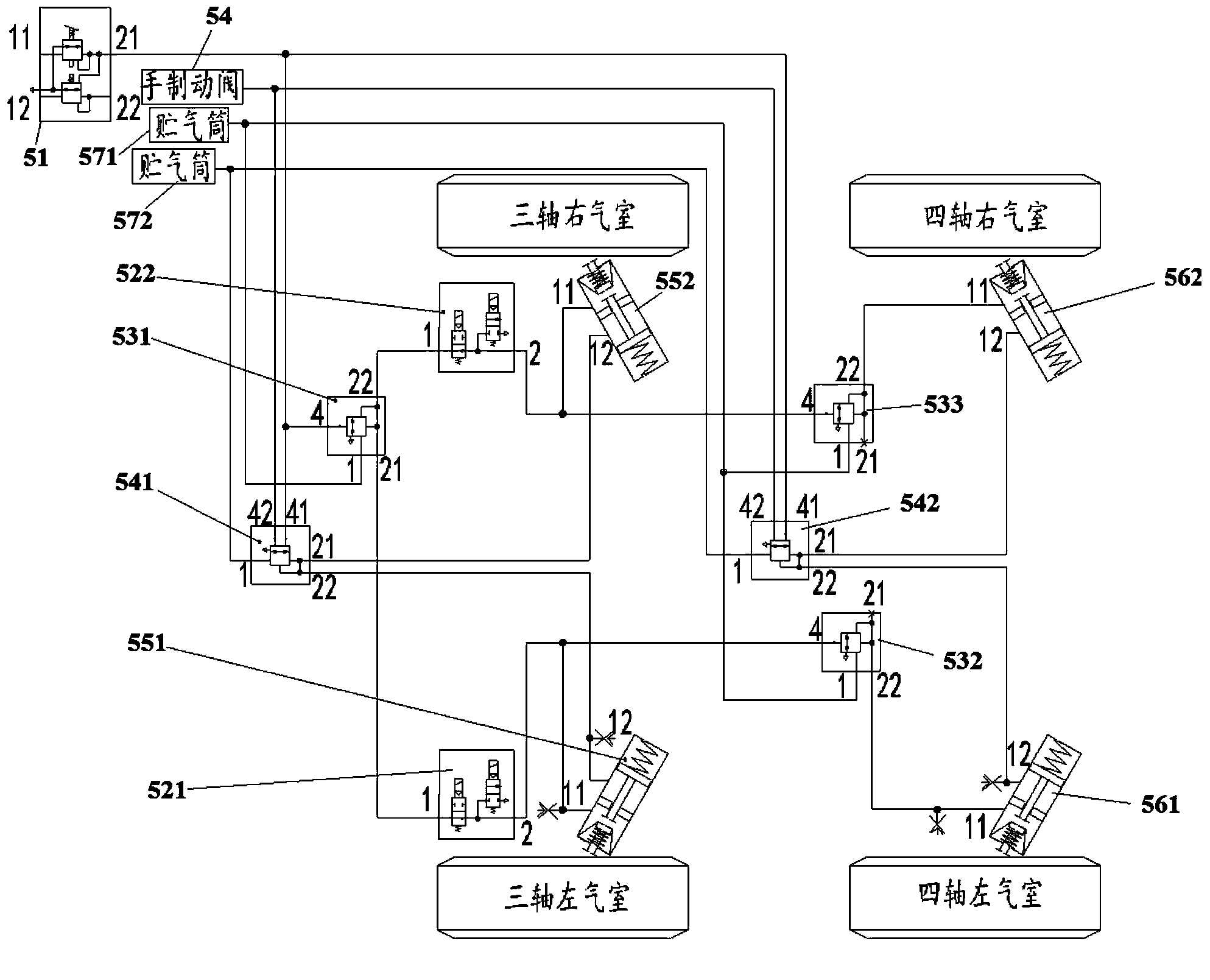

Engineering vehicle chassis brake control system and crane

ActiveCN103523001AIncrease intake flowImprove air intake efficiencyApplication and release valvesRelay valveControl system

The invention discloses an engineering vehicle chassis brake control system and a crane, and relates to the technical field of engineering vehicles. The technical problem that braking capacity in the prior art is poor is solved. The engineering vehicle chassis brake control system comprises a foot brake valve, a first foot relay valve, a three-shaft left brake chamber, a three-shaft right brake chamber and a first air tank, and an air inlet of the first foot relay valve is communicated with an air outlet of the first air tank. One of two air outlets of the first foot relay valve is communicated with a travelling brake airflow inlet of the three-shaft left brake chamber. The other of the two air outlets of the first foot relay valve is communicated with a travelling brake airflow inlet of the three-shaft right brake chamber. The crane comprises a rear axle brake air path, and the rear axle brake air path comprises the engineering vehicle chassis brake control system. The engineering vehicle chassis brake control system and the crane are used for improving the brake performance of the chassis brake control system of the crane.

Owner:XUZHOU HEAVY MASCH CO LTD

Air intake structure for saddle-ride type vehicle

The air intake structure for a saddle-ride type vehicle includes a front cowl, a pair of right and left air duct portions, an air cleaner box, and a vehicle body frame. The front cowl includes a pair of right and left air intake ports. The pair of the right and left air duct portions guides air taken from the pair of the right and left air intake ports. The air cleaner box cleans the air guided by the pair of the right and left air duct portions. The vehicle body frame is branched backward from a steering head pipe disposed on a front side of a vehicle into a bifurcated shape with a pair of right and left. The vehicle body frame includes the air cleaner box between the branches of the bifurcated shape. The air duct portion includes a first air duct and a second air duct. The first air duct guides air to the air cleaner box from the air intake port through the vehicle body frame. The second air duct branches from the first air duct in a middle to guide air to the air cleaner box.

