Patents

Literature

35results about How to "Improve current measurement accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

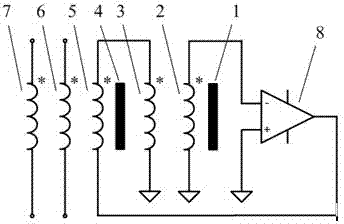

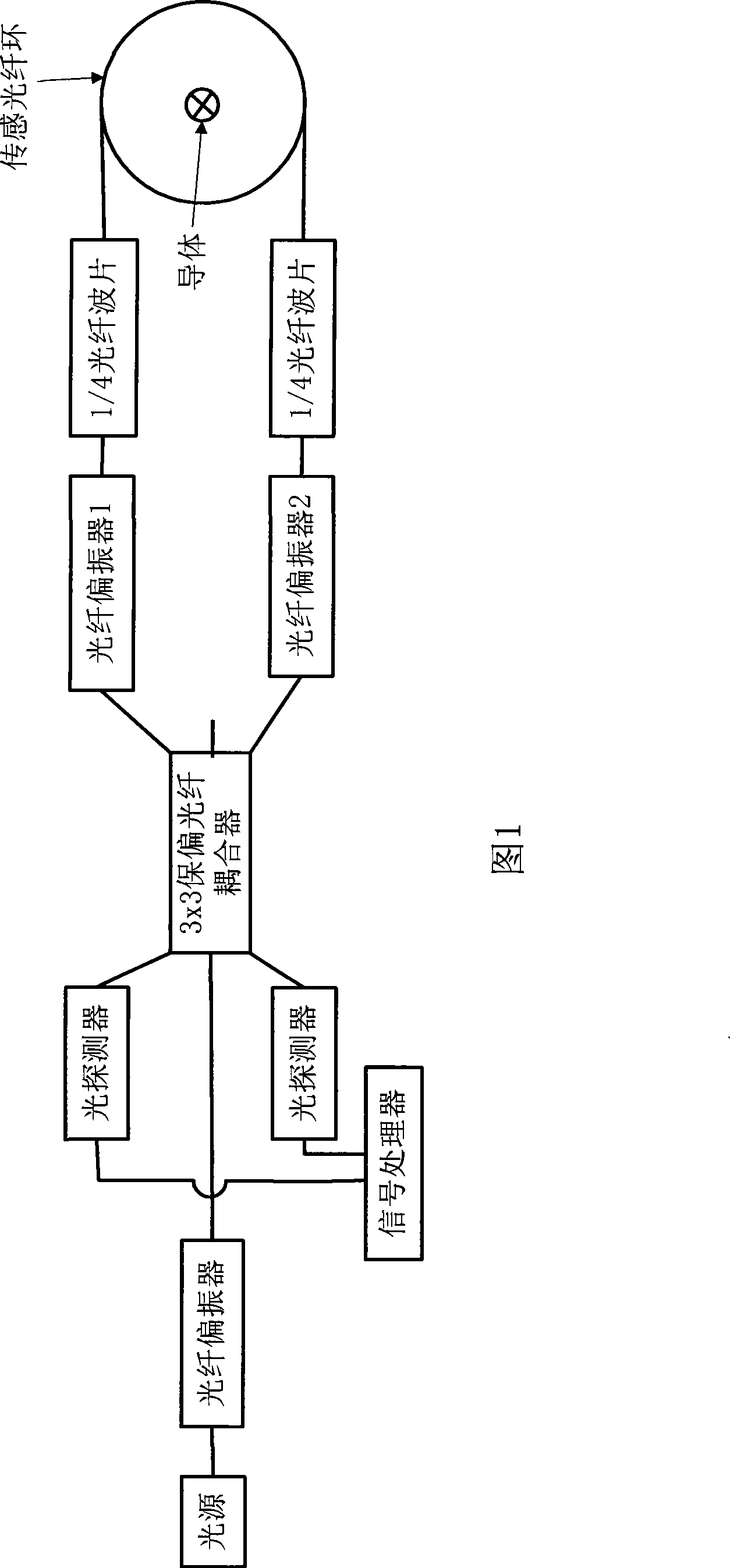

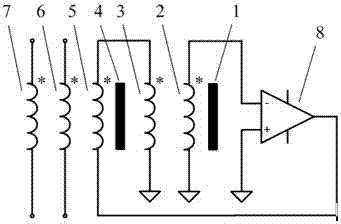

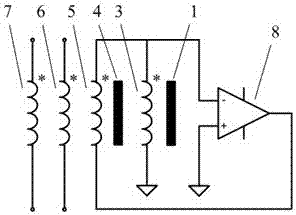

Full optical fiber current sensor

InactiveCN101320055AEliminate imperfectionsEliminate measurement errorsVoltage/current isolationOptical light guidesFiber couplerPhase difference

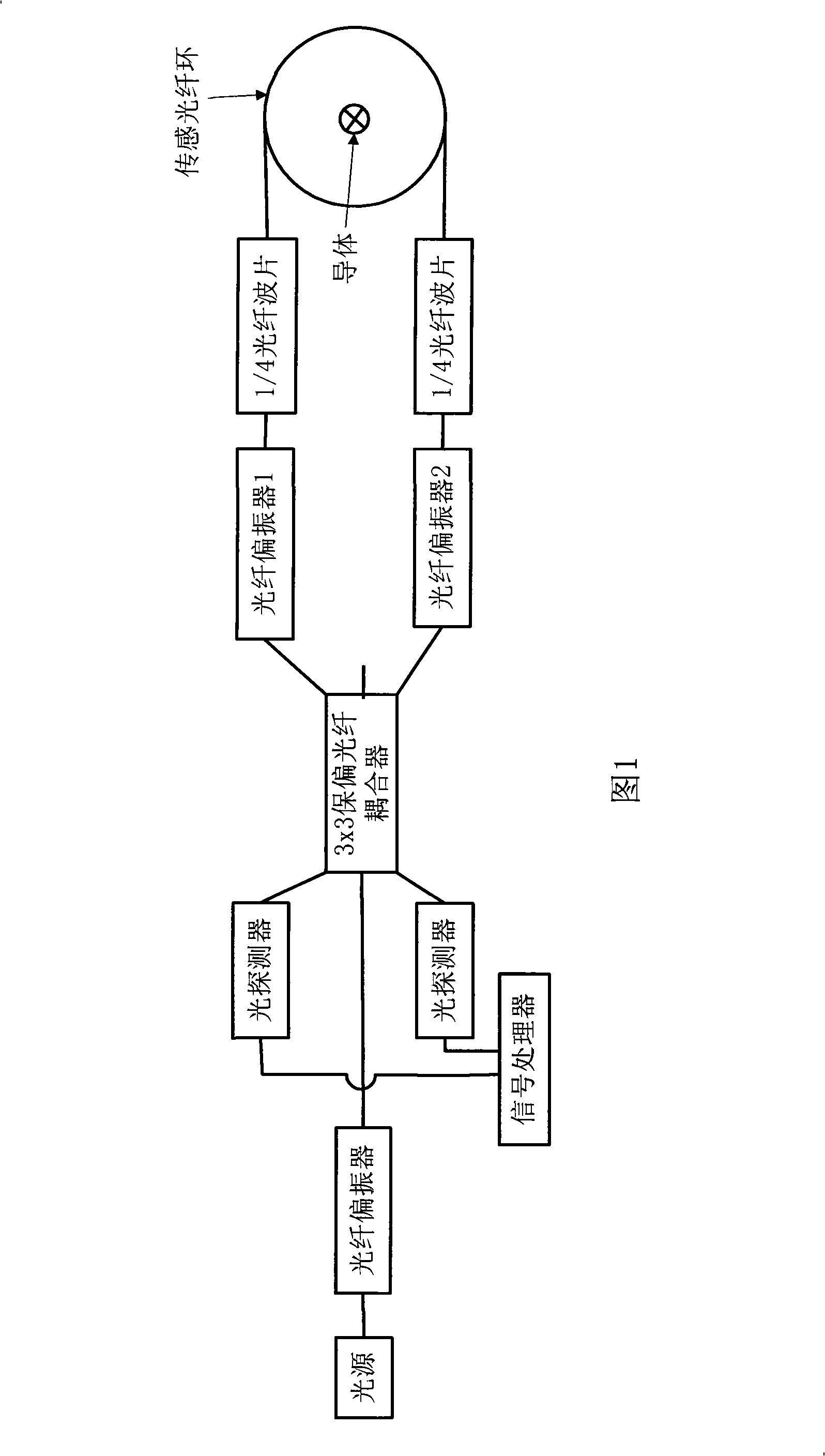

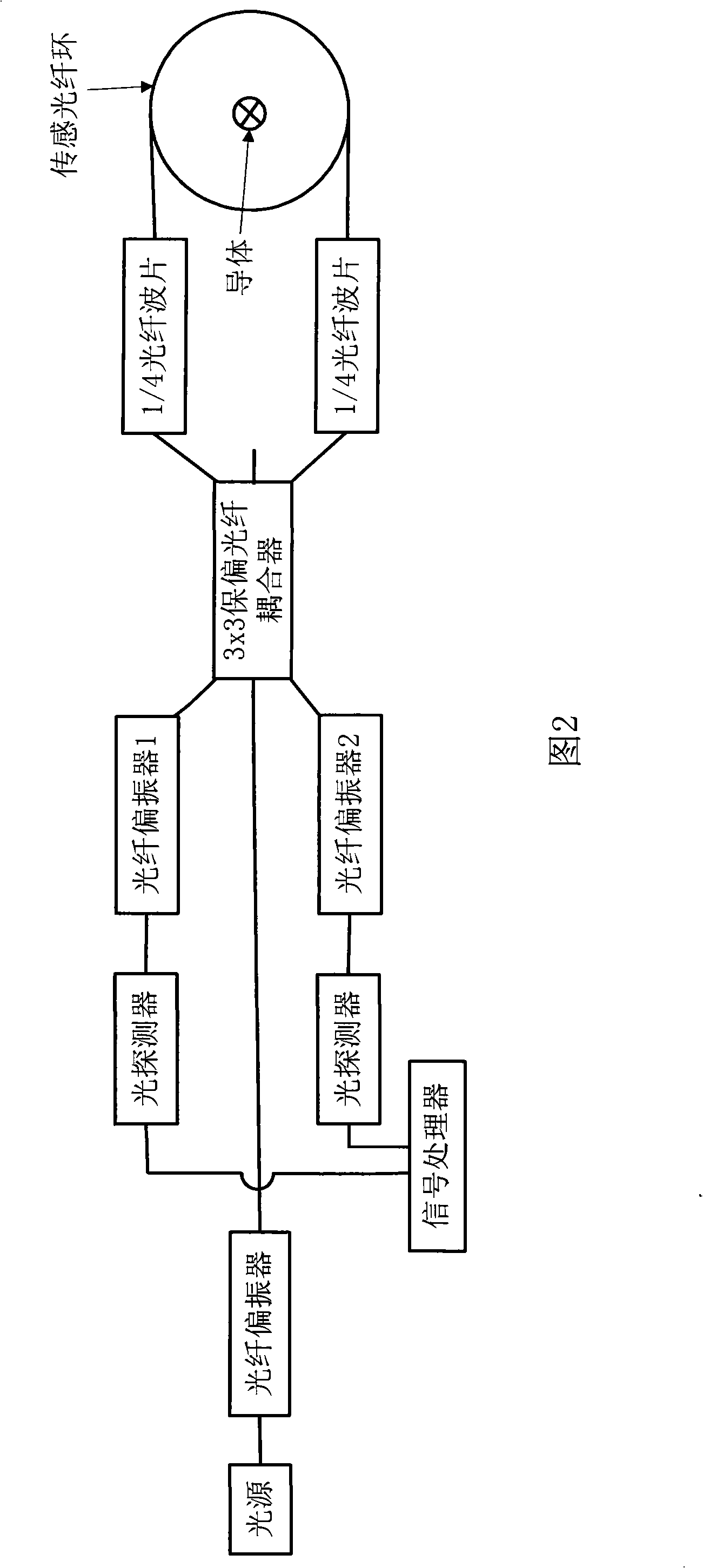

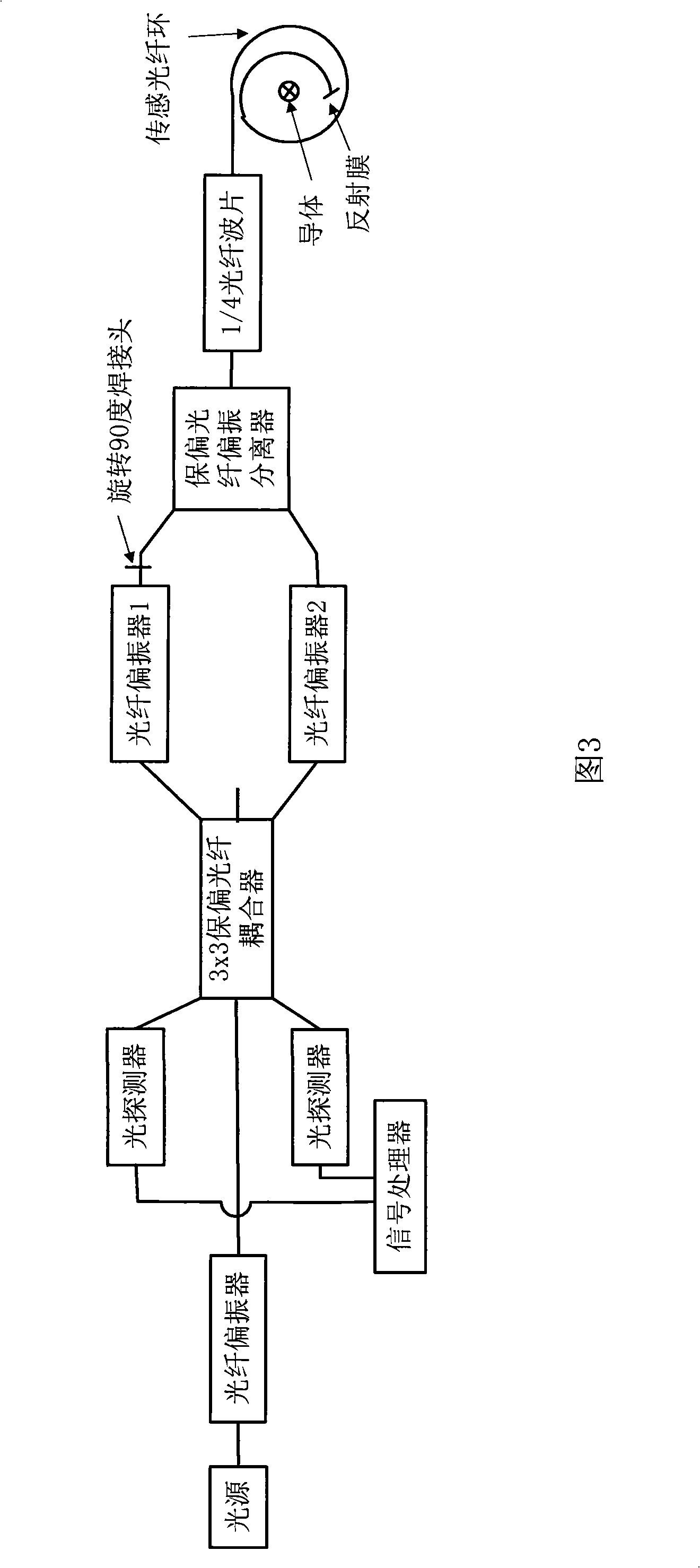

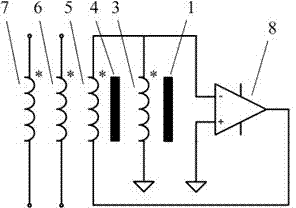

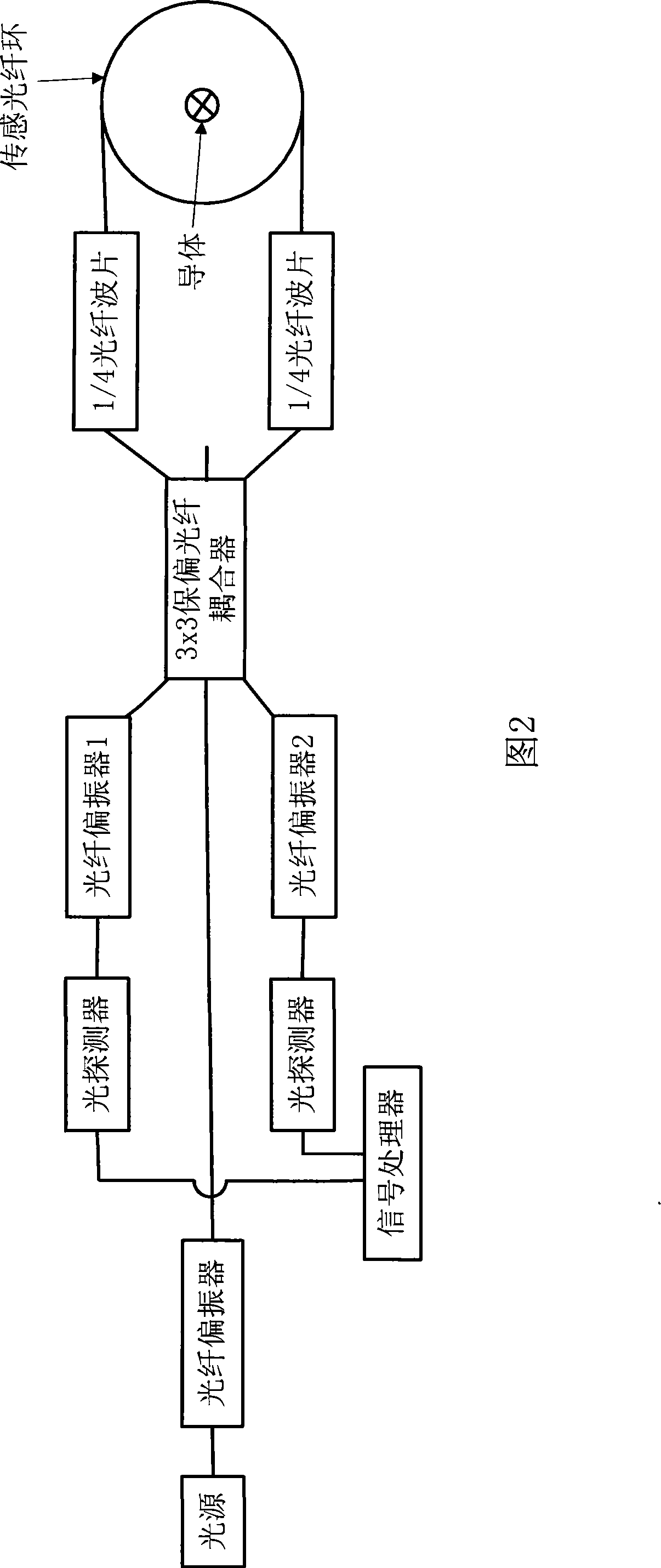

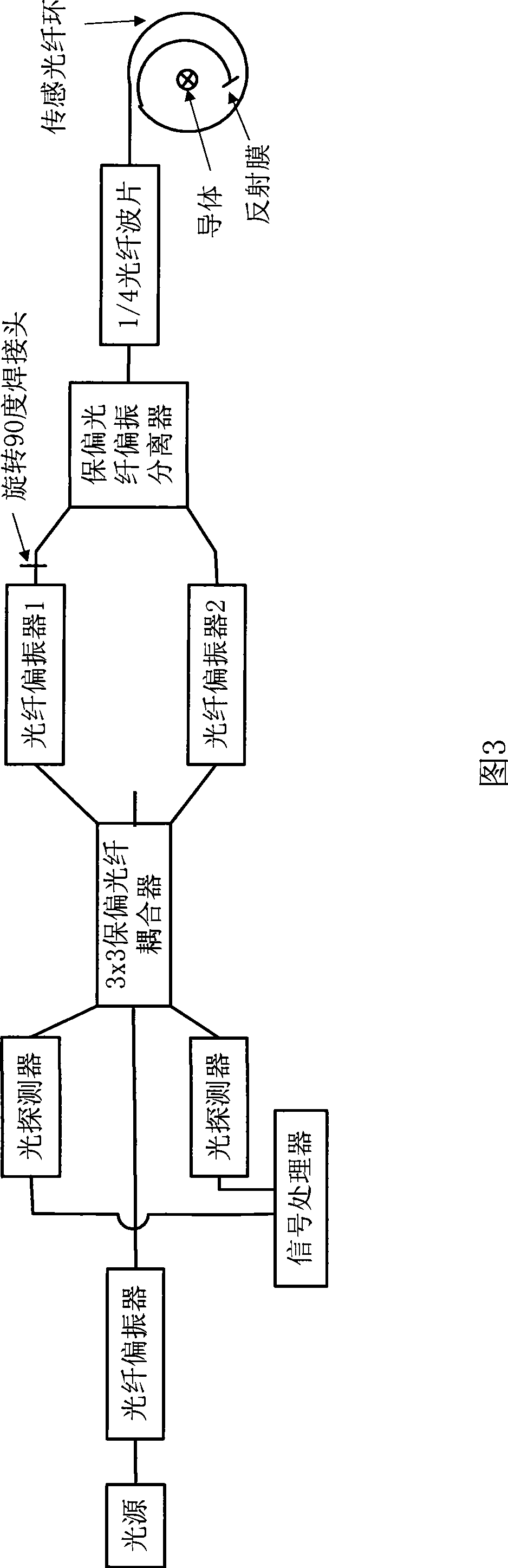

The invention discloses an all-fiber current sensor consists of a 3x3 polarization-maintaining fiber coupler. One embodiment of the invention, a straight-through type interferometric all-fiber current sensor, comprises a light source, a 3x3 polarization-maintaining fiber coupler, fiber polarizers, a 1 / 4 fiber wave sheet and a transduction fiber ring. The light source is connected with one end of the 3x3 polarization-maintaining fiber coupler; the two ports of the 3x3 polarization-maintaining fiber coupler are respectively connected with two fiber polarizers; and the other ends of the two fiber polarizers are respectively connected with the transduction fiber ring by the 1 / 4 fiber wave sheet; one port of the 3x3 polarization-maintaining fiber coupler is vacant; and the rest two ports of the 3x3 polarization-maintaining fiber coupler are respectively connected with a signal processor by two photoelectric detectors. In addition, another embodiment of the invention, a reflection type interferometric all-fiber current sensor, also uses the 3x3 polarization-maintaining fiber coupler. The all-fiber current sensor avoids phase differences made artificially and makes the current transduction system woke more stably.

