Flow control ejection system for aircraft model low-speed wind tunnel test

A wind tunnel experiment and flow control technology, which is applied to the testing of machines/structural components, instruments, and measuring devices, can solve problems such as limited intake flow, affecting experimental results, and congestion at the exhaust outlet of the main intake pipe. To achieve the effect of increasing the intake flow and improving the authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

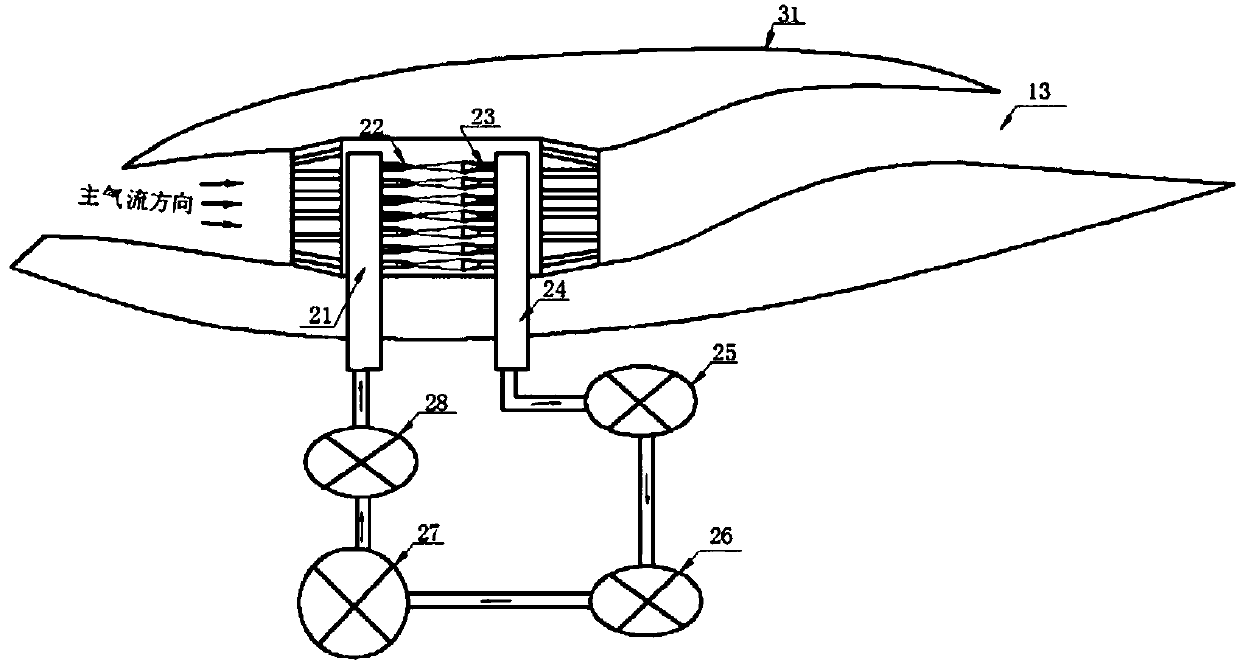

[0016] A flow control injection system for aircraft model low-speed wind tunnel experiments, comprising a body 31, the inside of the body 31 is provided with a main air intake duct 13, and also includes a high-pressure nozzle support 21, a high-pressure air intake nozzle support 24, a recovery Supercharging device 25, air intake controller 28, one-way valve 26 and high-pressure gas tank 27, described main air intake pipe 13 is provided with a cylindrical cavity inside, described high-pressure air intake nozzle support 24 and high-pressure nozzle The support 21 is arranged on both sides inside the cylindrical cavity, the bottom of the high-pressure air inlet nozzle support 24 passes through the body 31 and communicates with the recovery booster 25, and the high-pressure nozzle support 21 passes through the body 31 and connects with the inlet The air controller 28 communicates, the air intake controller 28 communicates with the high-pressure gas tank 27, the one-way valve 26 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com