Sliding structure and sliding method

a sliding structure and sliding technology, applied in the field of sliding structure, can solve the problems of inability to exert an effect, cannot be said that molybdenum-based solid lubricant always acts effectively, etc., and achieve the effects of reducing friction coefficient between sliding members, reducing friction coefficient, and improving wear resistance of sliding members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

(Sliding Member)

[0032] A block test piece and a ring test piece that serve as a pair of sliding members in the sliding structure of the present invention were produced in the manner described below.

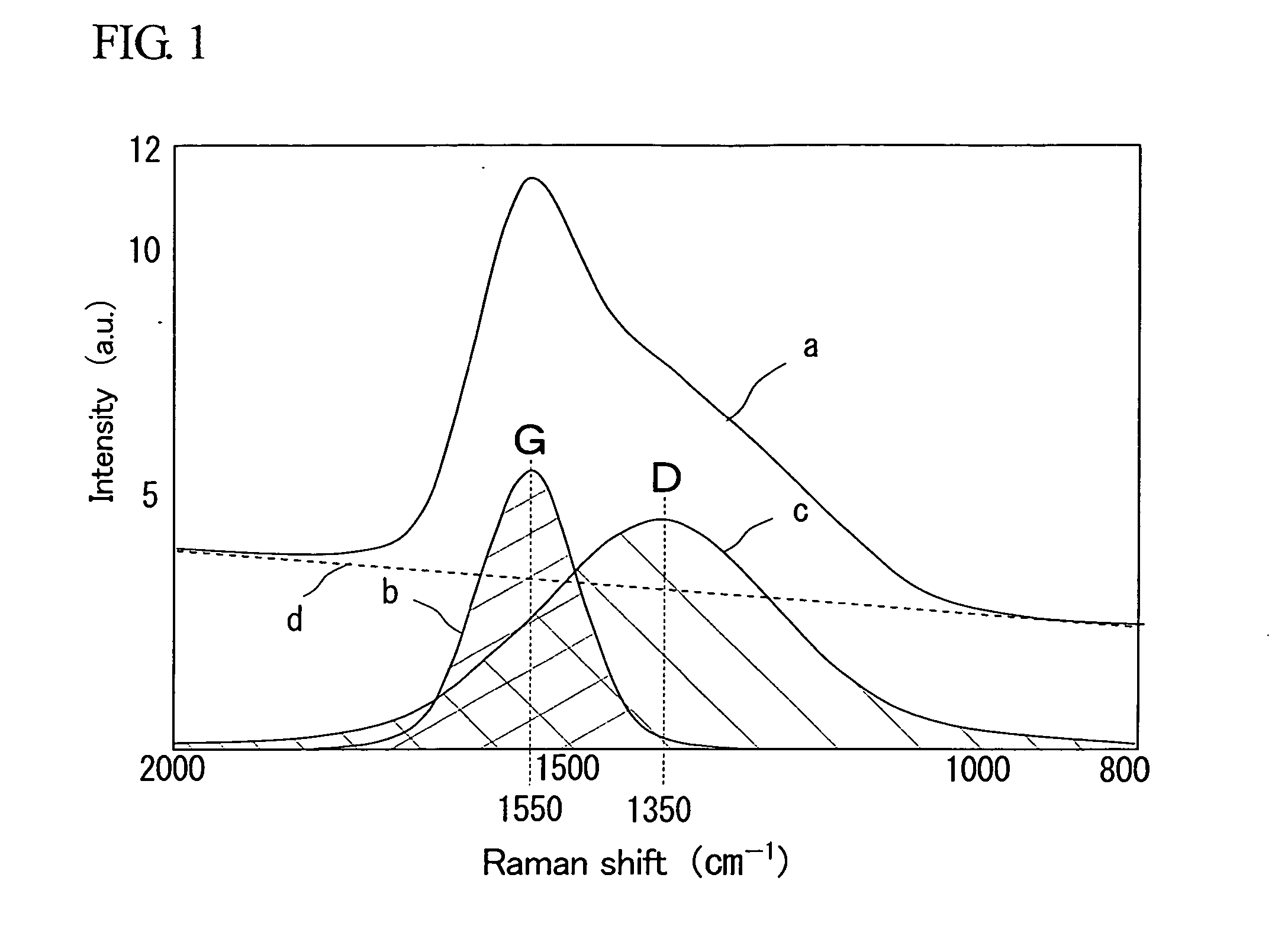

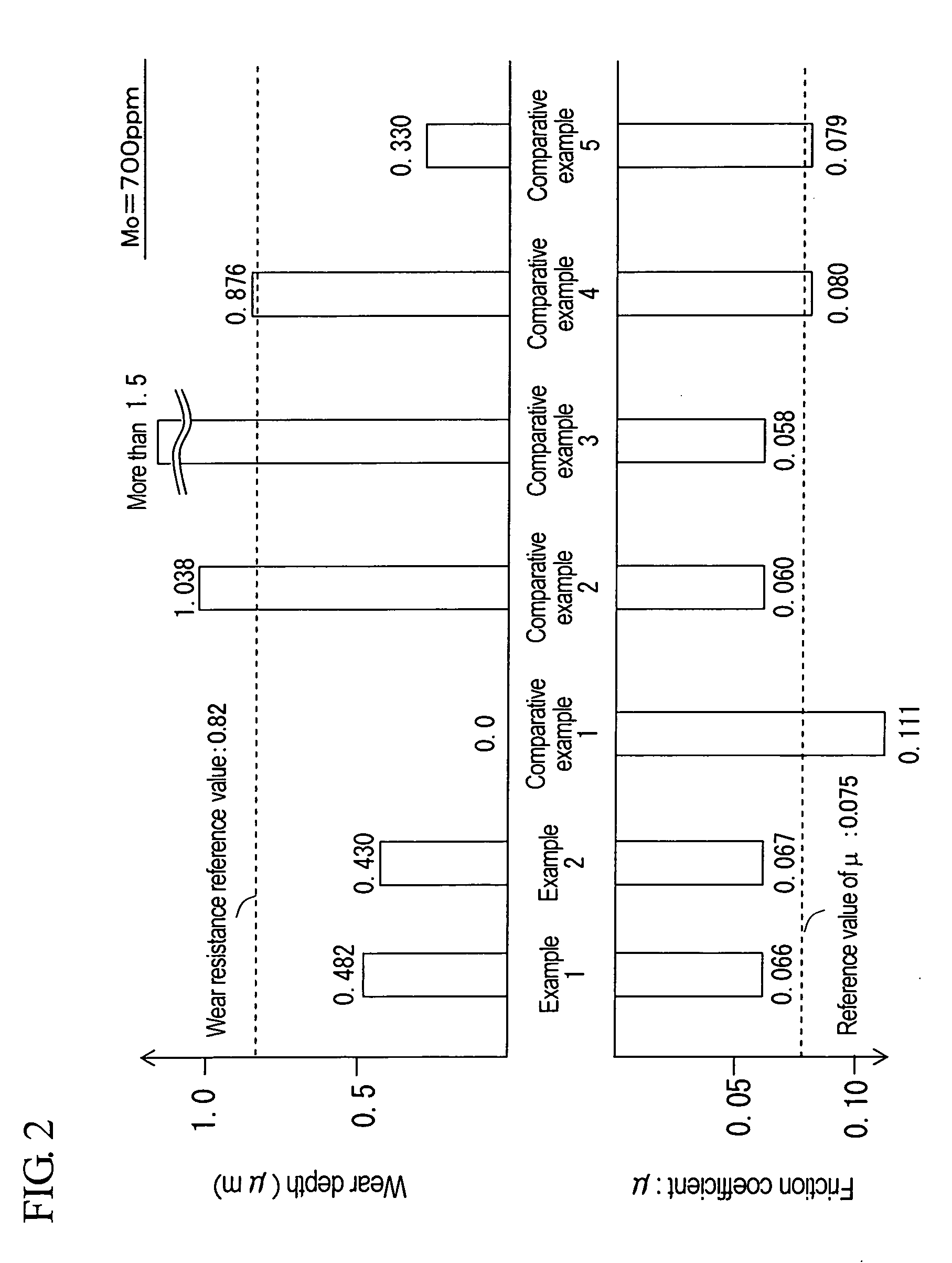

[0033] Block test piece: As a substrate on which an amorphous carbon film is formed, stainless steel (SUS440C; JIS) 15.7×10.0×6.3 mm in dimensions having as its surface roughness a center line average roughness of Ra 0.05 μm was prepared. As shown in FIG. 1, an amorphous carbon film was formed on the surface of the substrate (on the 15.7×6.3 mm side) by the plasma PVD method while adjusting the carrier gas flow rate, the applied plasma voltage, the temperature, and the like in a manner such that the D (line c in FIG. 1) to G (line b in FIG. 1) band integrated intensity ratio in the Raman spectrum (ratio of a hatched area below line c to a hatched area below line b) became 1.58 (see tables 1 and 2). In addition, the total intensity of scattered light relative to incident light shown as ...

example 2

[0037] After a substrate was produced as with the case of Example 1, a block test piece was produced in a manner such that an amorphous carbon film was formed on the surface of the substrate by the plasma CVD method while adjusting the concentration and the flow rate of hydrocarbon gas, the applied plasma voltage, the temperature of the substrate, and the like, resulting in a D to G band integrated intensity ratio in the Raman spectrum of 1.79 (see tables 1 and 2).

