Method of controlling landing strings in offshore operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

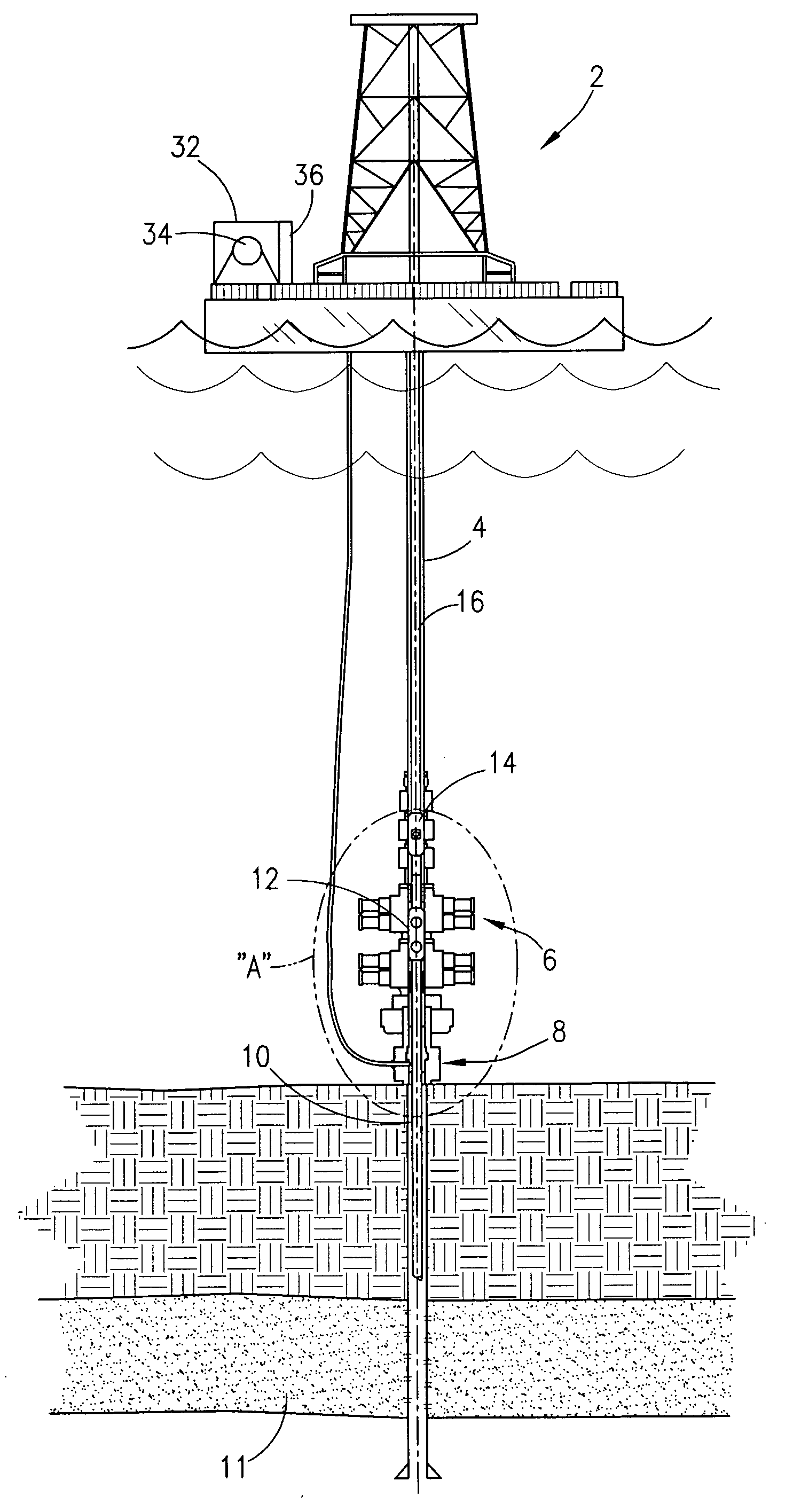

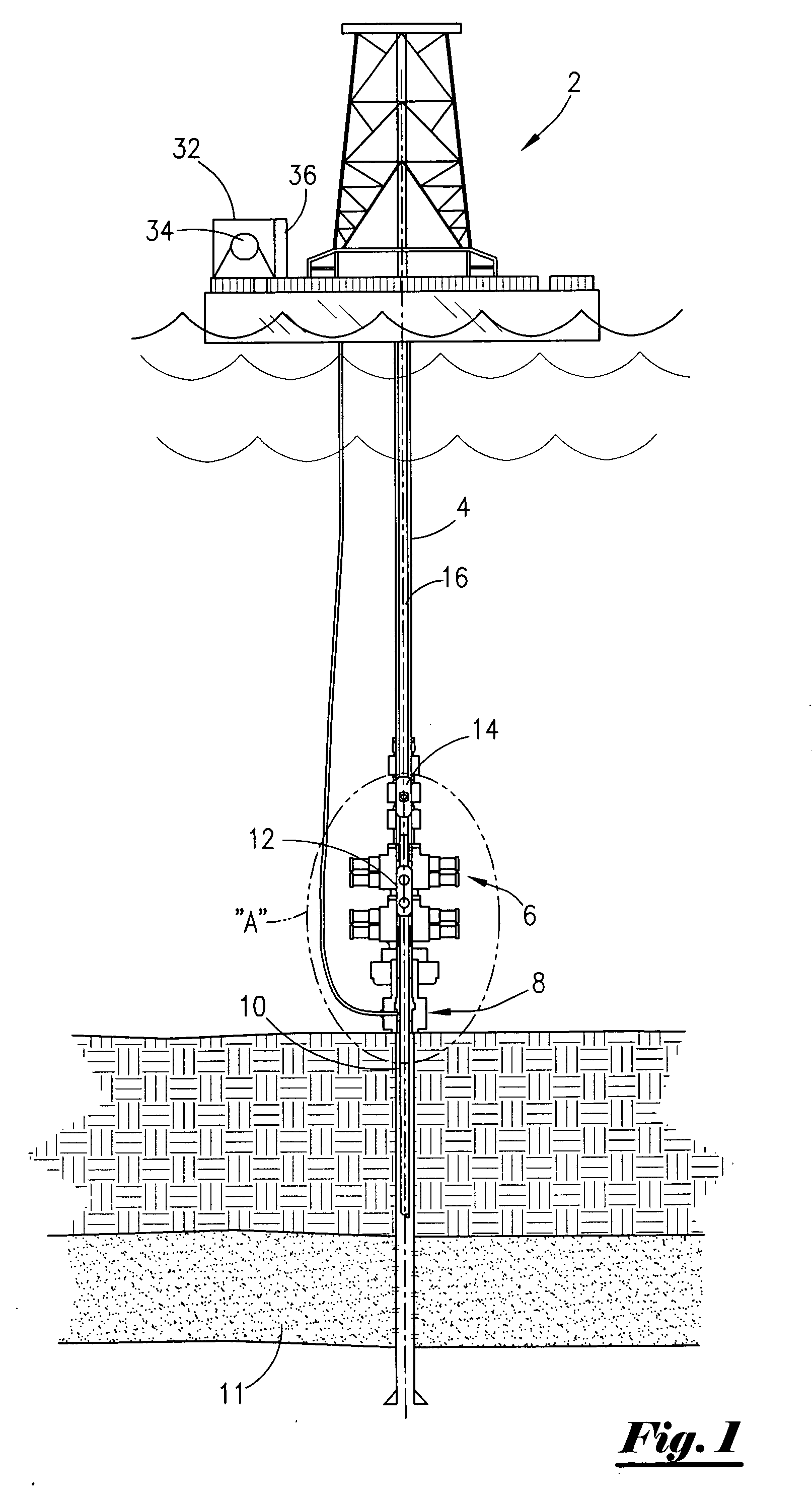

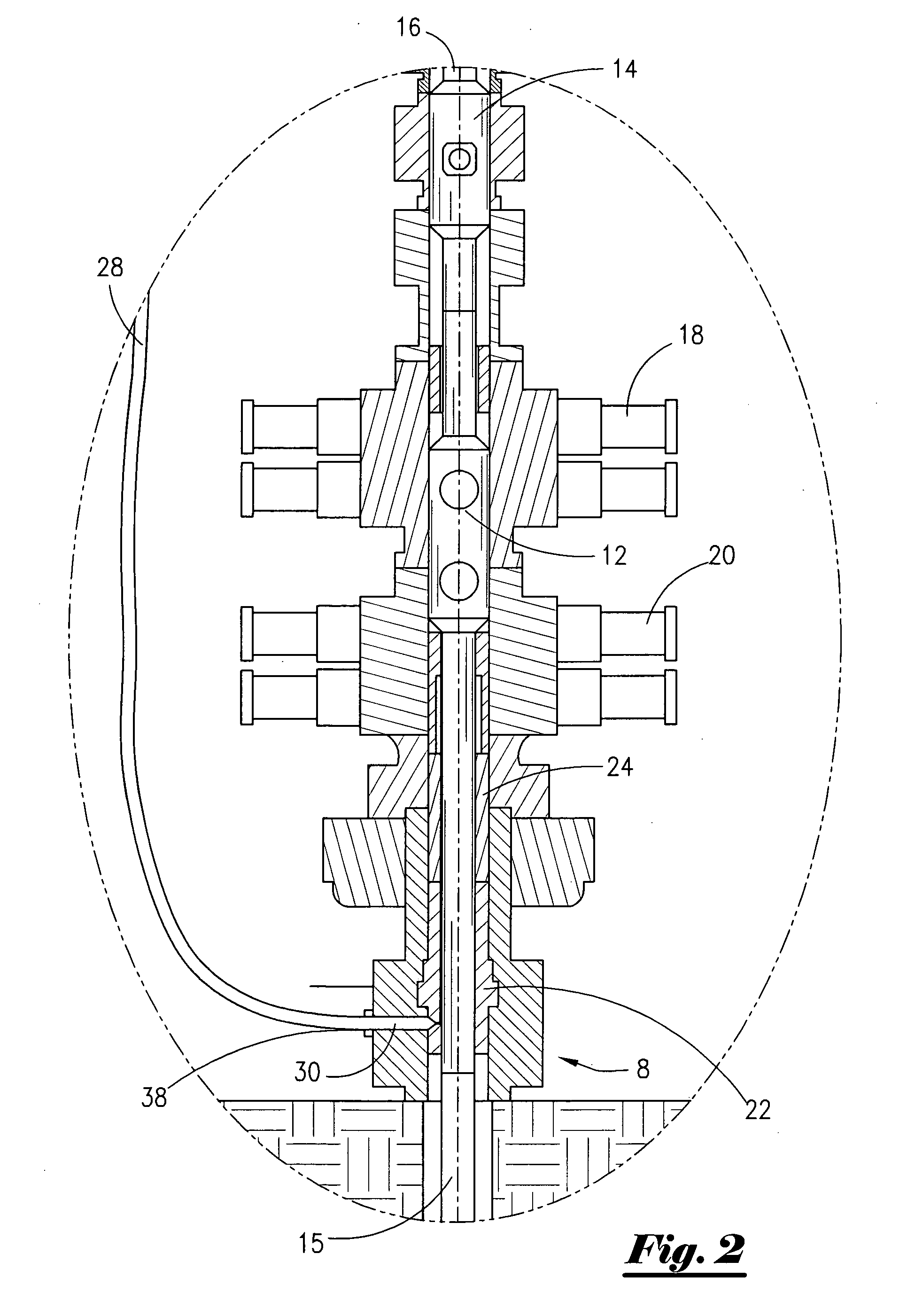

[0013]Referring now to FIG. 1, a well bore schematic of the preferred embodiment of the present system will now be described. As can be seen, a floating platform 2, such as a semi-submersible drilling vessel, is positioned over a well. It should be noted that the platform 2 may be an offshore floating platform, an anchored vessel, or even a jack-up type of platform. A marine riser 4 extends from the floating platform 2. The marine riser 4 is operatively connected to a subsea blow-out preventor system (BOP system), wherein the bop system is seen generally at 6. The BOP system 6 is made up of individual BOP components as will be more fully set later in the description. The BOP system 6 will be operatively connected to subsea production tree 8, and wherein the production tree 8 will in turn be operatively connected to the subterranean well 10. The subsea production tree 8 is adjacent the sea bed. As very well understood by those of ordinary skill in the art, the subterranean well 10 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com