Method for operating optical sensors

a technology of optical sensors and optical sensors, applied in the direction of instruments, using electrical/magnetic means, geological measurements, etc., can solve the problems of cumbersome, correspondingly expensive, and inability to constant measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

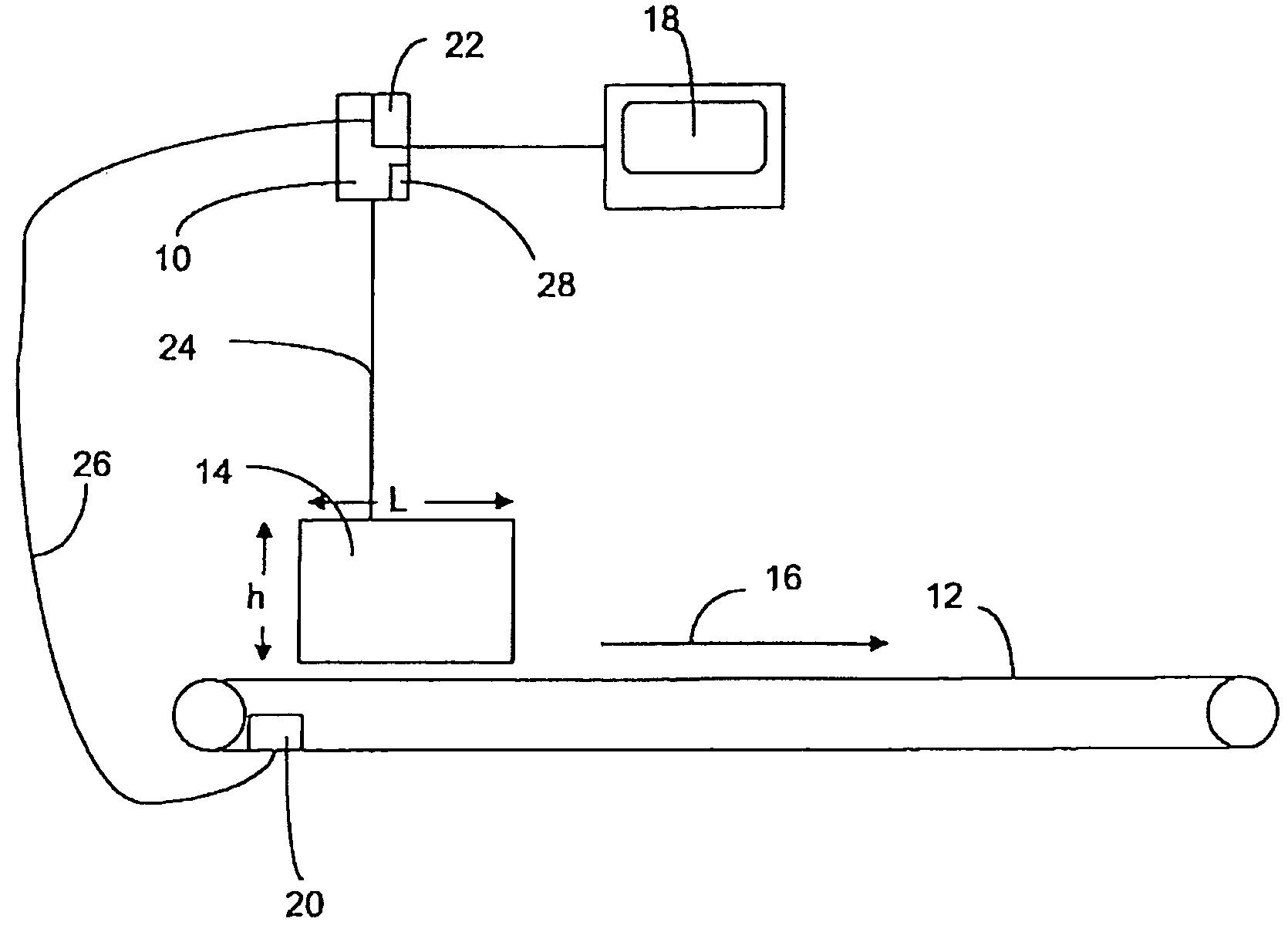

[0025]An optoelectronic sensor 10 according to the invention is arranged above a conveyor 12, on which goods such as packages 14 are being transported in any desired direction 16. The packages 14 are automatically measured by the sensor 10 during their transport to determine their volume. The measurement results can be indicated on a display unit 18 and / or they can be fed to a suitable signal output for further processing.

