Integrated measuring method for operating parameters of general centrifugal pump

A technology of operating parameters and measurement methods, applied in pump control, non-variable-capacity pumps, machines/engines, etc., can solve problems such as inadequate maintenance, blind ignorance, and increased costs, and achieve high accuracy, easy collection, and equipment. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

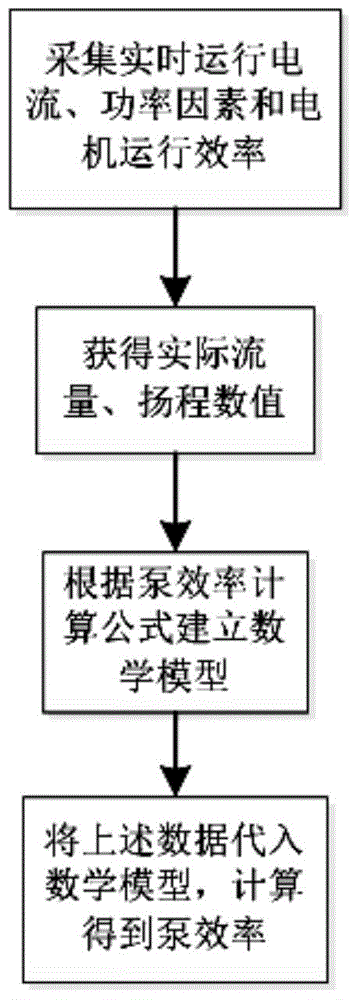

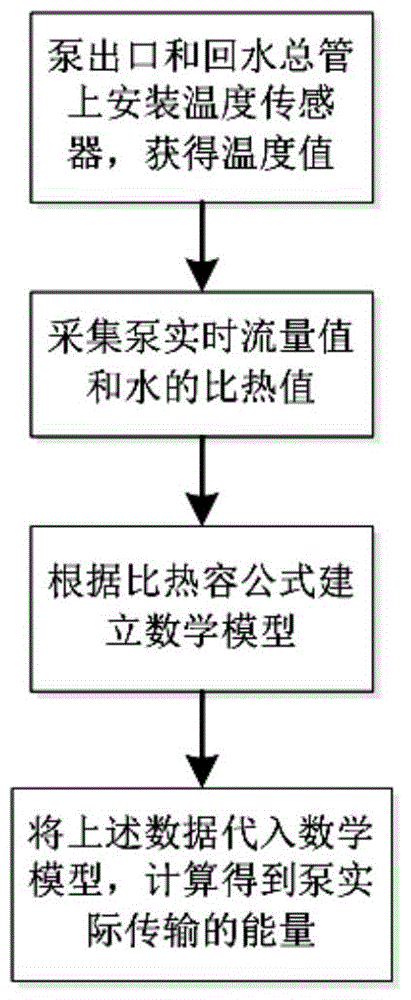

[0049] An integrated measurement method for the operating parameters of a general centrifugal pump, specifically including the measurement of: pump flow, pump operating efficiency, and heat removed by the pump.

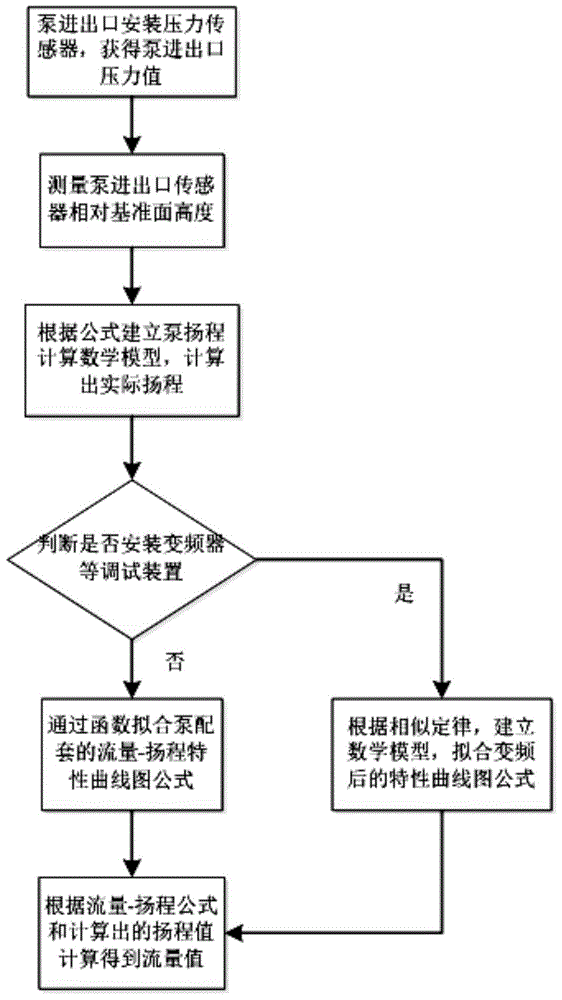

[0050] Such as figure 1 As shown, the measurement of the flow rate of the pump specifically includes the following steps:

[0051] Step A: Install pressure transmitters in the middle of the inlet and outlet straight pipe sections of the pump respectively. The installation positions are the inlet pressure measuring point and the outlet pressure measuring point. Use the pressure transmitter to collect the inlet pressure p when the pump is running. 1 and outlet pressure p 2 ;

[0052] Step B: Measure the height z of the pump inlet pressure measuring point relative to the reference plane 1and the height z of the outlet pressure measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com