Double-driving parallel sequential supercharging compressor

A sequential supercharging and compressor technology, applied in mechanical equipment, engine function, engine control and other directions, can solve the problems of high manufacturing cost, difficult design and production technology, and difficult promotion, etc., to improve compressor surge, improve Engine performance, effect of widening intake air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

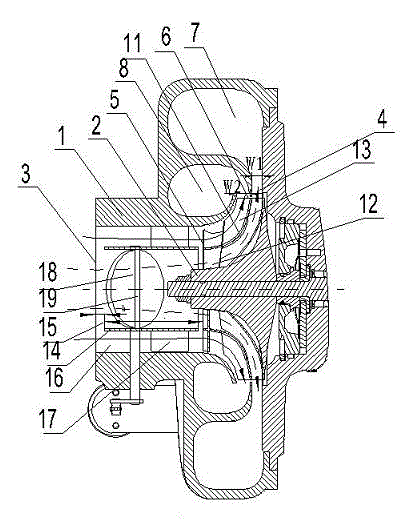

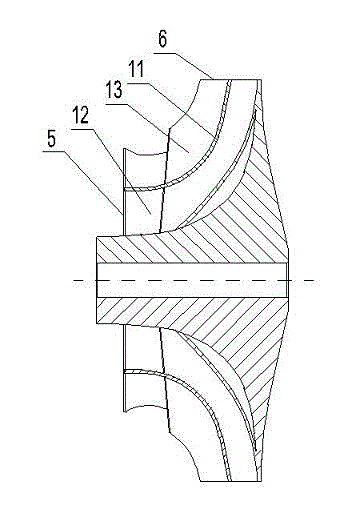

[0057] Example 1, such as figure 1 , figure 2 As shown, a double-drive parallel sequential booster compressor includes a compressor casing 1, a compressor impeller 2 is installed in the compressor casing 1, a compressor flow channel is arranged in the compressor casing 1, and a A compressor air inlet 3 and a compressor air outlet respectively communicated with the compressor flow channel are arranged, and it is characterized in that: the compressor impeller 2 is provided with an impeller inlet flow channel, and the impeller inlet flow channel is connected with the compressor air inlet respectively. 3 communicate with the flow path of the compressor.

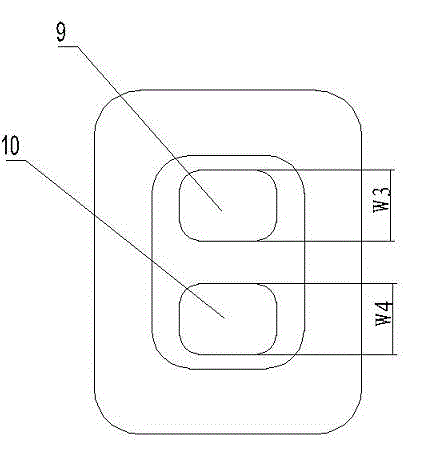

[0058] The compressor runner includes a compressor inner runner 7 and a compressor outer runner 8 arranged side by side on the compressor shell 1; The ratio of the mouth width W2 is 0.1-10.

[0059] A compressor diffuser 4 is provided at the air inlet of the compressor inner flow channel 7 .

[0060] The compressor outlet in...

Embodiment 2

[0074] Example 2, such as Figure 6 , Figure 7 As shown, on the basis of Embodiment 1, the butterfly valve 18 arranged in the inner channel 15 of the air inlet of the compressor is removed, and the position of the inner channel 7 of the compressor near the air outlet 9 of the inner channel of the compressor is set There is an adjustable valve 20, one end of the adjustable valve 20 is connected with a valve shaft 19, and the valve shaft 19 is connected with a control mechanism, and driven by the control mechanism, the opening or closing of the flow channel 7 in the compressor is realized.

[0075] The working process of this embodiment: as Figure 7As shown, when the engine is in the low-speed operating range, the adjustable valve 20 is in a closed state driven by the control mechanism (as shown by the solid line of the adjustable valve in the figure), at this time the centrifugal force generated by the rotation of the fresh air in the compressor impeller 2 Driven by the dri...

Embodiment 3

[0076] Example 3, such as Figure 8 , Figure 9 As shown, on the basis of Example 2, the adjustable valve 20 arranged near the air outlet 9 of the inner runner of the compressor is removed, and the air outlet 6 of the impeller in the diffuser 4 of the compressor is evenly arranged in a circular shape. There are several adjustable guide vanes 21, and the ratio of the number of the fixed guide vanes 17 to the number of the adjustable guide vanes 21 is 0.2-6.

[0077] Such as Figure 10 As shown, each of the adjustable guide vanes 21 is rotatably connected to a shift fork 22, and the fork 22 is rotatably connected to a shift fork plate 23, and the shift fork plate 23 is driven by the control mechanism to rotate to realize the adjustable flow guide The rotation of the vane 21 realizes the opening or closing of the flow channel 7 in the compressor.

[0078] The control mechanism in Embodiment 3 is not limited to the shift fork control mechanism, and any structure of the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com