Ram type engine air intake system for vehicle

A vehicle engine and air intake system technology, which is applied to engine components, machines/engines, charging systems, etc., can solve problems such as reduced engine efficiency, inability to generate intake pressure, and inability to overcome filter engine intake requirements, etc. Achieve the effect of eliminating efficiency reduction and increasing intake air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

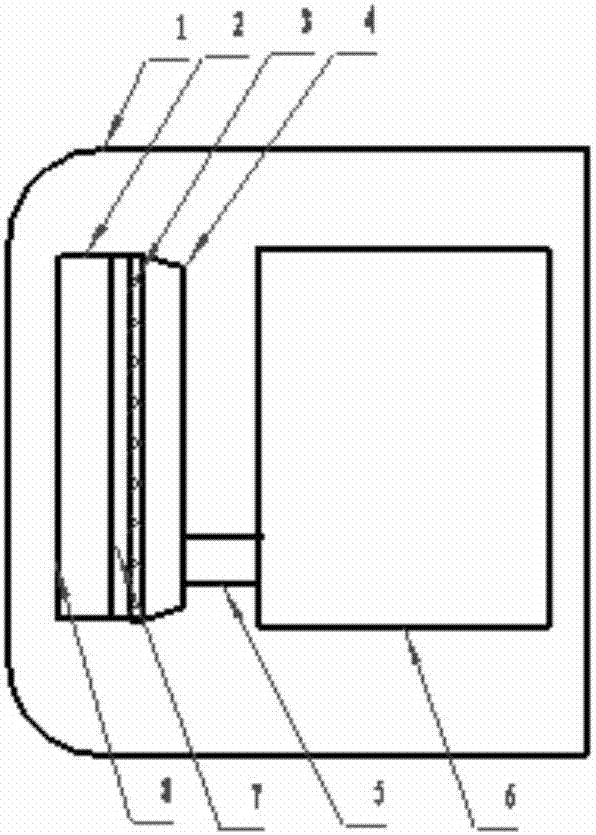

[0033] Such as figure 1 As shown, an air intake filter 3 is arranged on one side of the water tank air outlet surface 7, and is connected to one side of the water tank air outlet surface by a connecting member. The other side of the air intake filter screen is provided with a chamber 4, which is connected with the engine air intake through a pipeline. It constitutes a ram type air intake system for air intake on one side of the air outlet side of the water tank. The high-speed air flow passing through the water tank is used to provide pressurized air intake for the engine, and the temperature of the water tank is used to heat the air passing through the water tank, which solves the problem of low engine air intake pressure and low engine air intake temperature in winter and high fuel consumption. It can improve engine efficiency, reduce fuel consumption and emission pollution.

Embodiment 2

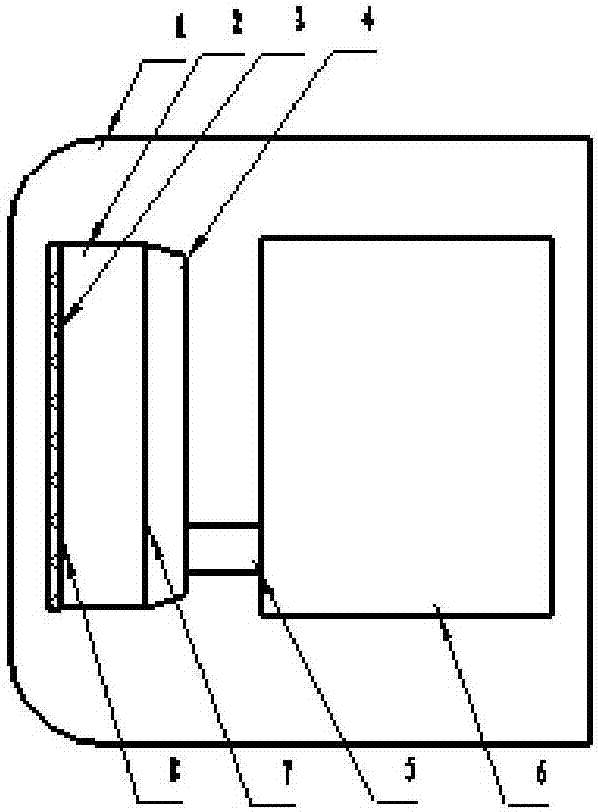

[0035] Such as figure 2 As shown, the filter screen 3 is set on the air inlet surface of the water tank

Embodiment 3

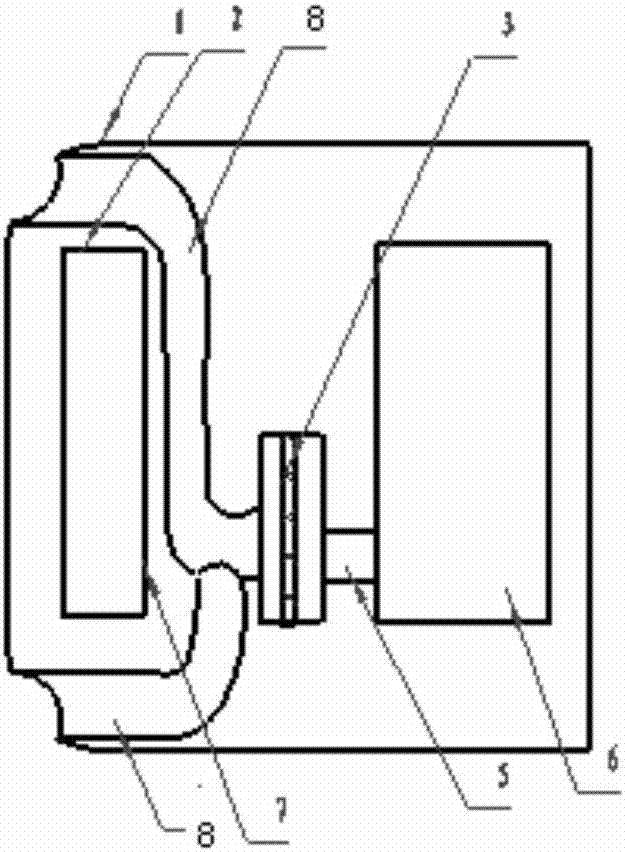

[0037] Such as image 3 As shown, the filter screen 3 is arranged behind the water tank, and its air inlet is the air inlet chamber formed by the air intake duct 8 on both sides of the water tank 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com