Engine oil control valve for end part oil supply

An oil control valve and oil supply technology, applied in the direction of controlling the pressure of lubricant, valve device, mechanical equipment, etc., can solve the problems of high requirements on mechanical strength of the filter screen and failure of the filter, so as to reduce the mechanical strength requirements and reduce the Small bending stress, the effect of meeting oil supply requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

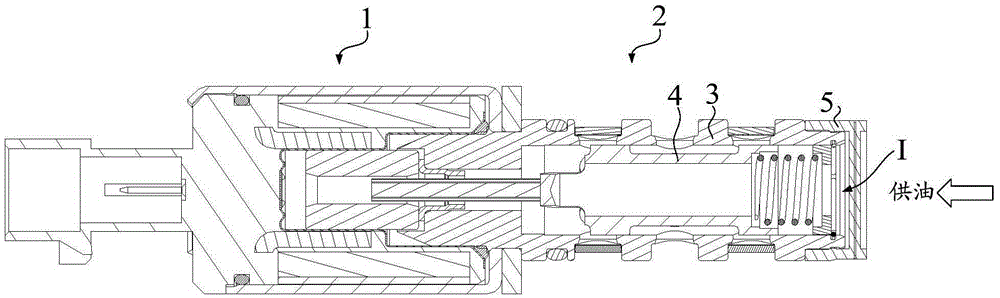

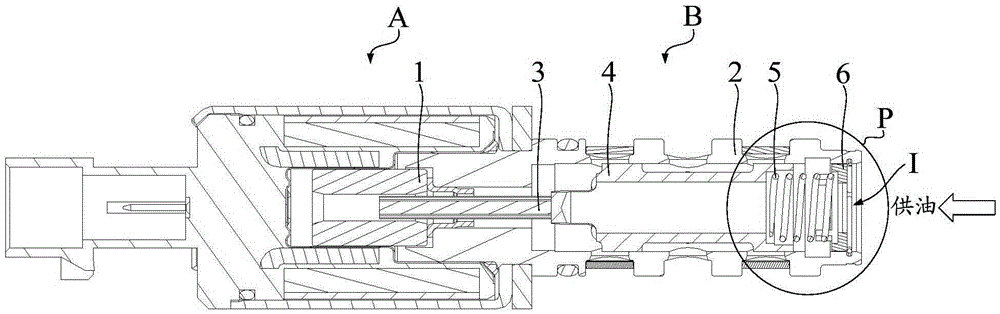

[0032] like image 3 As shown, the oil control valve of this embodiment includes two parts: a proportional solenoid A and a hydraulic body B. Among them, the proportional electromagnet A includes a movable armature 1 . The hydraulic body B includes a valve body 2, one axial end of the valve body 2 is fixedly connected with the proportional electromagnet A, and the other axial end has an oil inlet I. The valve body 2 is provided with a push rod 3 , a piston 4 , an elastic member 5 and a filter 6 arranged axially from the inside to the outside (that is, the direction from the proportional electromagnet A to the oil inlet I). One end of the push rod 3 is fixedly connected with the movable armature 1 , and the other end is fixedly connected with the piston 4 . The elastic member 5 is clamped between the piston 4 and the filter 6 in a compressed state. In this embodiment, the elastic member 5 is a coil spring. In the modification of this embodiment, the elastic member 5 can also ...

no. 2 example

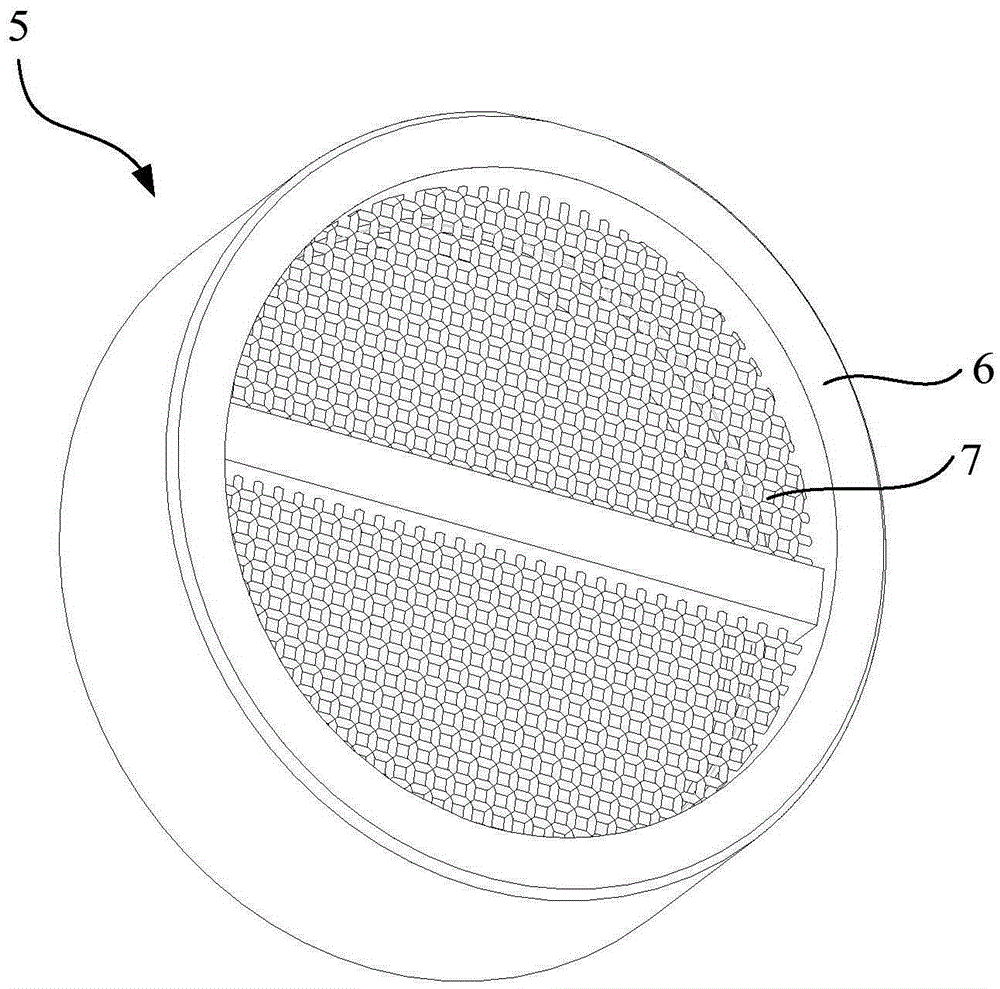

[0046] The difference between the second embodiment and the first embodiment is that in the second embodiment, the combination Figure 8 to Figure 9 As shown, there is no guide foot provided on the annular body portion 60 , and all the oil passages 64 do not pass through the annular body portion 60 in the axial direction B pointing to the piston 4 , that is, the oil passages 64 are in a closed ring shape. like Figure 9 As shown, when the annular body portion 60 moves to the point where the axially outer end of the annular body portion 60 is separated from the inner wall of the valve body 2 and is arranged radially opposite to the opening 22, the opening 22 and the inlet of the oil passage 64 are radially Overlapping, the hydraulic oil flowing in from oil inlet I follows Figure 6 The direction indicated by the dashed arrow in the middle flows through the groove 21 and the oil channel 64 on the annular main body 60 to the space in the valve body 2 axially inside the filter sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com