Cyclic air-exhausting method for obtaining high-purity terahertz working substance and optical maser

A working substance, terahertz technology, applied in the terahertz field, can solve the problems of increasing the difficulty and cost of the lens process, increasing the attenuation of pump light and signal light, etc., and achieve the effects of reducing mechanical strength requirements, optimizing purity, and high-efficiency purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

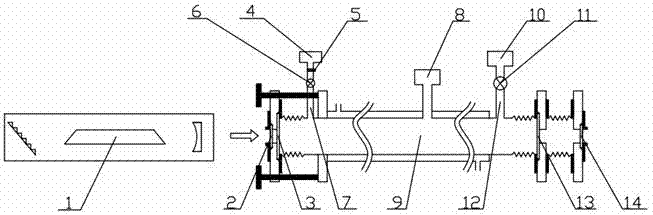

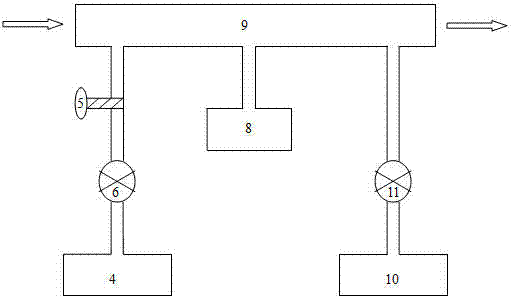

[0044]Embodiment 1, a laser for obtaining a high-purity terahertz working substance by cyclic pumping, including a pump source 1, a terahertz sealed cavity 9, an input mirror 3, and an output mirror 13; the terahertz sealed cavity 9 and the input mirror 3, the output The mirror 13 constitutes a laser resonant cavity; the front end of the terahertz sealed cavity is provided with an input window 2, and the rear end is provided with an output window 14; the side of the terahertz sealed cavity is provided with a working substance input terminal 7, a capacitance film vacuum gauge 8, and a vacuum pump connection port 12; a vacuum pump 10 The vacuum pump connection port 12 is connected to the terahertz sealed cavity, and the vacuum pump manual valve 11 is set at the connection; the working substance container 4 is connected to the terahertz sealed cavity 9 through the working substance input port 7, and the working substance manual valve 6 and high vacuum micrometer are set at the conn...

Embodiment 2

[0053] Embodiment 2 is basically the same as Embodiment 1, except that the output mirror 13 as the output coupling end of the terahertz laser is a quartz gold-plated or silver-plated mirror, and there is an uncoated part for coupling output in the middle, with a diameter of 11 mm and an edge opening of 3 mm. A vent hole with a diameter of 3mm, this solution is more convenient for the adjustment of the laser.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com