[0026]The optoelectronic sensor 10 can be a laser scanner, such as is marketed by the assignee of this invention, SICK AG of Germany, under the designation LMS 200, which scans the package 14 in familiar manner with a laser beam 24. The volume can ultimately be determined from the angle and distance information of the reflected laser beam.

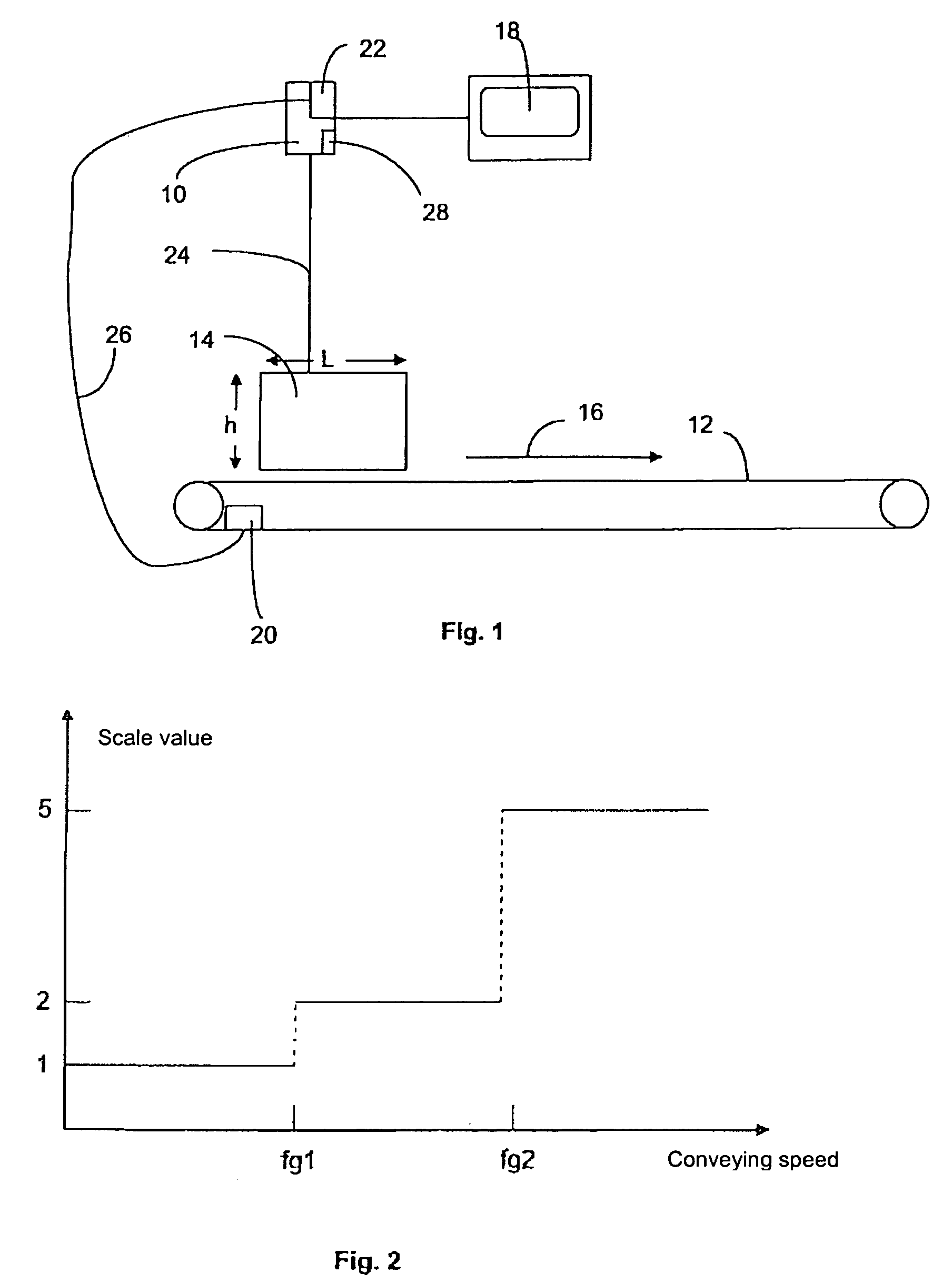

