Heavy oil reforming method, an apparatus therefor, and gas turbine power generation system

a technology of heavy oil and gas turbines, which is applied in the direction of machines/engines, bulk chemical production, supercritical condition processes, etc., can solve the problem of not being able to make all the hydrocarbons in a heavy oil applicable as fuel, and achieve the effects of preventing corrosion of plant equipment, accelerating reaction, and accelerating carbon chain cleavag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

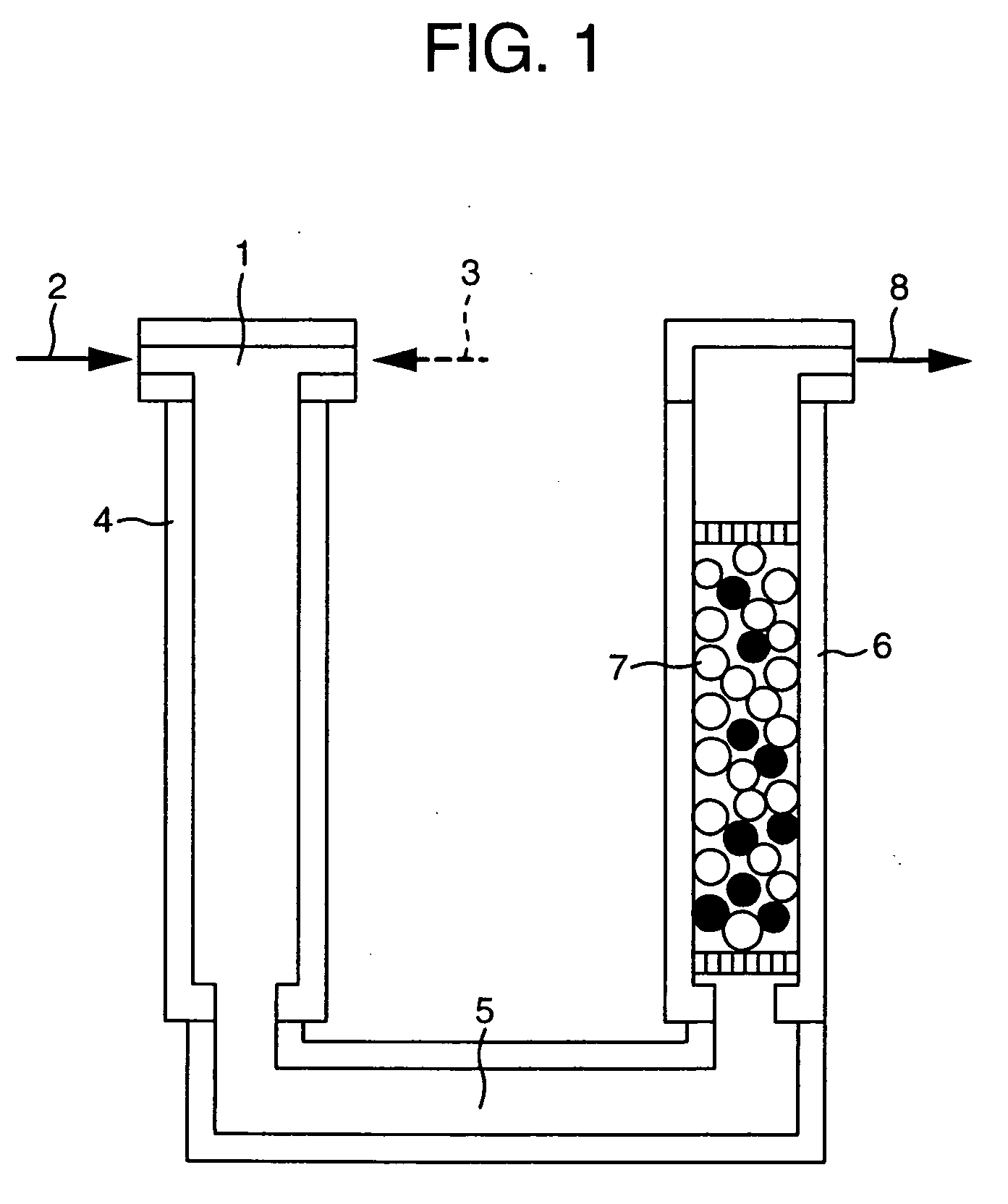

[0031]FIG. 1 is a schematic sectional view of the primary portion of the heavy oil reforming apparatus according to the present invention. At the inlet of the apparatus is provided a mixer 1 designed to receive and mix high-temperature and high-pressure water such as supercritical water 2 and a heavy oil 3. This water and heavy oil are mixed by the solvent action of the supercritical water in mixer 1, and the mixed liquid is led into a reactor 4. Mixing of supercritical water 2 and heavy oil 3 may be effected not only by simple joining of both fluids but can be also effected by forming a whirling flow or by making use of impingement of the counter flows of the two fluids for accelerating mixture.