Owner:上海康阔光智能技术有限公司

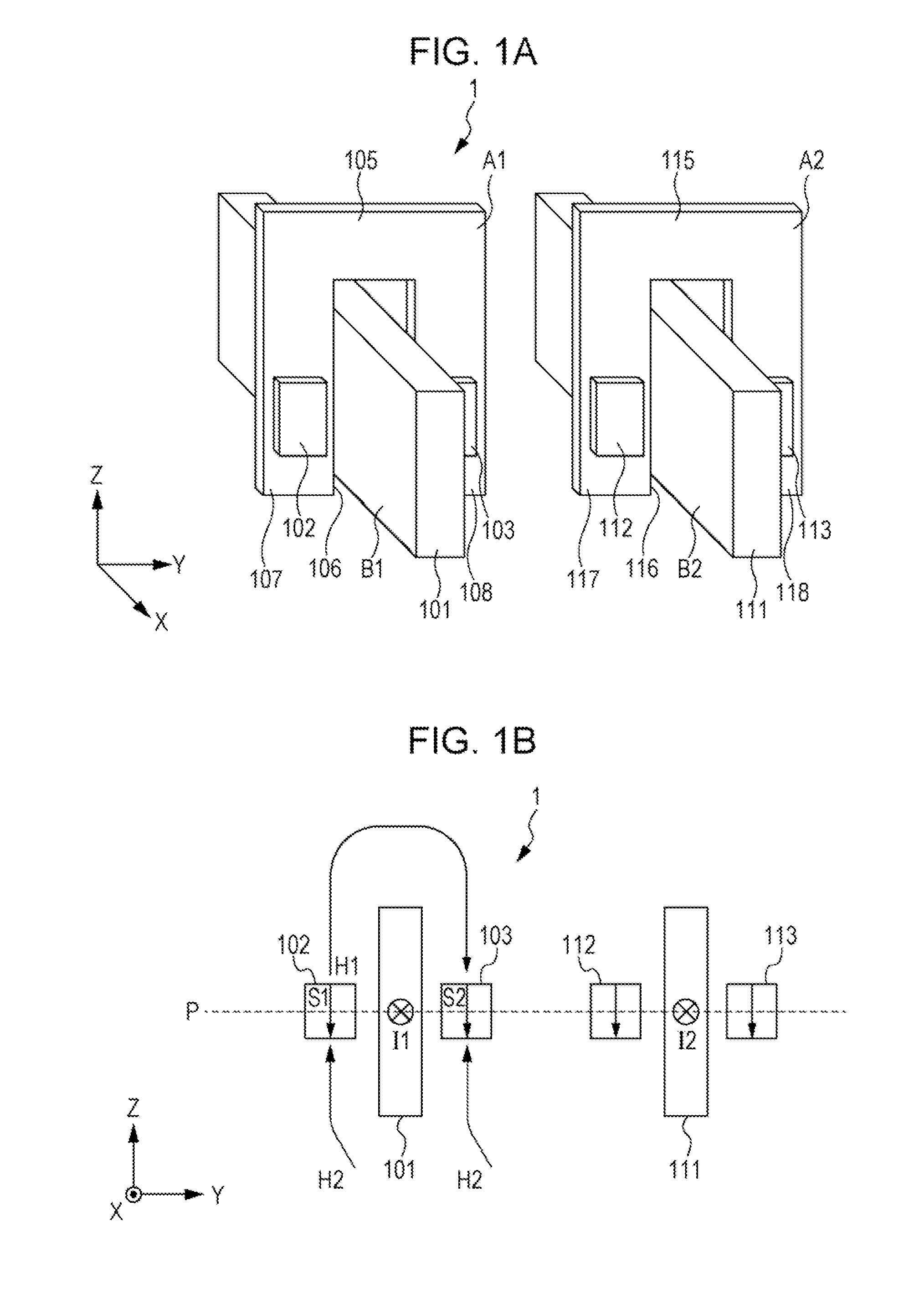

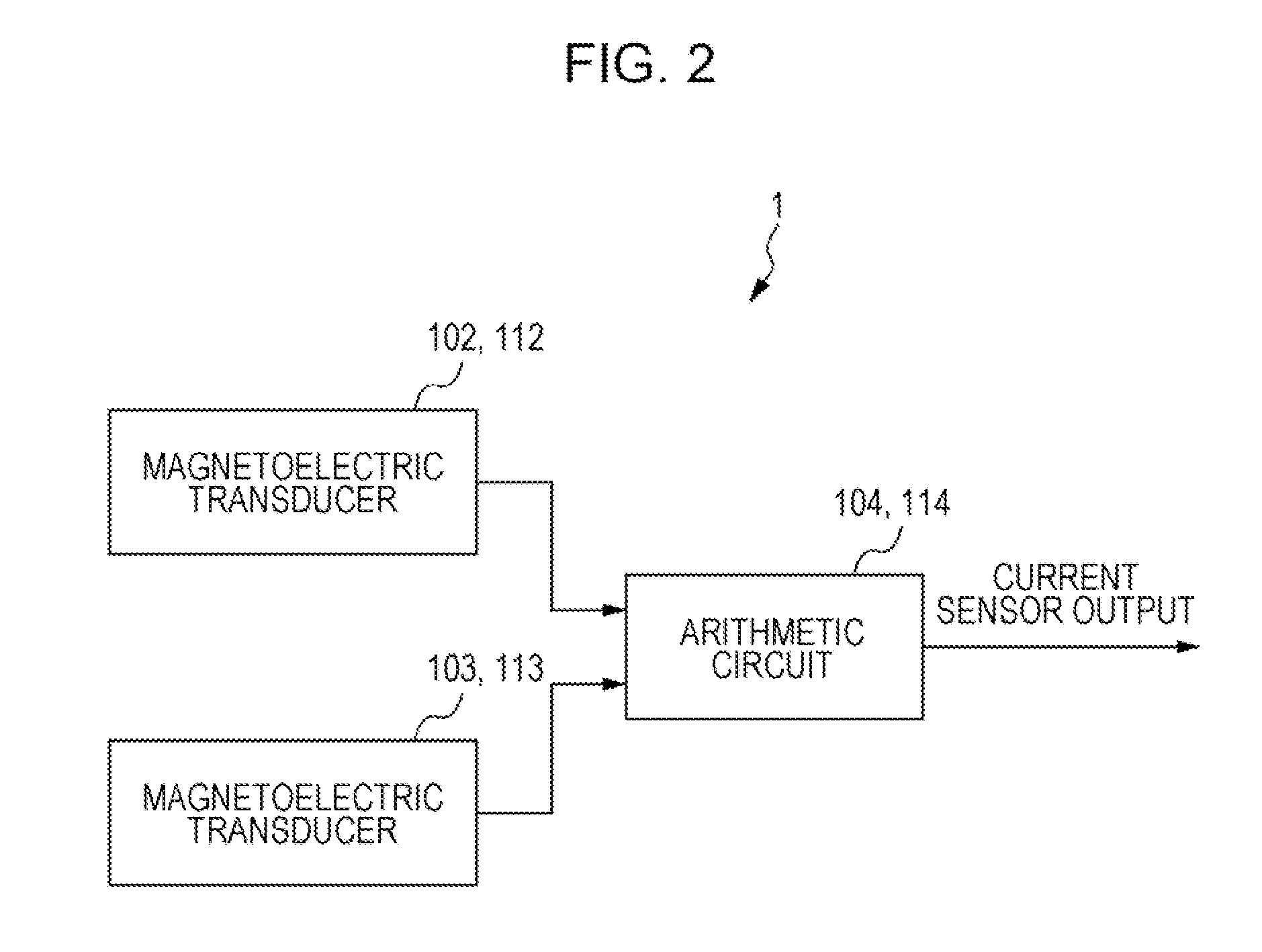

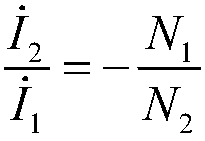

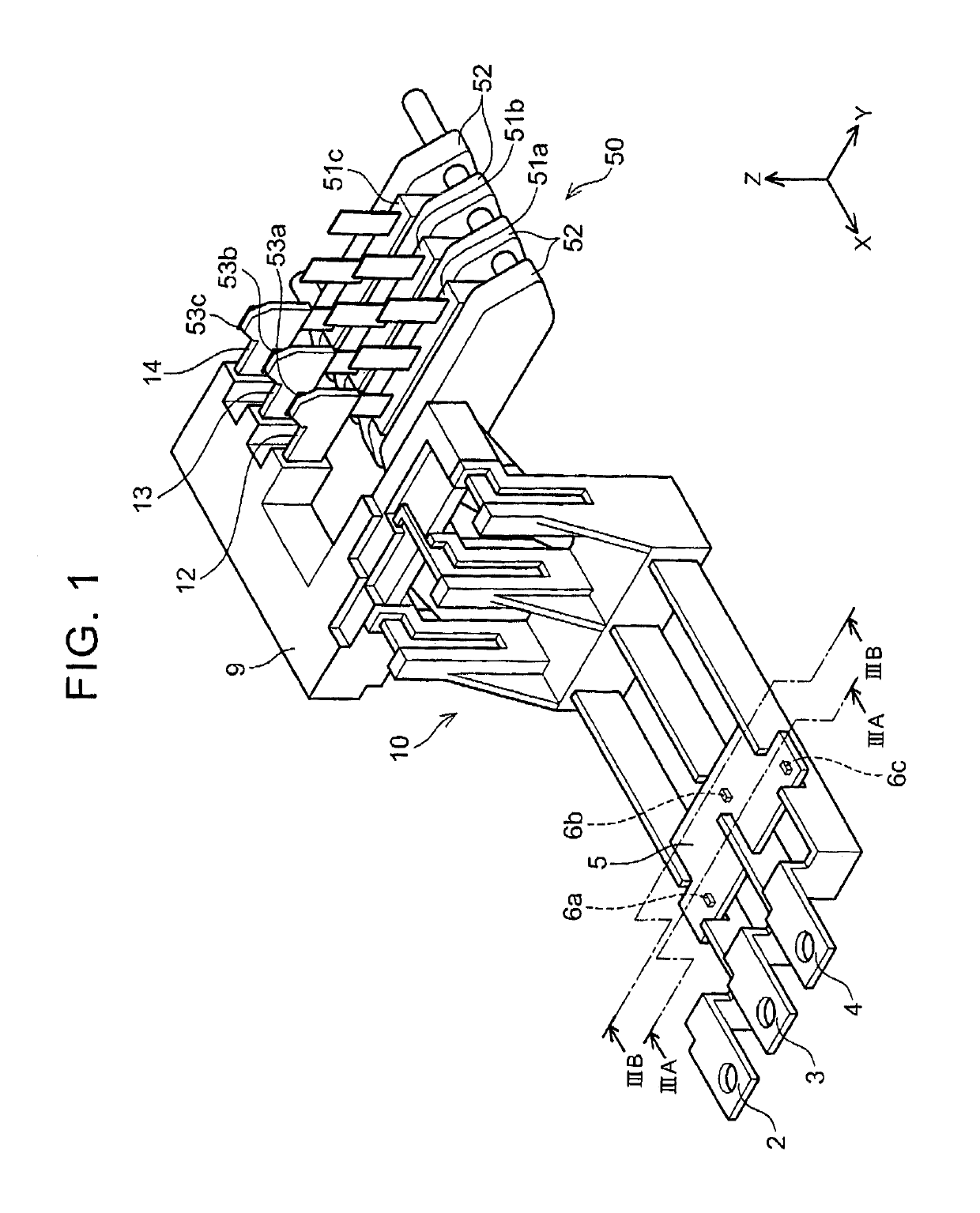

Current sensor

ActiveUS20140070801A1Suppress feverImprove current measurement accuracyCurrent/voltage measurementVoltage/current isolationPower flowElectrical conductor

A current sensor includes a first conductor and a second conductor arranged so as to form current paths parallel to each other; a circuit board arranged such that a surface thereof is perpendicular to the current paths; and a first magnetoelectric transducer and a second magnetoelectric transducer arranged on the surface of the circuit board such that the first conductor is interposed therebetween. The first conductor, the second conductor, the first magnetoelectric transducer, and the second magnetoelectric transducer are located on a same plane.

Owner:ALPS ALPINE CO LTD

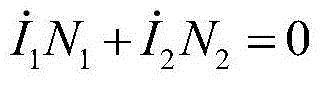

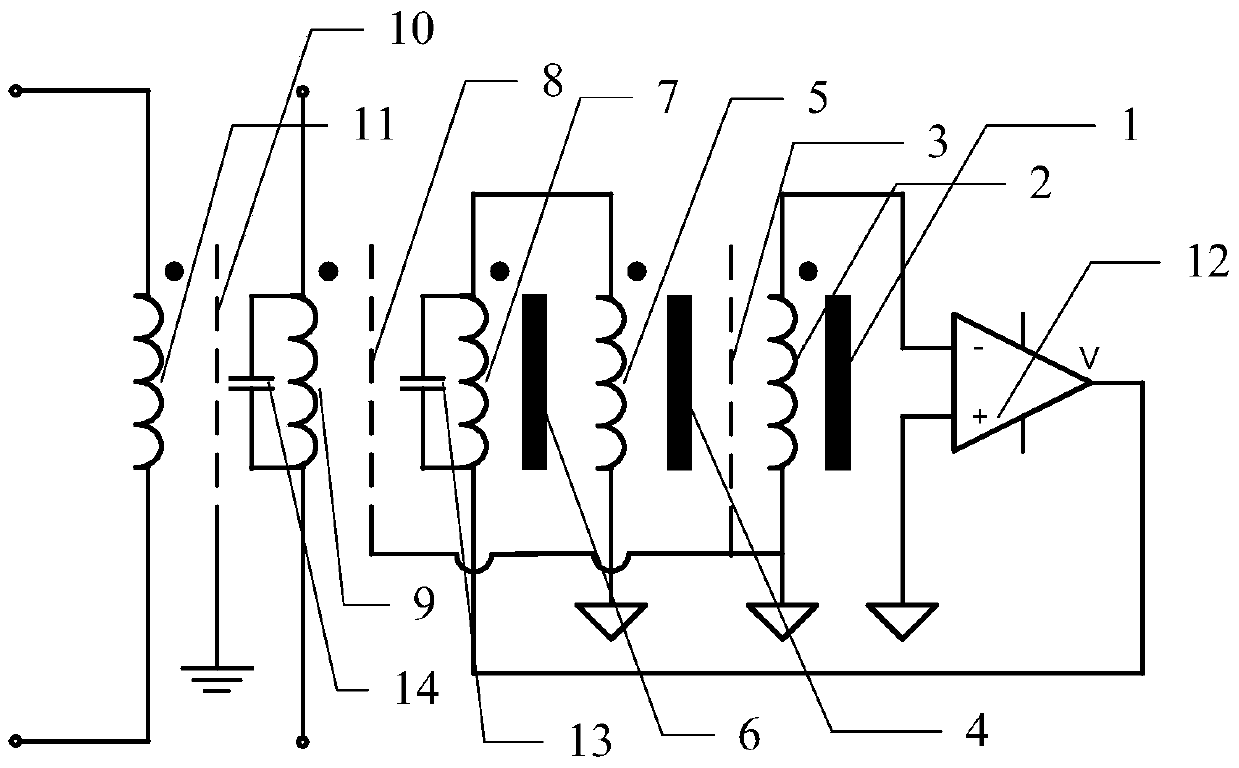

High-accuracy electronic compensated current transformer

InactiveCN103592490AMagnetic flux is not generatedImprove current measurement accuracyVoltage/current isolationExcitation currentConductor Coil

The invention relates to a high-accuracy electronic compensated current transformer, and belongs to the field of current measuring. The compensated current transformer is composed of an iron core, a winding and an auxiliary circuit used for compensating a magnetizing current. The iron core is a nested structure composed of a detecting iron core and a shielding iron core, the detecting iron core detects the zero magnetic flux state of the iron core through the winding wound on the detecting iron core and then controls the auxiliary circuit to provide the excitation current necessary for the current transformer, so that the error source of the current transformer is eliminated, and accuracy of the current transformer is greatly improved. A 0.001-level high-accuracy current transformer which is insensitive to secondary loads and an open type current transformer with the accuracy degree superior to 0.01level can be developed by using the high-accuracy electronic compensated current transformer.

Owner:STATE GRID CORP OF CHINA +2

Multi-channel galvanic corrosion measurement device

ActiveCN102507431AEliminate mutual interferenceHigh linear precisionWeather/light/corrosion resistanceMeasurement deviceMetallic materials

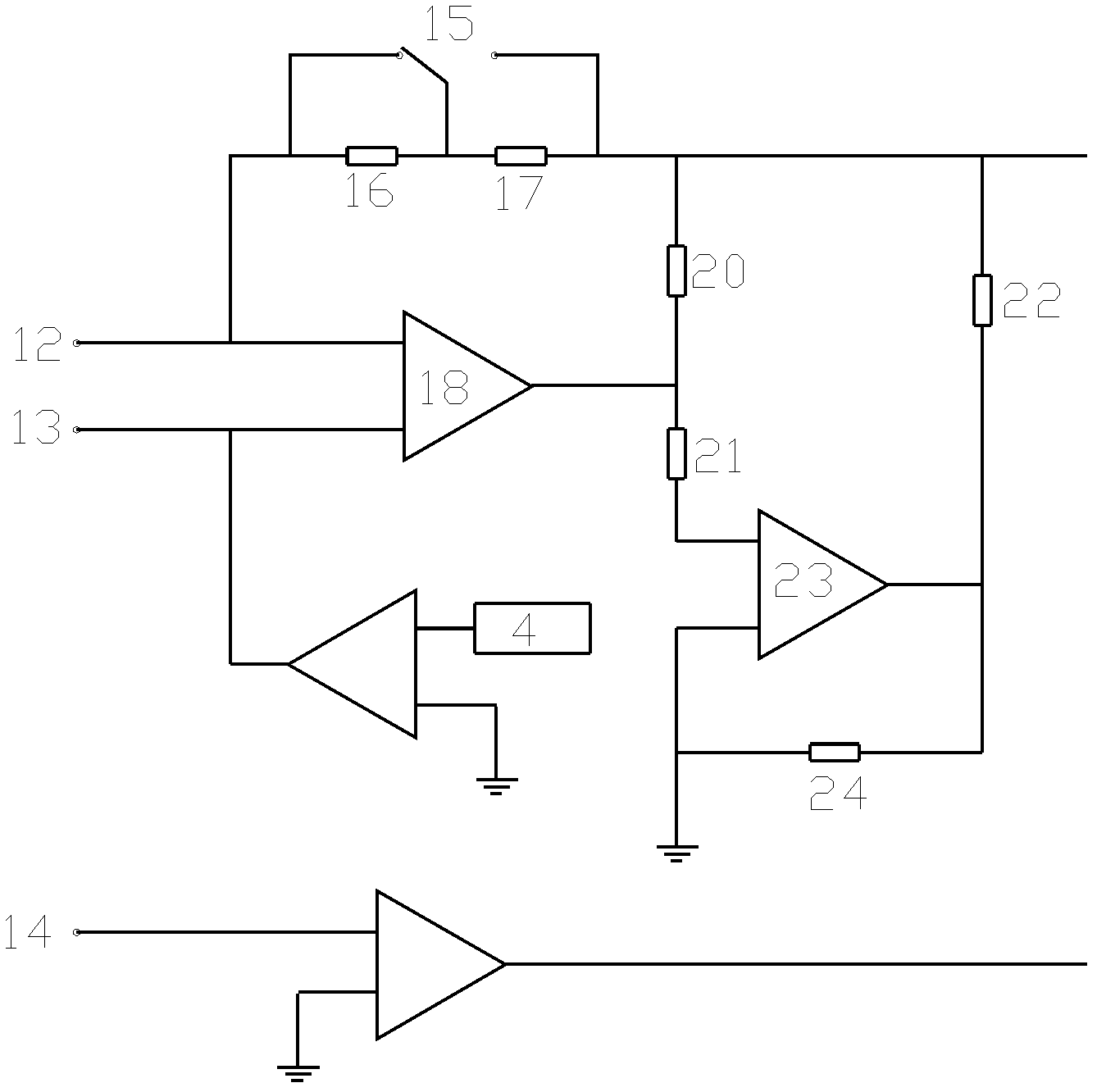

The invention belongs to the technical field of galvanic corrosion measurement for metal materials, in particular relates to a multi-channel galvanic corrosion measurement device. According to the multi-channel galvanic corrosion measurement device, an SOC (System on a Chip) processor structural design is adopted; the front end of an electrode connection cable is connected with an electrode; the rear end of the electrode connection cable is connected into a voltage / current measurement switching unit; two ends of a front end signal conditioning circuit are bridged with a reference source afterbeing electrically communicated with an A / D (Analog-to-Digital) conversion circuit; the front end of the front end signal conditioning circuit is electrically connected with the voltage / current measurement switching unit; the output end of the A / D conversion circuit is electrically communicated with a main control module after being connected in series with a multi-channel electric isolation unit; an SOC processor is arranged in the main control module; the main control module is electrically connected with a display module, a storage module and a communication module respectively, so that electric information control is realized; and a signal input by a reference electrode is incorporated into the front end signal conditioning circuit after being amplified, so that a signal processing system is formed. The multi-channel galvanic corrosion measurement device has the characteristics of simple overall structure, reliable principle, convenience for use and operation, accuracy in measurement data, flexibility for control and wide application range.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

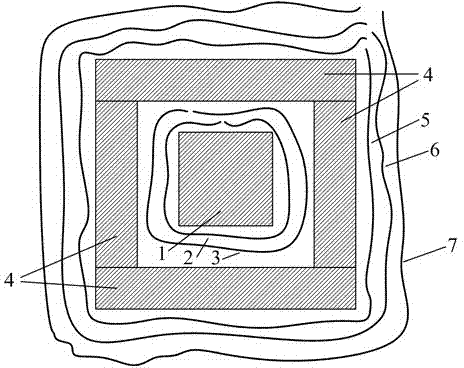

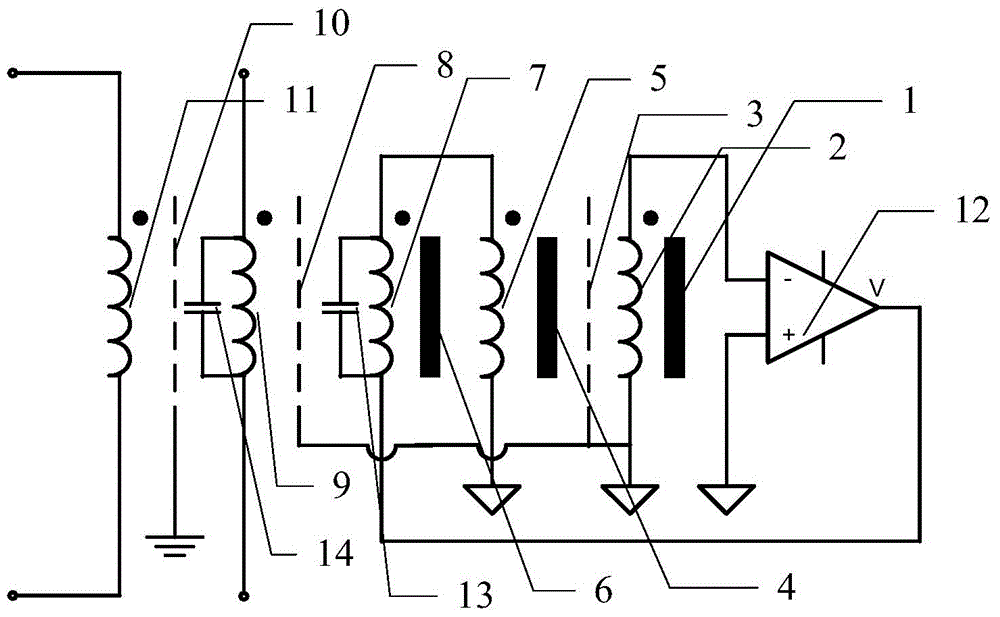

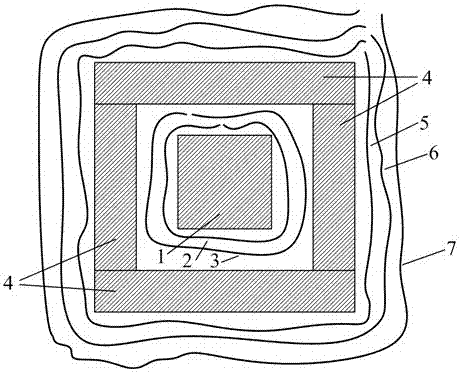

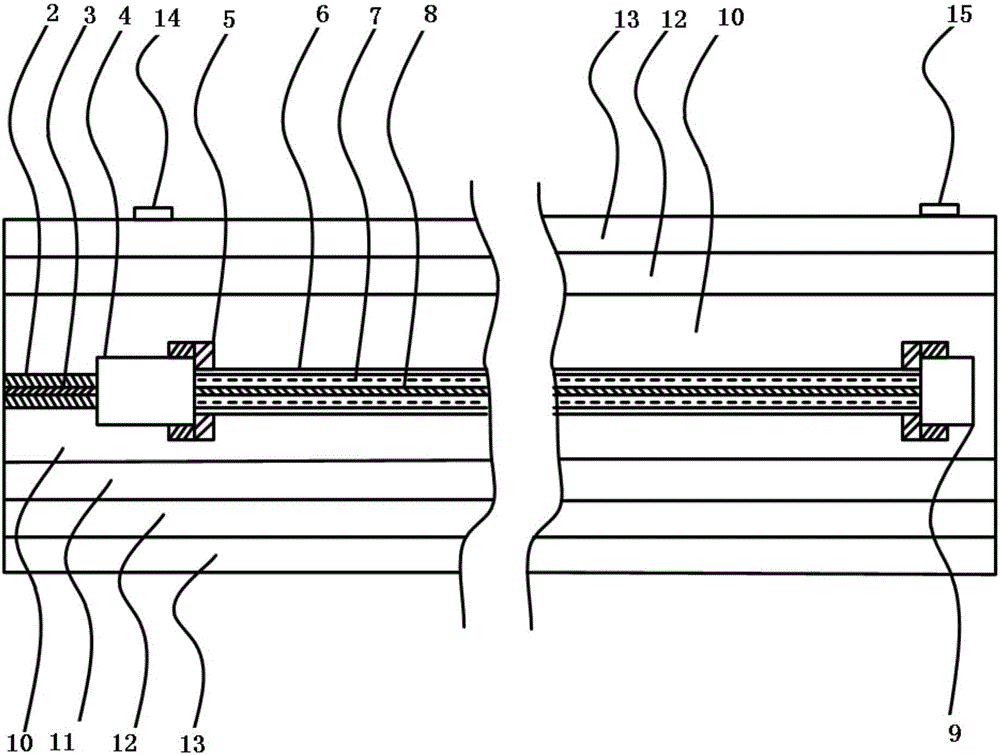

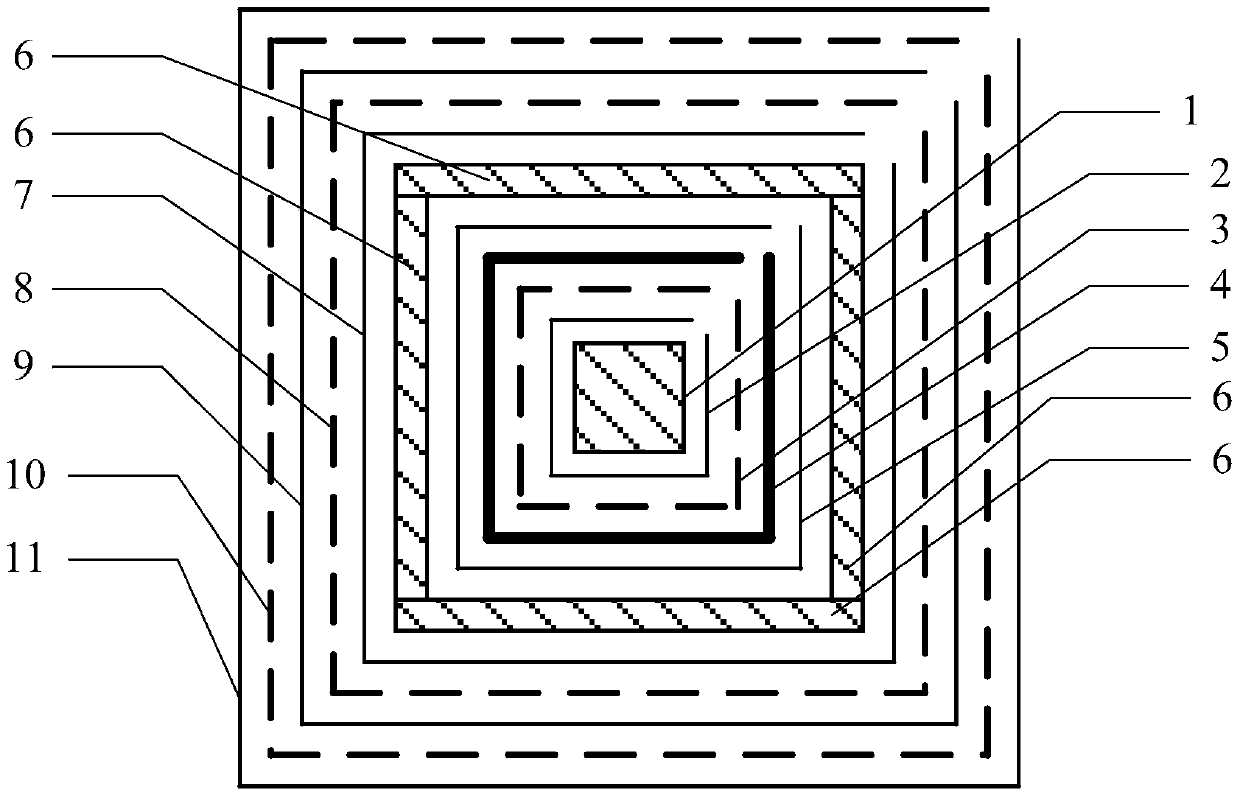

Broadband current transformer

ActiveCN105575639ASignificant progressImprove measurement accuracyTransformersTransformers/inductances coils/windings/connectionsCapacitanceBroadband

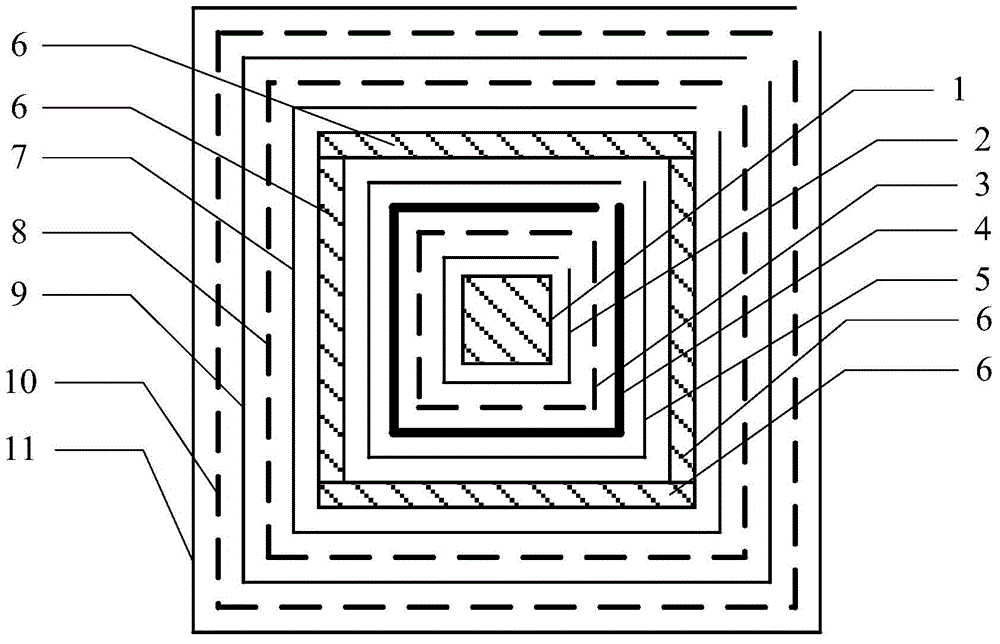

The invention provides a broadband current transformer. The broadband current transformer comprises a detection iron core (1), wherein a detection winding (2), a detection winding copper screen (3), an inner magnetic screen (4), an inner compensation winding (5), an outer magnetic screen (6), an outer compensation winding (7), an outer compensation winding copper screen (8), a secondary winding (9), a secondary winding copper screen (10) and a primary winding (11) are arranged outside the detection iron core (1) from an inner layer to an outer layer in sequence; compensation capacitors (13) are connected at two ends of the outer compensation winding (7) in parallel, and compensation capacitors (14) are connected at two ends of the secondary winding (9) in parallel; and the number of windings of the inner compensation winding (5) is equal to that of the outer compensation winding (7). According to the broadband current transformer, main error sources of the current transformer are eliminated, the capacitive error of the broadband current transformer is reduced, and the measurement accuracy of high-frequency current is improved.