Owner:SUZUKI MOTOR CORP

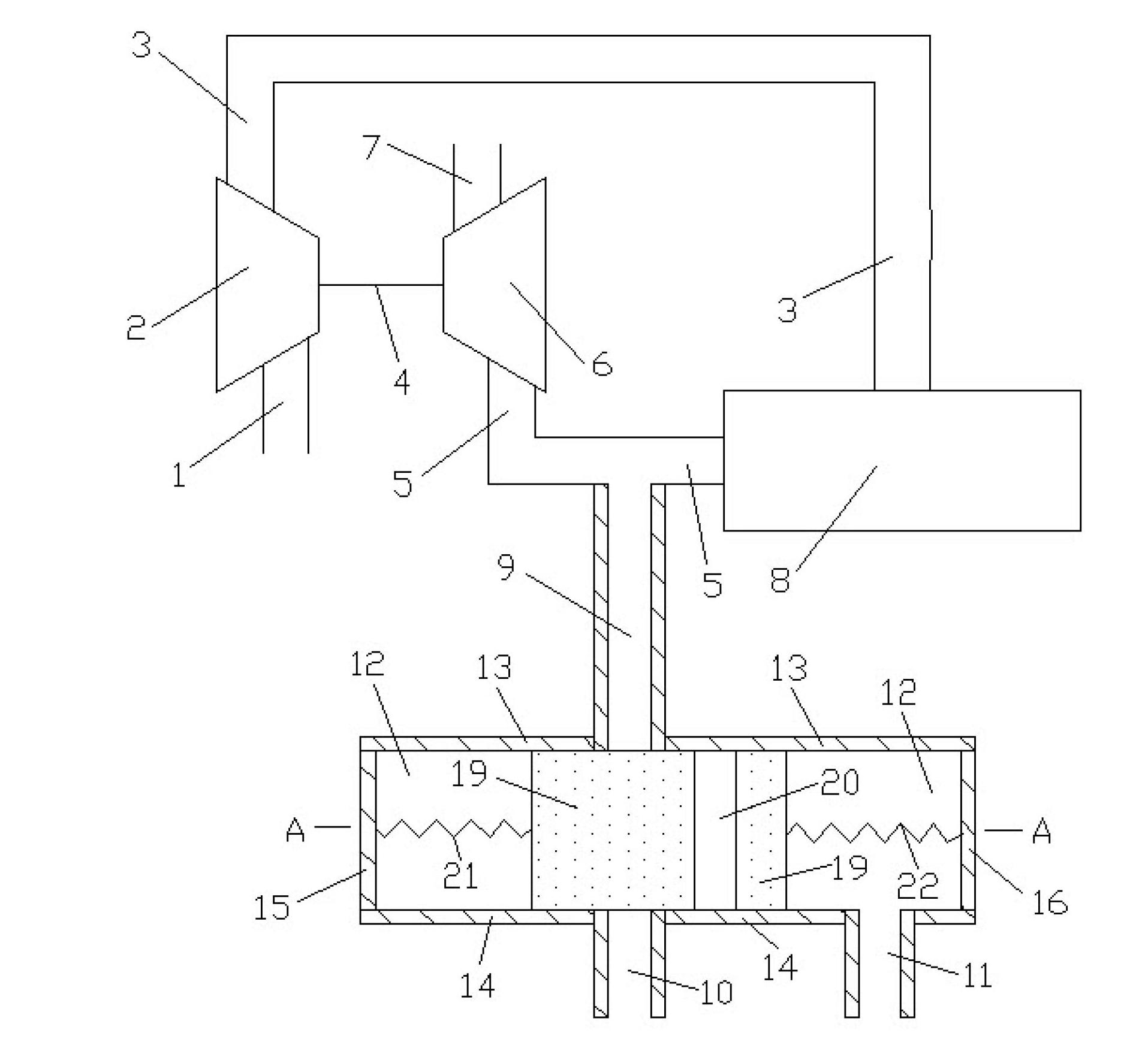

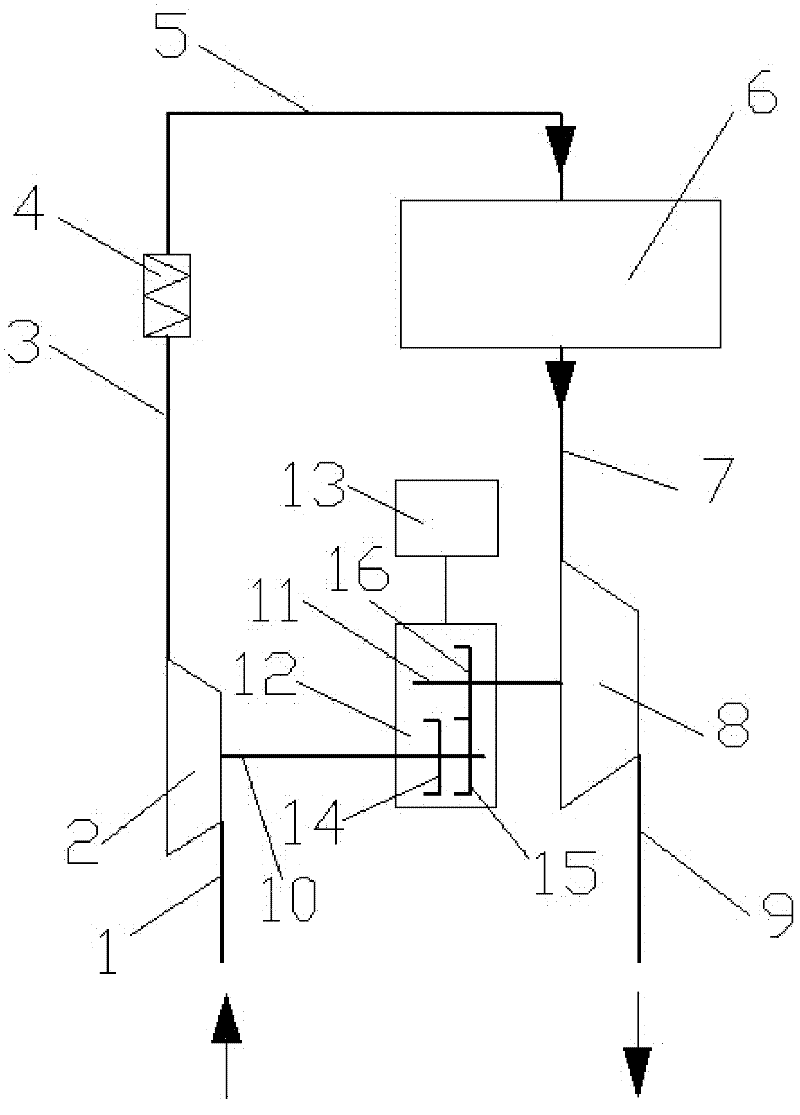

Turbine exhaust device with penetrating pipe

InactiveCN102678281AReduce the temperatureSolve the sealing problemInternal combustion piston enginesCombustionLow speed