[0032] Mixer 1 may not be provided, and super-critical water 2 and heavy oil 3 may be directly supplied into reactor 4. In reactor 4, there proceeds a reaction for eliminating from the hydrocarbon compounds the harmful components, i.e. sulfur and / or vanadium in the heavy oil under the actio...

example 2

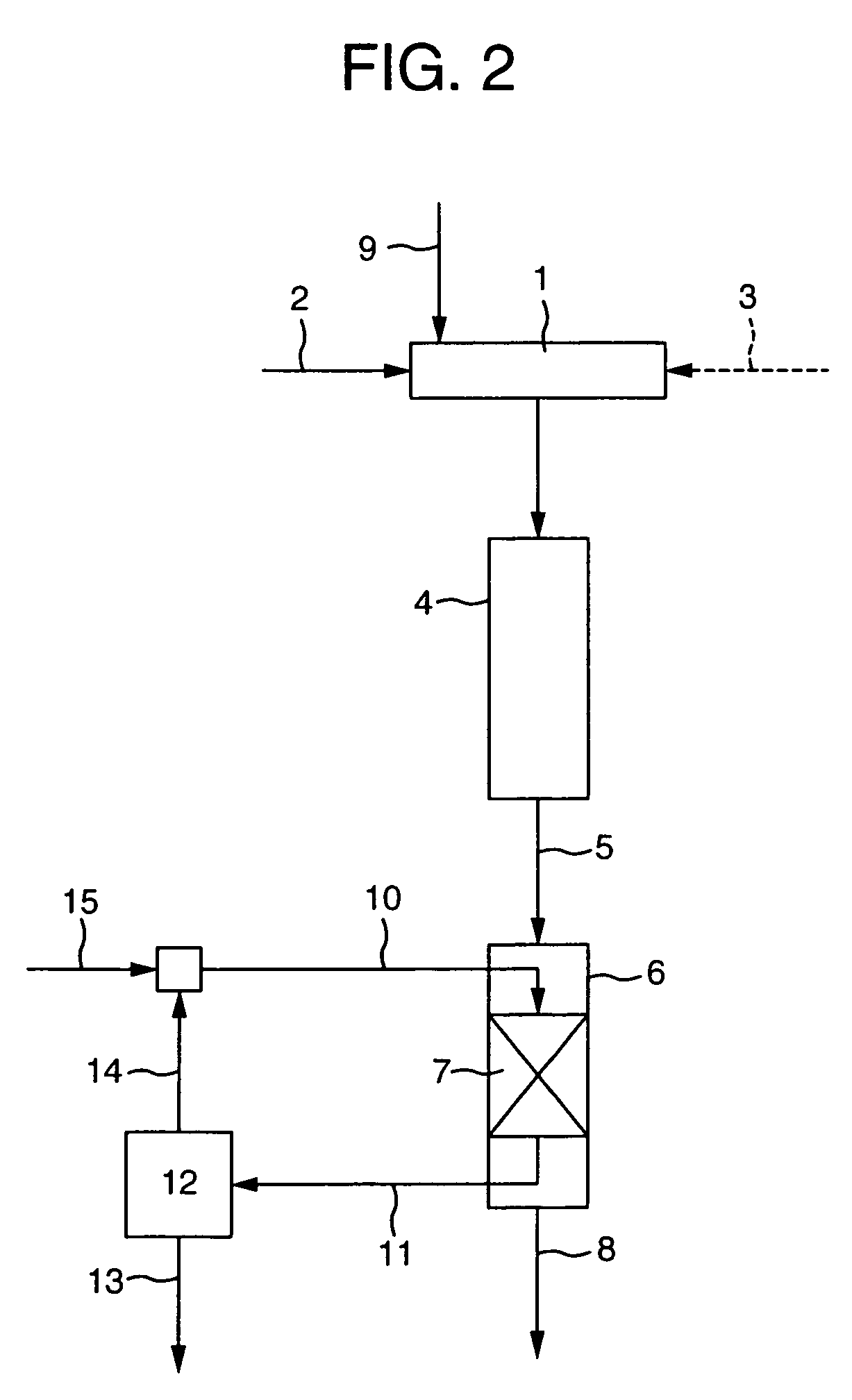

[0037]FIG. 2 is a block diagram showing the layout of the heavy oil reforming apparatus according to the present invention. In this example, a reaction assistant 9 which functions to accelerate the harmful component elimination reaction in reactor 4 is applied in addition to supercritical water 2 and heavy oil 3 in mixer 1. Reaction assistant 9 is a material selected from alkali metal or alkaline earth metal which acts to eliminate sulfur, a harmful component, in the form of a sulfate, hydrogen peroxide solution which accelerates the hydrolytic reaction, nitrate, formic acid and the like, or a mixture of such materials.