Owner:STATE GRID CORP OF CHINA +1

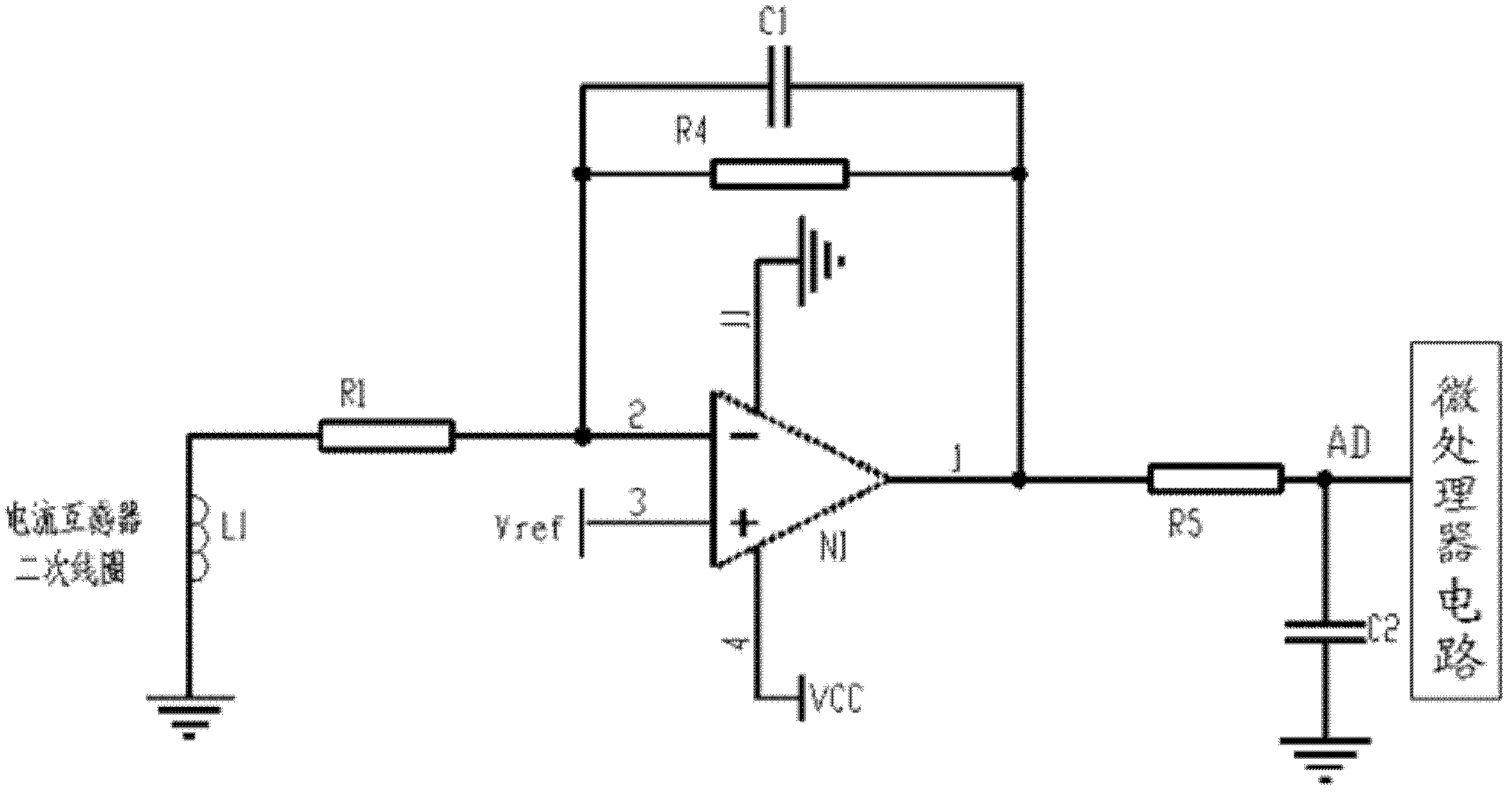

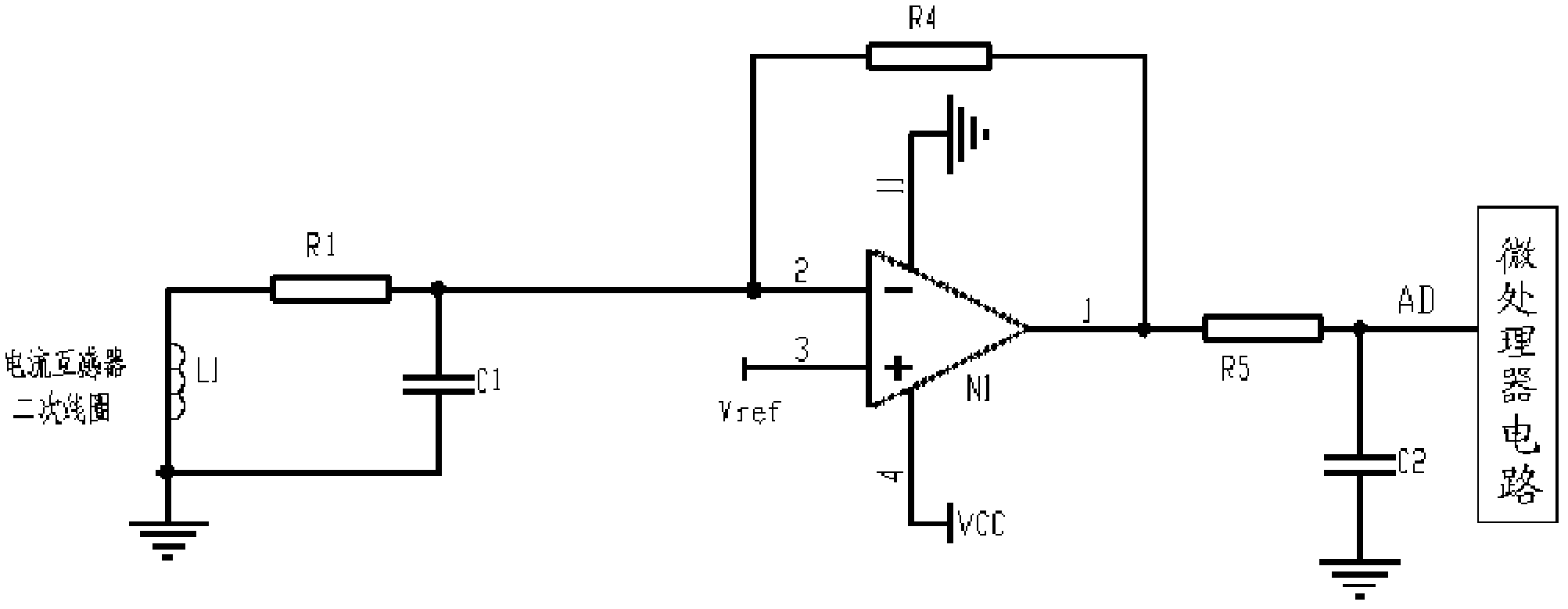

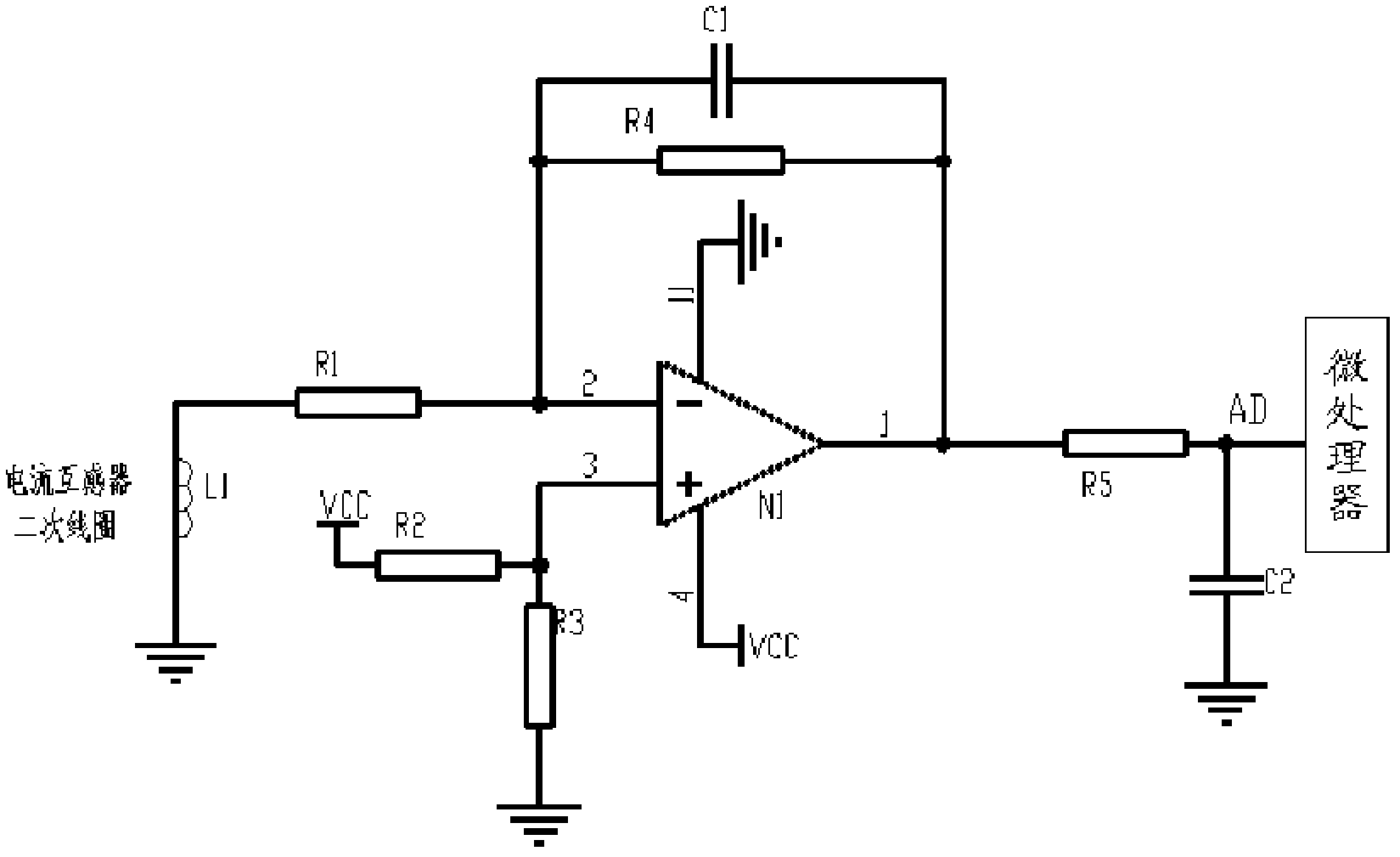

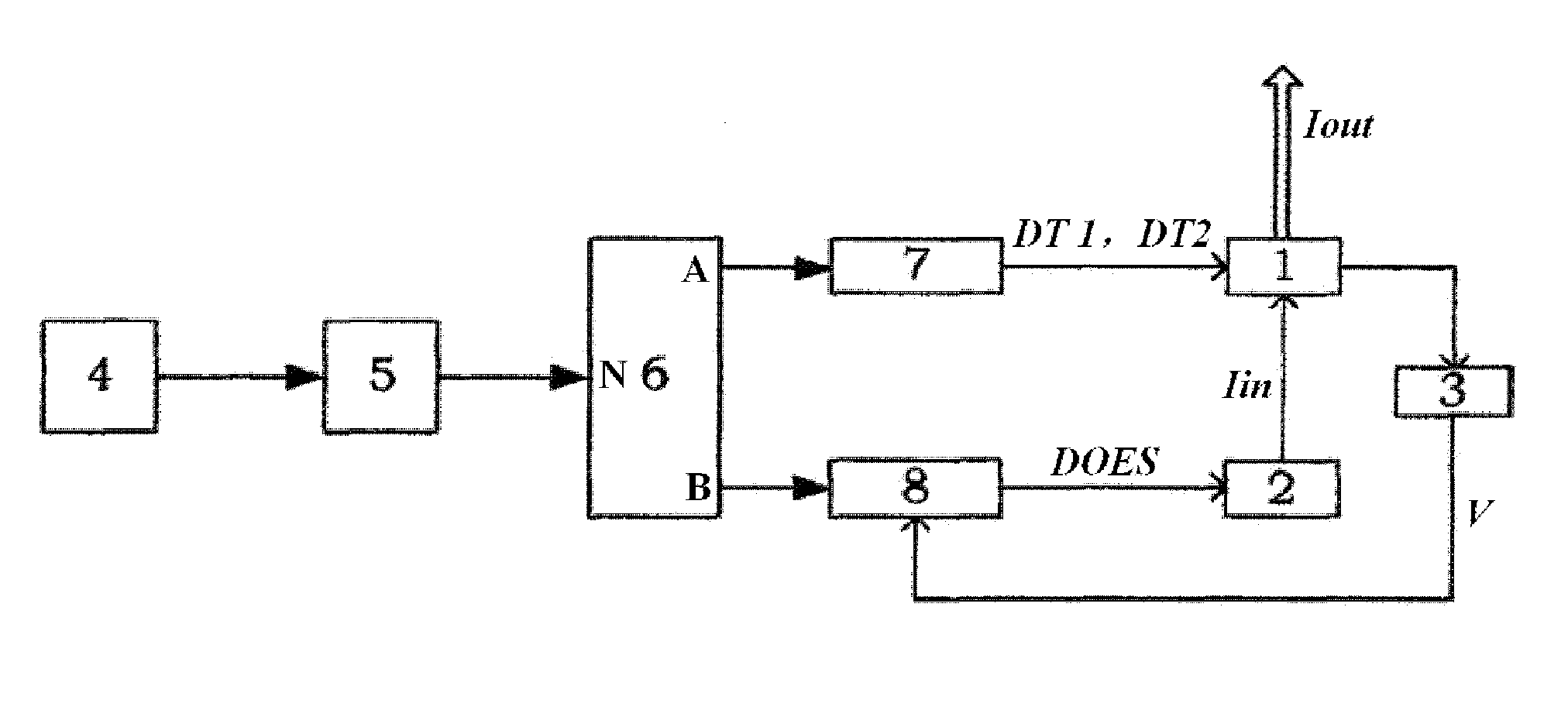

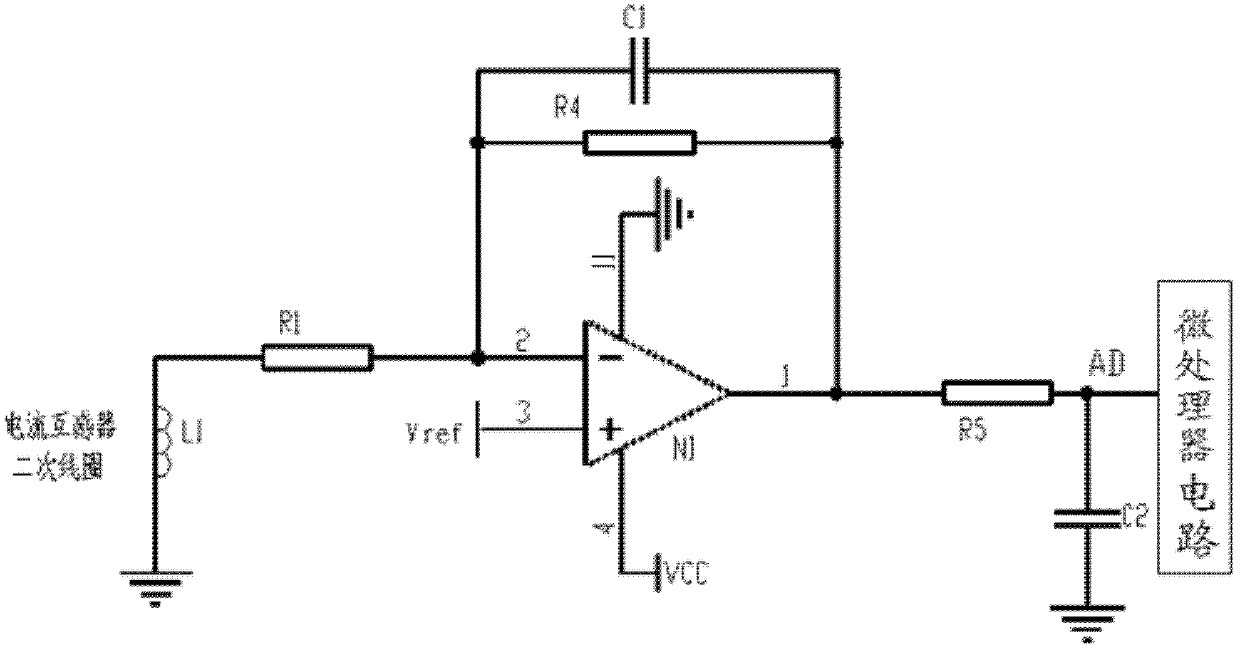

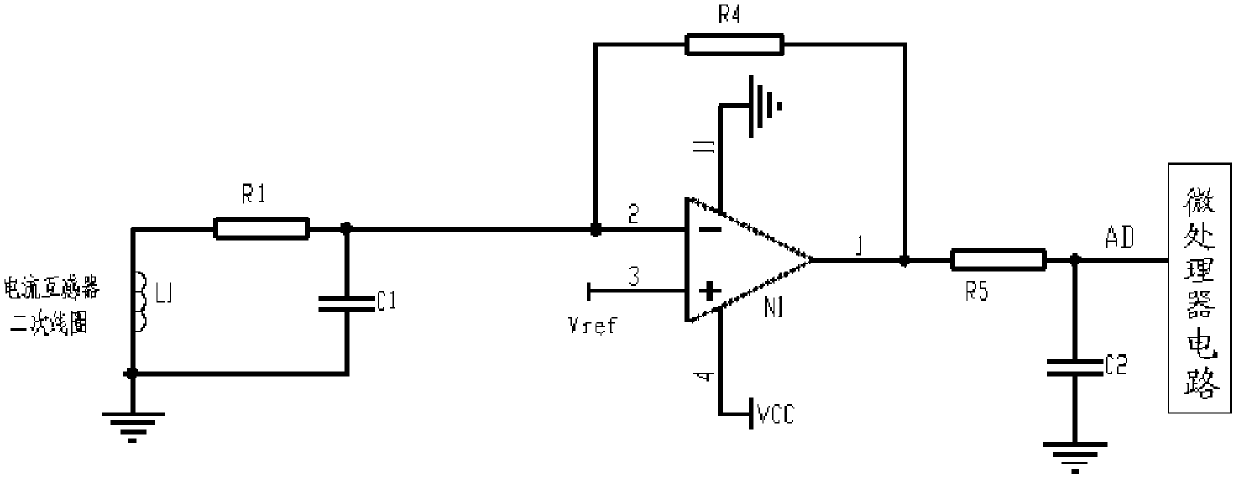

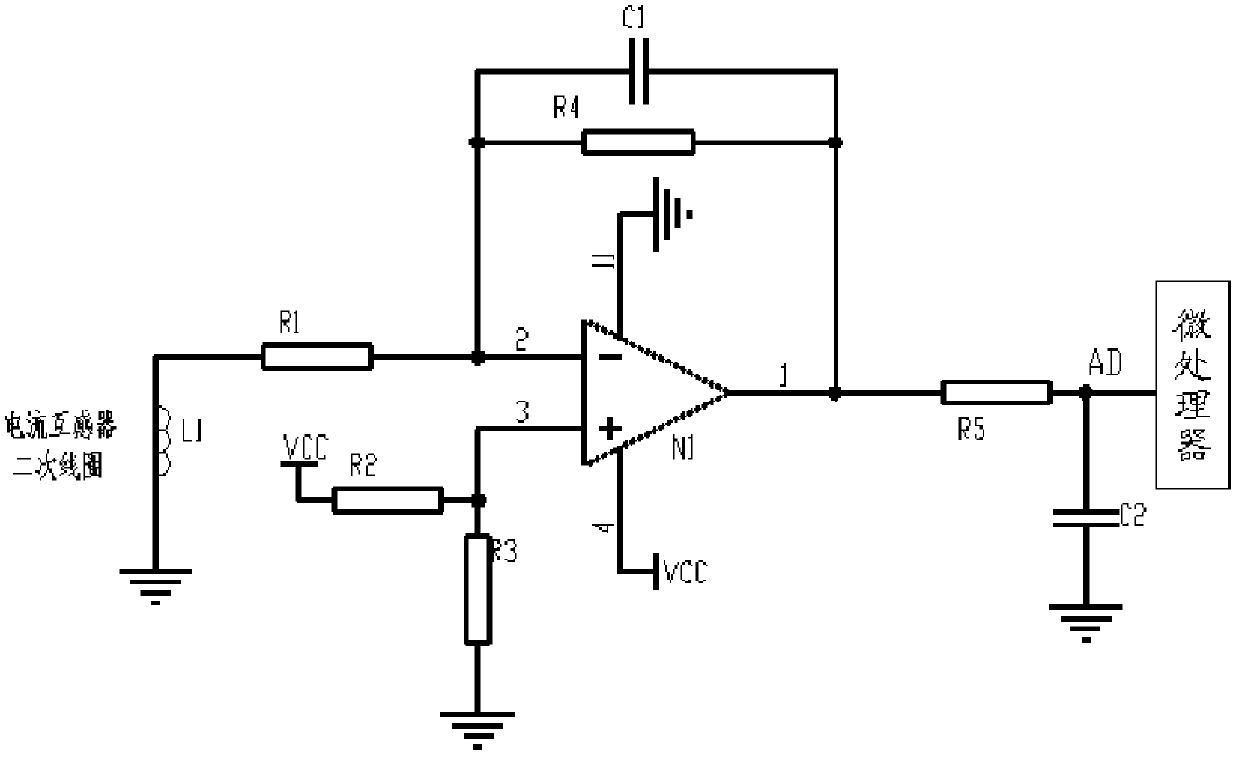

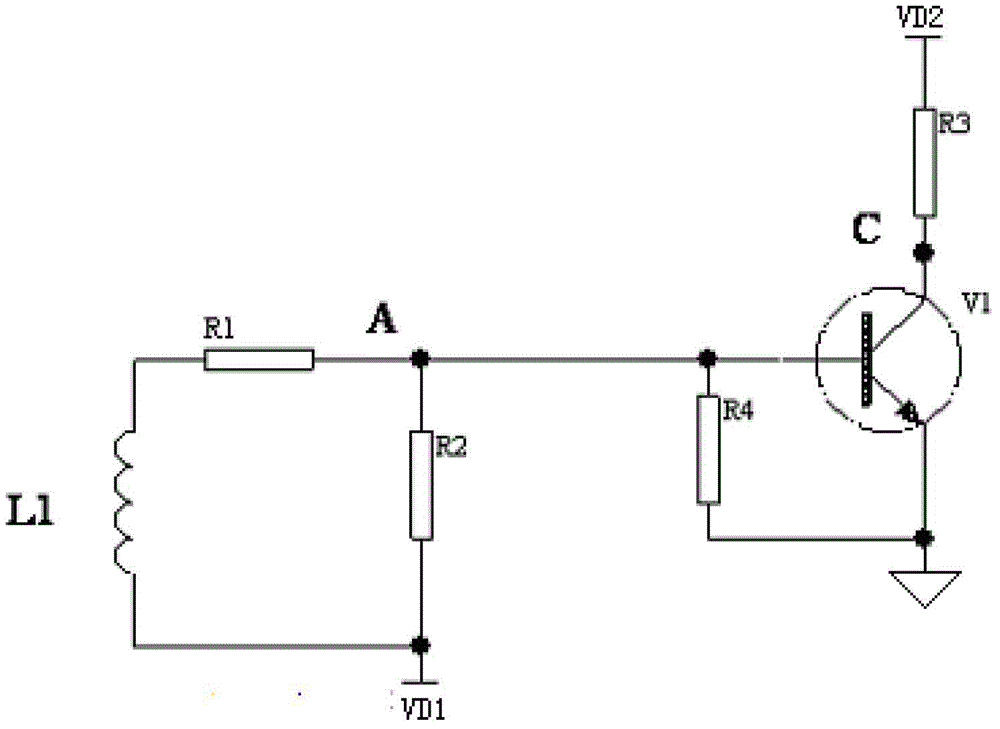

Detection circuit for monitoring state of current transformer

ActiveCN102590591AOvercome the disadvantage of status signal influenceAvoid disadvantagesCurrent/voltage measurementVoltage/current isolationInstrument transformerMeasurement precision

The invention discloses a detection circuit for monitoring state of a current transformer, which is serially connected between the transformer and a microprocessor circuit, wherein a microprocessor is used for judging the working state of the existing current transformer according to signals from the detection circuit. The detection circuit is independent to a current signal collecting circuit and overcomes the disadvantage that a current collection signal is affected by a state signal of the current transformer, so that the current measurement precision of an intelligent circuit breaker is improved.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

