Engine cylinder cover air channel structure

An engine cylinder head and engine technology, applied in engine components, machines/engines, cylinder heads, etc., can solve problems such as unsmooth exhaust and inability to increase intake air flow, and achieve increased intake air volume, power and torque. , the effect of increasing the flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be described in detail below through the examples. It should be understood that the following examples are exemplary only, and can only be used to explain and illustrate the technical solution of the present invention, and cannot be interpreted as the technical solution of the present invention. limits.

[0020] In the present invention, a four-cylinder engine is designed, and when the cylinder of the engine is higher or lower than the four-cylinder, the technical solution of the present invention is equally applicable.

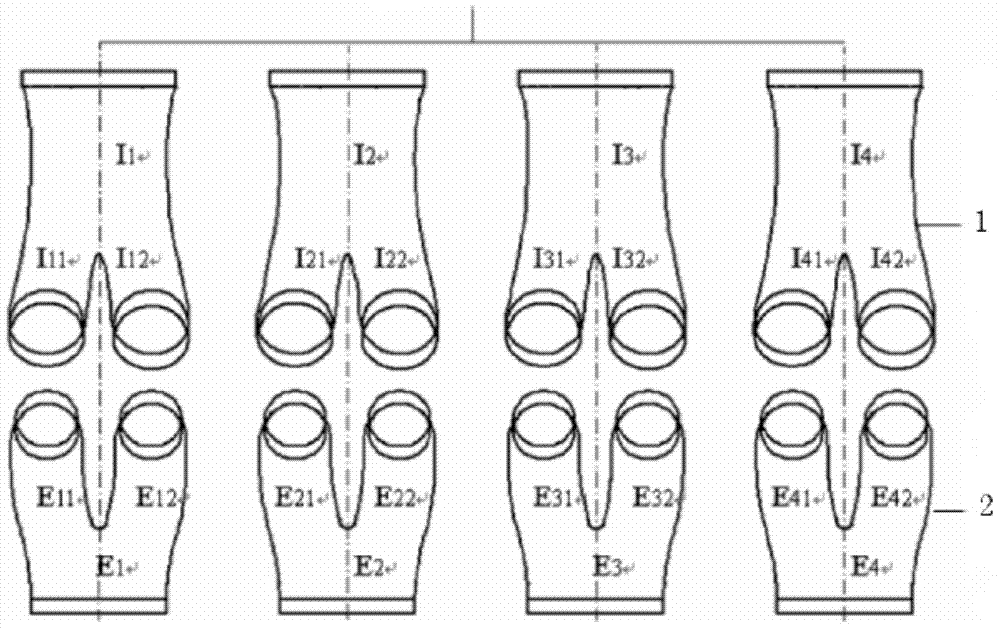

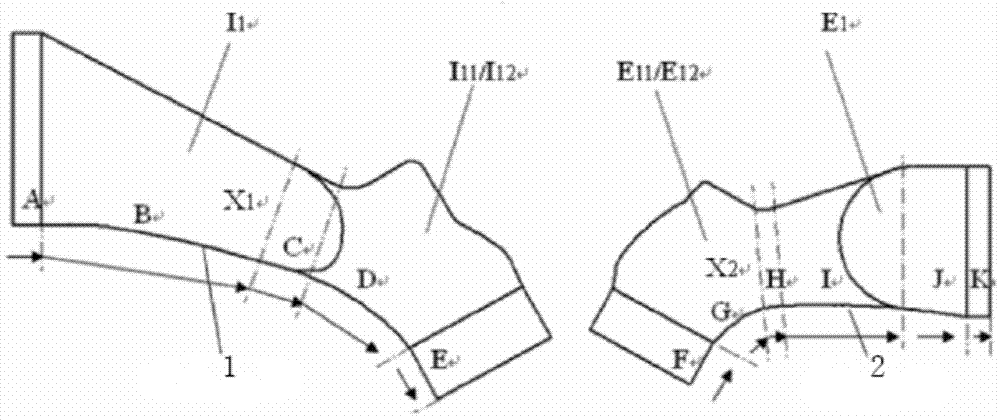

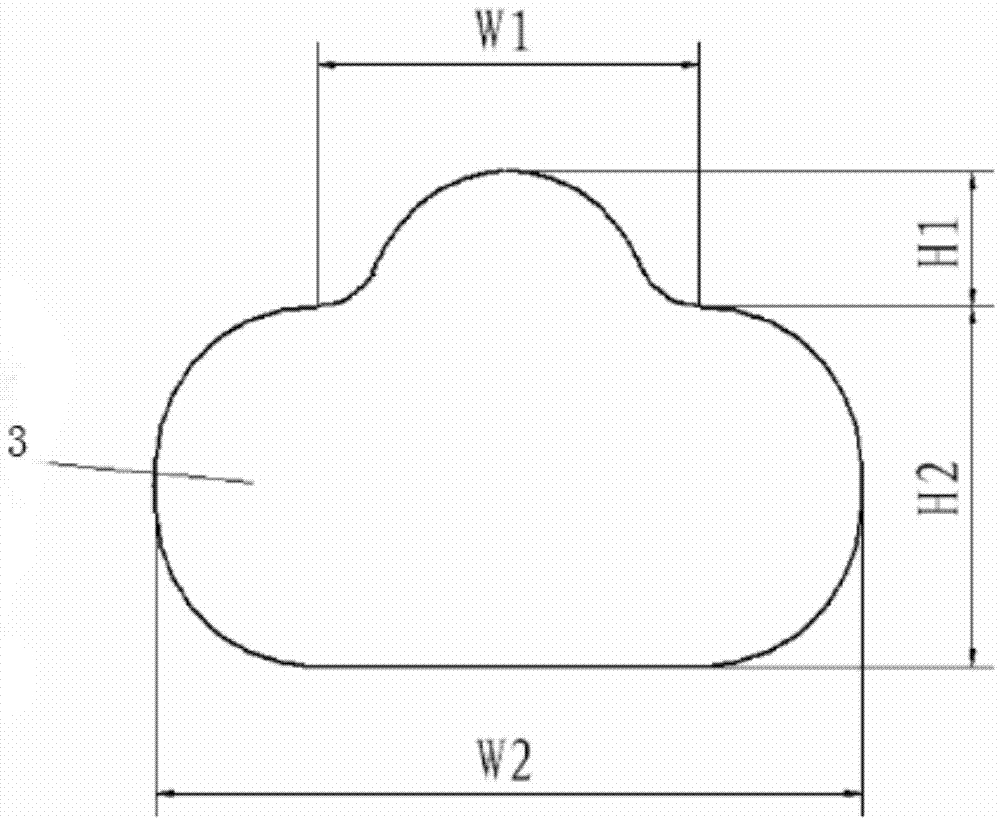

[0021] refer to figure 1 , the engine cylinder head air passage structure is composed of four groups of identical air passages, each group of air passages includes an intake passage 1 and an exhaust passage 2, each intake passage consists of an intake passage and two intake passages The airway branches are composed of the first-cylinder intake duct I1, the second-cylinder intake duct I2, the three-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com