The invention discloses a turbine exhaust device with a penetrating pipe in the technical field of internal combustion engines. The device comprises a compressor, a turbine, an engine, a connecting pipe, a volume cavity, a moving body, the penetrating pipe and an elastic part, wherein two ends of a first connecting pipe are respectively communicated with an exhaust pipe of the engine and the upper wall surface of the volume cavity; two ends of a third connecting pipe are respectively communicated with a right wall surface of the volume cavity and an air inlet pipe of the engine; and the penetrating pipe penetrates through the upper and lower walls of the moving body. In the operating process of the engine, the moving body can move left and right in the volume cavity; the pressure on the right side of the moving body is low and the moving body moves to the right side under low-speed working conditions, the first connecting pipe cannot be communicated with a second connecting pipe, the air inlet quantity of the engine is relatively increased, and the power of the engine is raised; and the pressure on the right side of the moving body is high and the moving body moves to the left side under high-speed working conditions, the first connecting pipe is communicated with the second connecting pipe, the air inlet quantity of the engine is relatively reduced, and the detonation pressure of each cylinder is reduced. The turbine exhaust device is reasonable in design, simple in structure and suitable for a turbocharging system of the engine.

Owner:SHANGHAI JIAO TONG UNIV

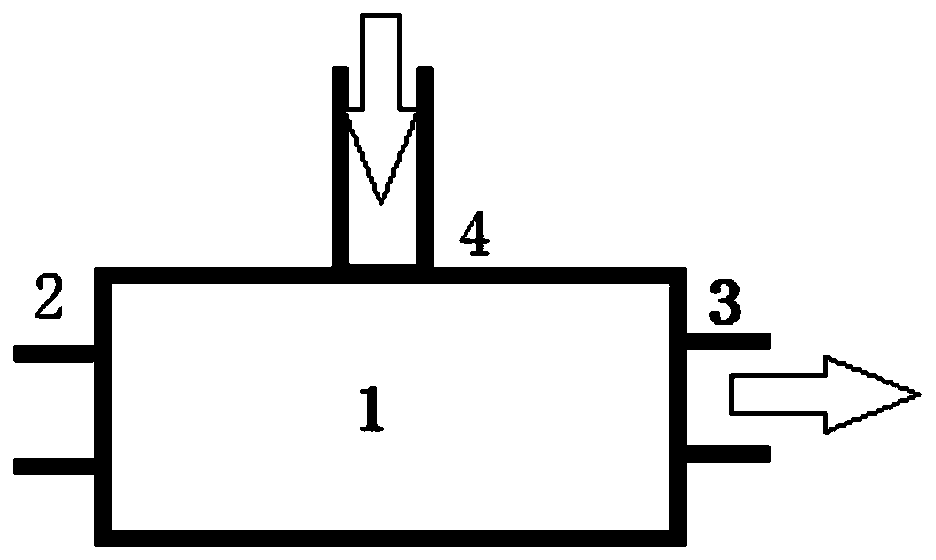

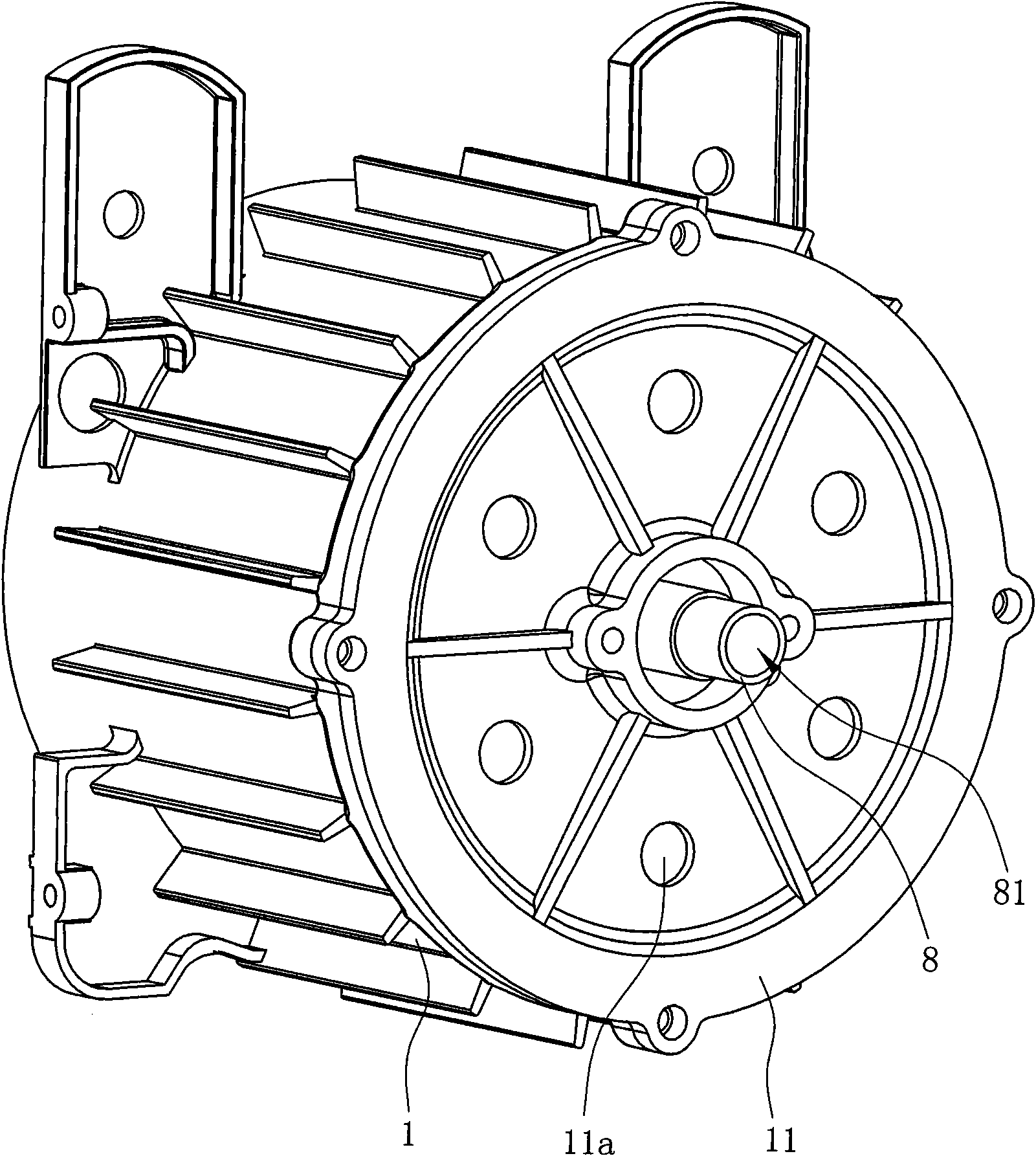

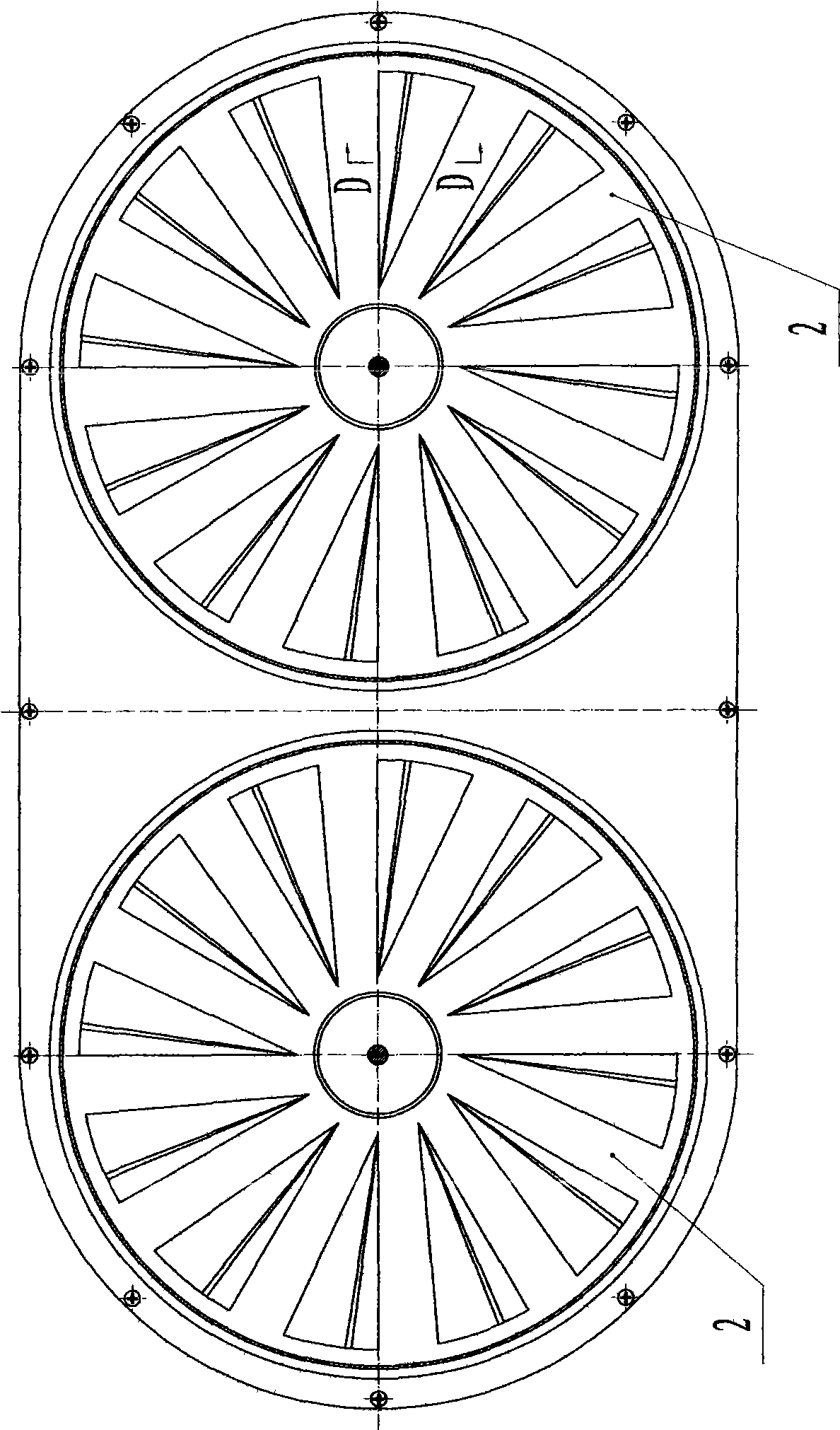

Spiral-flow auxiliary air intake device and compression pump thereof

ActiveCN101603538AImprove work efficiencyReduce energy consumptionRotary piston pumpsRotary piston liquid enginesCompression PumpEngineering

The invention discloses a spiral-flow auxiliary air intake device, which comprises end covers (2) and a flow deflector (4), wherein the end covers (2) are respectively fixed on both sides of a cylinder body (3) during installation; the flow deflector (4) is arranged between the end covers (1) on both sides, and the front of the flow deflector (4) faces an air intake (31) arranged on the circumference of the cylinder body (3) during installation; and each of the end covers (2) is provided with an air intake (21) at a position behind the back of the flow deflector (4). Compared with the prior art, the auxiliary air intake device can effectively reduce energy consumption as air input into the cylinder body withstands no pre-pressure; in addition, the spiral-flow air intake mode can greatly increase air intake flow considerably improve working efficiency of a compression pump and be applied to various compression pumps. The invention also discloses a compression pump applying the spiral-flow auxiliary air intake device. The flow deflector fits a pump casing and the cylinder body to ensure the flow deflector has maximum flow deflecting effect.