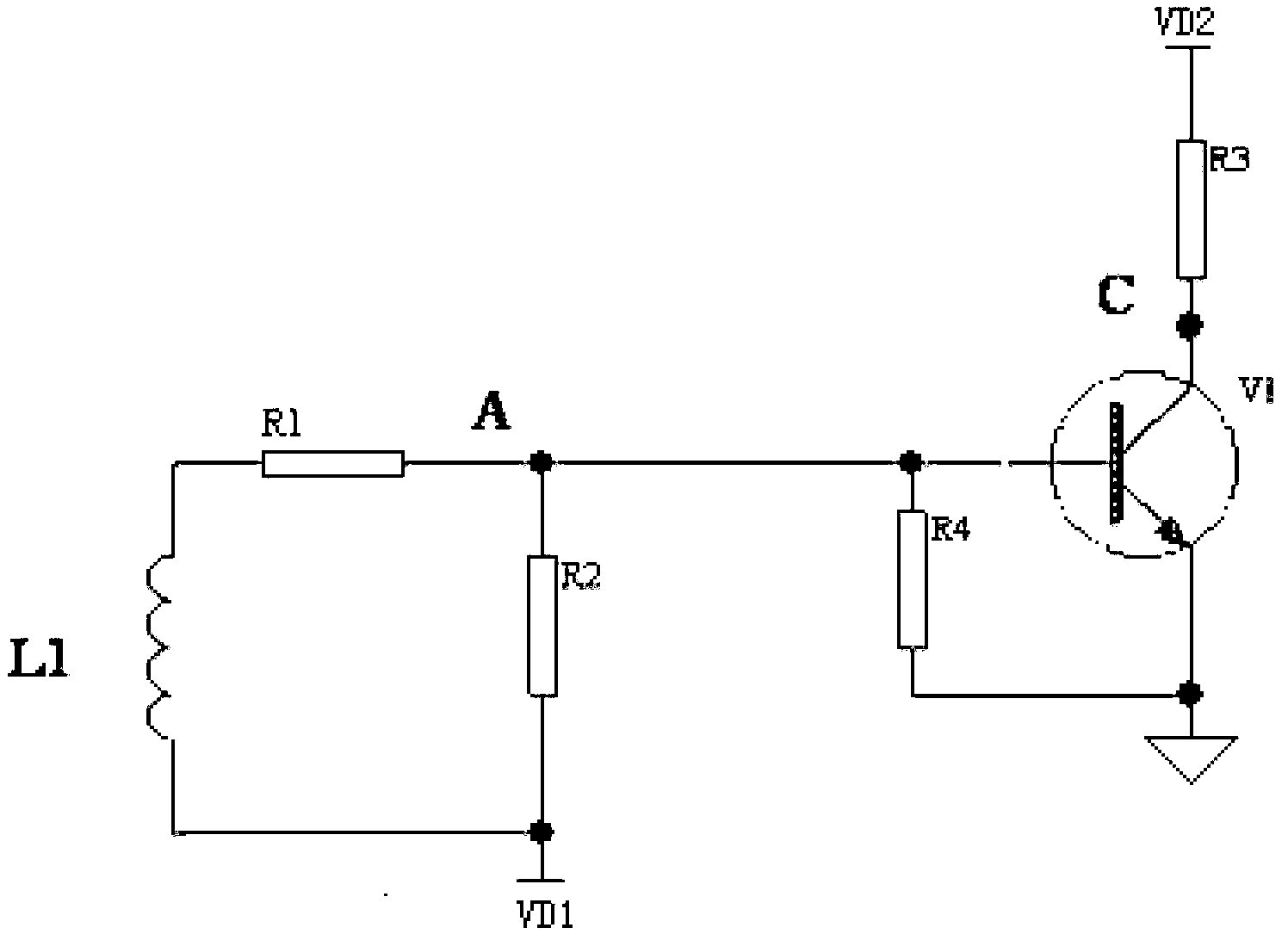

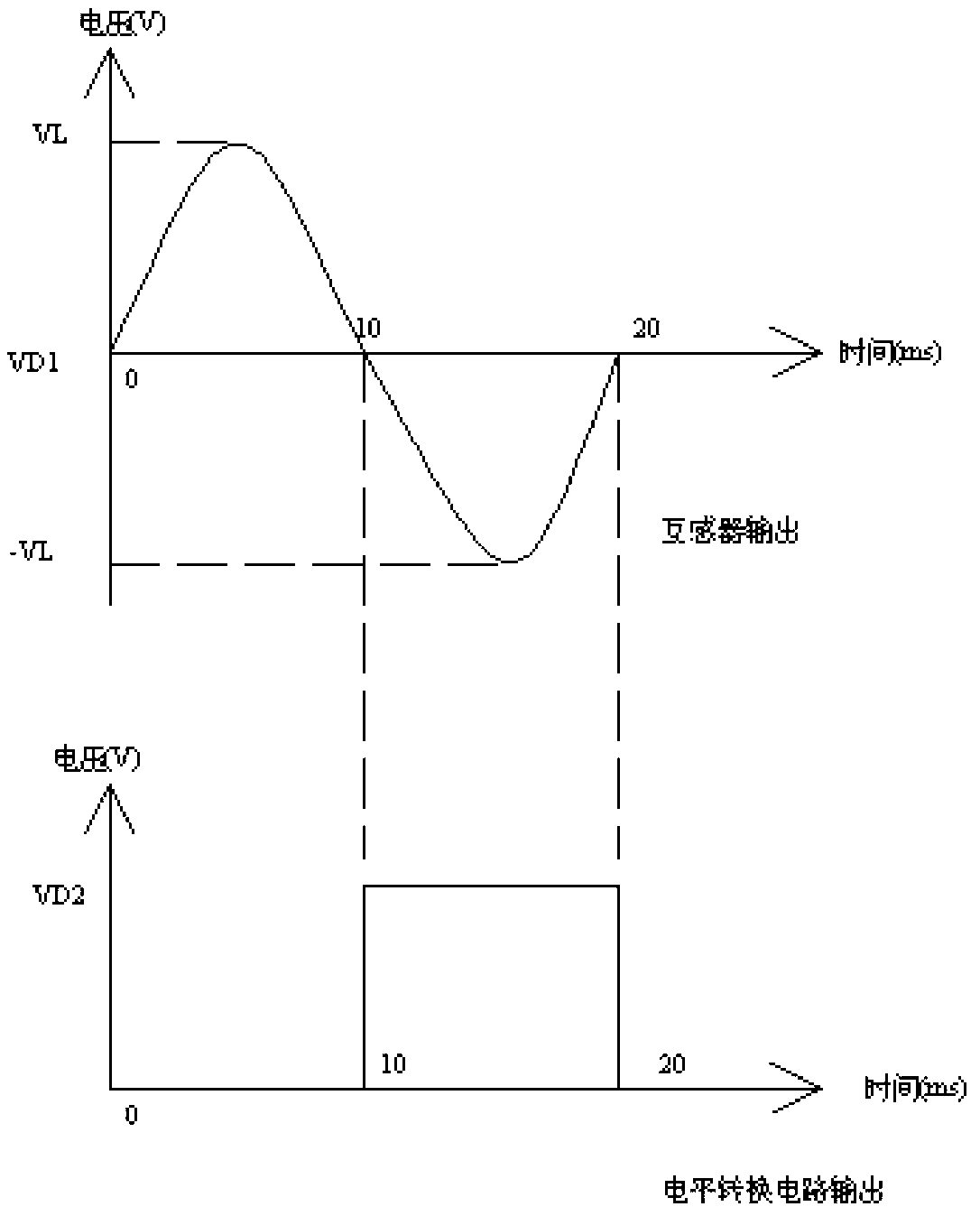

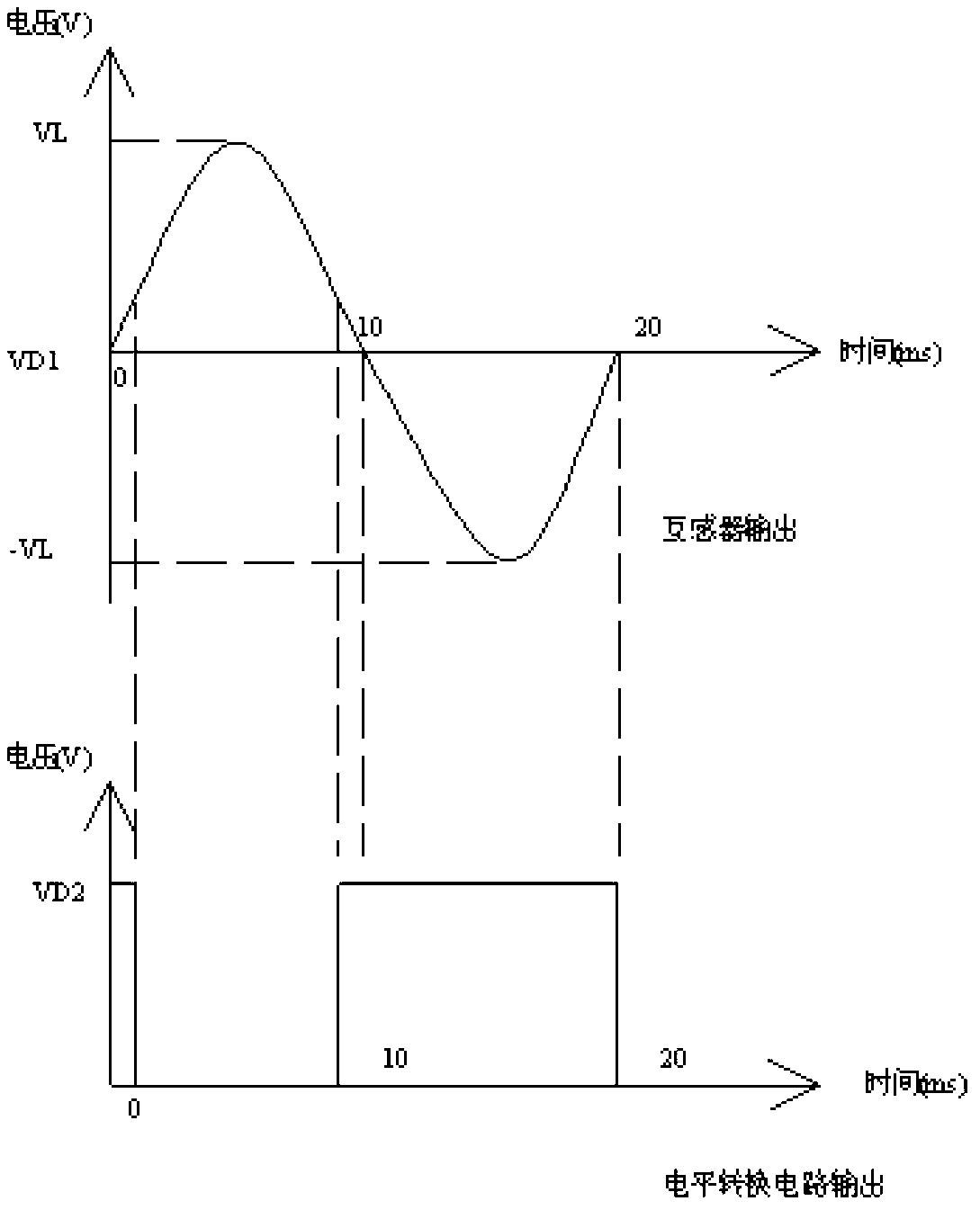

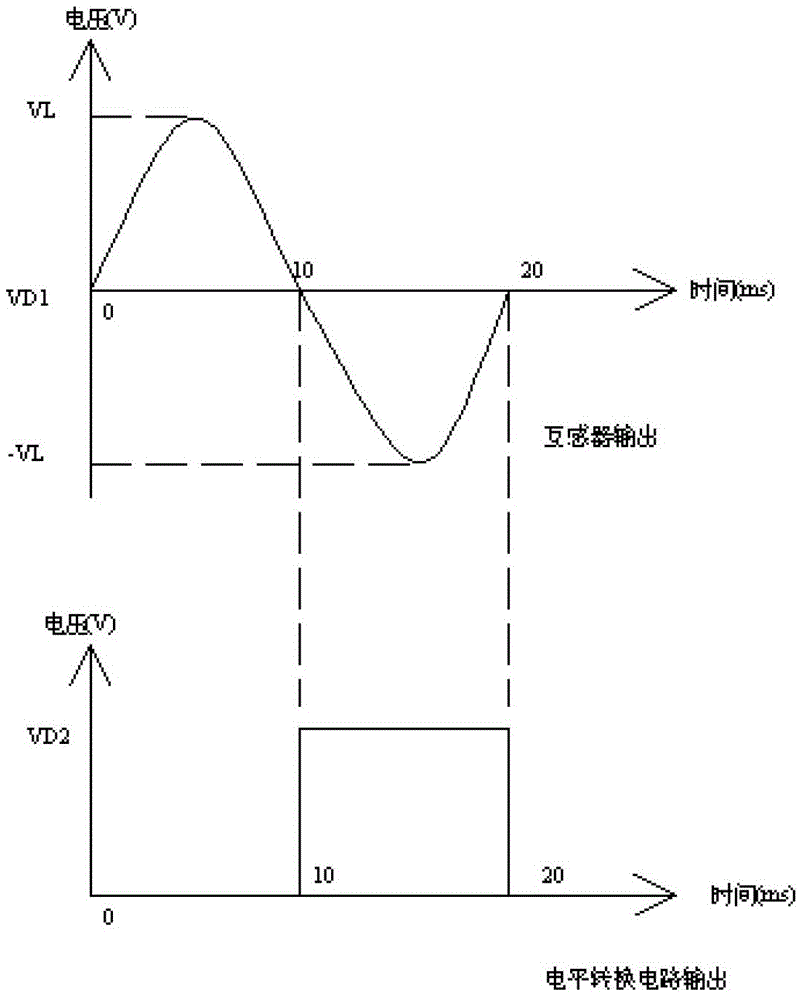

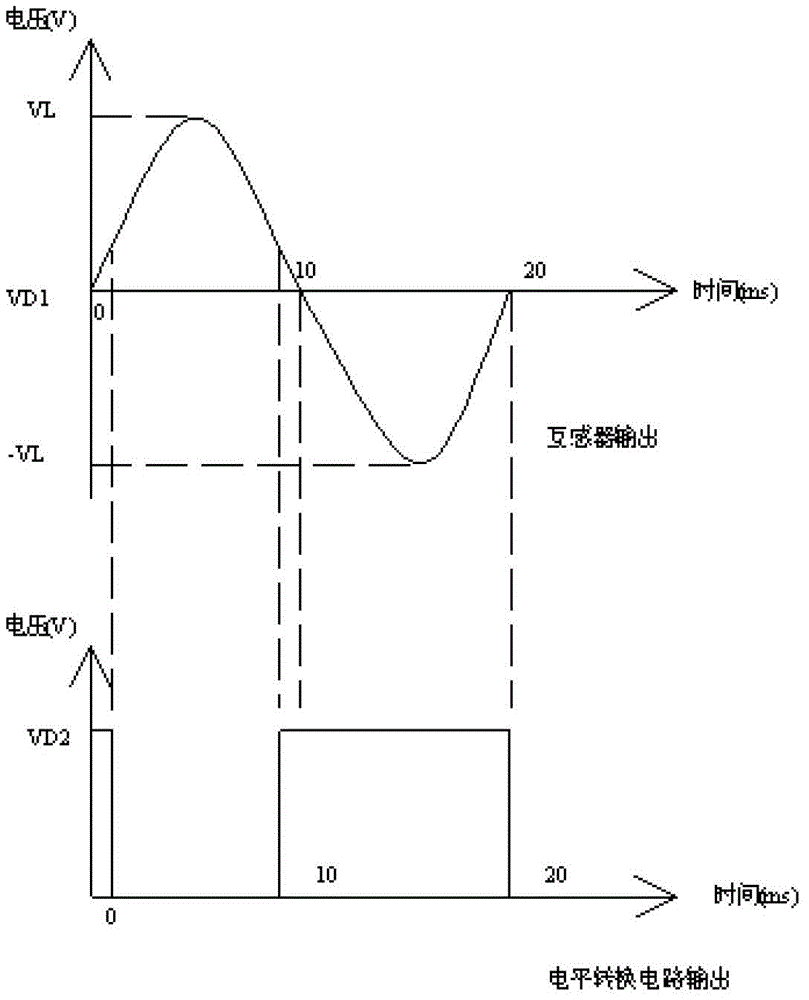

Transformer state detection device and breaker

ActiveCN103308807AImprove securityOvercoming sampling effectsElectrical testingPower flowInternal resistance

The invention discloses a transformer state detection device. The transformer state detection device is characterized in that according to internal distance changes under various working states of transformers, the internal resistance changes are converted into changes of level waveforms by the aid of independent detection circuits and a level conversion circuit, and the current working states of the transformers are judged according to different level waveforms. The invention further discloses a breaker with the transformer state detection device. Compared with the prior art, the transformer state detection device and the breaker have the advantages that disconnection faults of the transformers can be detected, internal resistance changes of the transformers caused by other faults can be detected accurately, and integral system safety can be improved greatly. The independent detection circuits are used, so that influences of transformer state detection on current signal sampling are eliminated, and current measurement precision of the intelligent breaker is improved.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