[0038] In addition, a ring test piece and lubricating oil were provided as with the case of Example 1. As with the case of Example 1, a frictional wear test was conducted so as to determine the friction coefficient and the wear volume. The results are shown in table 2 and FIG. 2.

examples 3 to 6

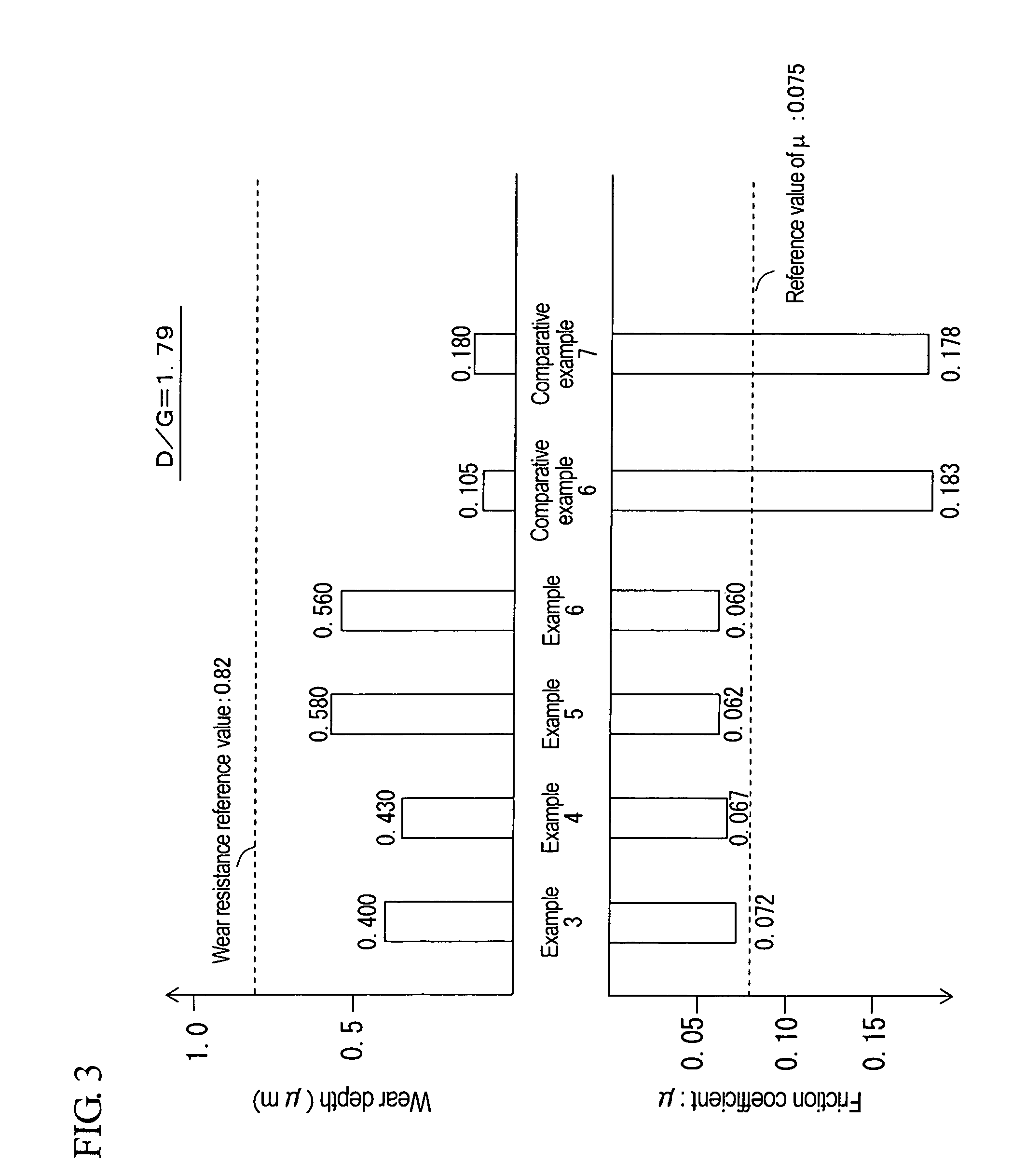

[0053] A block test piece and a ring test piece were provided as with the case of Example 2, and lubricating oils to be fed between them were also provided. Examples 3 to 6 were different from Example 2 in that the lubricating oils used in Examples 3 to 6 contained Mo-DTC in a manner such that the molybdenum contents in the lubricating oils became 400 ppm, 700 ppm, 800 ppm, and 900 ppm, respectively. Also, as with the case of Example 2, a frictional wear test was conducted so as to determine the friction coefficient and the wear volume in Examples 3 to 6. In addition, Example 4 was conducted under the same conditions as in Example 2. The results are shown in table 3 and FIG. 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com