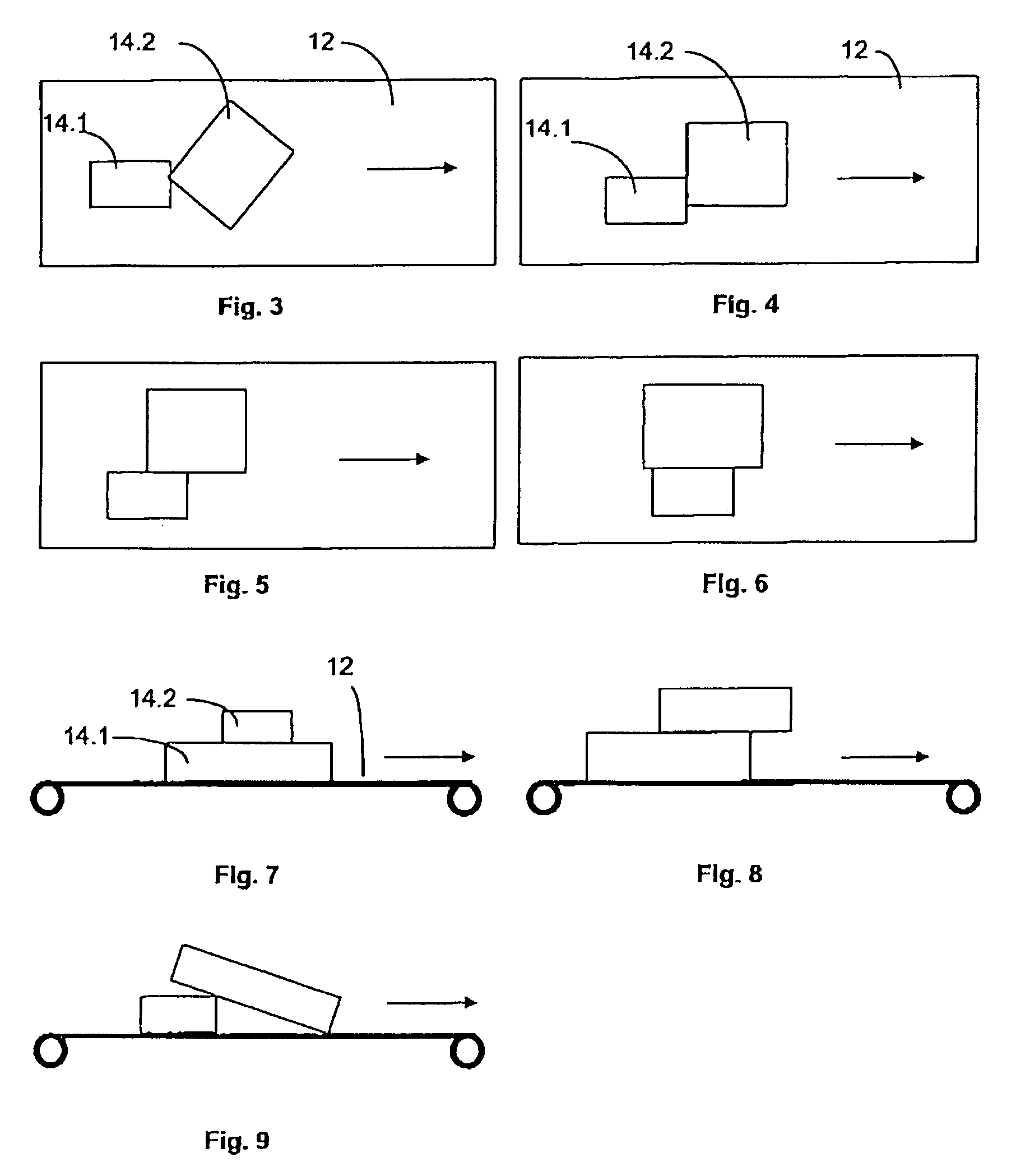

[0027]When determining the volume of a square-shaped package 14, it is necessary to determine its height h, width and length L. The accuracy of the length measurement in the transport direction 16 is, as mentioned above, dependent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| physical quantity | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com