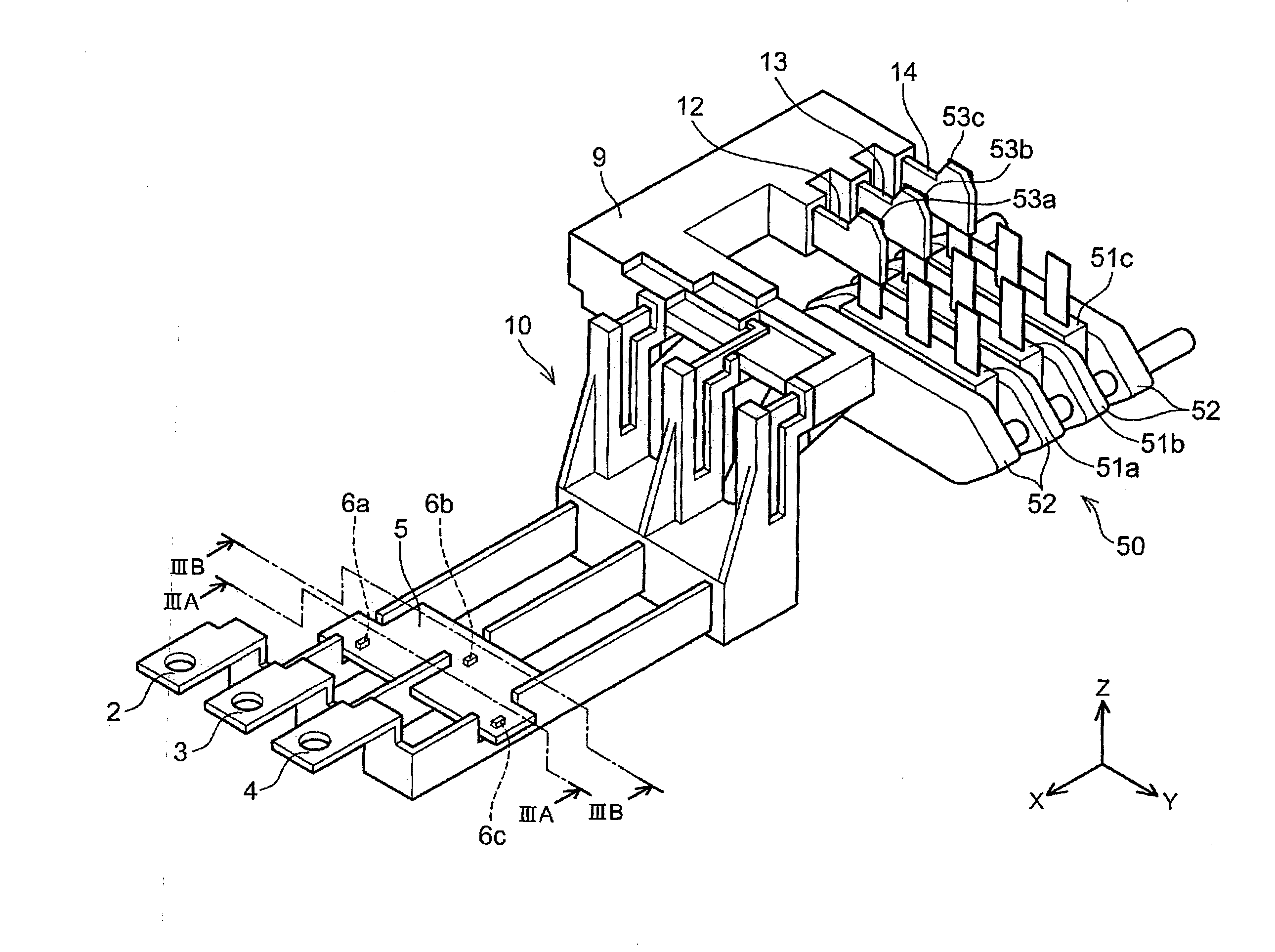

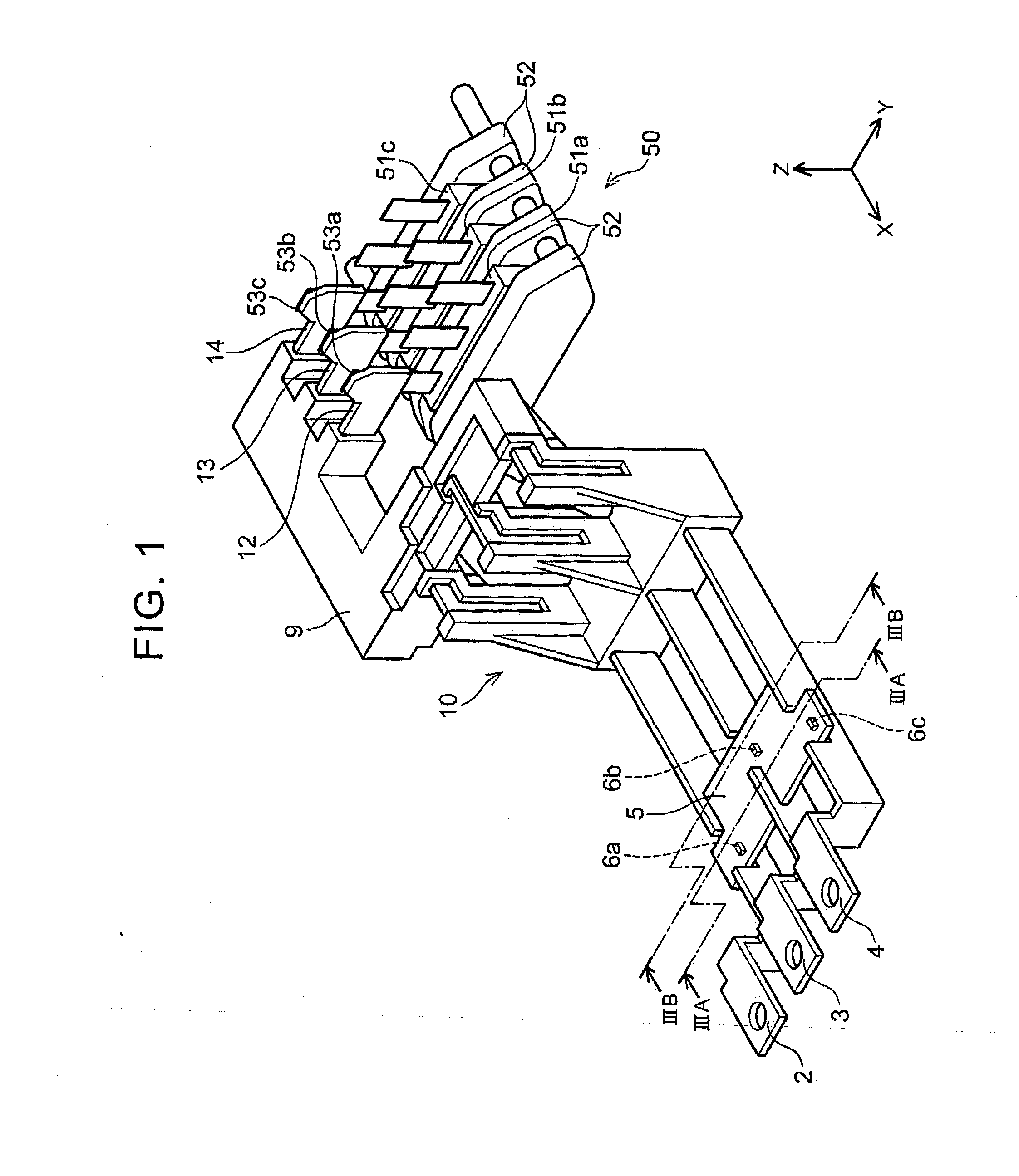

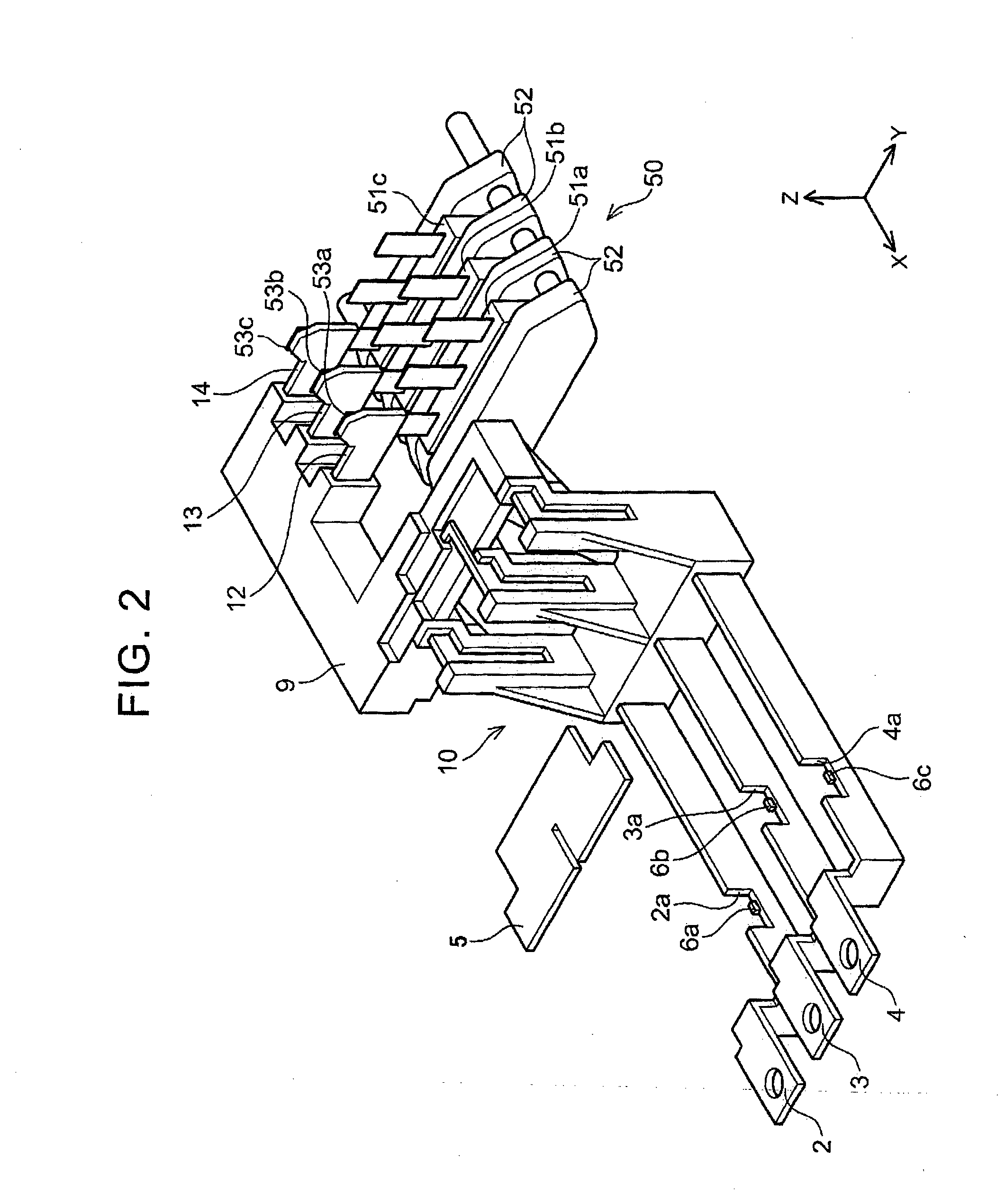

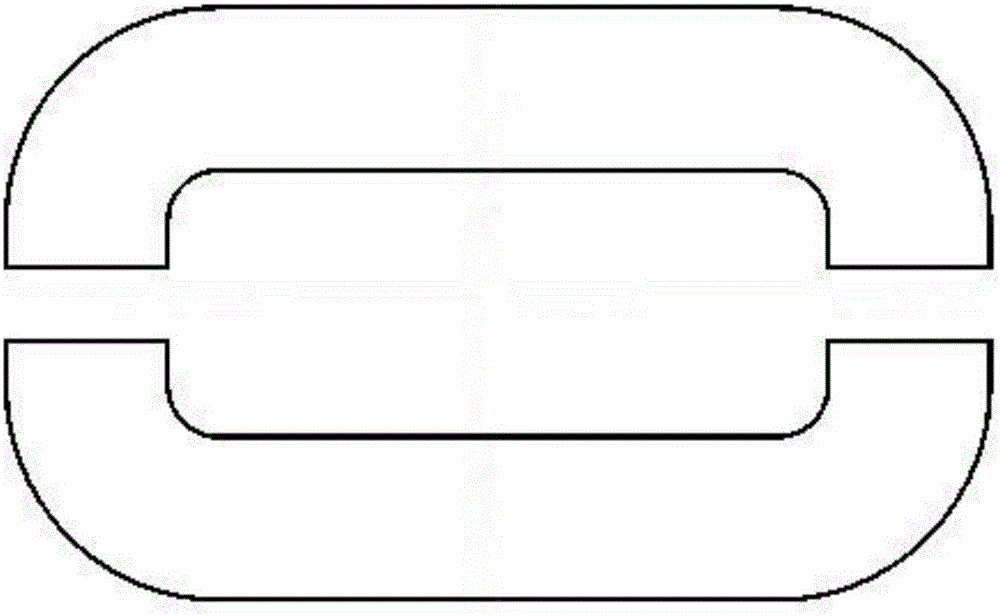

Bus bar module

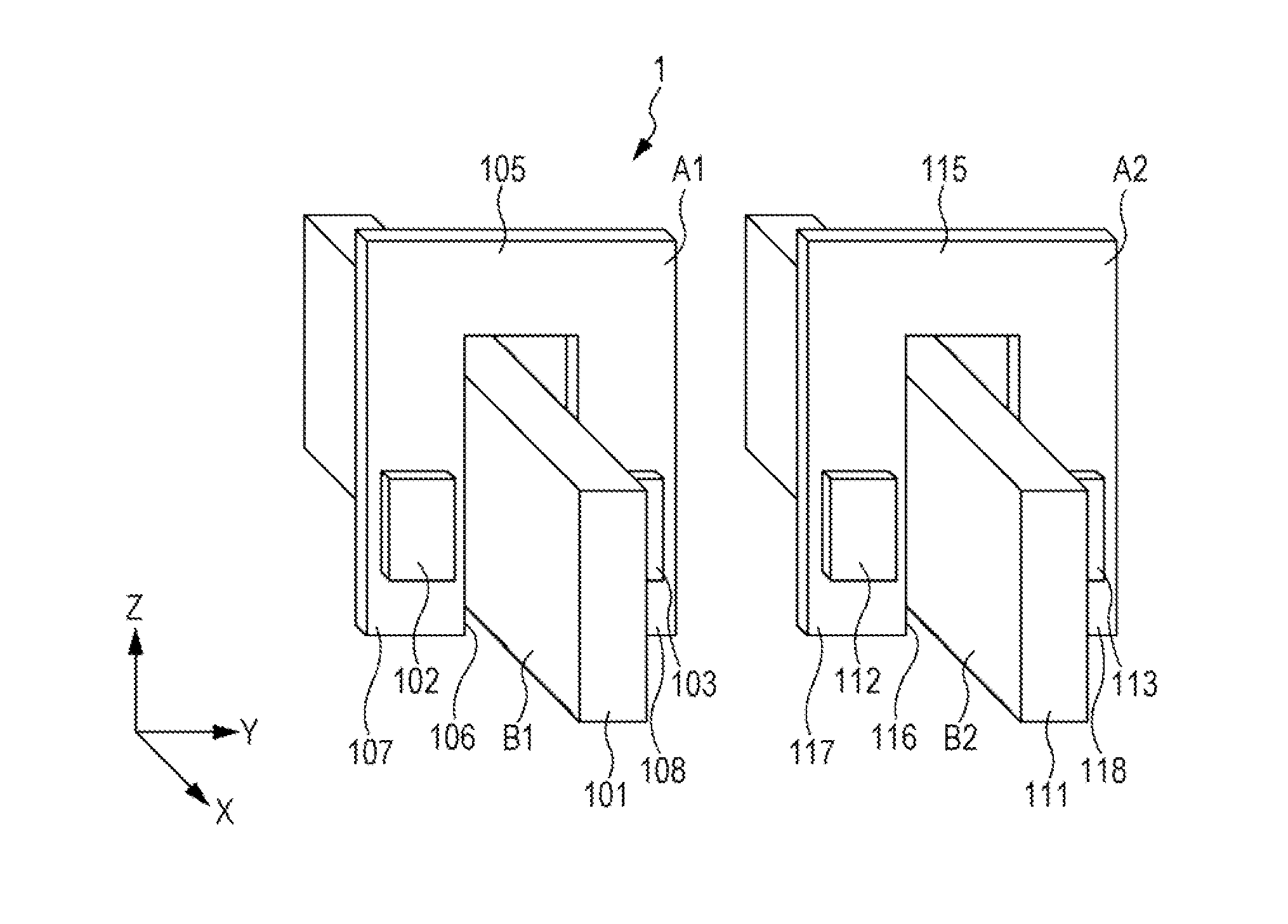

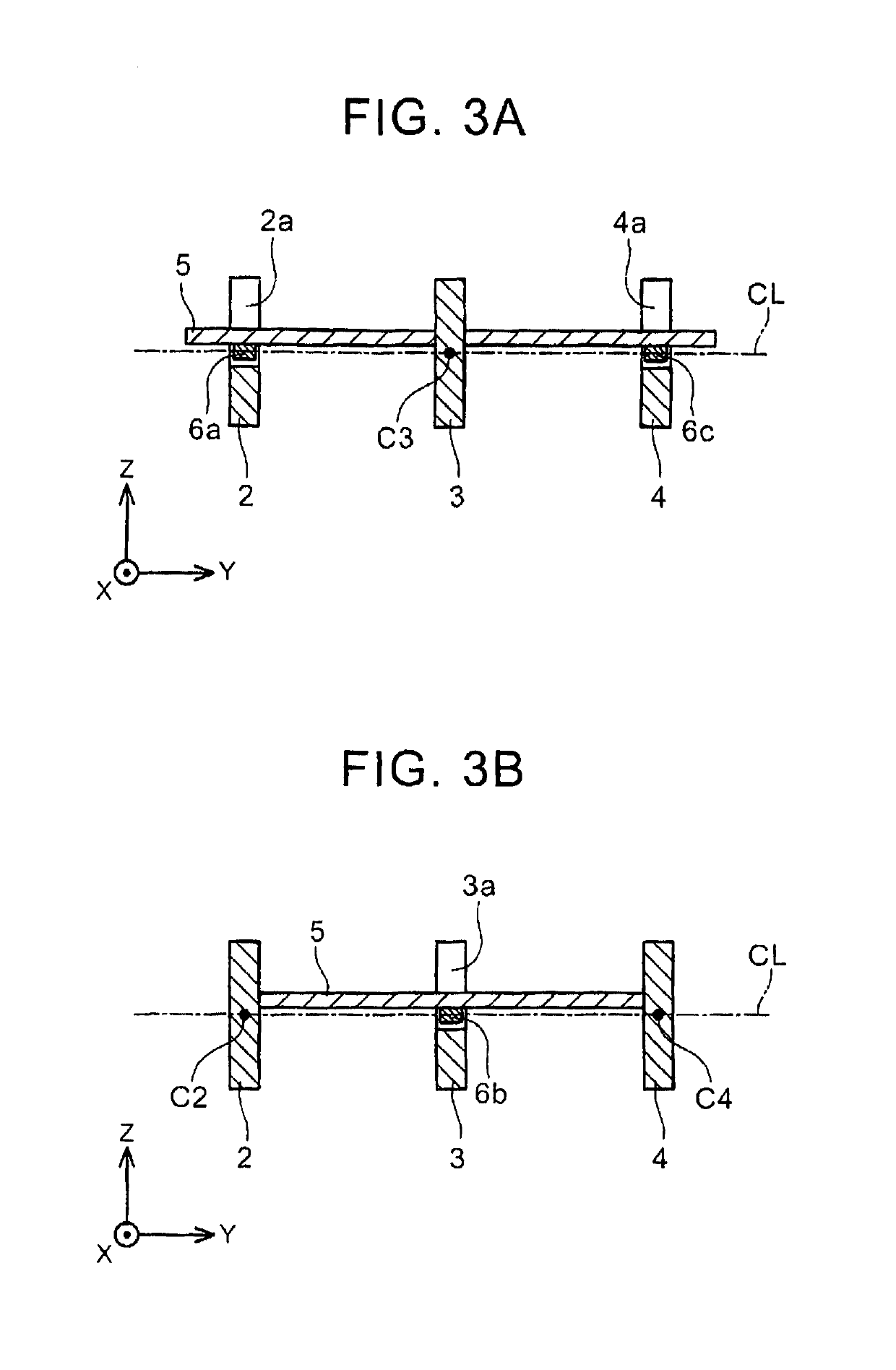

ActiveUS20170003323A1Improve current measurement accuracyImprove accuracyConversion constructional detailsVoltage/current isolationTransducerCurrent sensor

A bus bar module equipped with a current sensor includes a first bus bar, a second bus bar, a substrate, and a first magnetoelectric transducer. The first bus bar has a first notch. The second bus bar has a second notch and is placed in parallel to the first bus bar. The second notch is provided at a position different from the first notch in an extending direction of the first bus bar. The substrate is fitted to both the first notch and the second notch. Further, the substrate is sandwiched between those side surfaces of the first bus bar and the second bus bar which are opposed to each other. The first magnetoelectric transducer is placed inside the first notch and fixed to the substrate.

Owner:DENSO CORP

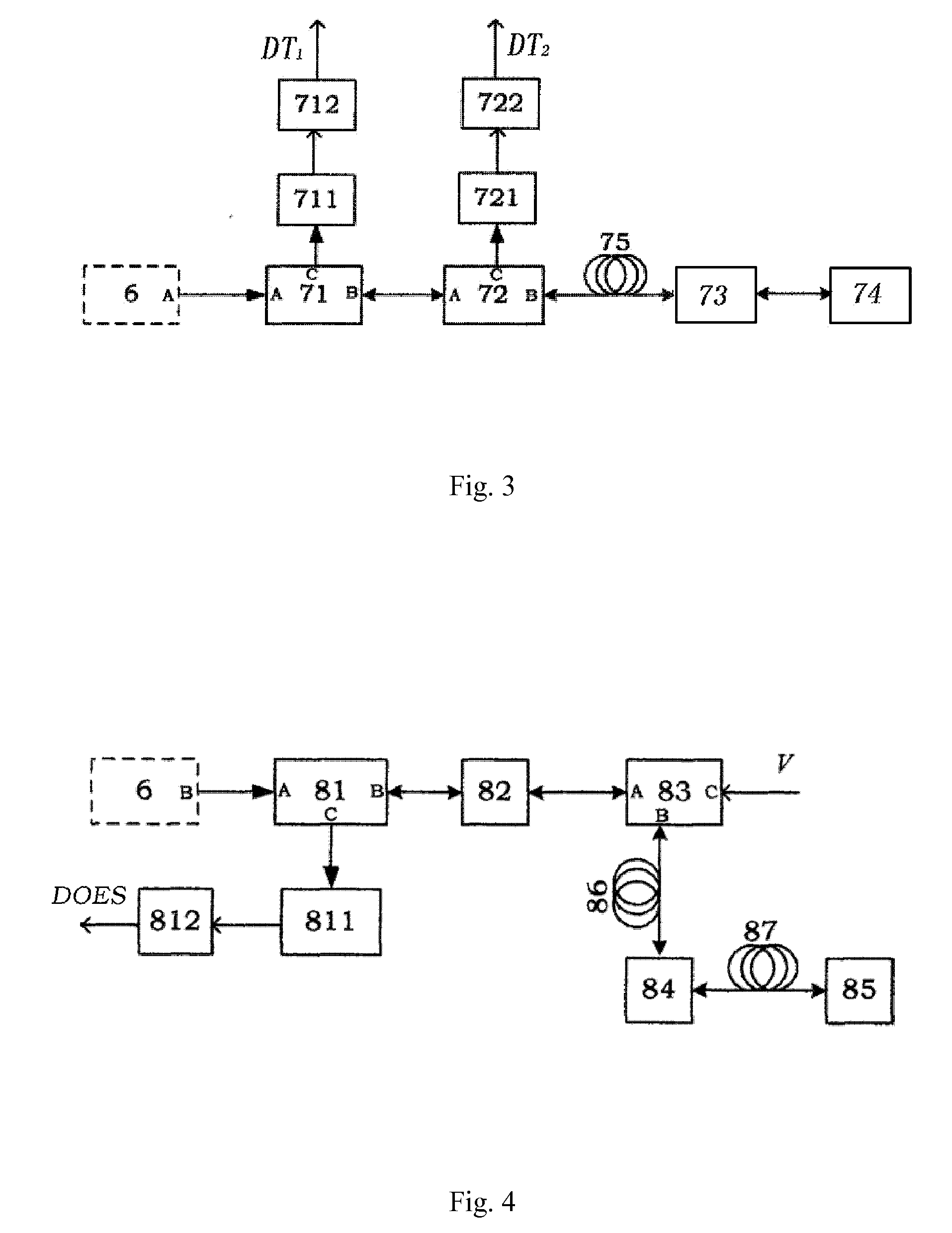

Optical fiber current transformer with optical fiber temperature acquisition and temperature compensation

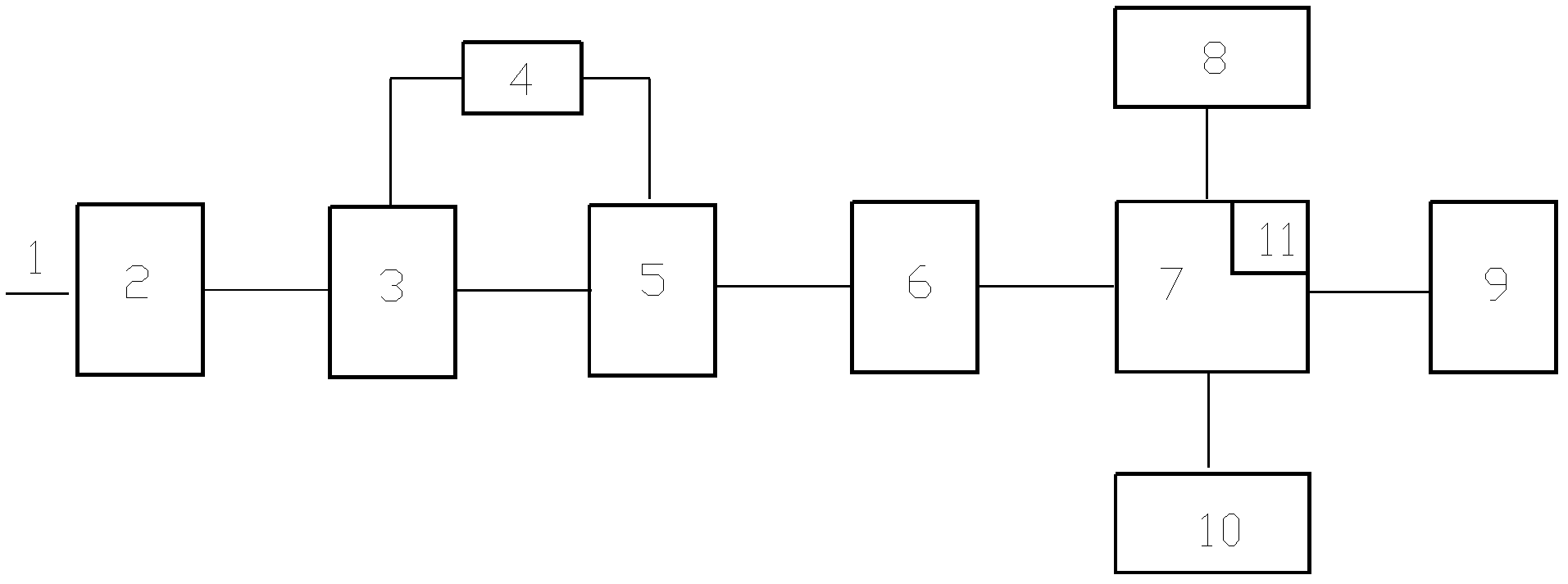

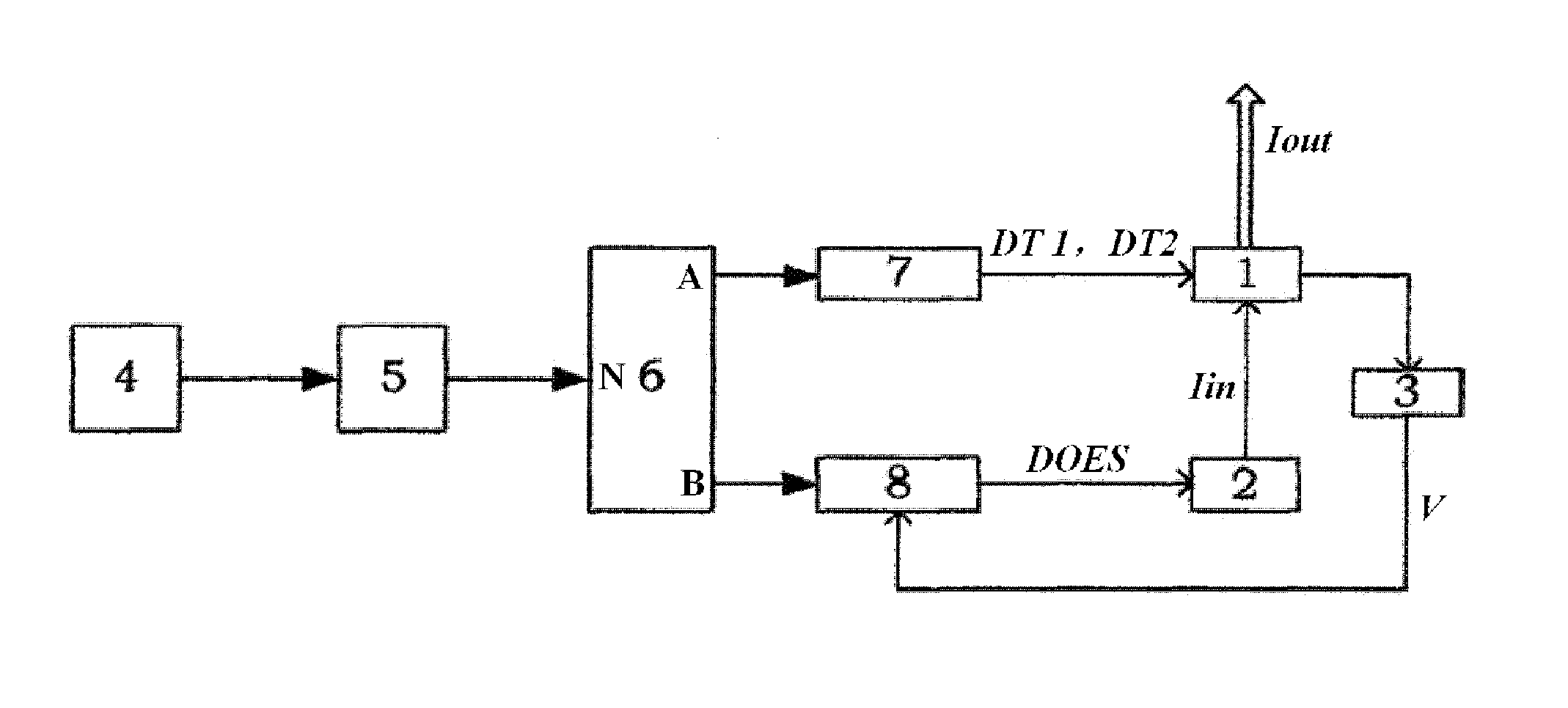

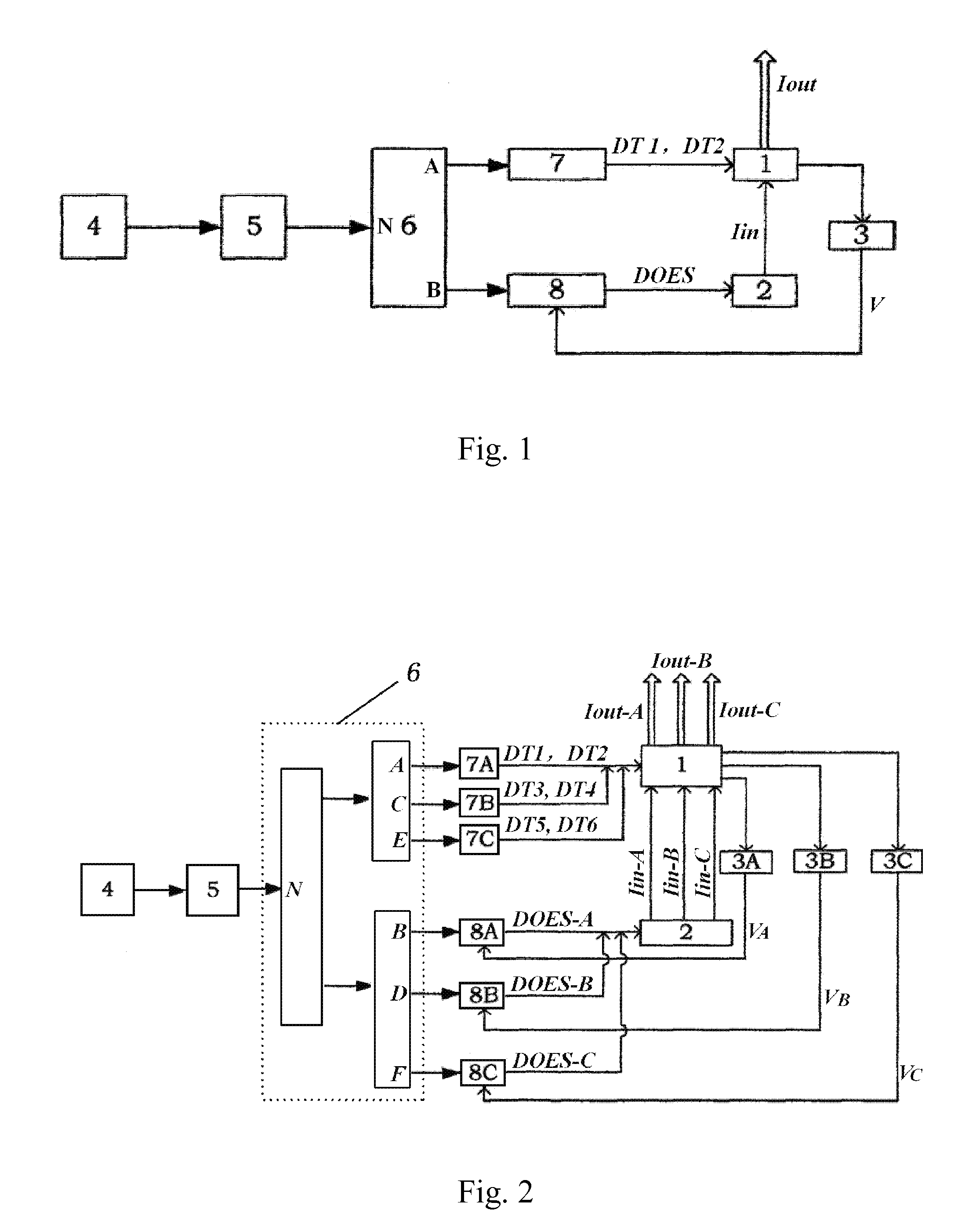

ActiveUS20110060544A1Improve current measurement accuracyImprove accuracyCurrent/voltage measurementThermometers using physical/chemical changesBeam splitterLight source

An optical fiber current transformer includes a broadband light source, a depolarizer, a beam splitter, a temperature acquisition unit, a current acquisition unit, a modulation waveform generating unit, a data processing unit and a calculating compensation unit. The broadband light source is connected with the beam splitter by the depolarizer. A first output of the beam splitter is connected with the calculating compensation unit by the temperature acquisition unit. A second output of the beam splitter is connected with the data processing unit by the current acquisition unit. The data processing unit is connected with the calculating compensation unit. The calculating compensation unit is connected with the current acquisition unit by the modulation waveform generating unit. The optical fiber current transformer uses the temperature-current compensation curve in the calculating compensation unit to synchronously process the temperature and current, thereby improving the accuracy of real-time current measurement.

