Combustion gas turbine

A gas turbine and gas technology, applied in the direction of gas turbine devices, mechanical equipment, machines/engines, etc., can solve the problems of large axial force, large volume and power, low stage pressure, etc., and achieve the effect of reducing axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

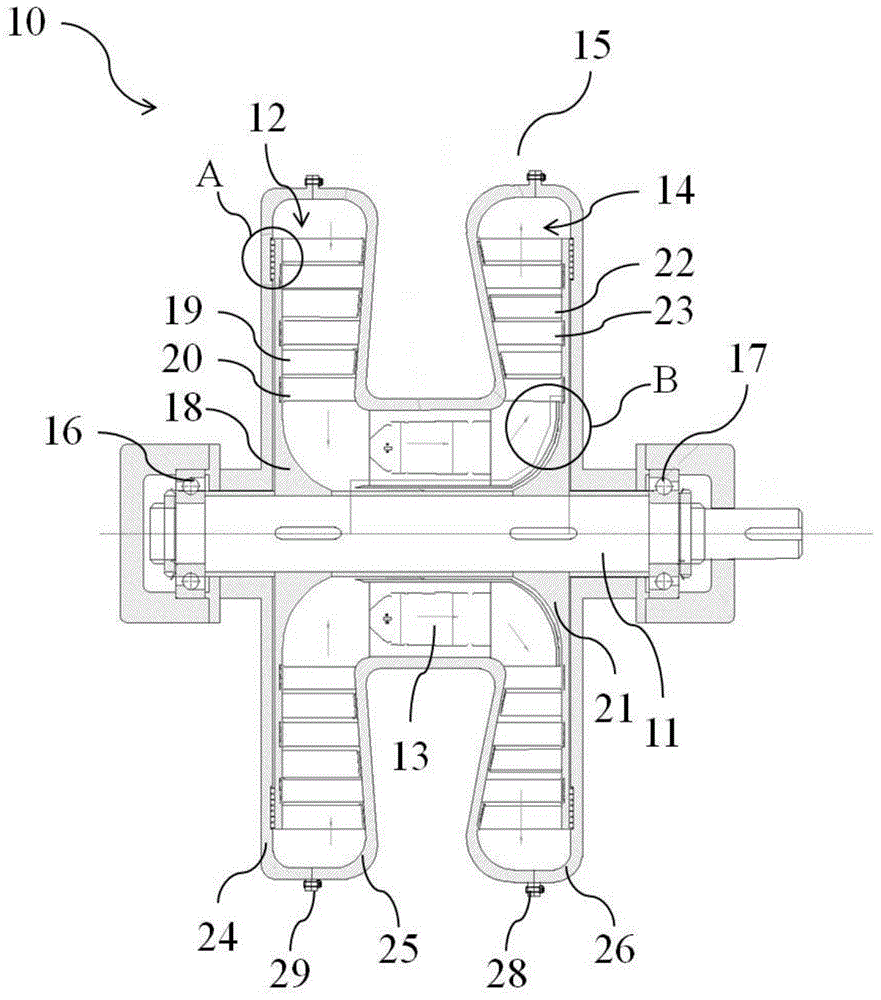

[0027] figure 1 is a sectional view of the gas turbine of the first embodiment.

[0028] Such as figure 1 As shown, the gas turbine 10 includes a main shaft 11 , a radial compressor 12 , a combustor 13 , a centrifugal turbine 14 and a casing 15 .

[0029] The two ends of the main shaft 11 are installed in the bearing 16 and the bearing 17 respectively, and one end of the main shaft 11 is connected to a load (not shown in the figure), and the rotation of the main shaft 11 outputs mechanical work to the load.

