Computer simulation pre-assembly method of construction steel structure

A technology of computer simulation and steel structure parts, which is applied in calculation, 3D modeling, image data processing, etc., can solve the problems of large work difficulty, large measurement deviation of multi-angle component connections, and low measurement accuracy, so as to improve scientific and technological productivity, Strategically significant and measured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with embodiment.

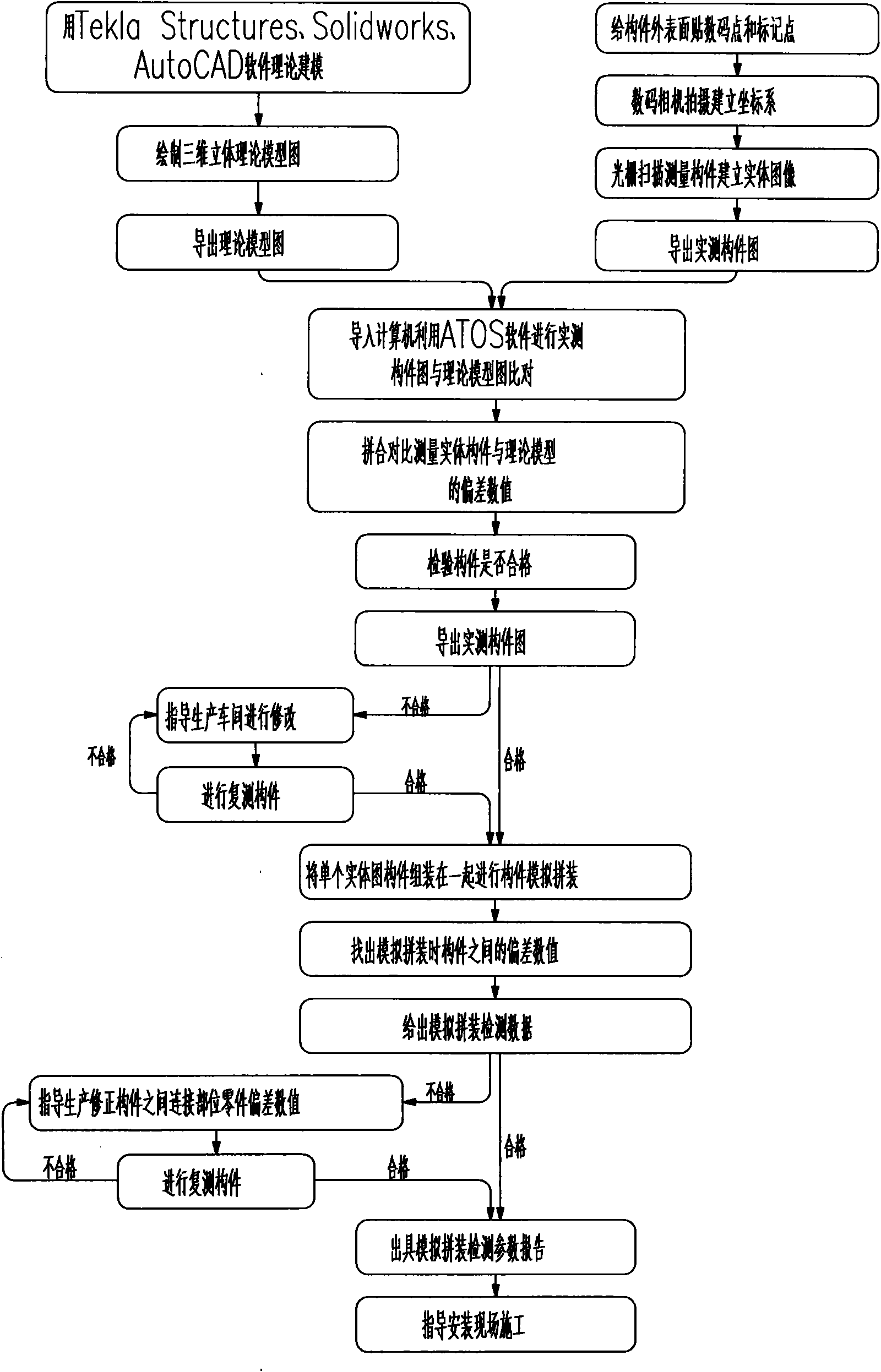

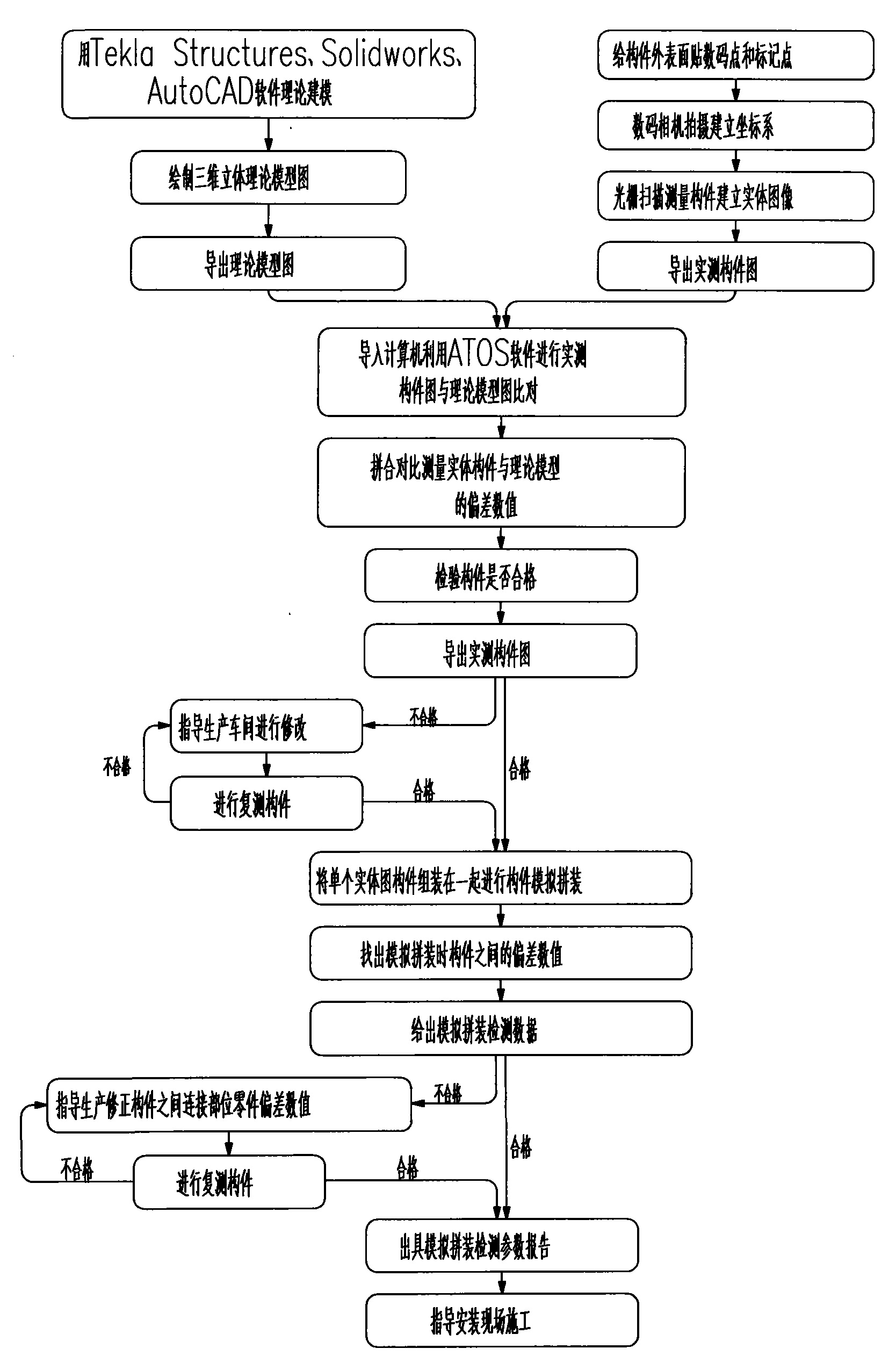

[0026] see figure 1 , this embodiment is illustrated by taking the T1 project of No. 1 Shimao Bay, Yantai, Shandong as an example. The construction area of the project is 95,000 m 2 , with a building height of 323m, 3 floors underground and 62 floors above ground. The steel frame of the building structure is a concrete cylinder hybrid structure, and the building shape is a hexagonal structure. The steel structure of the building is about 13,500 tons.

[0027] Next, through the pre-assembly detection process of steel pillars and steel beams, the computer simulation simulation pre-assembly method of building steel structure parts according to the present invention is described, and the steps are as follows:

[0028] 1. Use Tekla Structures software to draw the theoretical three-dimensional diagram of engineering design and building steel structure.

[0029] 2. After the actual compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com