[0038] Addition of such a reaction assistant 9 is intended to elevate the harmful component elimination efficiency in reactor 4. As mentioned in Example 1, supercritical water 2, heavy oil 3 and reaction assistant 9 may be directly supplied to and mixed in reactor 4 without providing a mixer. Also, reaction assistant 9 may be either mixed in the system or may be prev...

example 3

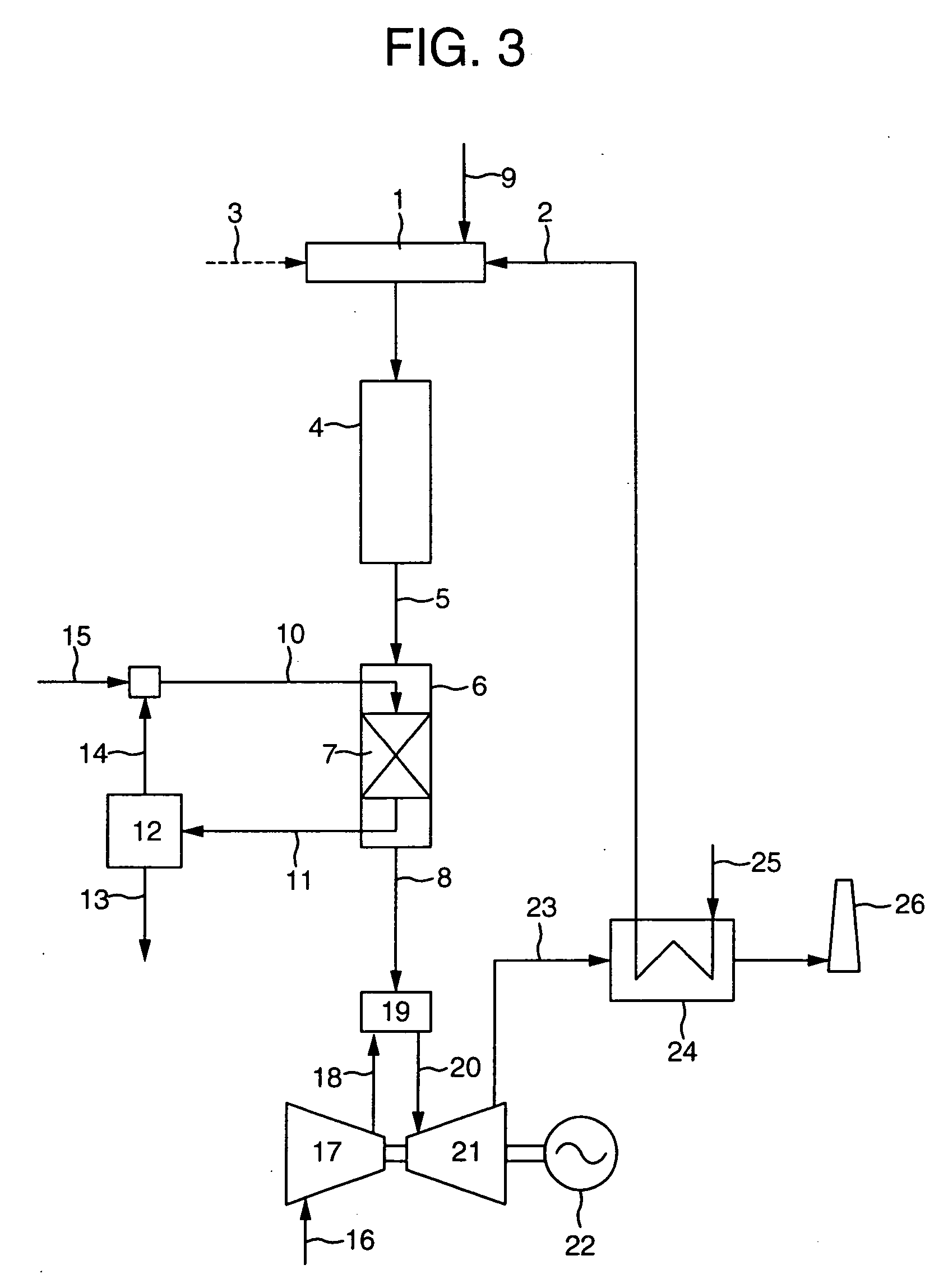

[0041]FIG. 3 is a block diagram showing an example of the gas turbine power generation system using the heavy oil reforming apparatus according to the present invention. In Examples 1 and 2, the reformed fuel 8 may be kept in storage or transported for use in a power plant, but in the instant example, the reformed fuel is immediately burned by a burner in the power generation system. Like in Example 2, a reaction accelerator 9 which accelerates the target substance elimination reaction in reactor 4 is mixed in addition to supercritical water 2 and heavy oil 3 in mixer 1.

[0042] Reaction accelerator 9 is a material selected from alkali metal or alkaline earth metal which eliminates sulfur, which is a substance to be removed, in the form of a sulfate, hydrogen peroxide solution which accelerates the hydrolytic reaction, and other materials such as nitrate and formic acid, or a mixture of such materials. The substances to be removed are eliminated from oil in reactor 4 and scavenged by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com