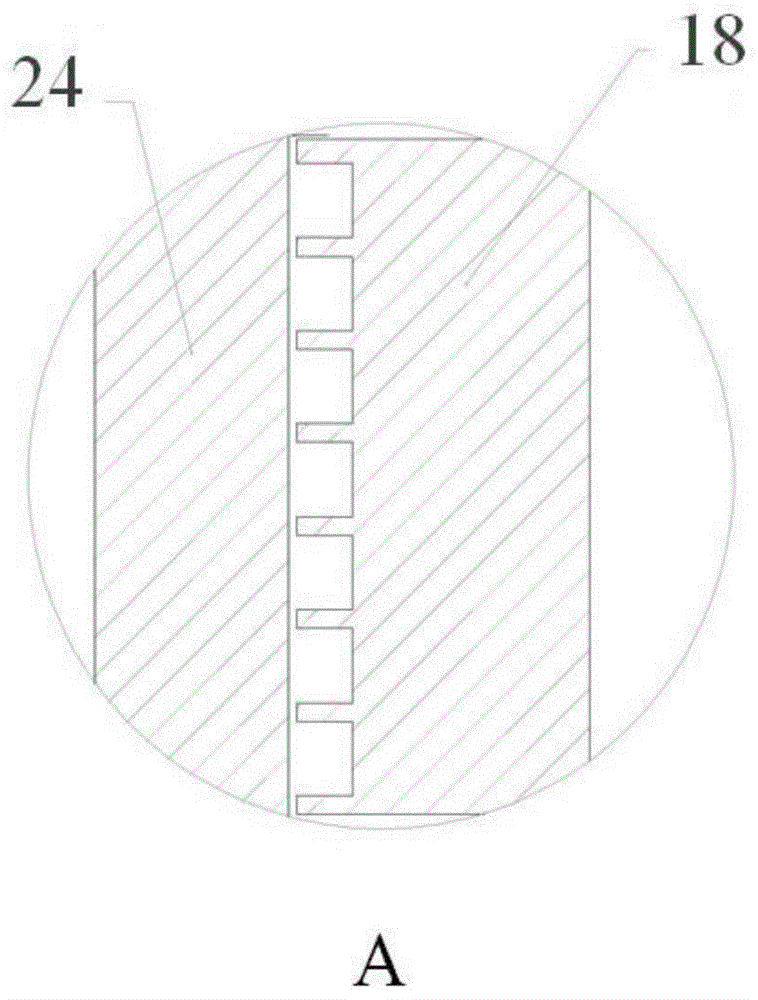

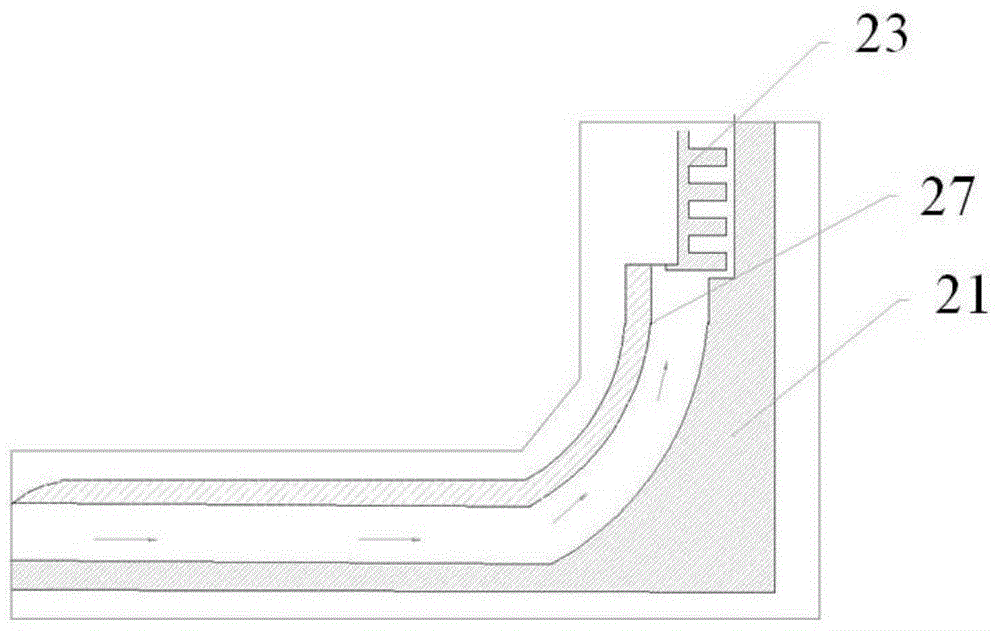

[0030] The centripetal compressor 12 is set on one end of the main shaft 11 and includes a compressor disc 18 , multiple sets of moving blade cascades 19 and multiple sets of static blade cascades 20 . Both the moving blade cascade 19 and the stationary blade cascade 20 are straight blades. The moving blade cascades 19 are installed on the compressor discs 18 respectively. In order to reduce wear and heat, magnetic suspension is used to reduce the friction between the...

Embodiment 2

[0043] Figure 4 is a schematic structural view of the gas turbine of Embodiment 2; and

[0044] Figure 5 is a sectional view of the gas turbine of the second embodiment.

[0045] Such as Figure 4 , 5 As shown, the gas turbine 100 of this embodiment includes a main shaft 101 , a radial compressor 102 , a radial compressor 103 , a combustion chamber 104 , a combustion chamber 105 , a two-way intake centrifugal turbine 106 and a casing 107 .

[0046] The two ends of the main shaft 101 are installed in the bearing 108 and the bearing 109 respectively, and one end of the main shaft 101 is connected to a load (not shown in the figure), and the rotation of the main shaft 101 outputs mechanical work to the load.

[0047] The centripetal compressor 102 and the centripetal compressor 103 are set on both ends of the main shaft 101 respectively. The structural composition of the centripetal compressor is the same as that in Embodiment 1, and both the moving blade cascade and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com