Owner:BEIJING QIRED ELECTRO OPTIC TECH LIMITED

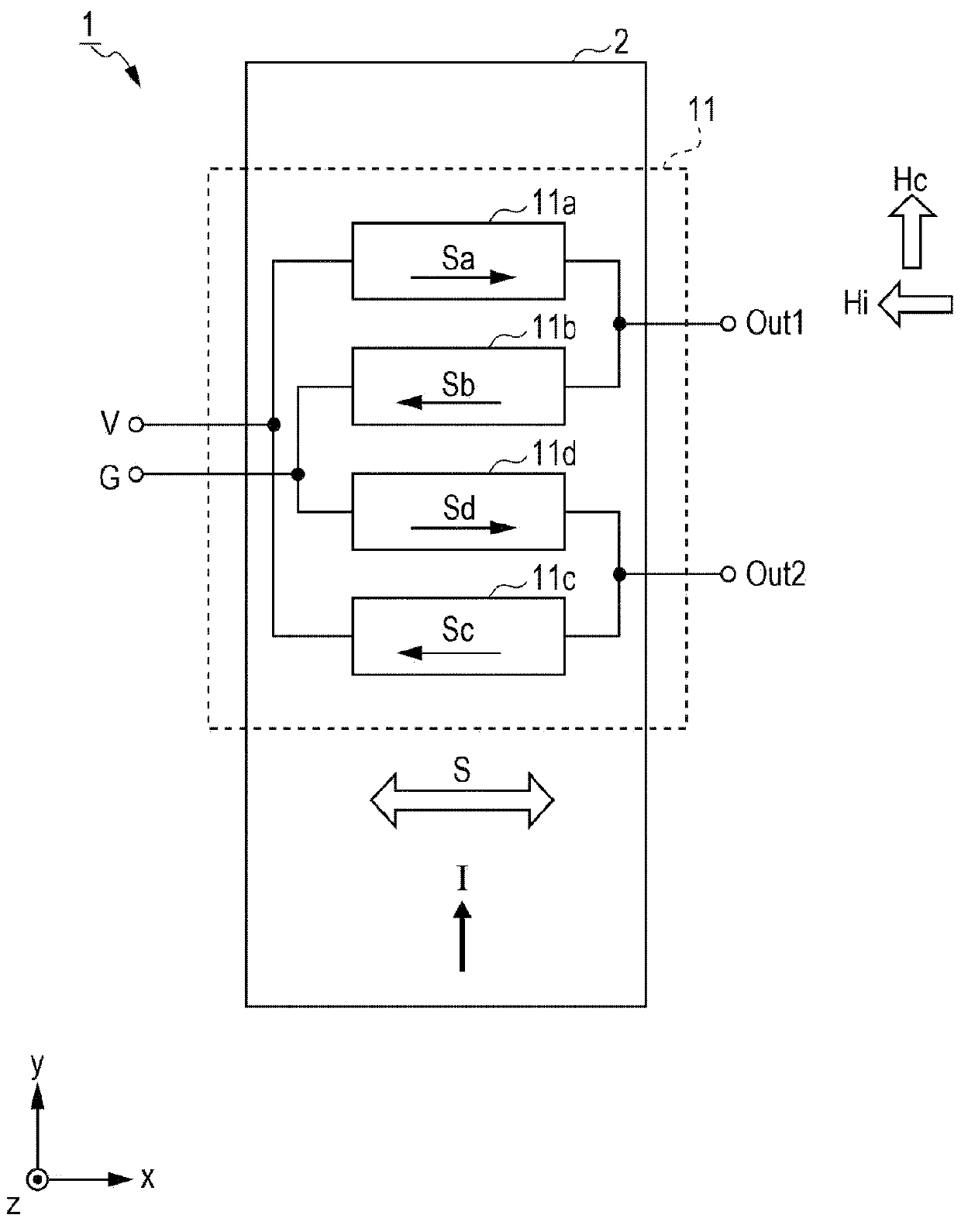

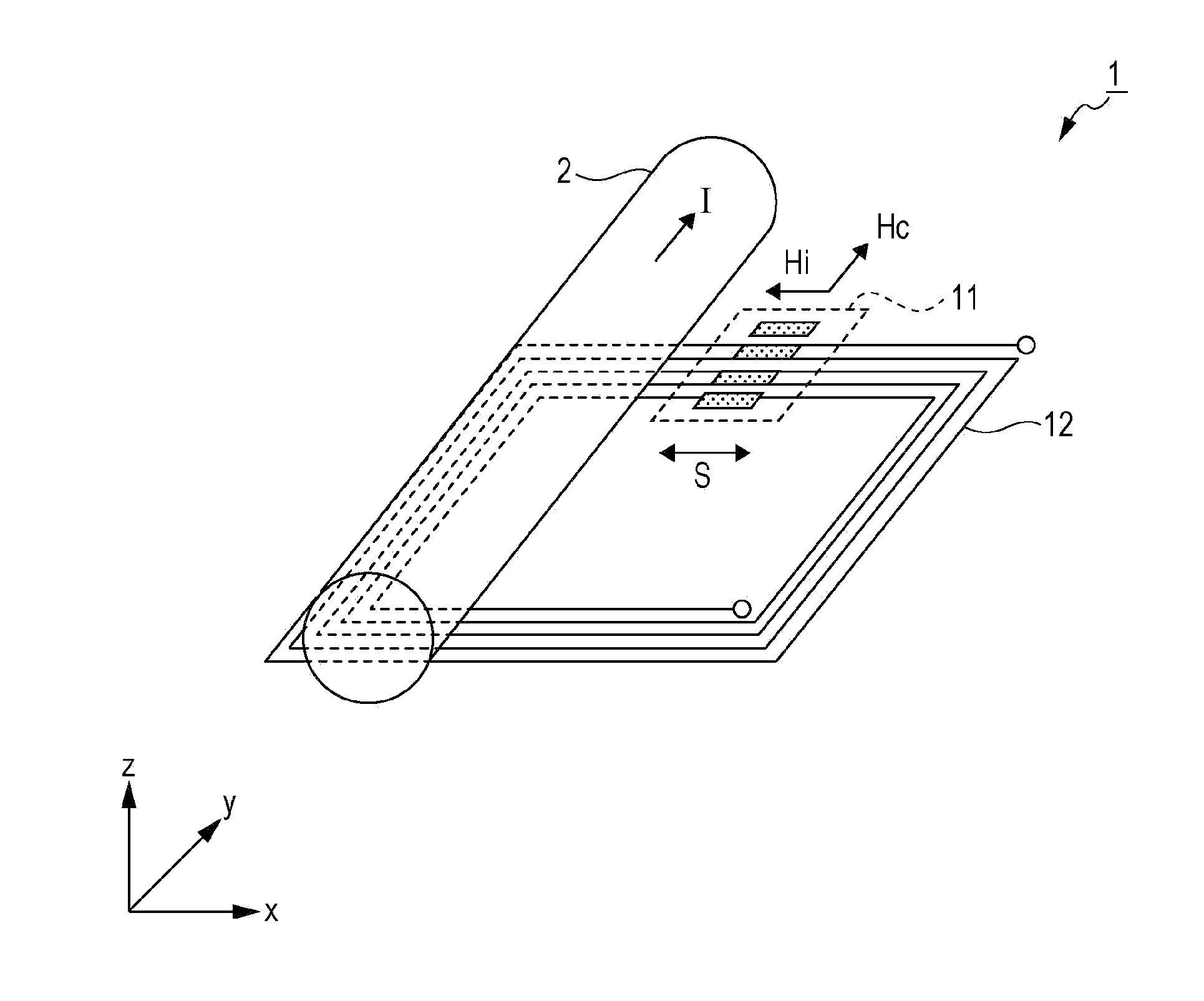

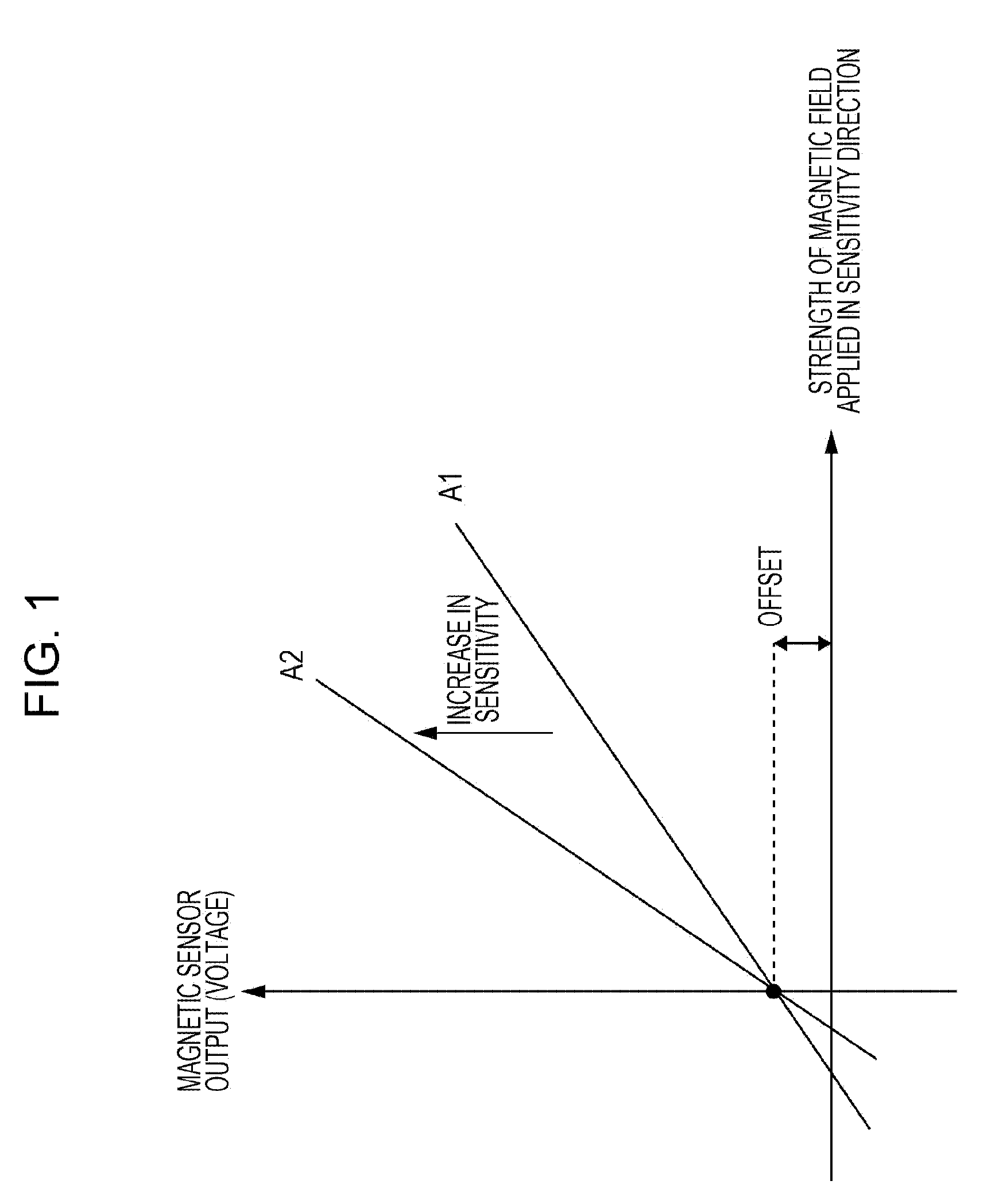

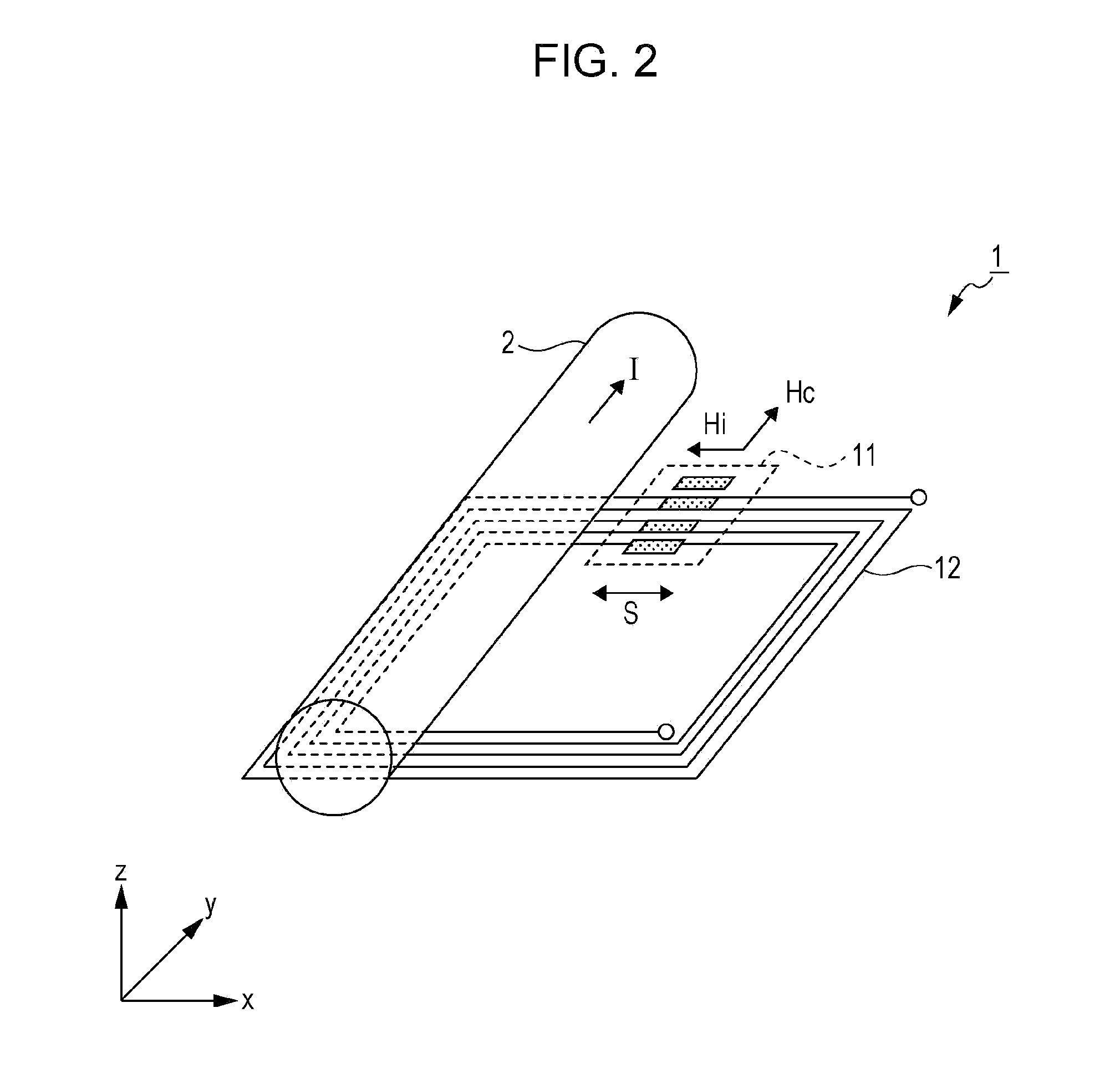

Current sensor

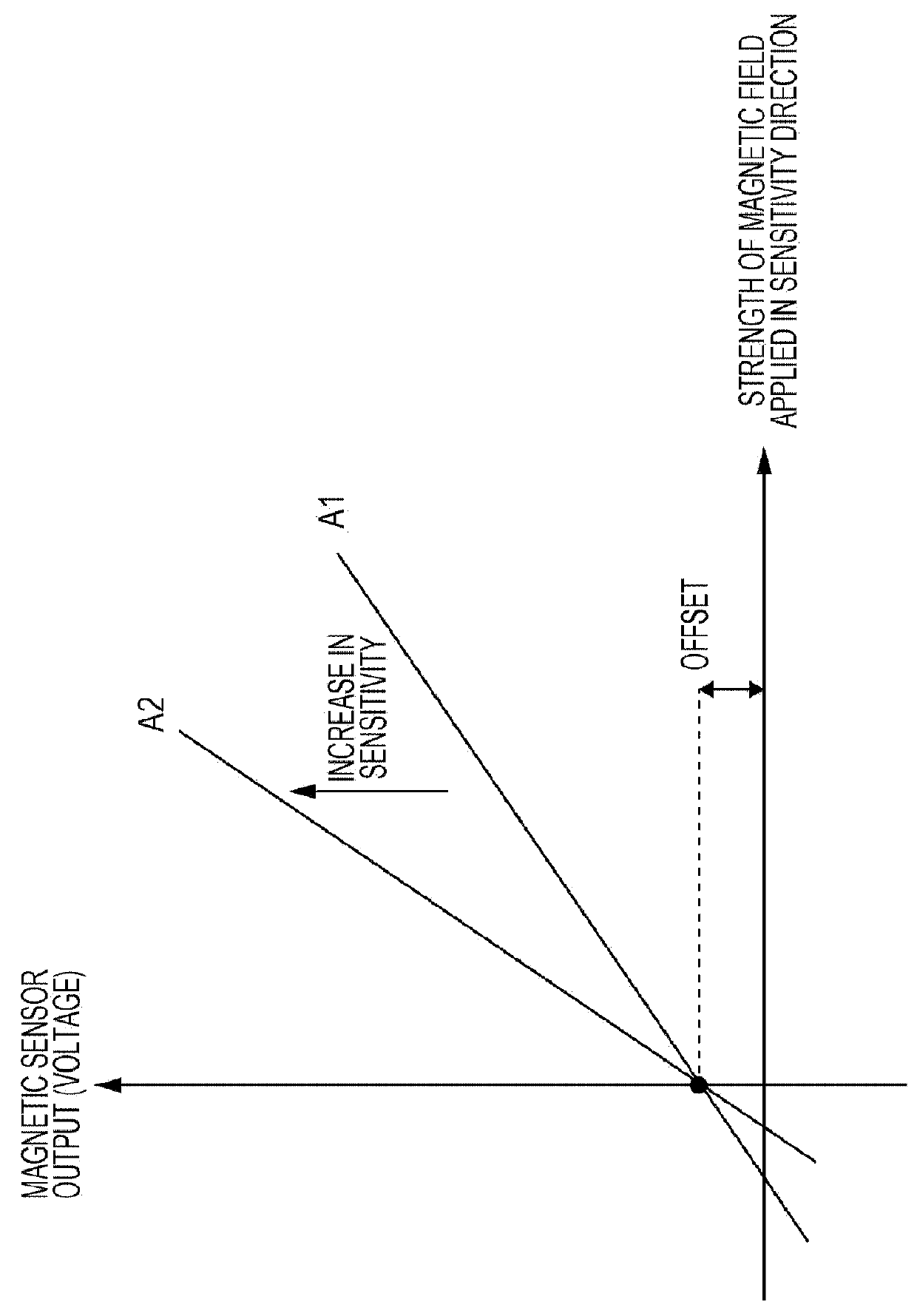

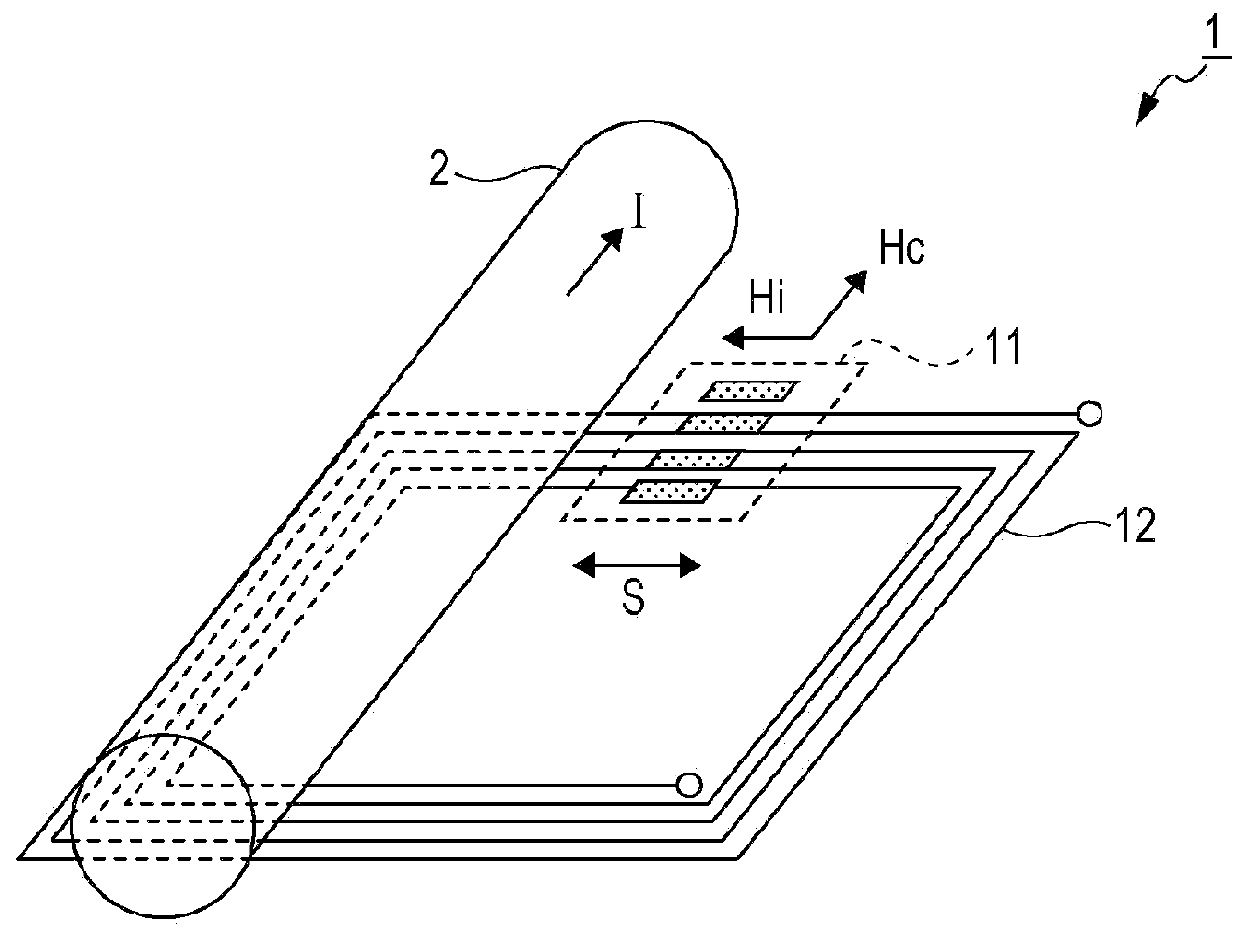

InactiveUS20130082698A1Precise managementImprove current measurement accuracyTesting electric installations on transportMagnitude/direction of magnetic fieldsInduction fieldCurrent sensor

A current sensor includes a magnetic sensor including magnetoresistive sensors configured to detect induction fields generated by a measurement current passing through a current line, a magnetic field application unit configured to apply to the magnetoresistive sensors a magnetic field having a direction perpendicular to sensitivity directions of the magnetoresistive sensors; and a computing unit configured to calculate from an output of the magnetic sensor a compensation value for the output. The computing unit is configured to be capable of calculating the compensation value from the outputs of the magnetic sensor obtained in at least two states in which magnetic fields applied by the magnetic field application unit are different from each other.

Owner:ALPS ALPINE CO LTD

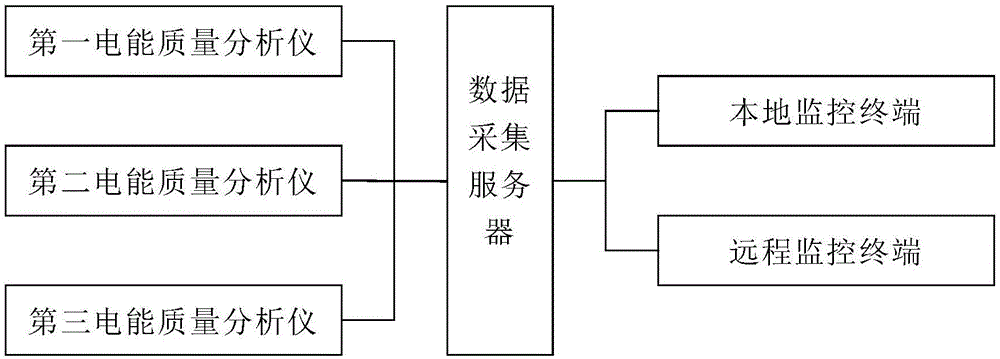

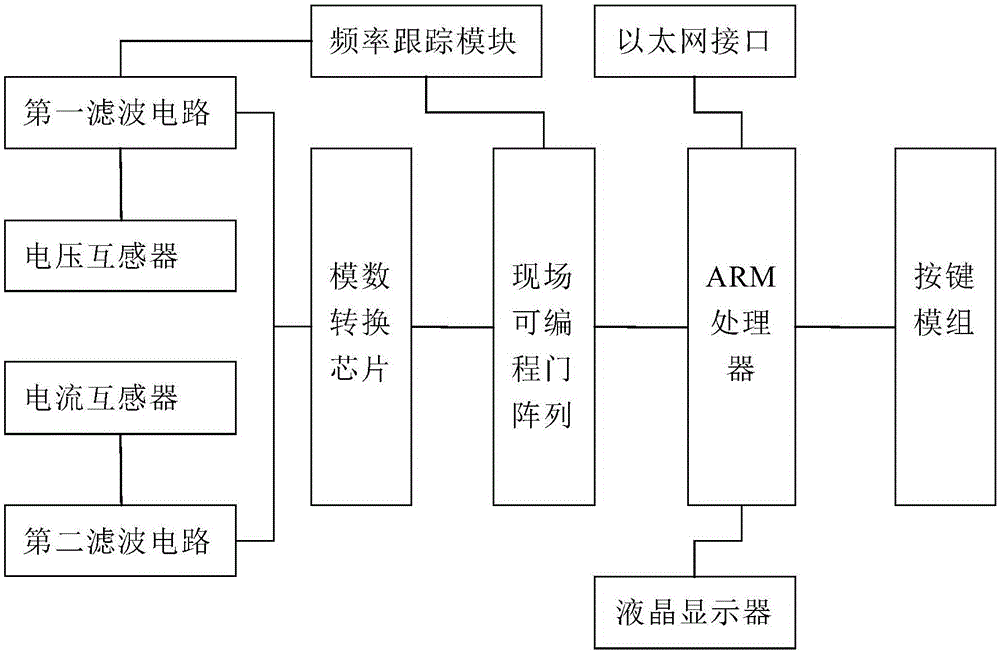

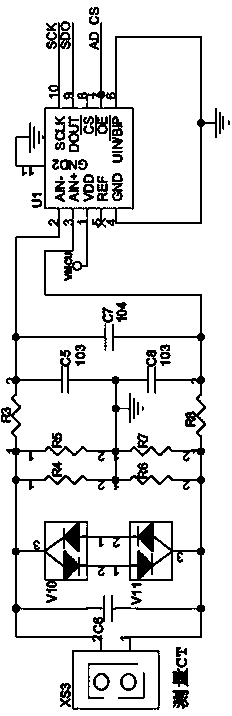

Online electric energy quality monitoring system based on ARM and FPGA

InactiveCN106707075AOvercome the defects of slow tracking speed and low multiplierImprove work efficiencyElectrical testingFrequency analysisPower qualityDigital conversion

The invention belongs to the technical field of electric energy quality analysis and discloses an online electric energy quality monitoring system based on an ARM and an FPGA. The online electric energy quality monitoring system comprises an electric energy quality analysis meter, a data collection server, a local monitoring terminal and a remote monitor terminal, wherein the electric energy quality analysis meter is connected with the data collection server, and the local monitoring terminal and the remote monitor terminal are respectively connected with the data collection server; the electric energy quality analysis meter comprises a voltage measurement structure, a first filter circuit, a current measurement structure, a second filter circuit, a frequency tracking module, an analog-digital conversion chip, an FPGA chip and an ARM processor; the voltage measurement structure is connected with the analog-digital conversion chip through the first filter circuit; the current measurement structure is connected with the analog-digital conversion chip through the second filter circuit; the analog-digital conversion chip is connected with the FPGA chip; the first filter module is connected with the FPGA chip through the frequency tracking module; and the FPGA chip is connected with the ARM processor.