Owner:NINGBO TIANSHENG SEALING PACKING

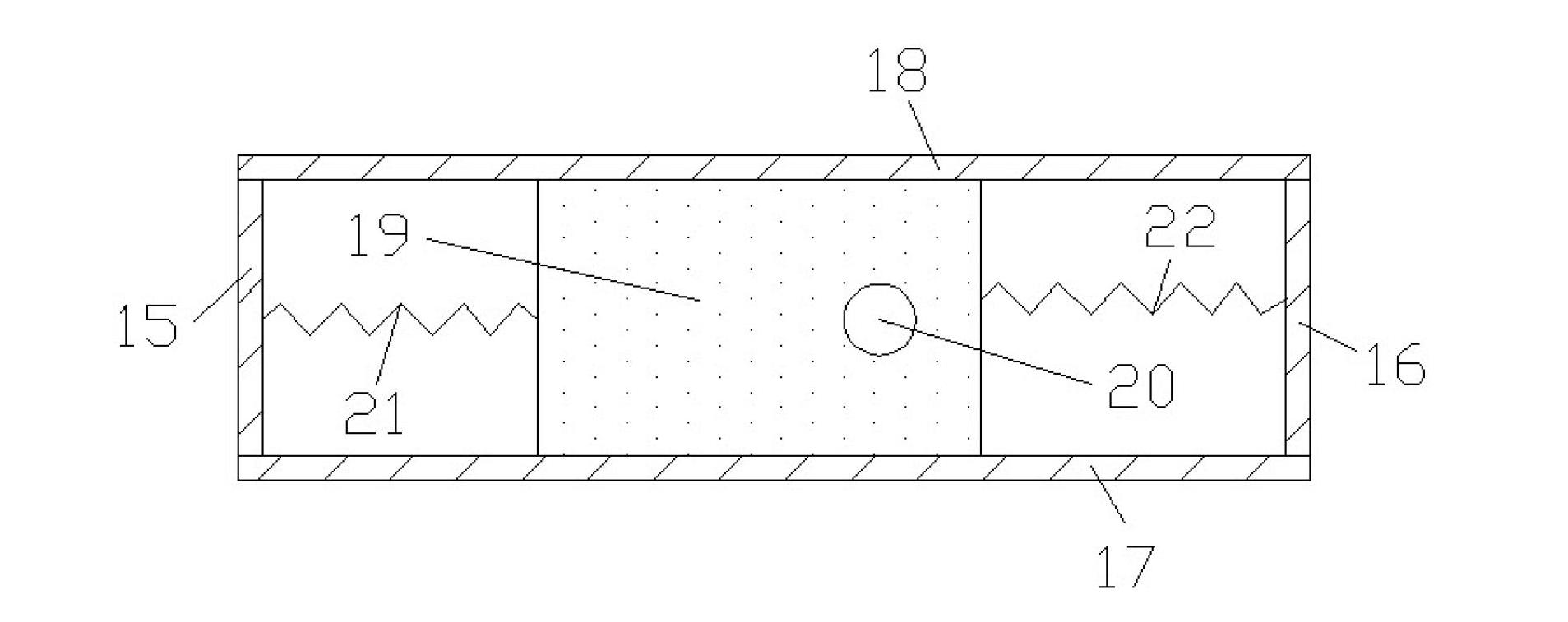

Box type mixer for diesel engine tail gas treatment

PendingCN110359989AReduce heat lossOptimize the hole diameterExhaust apparatusSilencing apparatusHeat lossesEngineering

The invention discloses a box type mixer for diesel engine tail gas treatment. The box type mixer comprises a rotational flow pipe and an inner layer hole pipe, wherein the inner layer hole pipe is arranged inside the rotational flow pipe, one end of the rotational flow pipe and one end of the inner layer hole pipe are connected to a nozzle base, a nozzle for spraying urea solution is mounted on the nozzle base, one end, close to the nozzle base, of the rotational flow pipe is provided with a circle of rotational flow holes, rotational flow blades are arranged on the rotational flow holes, a plurality of vent round holes are uniformly distributed in the inner layer hole pipe, apertures of the vent round holes, corresponding to the position, of the rotational flow blades are larger than theapertures of the vent round holes in other parts, and a heat preservation part is arranged outside the rotational flow pipe. According to the box-type mixer, the opening diameter of the inner layer pore pipe is optimized, the gas inlet flow is increased, the mixing and crushing effects of the urea and the waste gas is enhanced, meanwhile, the heat preservation part is additionally arranged outside the rotational flow pipe, so that the heat loss of the mixer can be effectively reduced, the urea is not easy to form a crystal deposit inside the mixer, and the conversion efficiency of a catalystcan be improved.

