Wave velocity and thickness calibrating method for ultrasonic wave welding spot detection

A solder joint inspection and calibration method technology, applied in the direction of using ultrasonic/sonic/infrasonic, material analysis using sonic/ultrasonic/infrasonic, measurement of ultrasonic/sonic/infrasonic, etc., can solve the problem of increased production cost, low efficiency and waste of manpower and other problems, to achieve the effect of improving measurement accuracy, reliable measurement data, and reducing measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

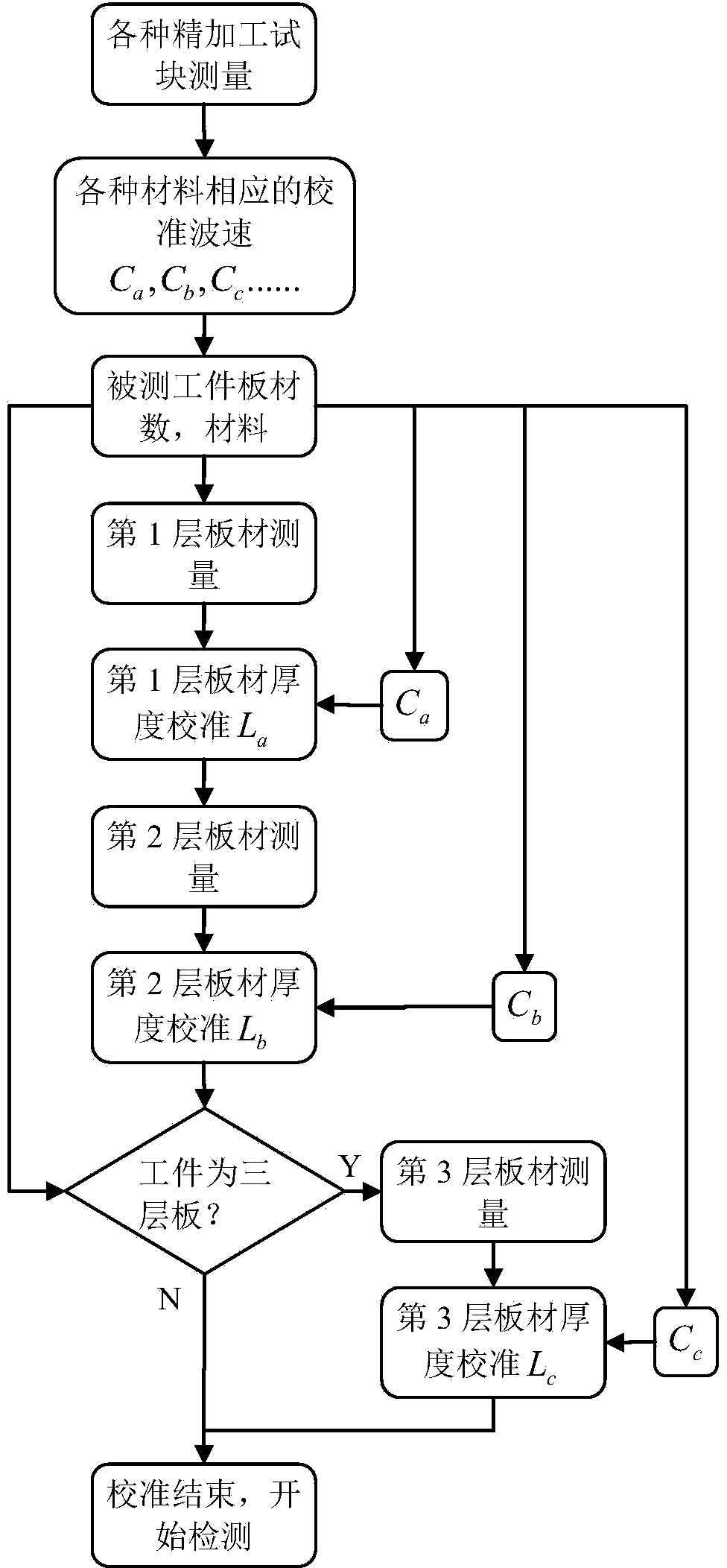

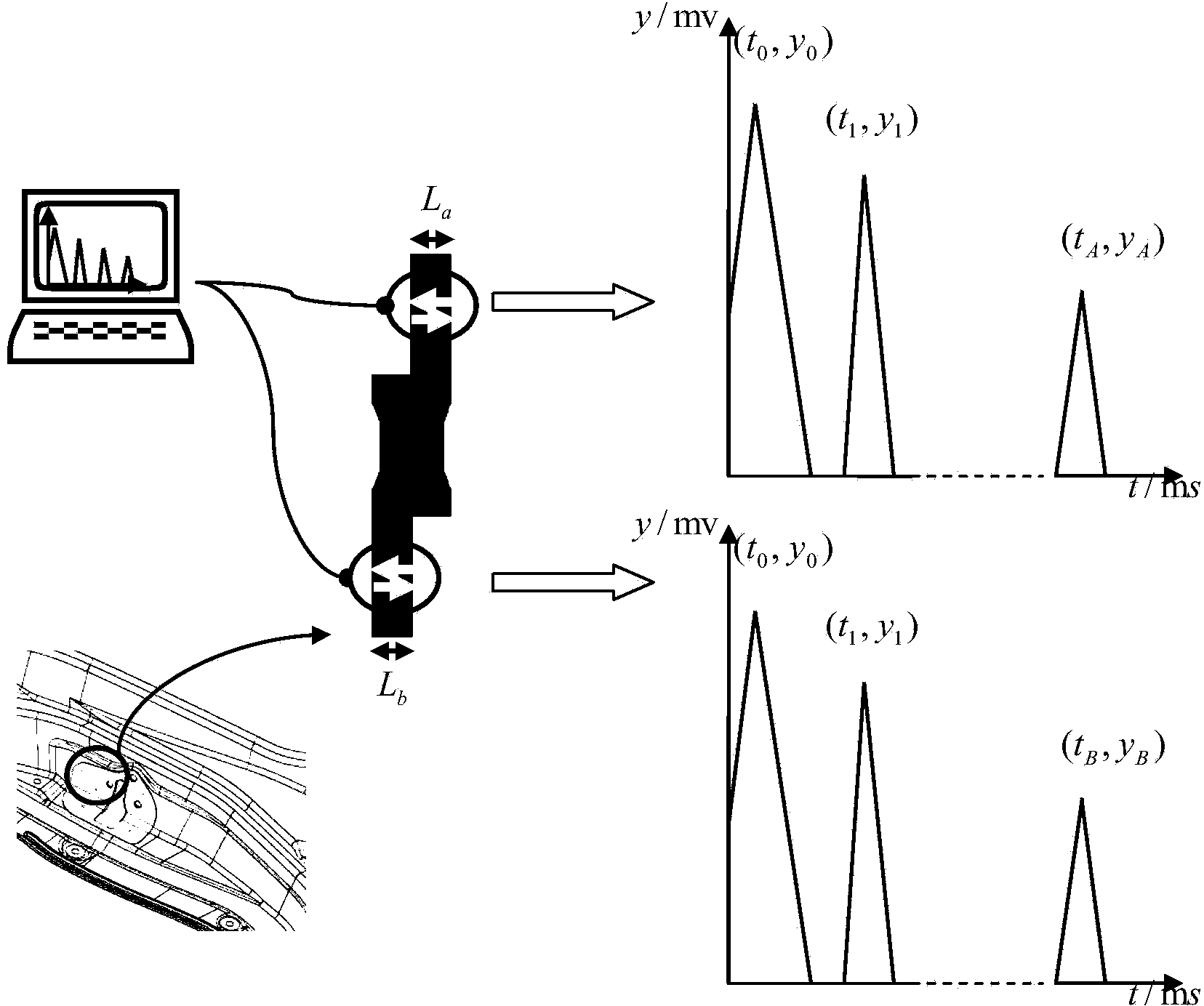

[0039] The following will be combined with Figure 1-3 Specific embodiments of the present invention will be described in detail.