Owner:QINGDAO HIGH TECH COMM

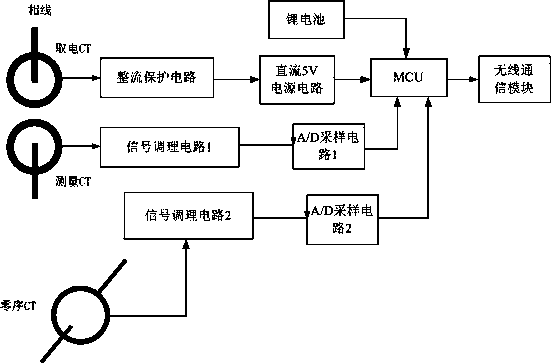

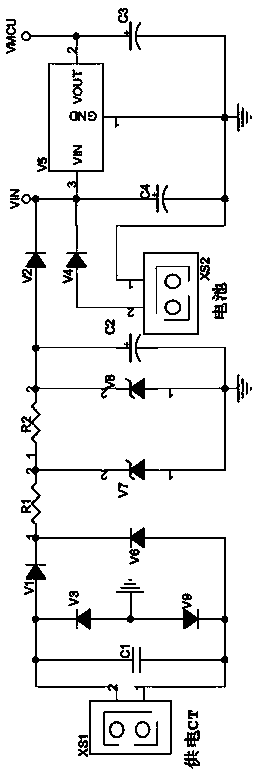

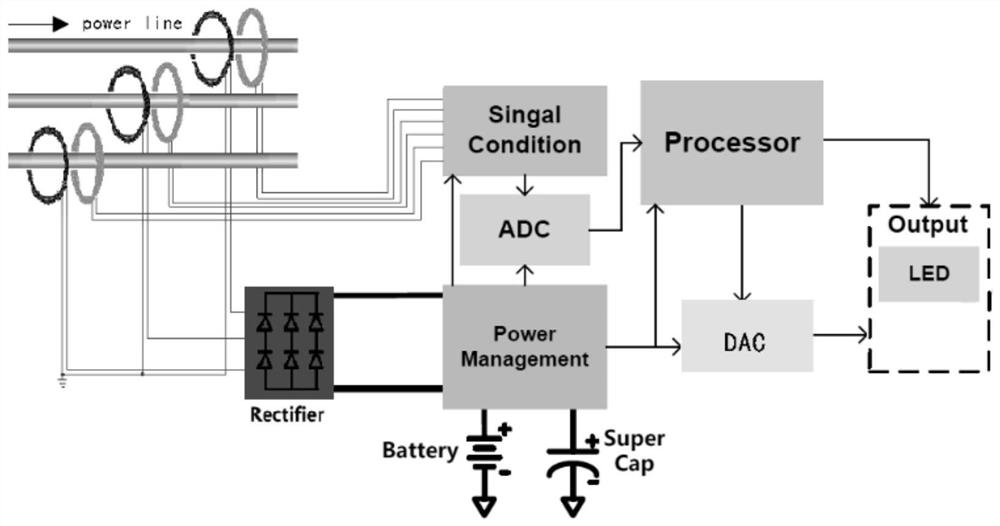

Cable type fault detector

InactiveCN103472356AImprove current measurement accuracyHigh measurement accuracyFault locationPhase currentsEngineering

The invention discloses a cable type fault detector. The cable type fault detector comprises a short-circuit fault indicator and a zero-sequence current mutual inductor. The short-circuit fault indicator comprises a power-taking current mutual inductor, a measuring current mutual inductor, a CT (Captive Test) power supply circuit, a phase current measuring circuit, a wireless communication module, an MCU (Microprogrammed Control Unit) and a zero-sequence current measuring circuit, wherein the power-taking current mutual inductor is connected with the power supply end of the MCU by virtue of the CT power supply circuit; the measuring current mutual inductor is connected with an I / O (Input / Output) port of the MCU by virtue of the phase current measuring circuit, and used for transmitting a detected phase current transmitting signal to the MCU; the zero-sequence current mutual inductor is connected with the A / D (Analog to Digital) sampling port of the MCU by virtue of the zero-sequence current measuring circuit, and used for transmitting a detected current transmitting signal to the MCU; the serial interface of the wireless communication module is connected with the I / O port of the MCU by virtue of an SPI (Single Program Initiation) bus. The cable type fault detector disclosed by the invention adopts a structural form with a plurality of current mutual inductors to carry out short-circuit and grounding fault detection, thereby effectively improving the current measuring precision and lowering the equipment start-up current.