Owner:KAILONG HIGH TECH

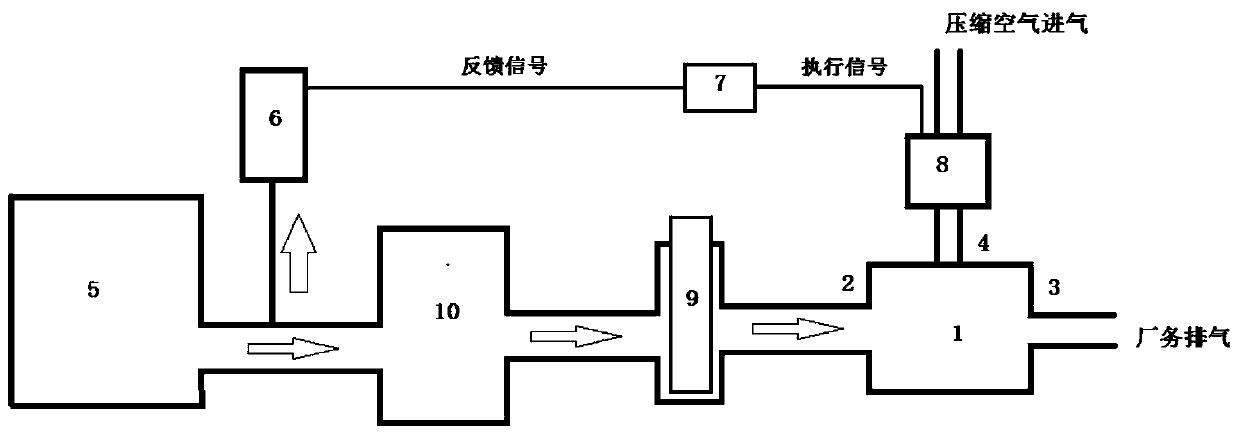

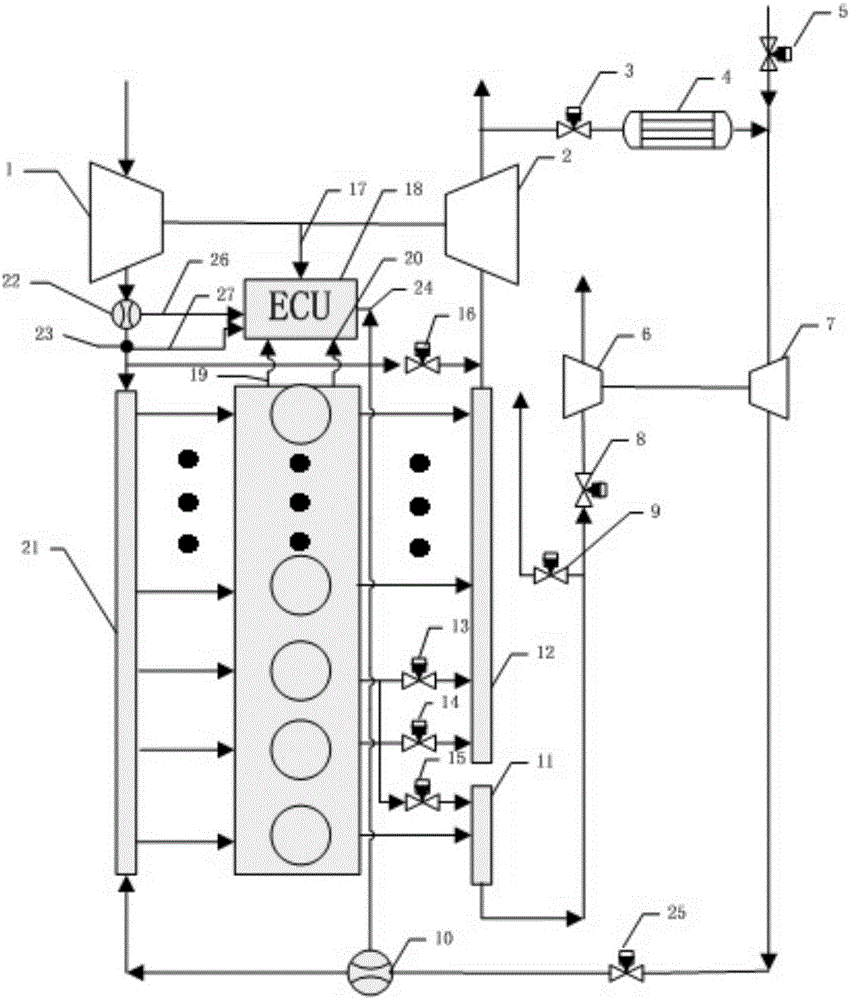

Supercharged diesel engine EGR realization device based on auxiliary turbosupercharger

ActiveCN106762242ASmall pressure fluctuationsPrevent surgeInternal combustion piston enginesExhaust gas recirculationTurbochargerAtmospheric air

The invention aims at providing a supercharged diesel engine EGR realization device based on an auxiliary turbosupercharger. The supercharged diesel engine EGR realization device comprises a main turbosupercharger and the auxiliary turbosupercharger; an exhaust manifold is divided into a main exhaust manifold part and an auxiliary exhaust manifold part; the main exhaust manifold part is connected with a turbine of the main turbosupercharger; the auxiliary exhaust manifold part is connected with a turbine inlet of the auxiliary turbosupercharger and the atmosphere; an air inlet manifold is connected with a gas compressor of the main turbosupercharger and a gas compressor of the auxiliary turbosupercharger; a gas compressor outlet of the main turbosupercharger is connected with a turbine inlet of the main turbosupercharger; and a gas compressor inlet of the auxiliary turbosupercharger is connected with a turbine outlet of the main turbosupercharger and the atmosphere. Exhausted gas at the rear part of the turbine of the main turbosupercharger can be pressurized in an EGR mode to allow the exhaust pressure of the rear part of the turbine to be higher than the intake pressure, so that EGR is realized, in the meanwhile, in a non-EGR mode, the auxiliary turbosupercharger can boost a part of air, and the quantity of fresh air in the air inlet manifold is increased.

