Device for testing axial loading/unloading gas permeability of coal

A gas permeability and testing device technology, applied in the testing field, can solve the problems of difficulty in testing coal seam permeability, high difficulty, low mechanical strength of tectonic coal, etc., and achieves the effects of wide practicability, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

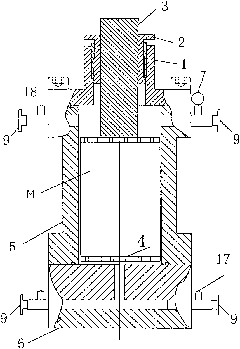

[0010] The following structural drawings further describe an embodiment of the present invention:

[0011] The coal axial loading and unloading gas permeability testing device of the present invention is mainly composed of a gas pressurizing device, a permeability testing device, an axial pressurizing unloading device, and a gas collecting device. Among them: the permeability test device is set in the axial pressurization and unloading device, and the gas pressurization device and the gas collection device are respectively connected with the permeability test device; the gas pressurization device consists of the gas cylinder 10, the gas cylinder pressure reducing valve 11 and the transmission The air pipe 12 is composed; the permeability test device is mainly composed of the pressure chamber 5 where the coal sample is set, the base 6 and the piston pressure device. The piston pressure device is composed of the pressure cover 1, the piston cavity 2 fixed on the pressure cover 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com