Industrial robot measurement method based on tail end numbered tool

An industrial robot and measurement method technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of narrow positioning and tracking field of view, low cost, expanding the fixed binocular vision measurement range, etc., to achieve low cost and improve positioning accuracy. , to solve the effect of narrow field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

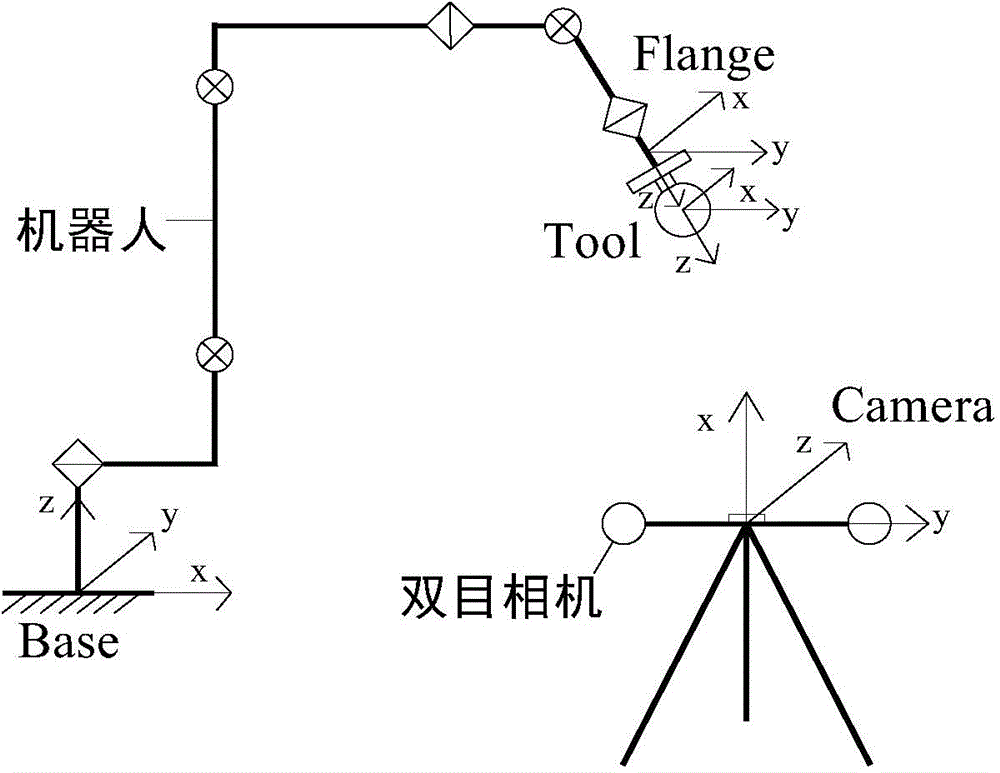

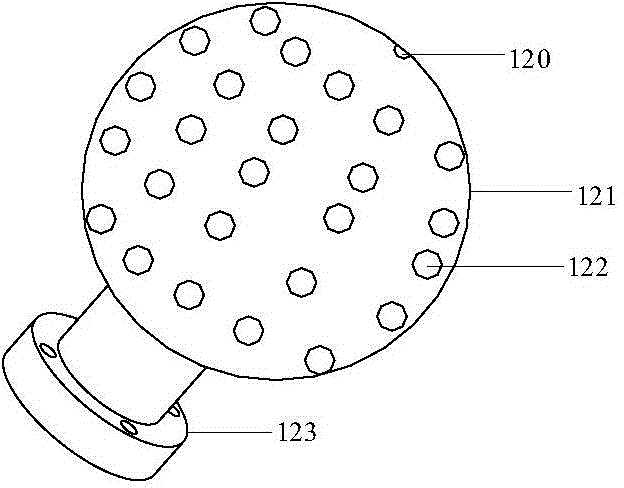

[0028] Attached below figure 1 , 2 , 3 and 4 describe in detail the specific embodiments of the present invention. The examples applied here are not only applicable to this example, but are applicable to different application fields of various tandem industrial robots.

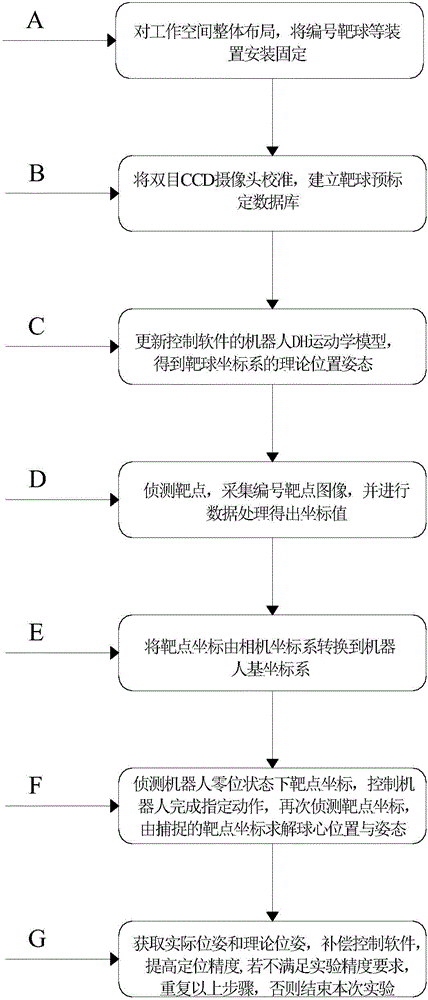

[0029] Refer to figure 1 , The industrial robot measuring method based on the end-numbered target ball of the present invention includes the following steps:

[0030] A. For the overall layout of the work space, install and fix the numbered target ball and other devices;

[0031] Try to choose a working environment with low vibration intensity and low environmental pollution. According to the working space of the industrial robot body and the motion trajectory of the end of the robot, reasonably plan the measurement layout and measurement network to ensure measurement accuracy. The binocular CCD camera and the light source generator Fix it within its measuring range and connect cables, capture cards and other device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com