Owner:HARBIN ENG UNIV

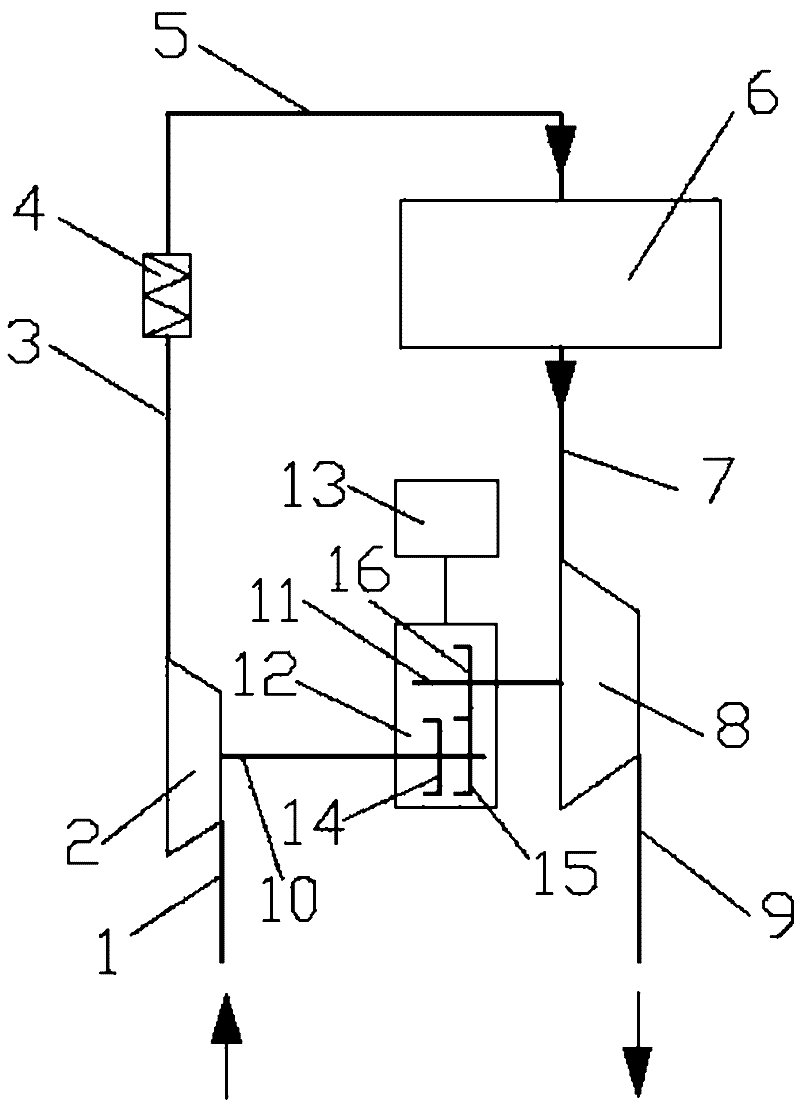

Exhaust back pressure and environmental pressure self-adaption type mechanical regulation device

InactiveCN102678285AIncrease intake flowThe air intake flow rate is relatively large in plateau working conditions.Internal combustion piston enginesCombustionInternal combustion engine

An exhaust back pressure and environmental pressure self-adaption type mechanical regulation device in the technical field of internal combustion engines comprises a compressor, a turbo, an engine, connecting pipes, a volume cavity, a moving body, a through pipe and elastic parts, both ends of the first connecting pipe are respectively communicated with an engine exhaust pipe and the upper wall of the volume cavity, one end of the second connecting pipe and one end of the third connecting pipe are communicated with the lower wall of the volume cavity, and the through pipe runs through the upper and lower walls of the moving body. In the process of engine operation, the moving body can move to the left and the right in the volume cavity; under the plateau condition, the pressure on the right side of the moving body is low, as a result, the moving body moves to the right, consequently, the first connecting pipe cannot be communicated with the second connecting pipe, the air intake of the engine is large, and the power is high; under the plain condition, the pressure on the right side of the moving body is high, as a result, the moving body moves to the left, consequently, the first connecting pipe is communicated with the second connecting pipe, the air intake of the engine is small, and the bursting pressure of each cylinder is low. The design of the exhaust back pressure and environmental pressure self-adaption type mechanical regulation device is reasonable, the structure is simple, and the exhaust back pressure and environmental pressure self-adaption type mechanical regulation device is applicable to the turbocharging systems of engines.

Owner:SHANGHAI JIAO TONG UNIV

Turbine pressurizing system with adjustable rotating speed of gas compressor

InactiveCN102518509AWill not leakReasonable designInternal combustion piston enginesLow speedCombustion

The invention relates to a turbine pressurizing system with adjustable rotating speed of a gas compressor. The turbine pressurizing system comprises the gas compressor, an engine, a turbine, a gas compressor connecting shaft, a turbine connecting shaft and gears, wherein a first gear and a second gear are both arranged on the gas compressor connecting shaft, the gear number of the first gear is less than that of the second gear, a third gear is arranged on the turbine connecting shaft, and the second gear is meshed with the third gear. When the engine is in a low-speed working condition, the first gear and the third gear are meshed by a control mechanism, the rotating speed and the efficiency of the gas compressor are both high, the engine has high air inflowing rate, combustion is good and the performances of the complete machine are excellent; when the engine is in a high-speed working condition, the second gear is meshed with the third gear by the control mechanism, the gas compressor has low rotating speed, the engine has low air inflowing rate, the blasting pressure is low, pumping loss is low, and the performances of the complete machine are excellent. The turbine pressurizing system is reasonable in design, is simple in structure and is suitable for the turbine pressurizing system without a valve control mechanism in an exhaust piping system.

Owner:SHANGHAI JIAO TONG UNIV

Heavy-duty car dual chamber non filtering net air filter

ActiveCN101509445AIncrease intake flowReduce intake resistanceAir cleaners for fuelImpellerAir filter

The invention discloses a dual-cavity air filter without a screen for a heavy vehicle, which is characterized in that a duplex inner cavity of a waterproof intake hood is connected with a fan impeller; a pyramidal intake dividing hood is connected in the inner cavity of the waterproof intake hood below the fan impeller at interval; the lower end of the inner cavity of the waterproof intake hood is connected with a dust collection shell; the excircle of an outlet pipe connected with the inner cavity of the dust collection shell is connected with a reverse suction hood by a loop; the reverse suction hood is connected with the dust collection shell to form a dust-collecting cavity; the orientation of an air inlet is arranged on the surface of the periphery of the reverse suction hood, which is opposite to that of an air inlet arranged on the fan impeller; a dust chimney is connected on the dust collection shell and is communicated with the dust-collecting cavity. The air filter completely filters the rain and snow drops and impurities contained in the air to be filtered and effectively prolongs the service life of paper filter elements. By forcibly compressing the air to be filtered into the outlet pipe by high speed rotation of the duplex fan impeller, the outlet flow is improved and smoothened and the resistance keeping the filtered air from entering the engine is obviously reduced.

