Six-dimensional force and torque sensor for measuring large force and small torque of large mechanical arm

A torque sensor and large-scale machinery technology, applied in the direction of measuring force components, measuring devices, instruments, etc., can solve the problems of sensor measurement range asymmetry, reduce sensor stiffness, reduce resolution, etc., achieve small coupling error, small size, The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

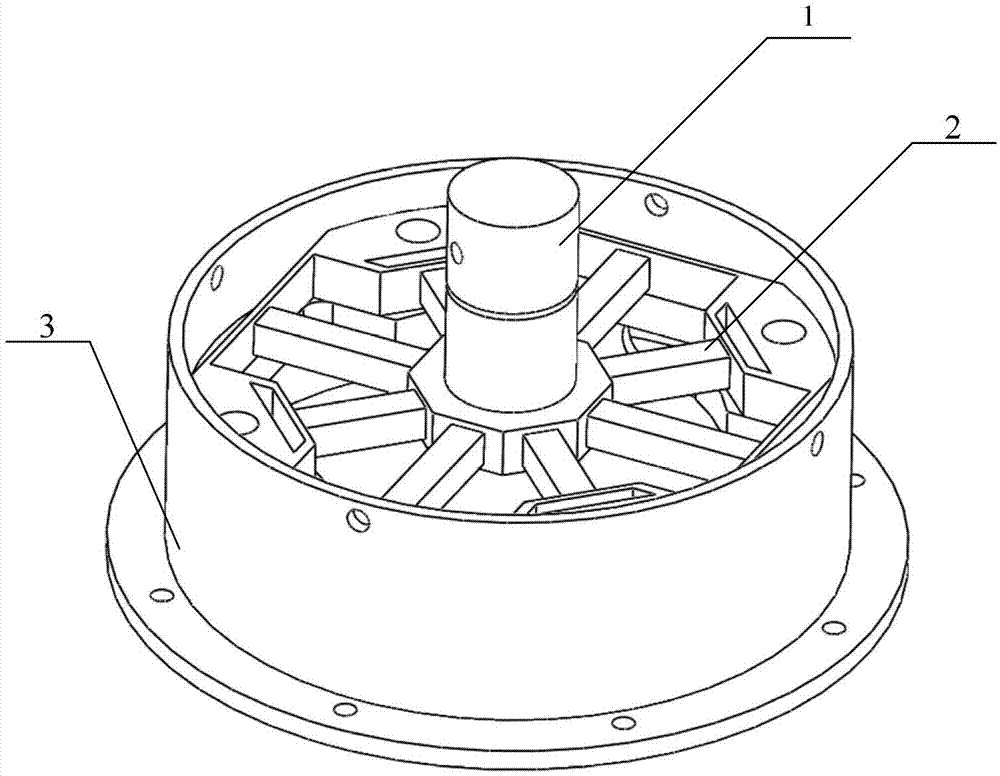

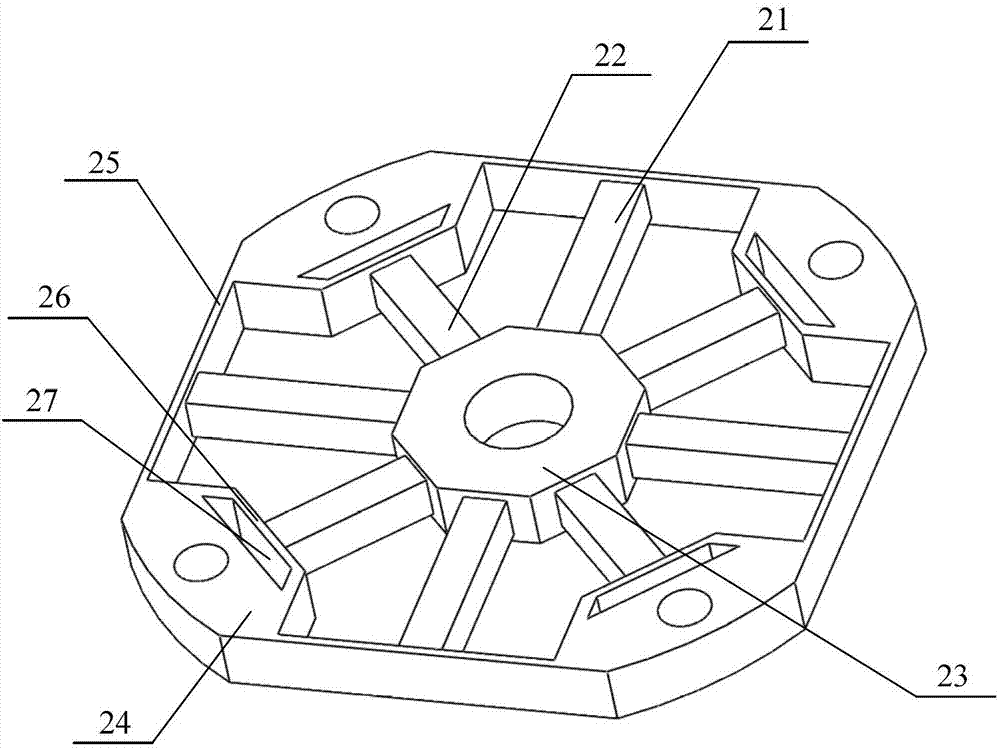

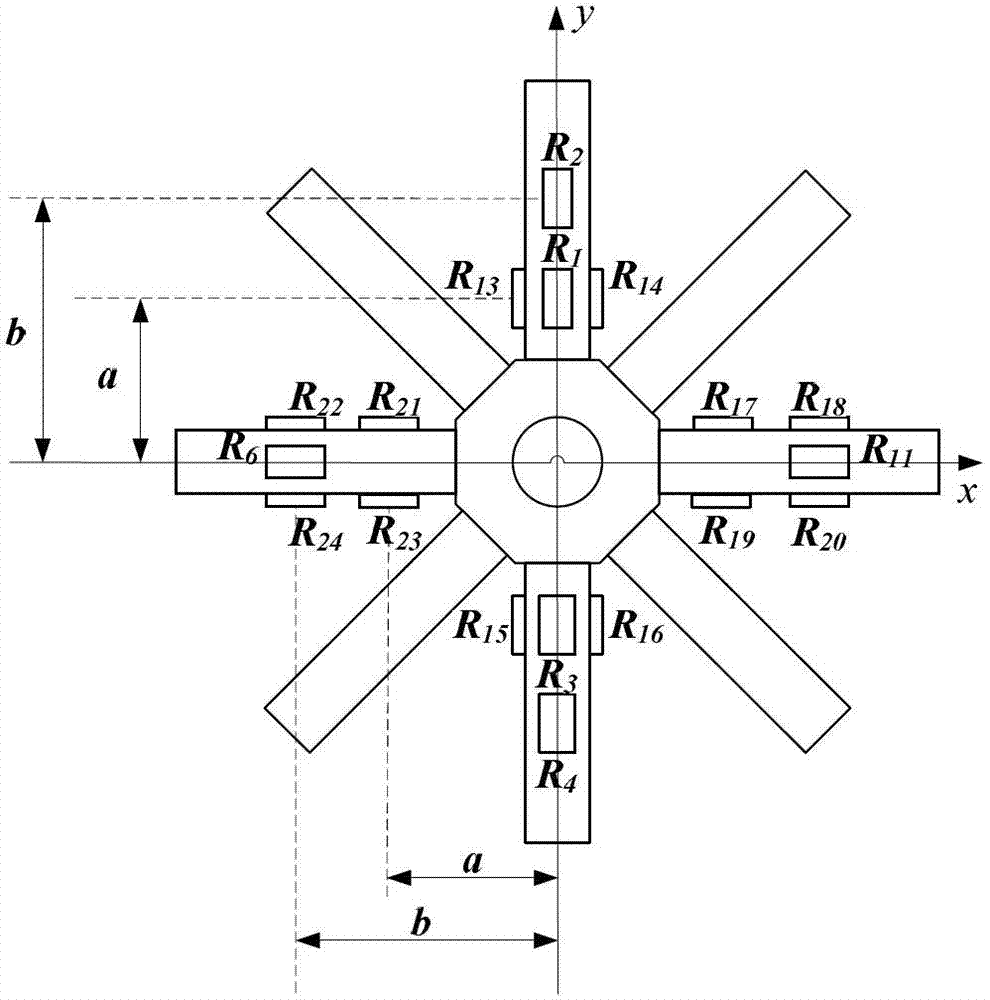

[0041] Such as Figure 1 to Figure 4 As shown, a six-dimensional force and moment sensor for measuring large forces and small moments of a large mechanical arm according to the present invention includes a central axis 1, a force sensitive element 2, a base 3 and a strain gauge assembly. The force sensitive element 2 is fixedly connected to the base 3 , the central axis 1 passes through the force sensitive element 2 and the base 3 , and the central axis 1 is in interference fit with the force sensitive element 2 , and the strain gauge assembly is attached to the force sensitive element 2 . Through the rotation of the central shaft 1, the rotation of the entire sensor is driven to realize the measurement of force and moment. The force-sensitive element 2 includes four elastic main beams 21 , four elastic sub-beams 22 , a regular octagonal ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com