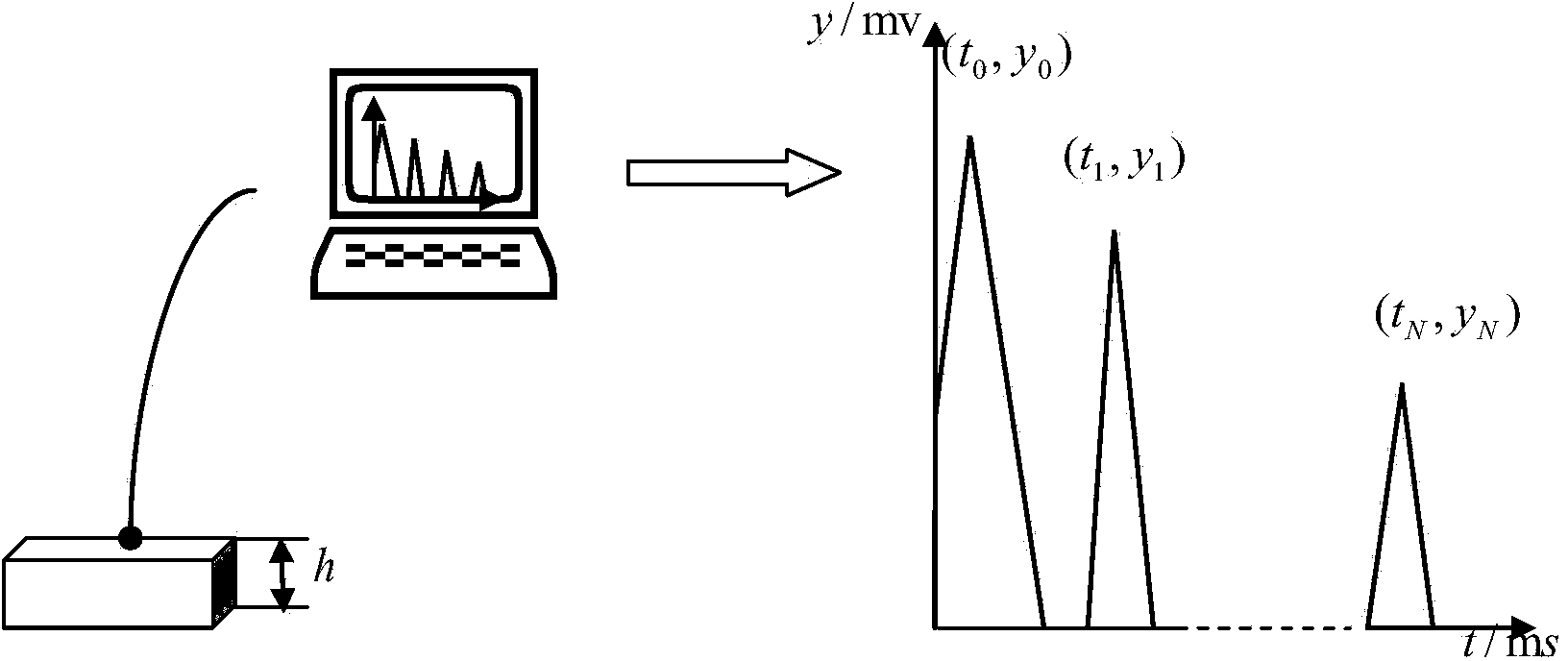

[0040] The method for calibrating the wave velocity and the thickness of the workpiece plate for ultrasonic solder joint detection according to the present invention first uses the finished test block to calibrate the wave velocity of different materials, and then uses ultrasonic equipment to measure several plates of the solder joint respectively, combined with the corresponding wave velocity , to calibrate the plate thickness. Such as figure 1 As shown, the specific flow of the calibration method of the present invention is as follows:

[0041] Step 1: Use the ultrasonic signal to measure the test block of the body-in-white material, and calculate the corrected wave velocity of the corresponding test block according to the measurement results;

[0042] In this step, the test blocks of the most commonly used materials for the body-in-white are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com