Owner:张春明

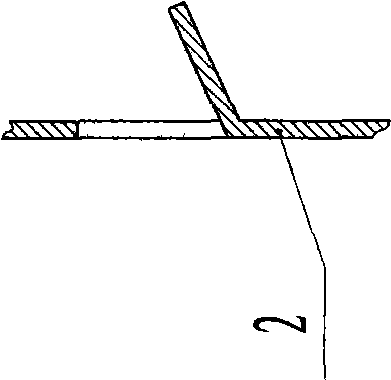

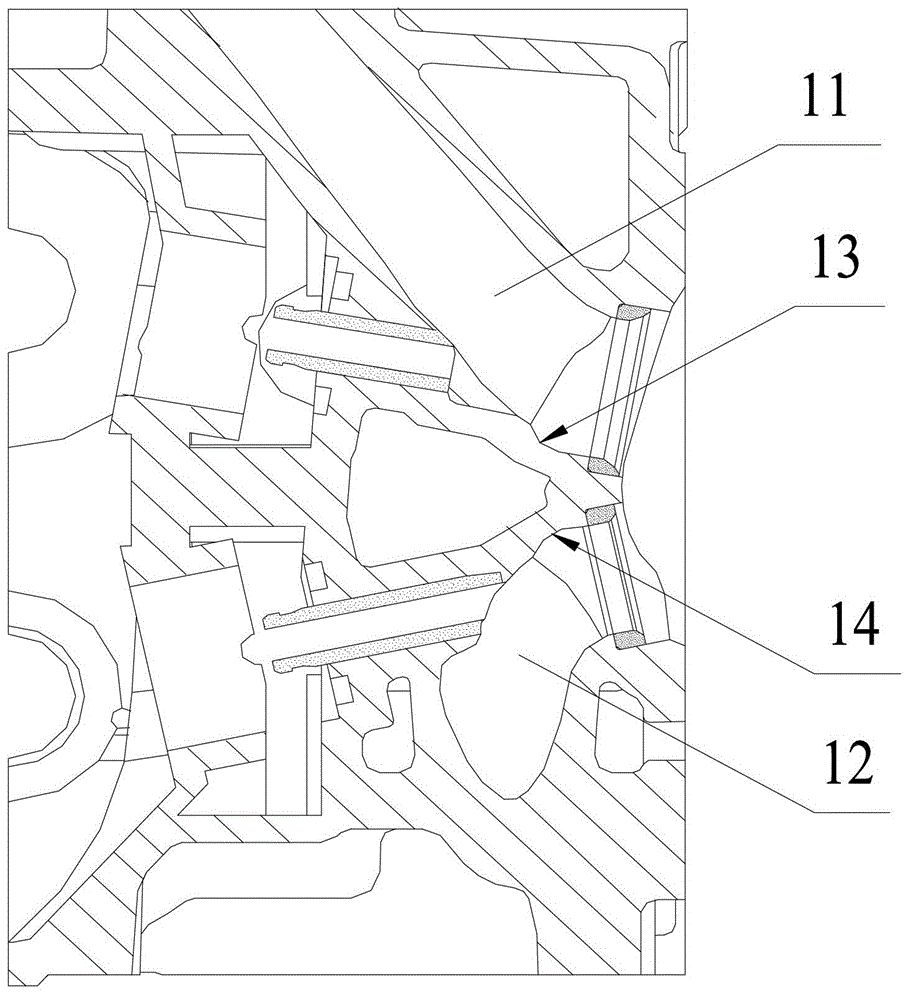

Engine and cylinder cover thereof

InactiveCN103147870AIncrease intake flowDoes not affect balanceCylinder headsCylindersInlet channelAirflow

The invention discloses a cylinder cover of an engine. The cylinder cover is internally provided with an air inlet channel and an air outlet channel; a first spherical groove is formed at an air inlet throat opening of the air inlet channel; and a second spherical groove is formed at an air outlet throat opening of the air outlet channel. With the adoption of the arrangement, the cylinder cover of the engine can reduce the resistance borne by an air flow in the air inlet channel effectively, increases air input of the engine, and allows oil and air to be mixed more sufficiently when the engine works. The invention further provides the engine comprising the cylinder cover.

Owner:力帆科技(集团)股份有限公司

Turbocharging system with rotation speed of air compressor changeable

InactiveCN102434270AWill not leakReasonable designInternal combustion piston enginesLow speedCombustion

A turbocharging system with rotation speed of an air compressor changeable belongs to the technical field of combustion engines and comprises an air compressor, an engine, a turbine, an air compressor connection shaft, a turbine connection shaft and gears. A first gear is arranged on the air compressor connection shaft, a second gear and a third gear are arranged on the turbine connection shaft, the number of teeth of the second gear is smaller than that of the third gear, and the first gear is meshed with the second gear. When the engine is in low speed work condition, the third gear is meshed with the first gear through a control mechanism so that the rotation speed and the efficiency of the air compressor are high, air inlet flow of the engine is large, combustion is good, and the whole machine performance is excellent. When the engine is in high speed work condition, the second gear is meshed with the first gear through the control mechanism so that the rotation speed of the air compressor is low, air inlet flow of the engine is small, explosion pressure is small, loss of pump air is small, and the whole machine performance is excellent. The turbocharging system is reasonable in design, simple in structure and suitable for turbocharging systems with exhaust pipes having no valve control mechanisms.

Owner:SHANGHAI JIAO TONG UNIV

Ram type engine air intake system for vehicle

PendingCN108005819AIncrease intake flowReduced efficiency of eliminationMachines/enginesAir intakes for fuelExhaust gasHigh energy

The invention discloses a ram type engine air intake system for a vehicle. A filter net of the air intake system is arranged at the windward position of a vehicle body, or the outer part of the vehicle body is provided with an air filter air inlet with a forward opening. Filtered air enters an engine air inlet pipe via a cavity or a pipeline. The filter net or the air filter air inlet is arrangedat the air outlet side of a water tank. The filter net or the air filter air inlet is arranged at the air inlet side of the water tank. An air inlet duct or an air filter is arranged at the outer partof the vehicle body or at any side or both sides of the water tank. All or part of air passing the air inlet duct or the air filter enters an engine after being heated by the inner part of the watertank, or the rear part of the water tank, or the upper part of the water tank, or the inner part of an engine exhaust pipe or the periphery of the exhaust pipe. The ram type engine air intake system has the beneficial effects that high-speed air flow forms shock pressure on the filter net, overcomes the resistance of the filter net and increases air intake flow, and the problem that insufficient air supply causes low engine efficiency, high energy consumption, severe exhaust pollution and the like is solved.

Owner:李桂江

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com