Multi-channel galvanic corrosion measurement device

A technology for galvanic corrosion and measuring devices, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as control methods, signal conditioning, noise interference, etc., to improve current drive capability, suppress power supply interference, Effect of Improving Linear Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

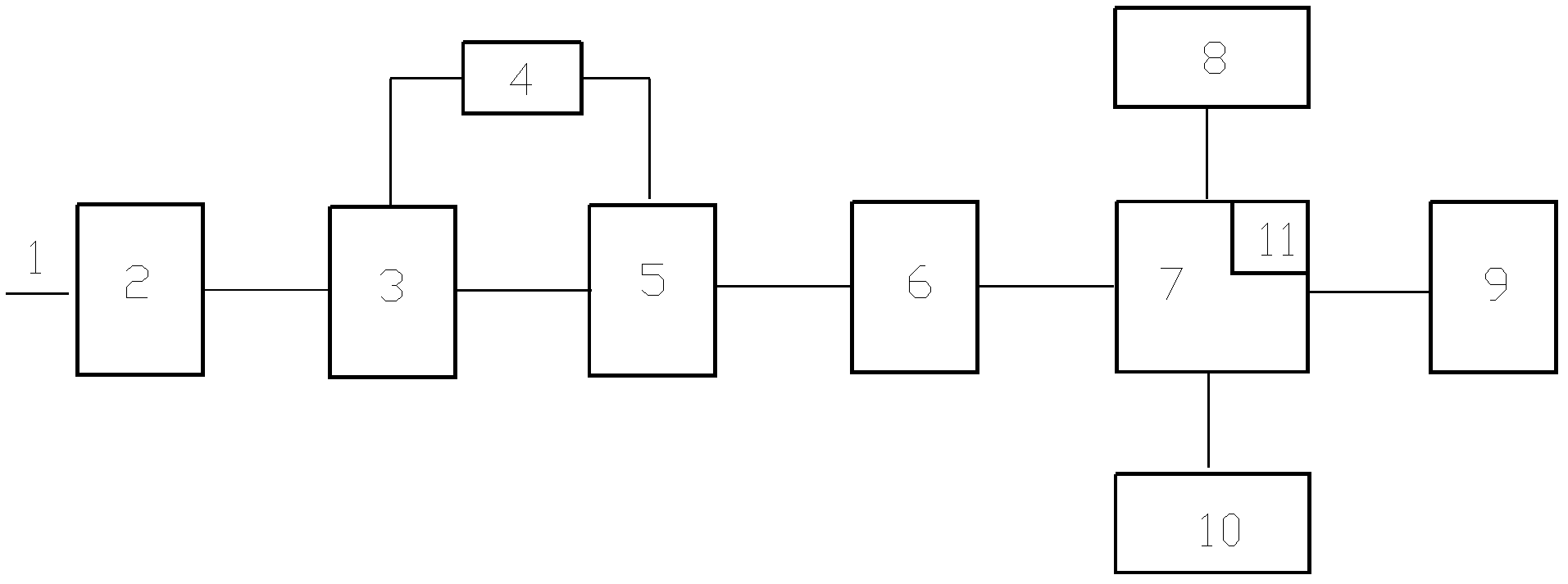

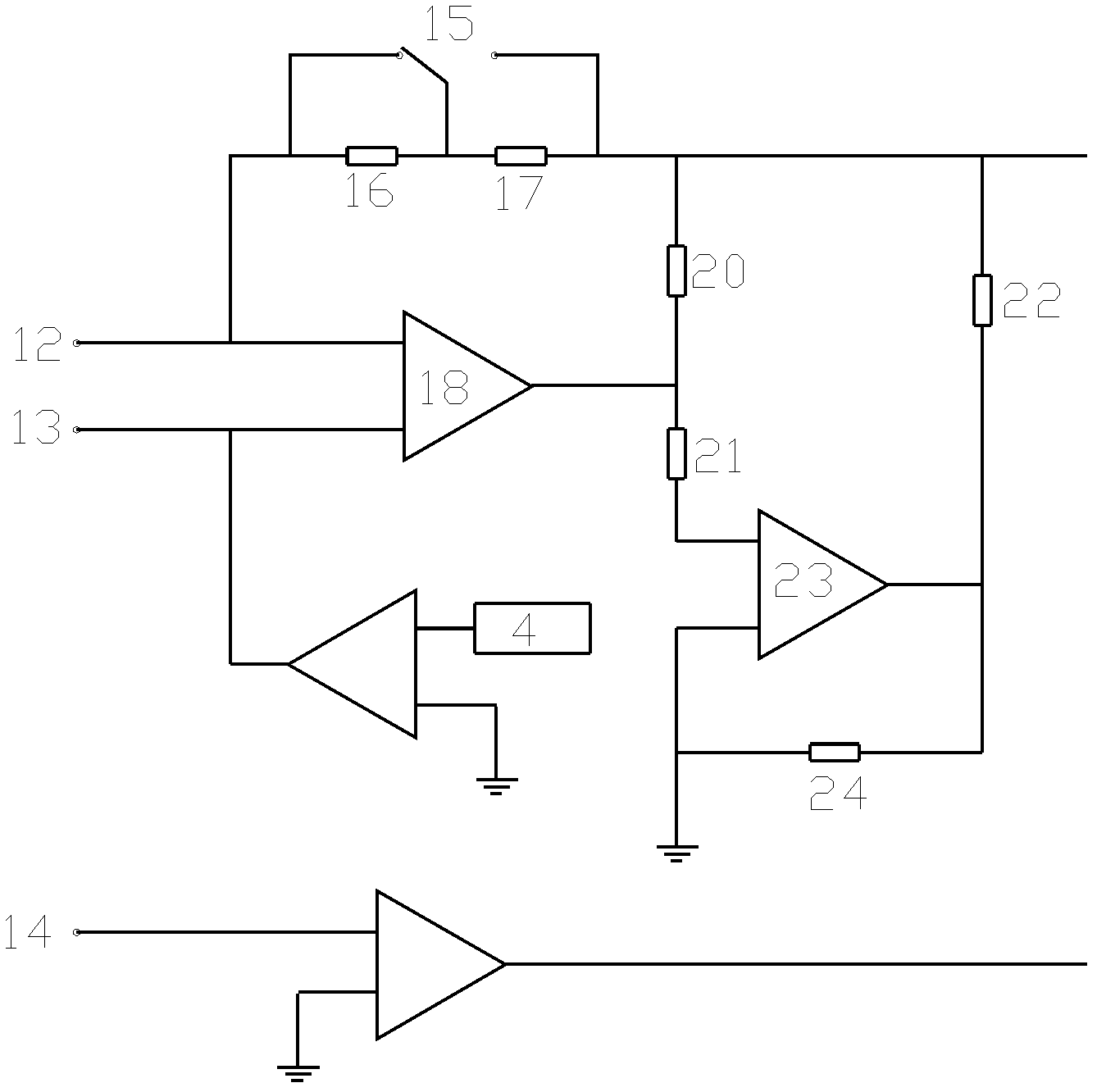

[0011] This embodiment adopts the SOC processor structure design, including electrode connection cable 1, voltage and current measurement switching unit 2, front-end signal conditioning circuit 3, A / D conversion circuit 5, reference source 4, multi-channel electrical isolation unit 6, and main control module 7. Display module 8, storage module 9, communication module 10 and SOC processor 11, wherein front-end signal conditioning circuit 3 includes working electrode input 12, auxiliary electrode input 13, reference electrode input 14, double throw relay 15, first Resistor 16, second resistor 17, first operational amplifier 18, reference source 4, first balancing resistor 20, second balancing resistor 21, third balancing resistor 22, second operational amplifier 23 and fourth balancing resistor 24; electrode connection The front end of the cable 1 is connected to the electrode, and the rear end is connected to the voltage and current measurement switching unit 2. After the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com