Owner:WILLFAR INFORMATION TECH CO LTD

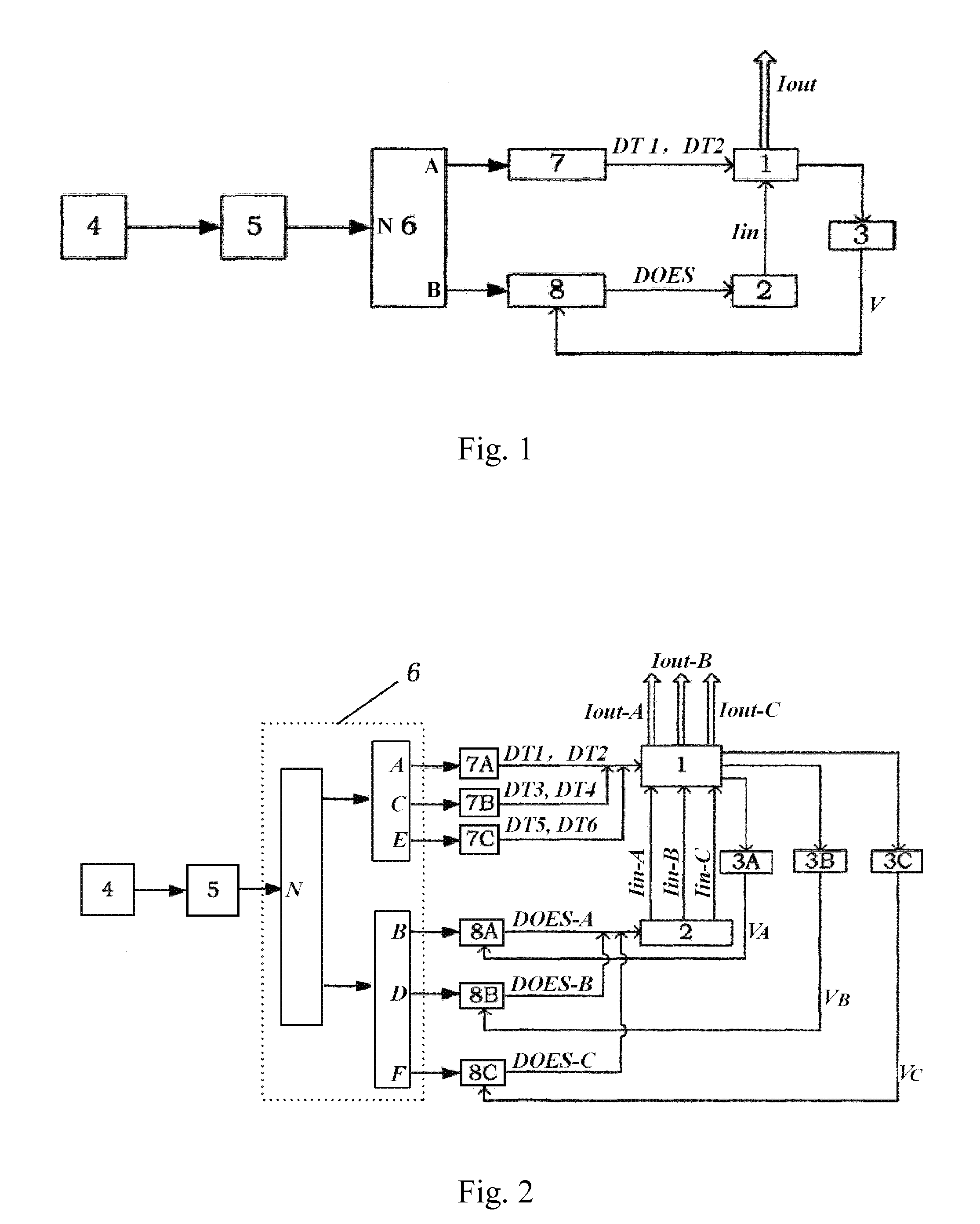

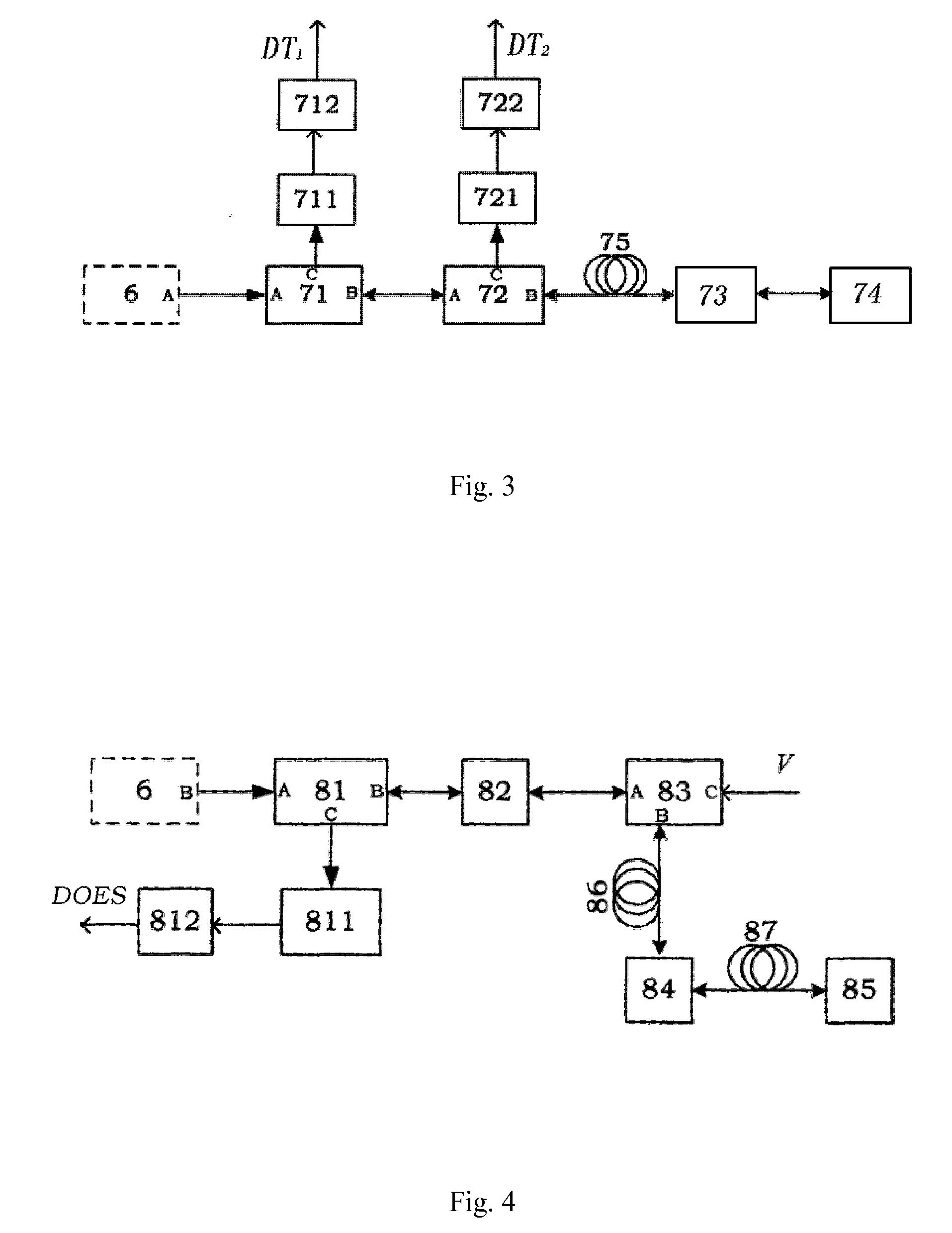

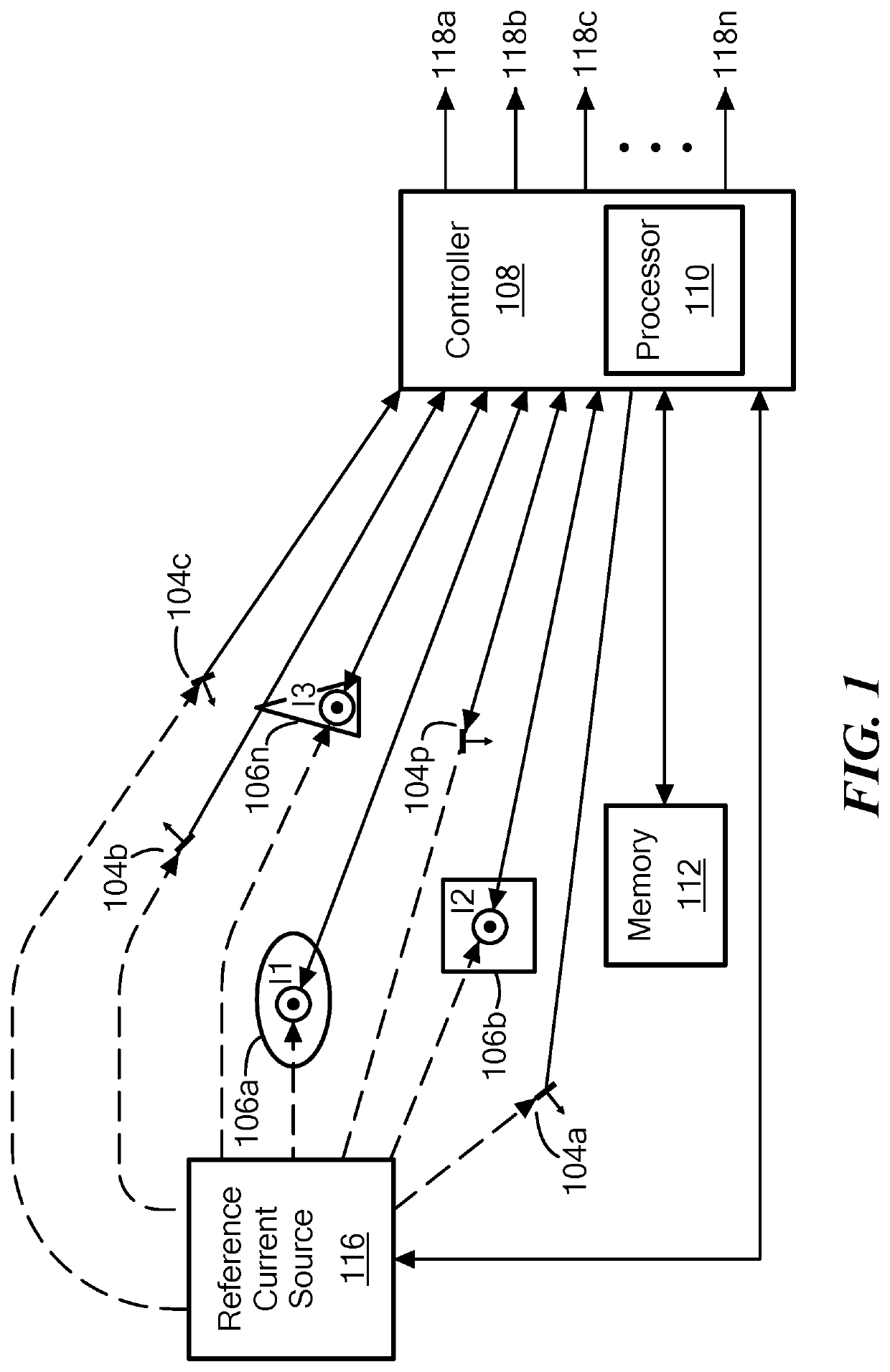

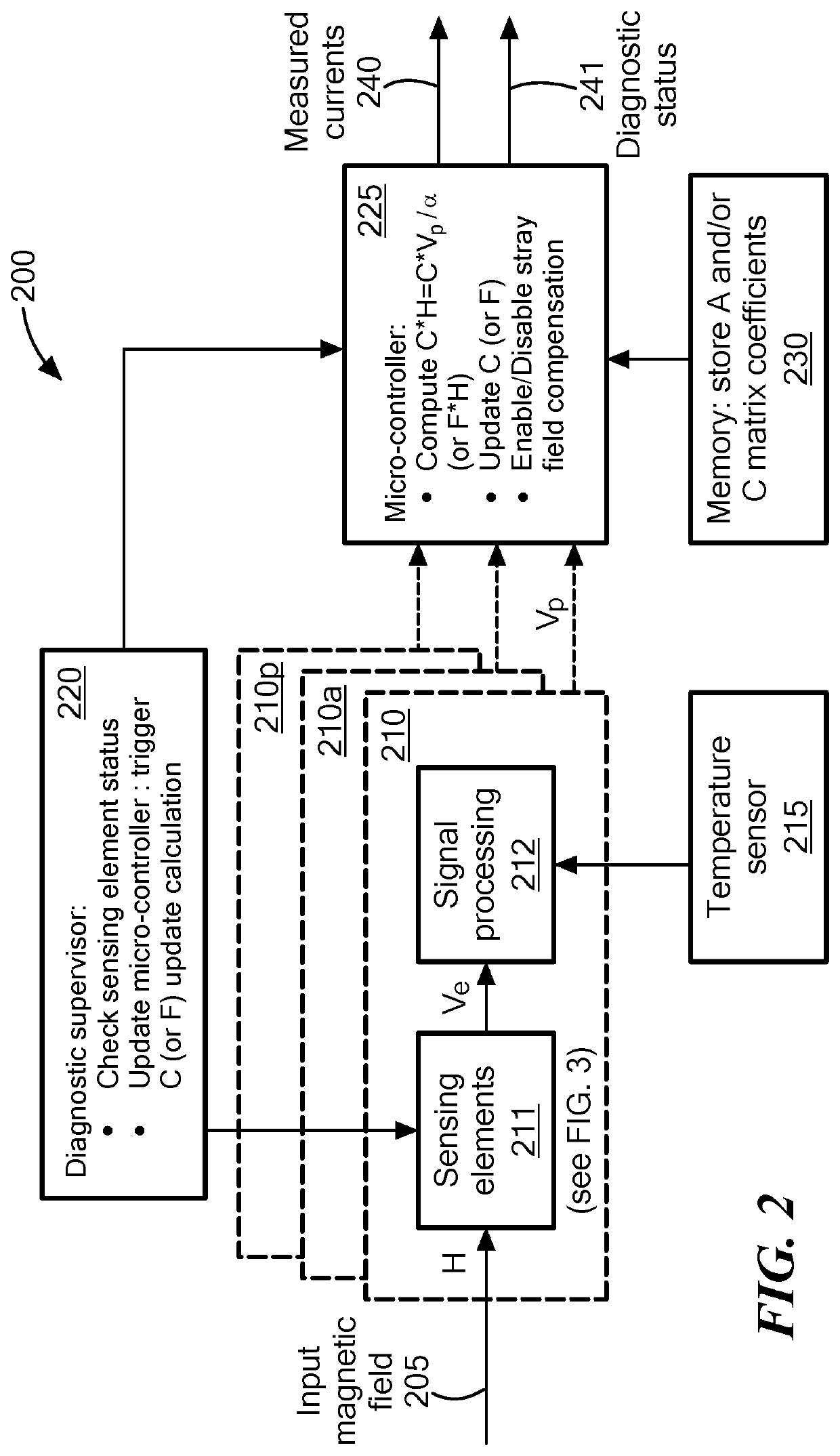

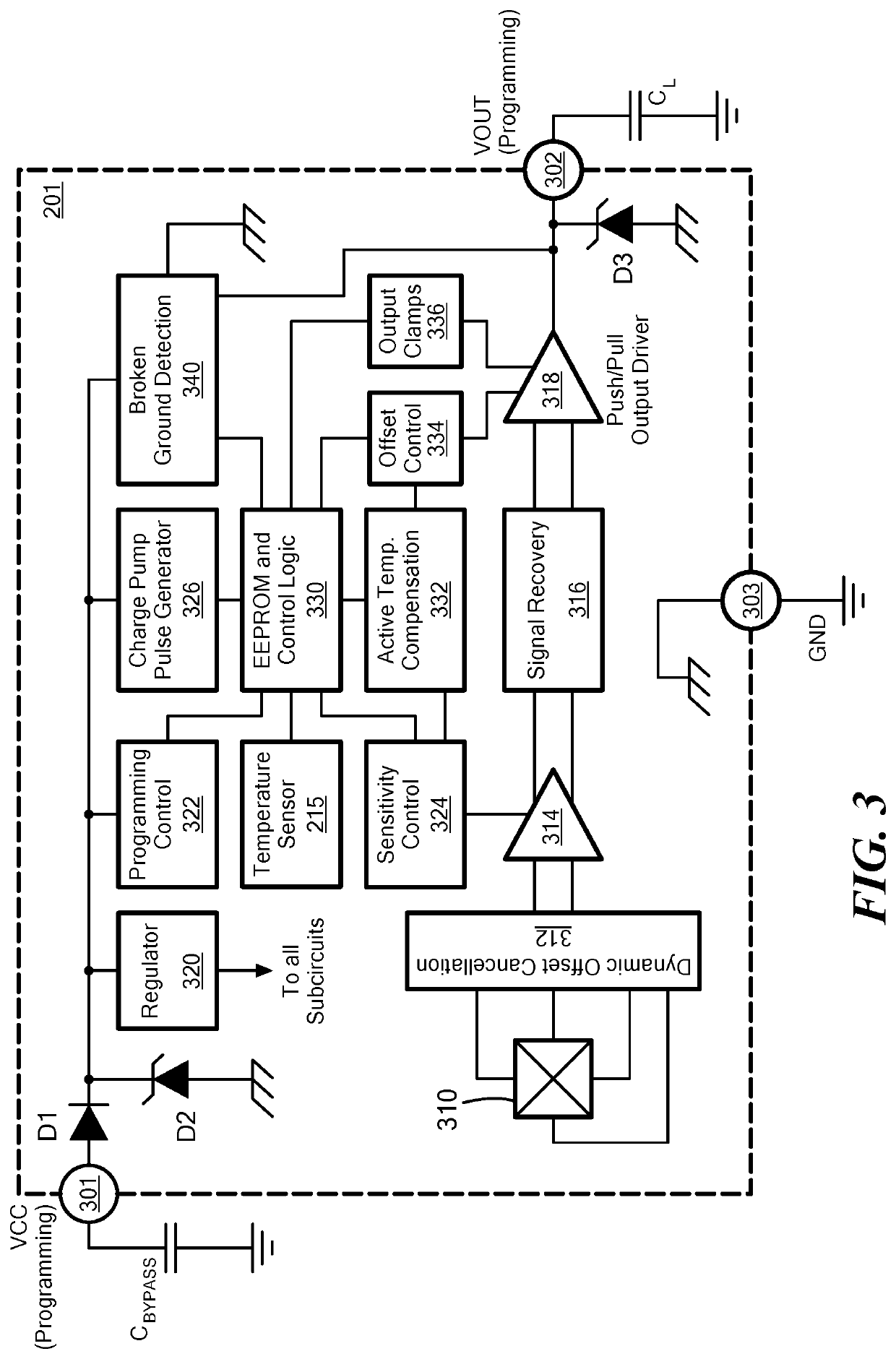

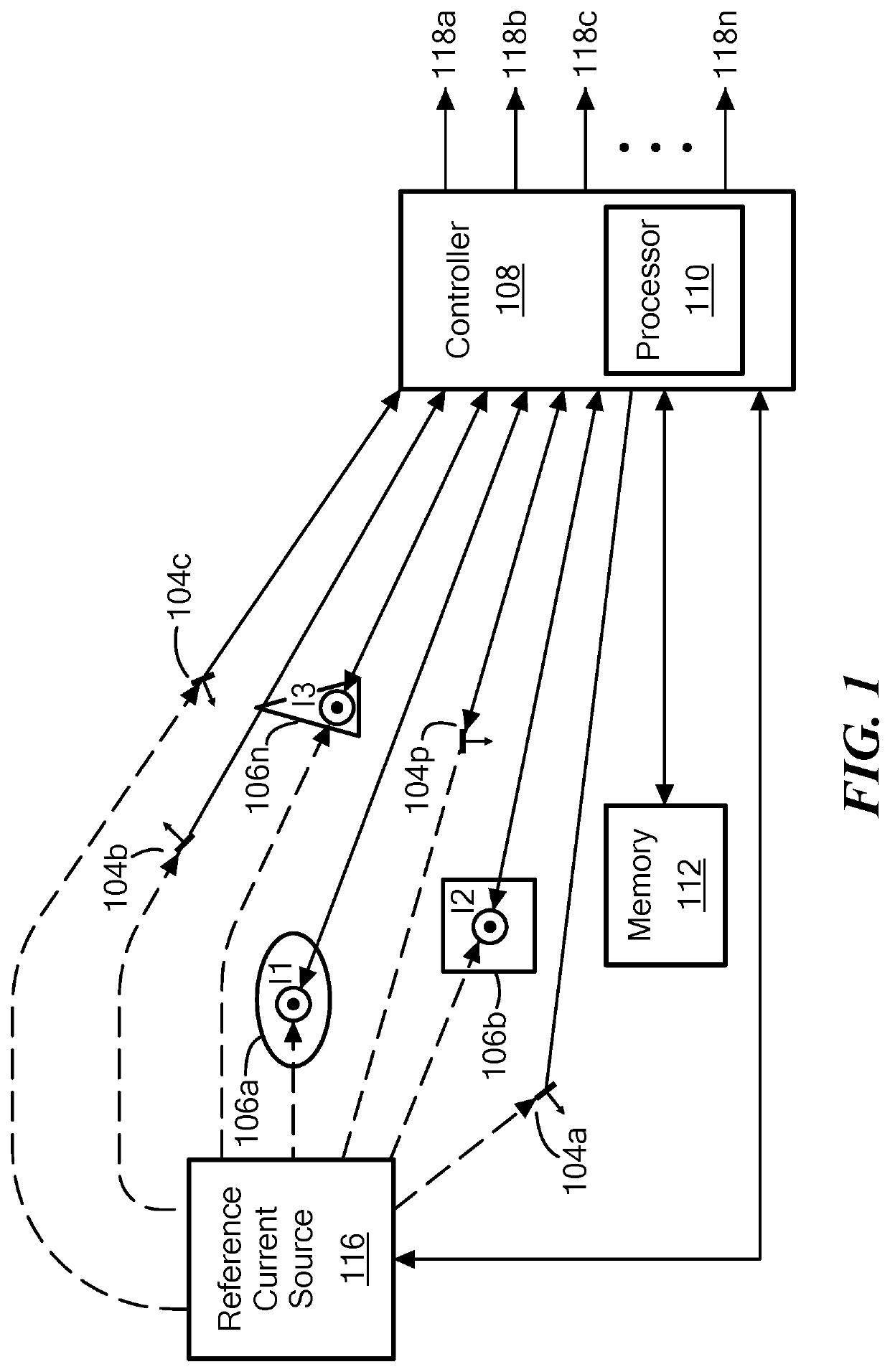

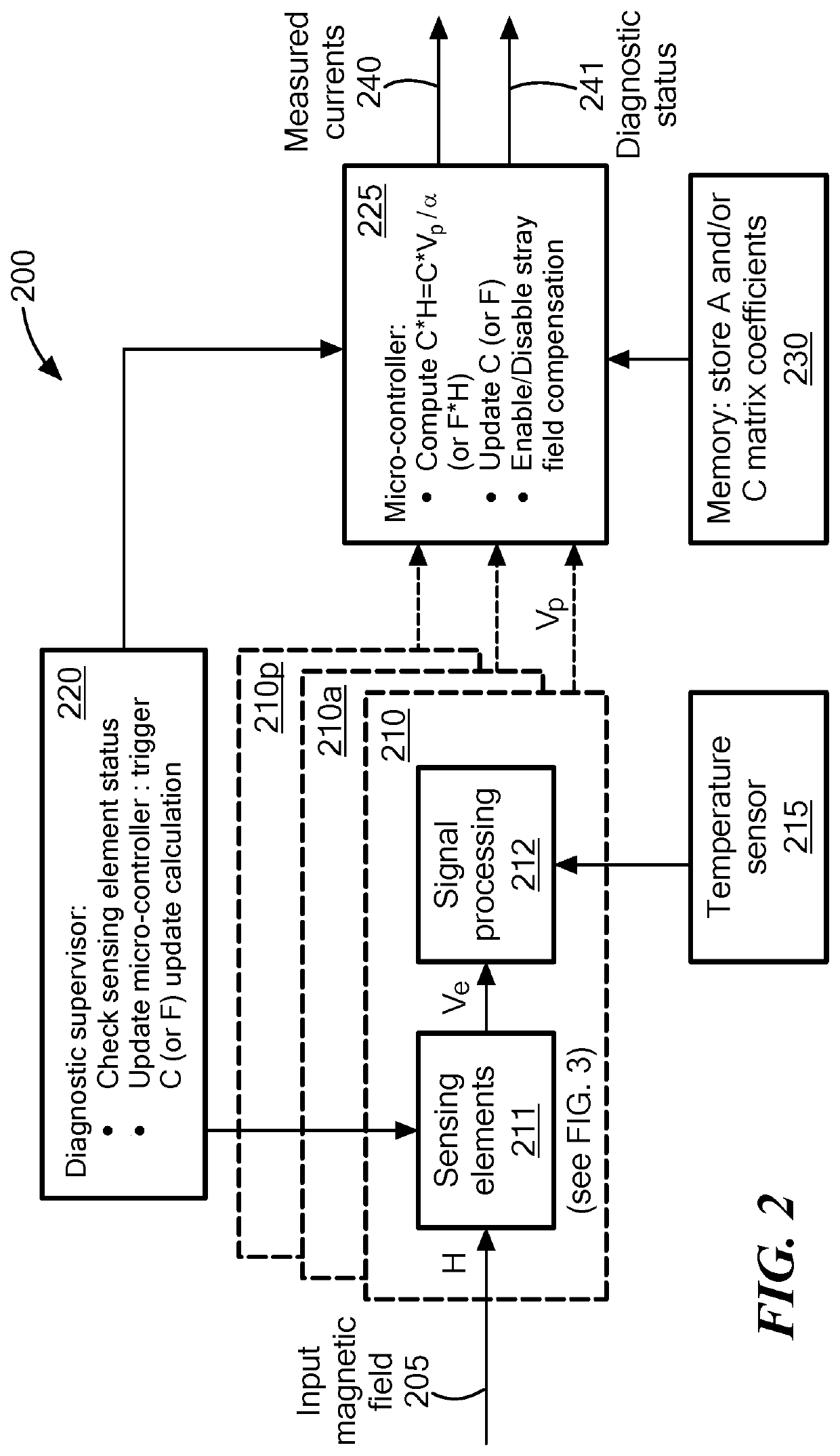

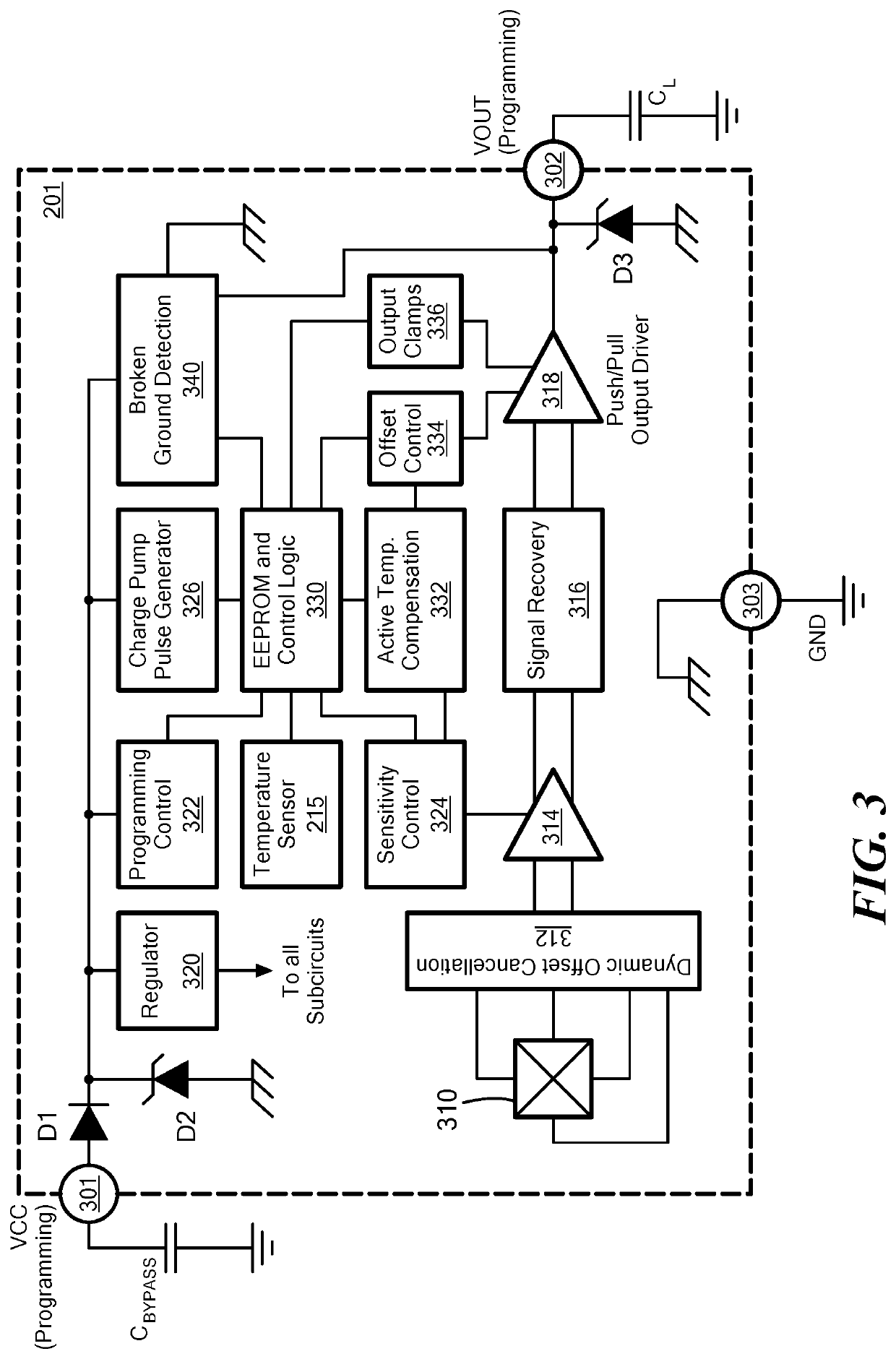

Current Sensor System

ActiveUS20200057097A1Reduce impactIncrease redundancyVoltage/current isolationStray field compensationCurrent transducerElectrical conductor

Apparatus and methods provide a current sensor system including a plurality of current sensors positioned proximate a plurality of conductors. Each conductor is configured to carry a current to be measured. Each current sensor comprises one or more magnetic field sensing elements configured to generate a respective magnetic field signal indicative of a detected magnetic field. The plurality of current sensors includes a first number of current sensors and the plurality of conductors includes a second number of conductors such that the first number is at least one more than the second number. A controller is coupled to receive the magnetic field signal from each of the current sensors and, for each magnetic field sensing element, is configured to characterize a magnetic coupling between the magnetic field sensing element and each of the plurality of conductors.

Owner:ALLEGRO MICROSYSTEMS INC

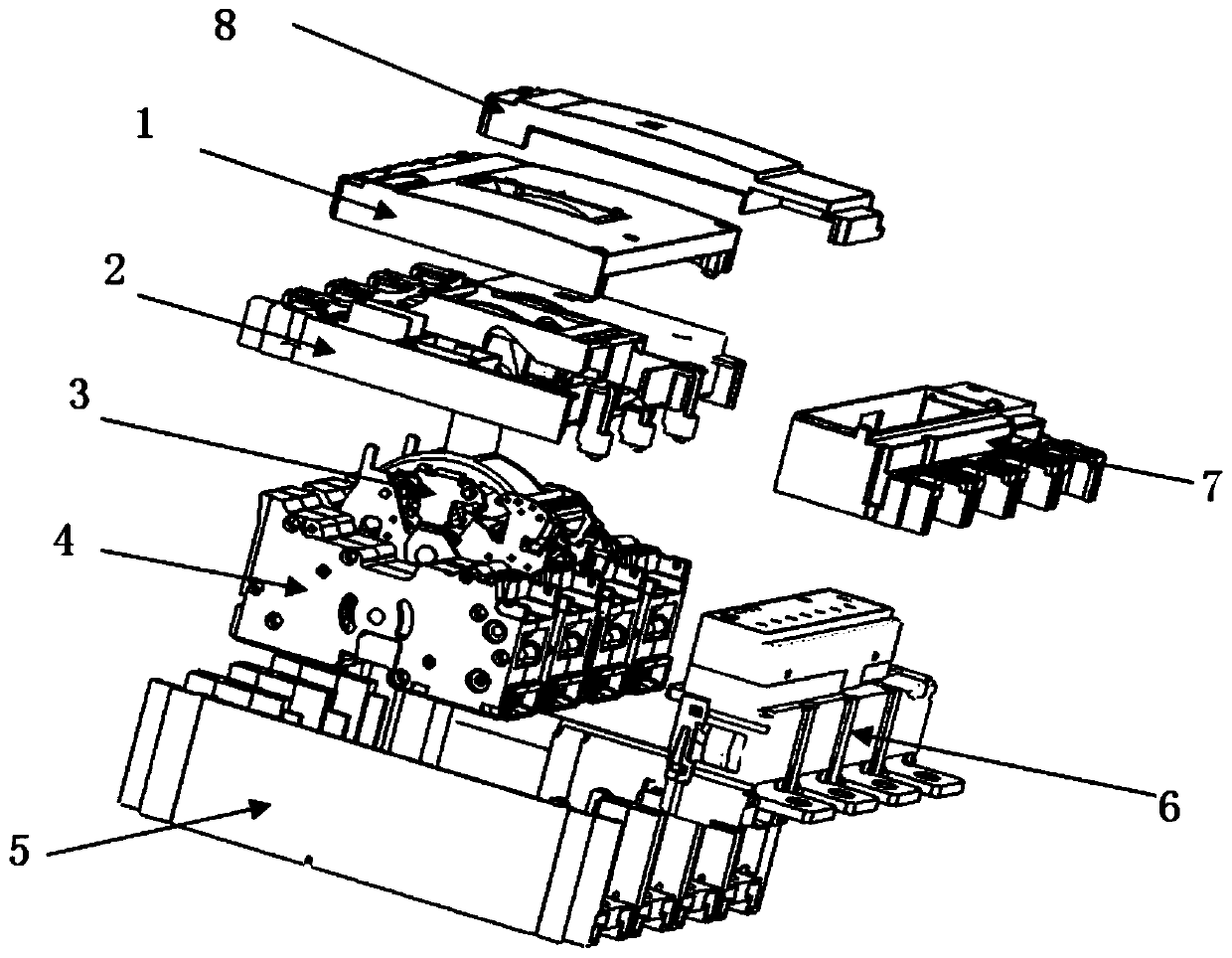

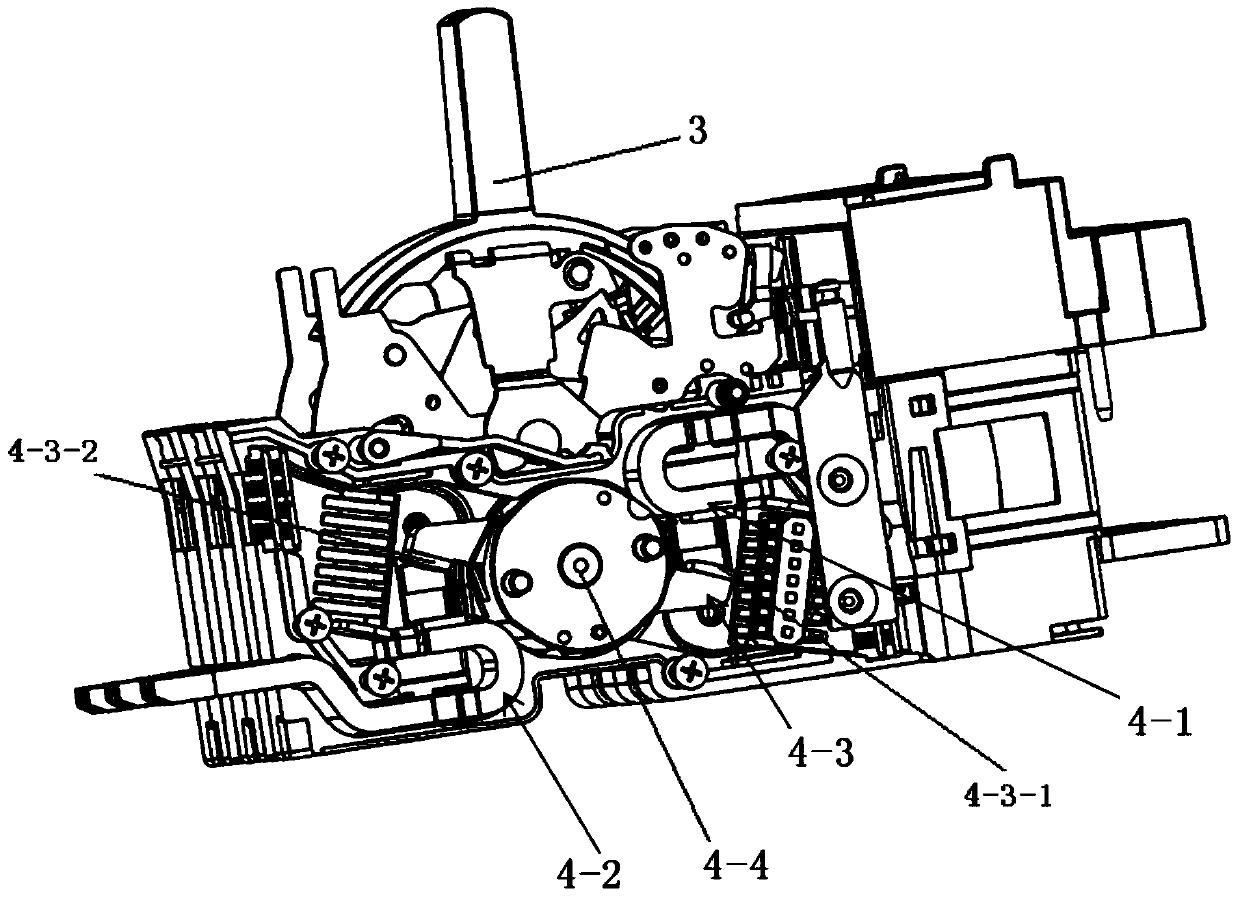

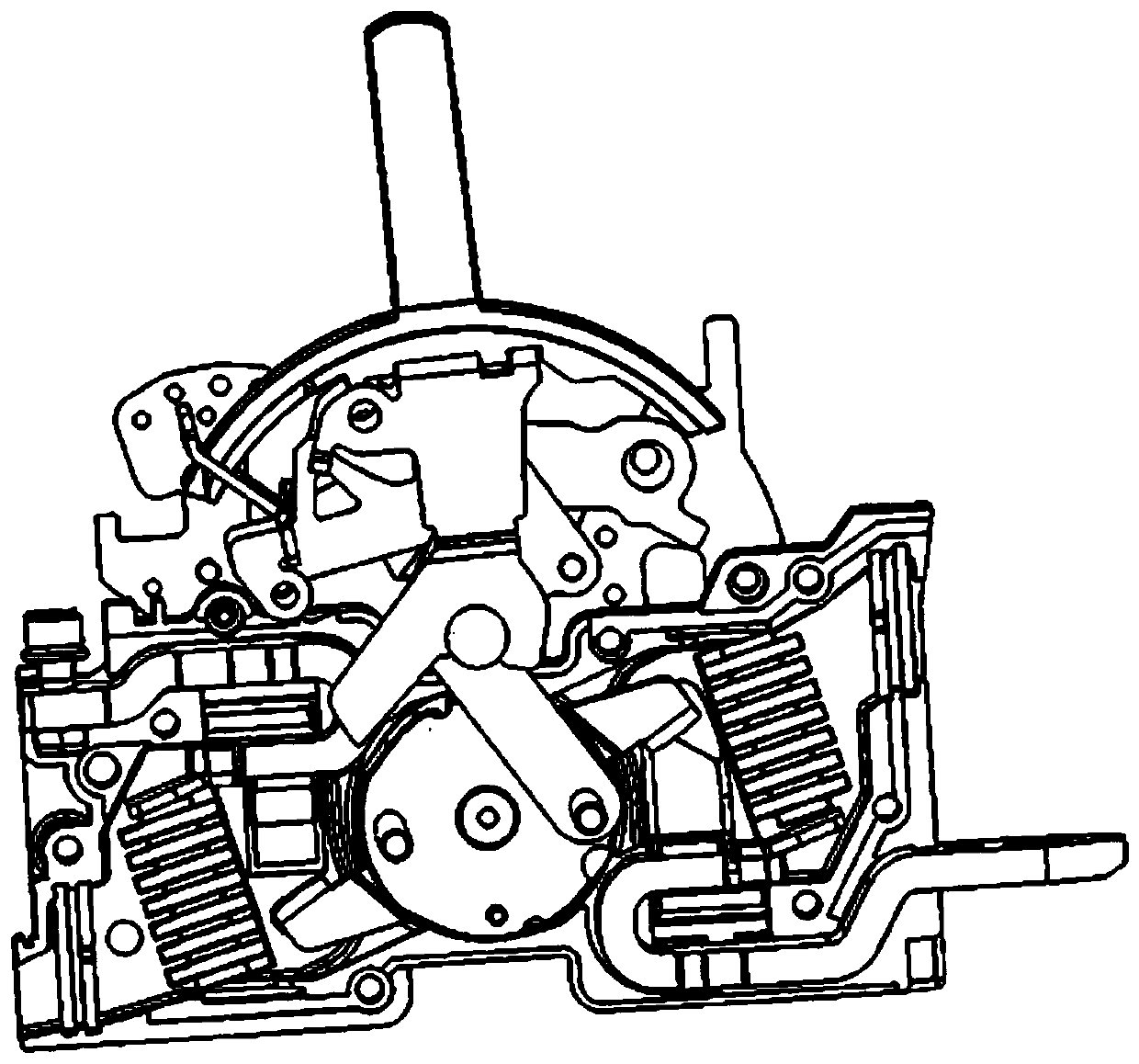

Intelligent molded case circuit breaker and manipulation method

PendingCN109887815AEasy to useImprove closing reliabilityProtective switch operating/release mechanismsCircuit-breaking switch contactsTransformerEngineering

The invention provides an intelligent molded case circuit breaker and a manipulation method. The intelligent molded case circuit breaker comprises an upper cover, a middle cover, an operating mechanism, a phase system, a base and an intelligent release; the intelligent release comprises a release cover, an intelligent release circuit board, a release base, a connection row, a power supply transformer, a measurement transformer, a magnetic flow unit and a release transfer reset unit. The intelligent molded case circuit breaker has the advantages as follows: (1) the circuit breaker has a doublebreak point structure, and through the design of a movable contact and a static contact in the phase system, the circuit breaker has the advantages of high closing reliability and high opening speed,thereby ensuring the use performance of the circuit breaker. (2) The opening and closing reliability of the circuit breaker is improved by the design of the intelligent release, comprising the designof the magnetic flow, a rocker, a reset member and a mechanism push rod and the like. (3) The intelligent release transformer adopts a double-coil structure, so that the current measurement accuracy is high, which is beneficial to realizing overcurrent release more accurately.

Owner:BEIJING BEVONE ELECTRIC CO LTD

Current sensor system

ActiveUS10884031B2Reduce impactIncrease redundancyCurrent/voltage measurementVoltage/current isolationCurrent transducerElectrical conductor

Apparatus and methods provide a current sensor system including a plurality of current sensors positioned proximate a plurality of conductors. Each conductor is configured to carry a current to be measured. Each current sensor comprises one or more magnetic field sensing elements configured to generate a respective magnetic field signal indicative of a detected magnetic field. The plurality of current sensors includes a first number of current sensors and the plurality of conductors includes a second number of conductors such that the first number is at least one more than the second number. A controller is coupled to receive the magnetic field signal from each of the current sensors and, for each magnetic field sensing element, is configured to characterize a magnetic coupling between the magnetic field sensing element and each of the plurality of conductors.

Owner:ALLEGRO MICROSYSTEMS INC

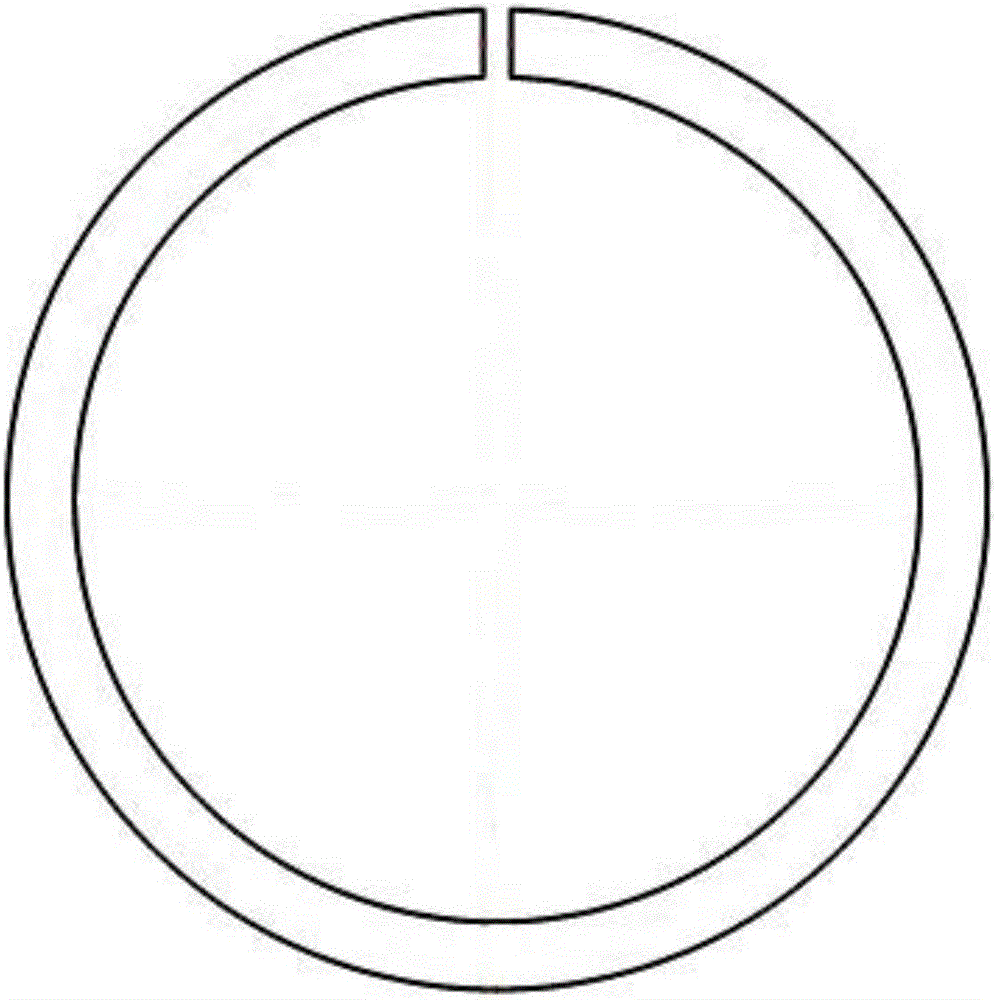

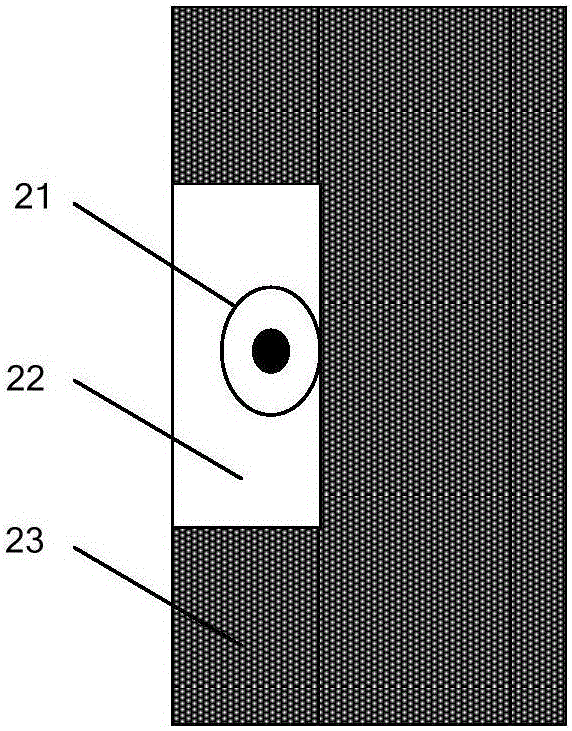

Magnetic core air gap fixing structure assembly for core passing type Hall current sensor

ActiveCN106706990AGuaranteed widthEnsure consistencyElectrical measurement instrument detailsElectrical testingPunchingHall element

The invention relates to the field of a magnetic core fixing structure assembly of a Hall current sensor, in particular to a magnetic core air gap fixing structure assembly for a core passing type Hall current sensor. The magnetic core air gap fixing structure assembly is characterized in that a fixing hole or a positioning groove is formed in a single magnetic core with an air gap formed by lamination riveting and punching; a non-conductive metal sheet is riveted and punched or welded onto the upper top layer or the outermost upper and lower layers of the single magnetic core; the non-conductive metal sheet is welded onto the outer side surface or the top of the magnetic core air gap position by a single magnetic core with an air gap formed by winding; when the two single magnetic cores with the same dimension or the single magnetic cores with one or even air gaps and one fixing frame or framework is used, the two single magnetic cores with the air gaps are arranged on the upper and lower surfaces of the fixing frame or the framework; the even number of air gaps are in staggered arrangement or symmetrical distribution or uniformly divide the whole magnetic paths; the side surface of the fixing frame or the framework is provided with an insertion groove communicating the air gaps of the magnetic core; the conversion plate is inserted in the insertion groove; a Hall element arranged in the magnetic core air gap is directly connected with a printed circuit board or is connected with the printed circuit board through a conversion plate.

Owner:南京普肯传感科技有限公司

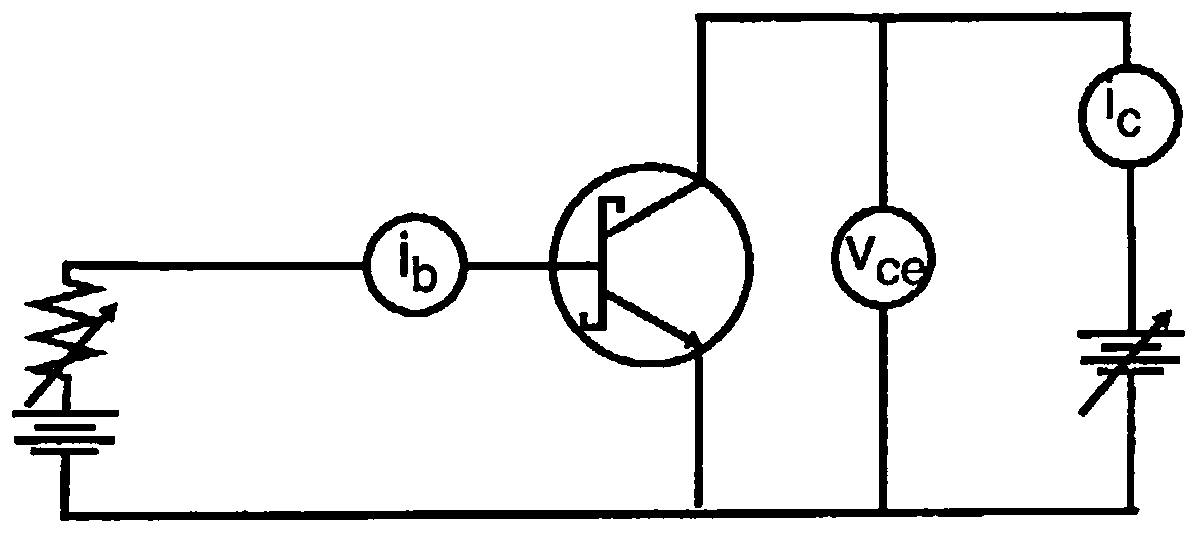

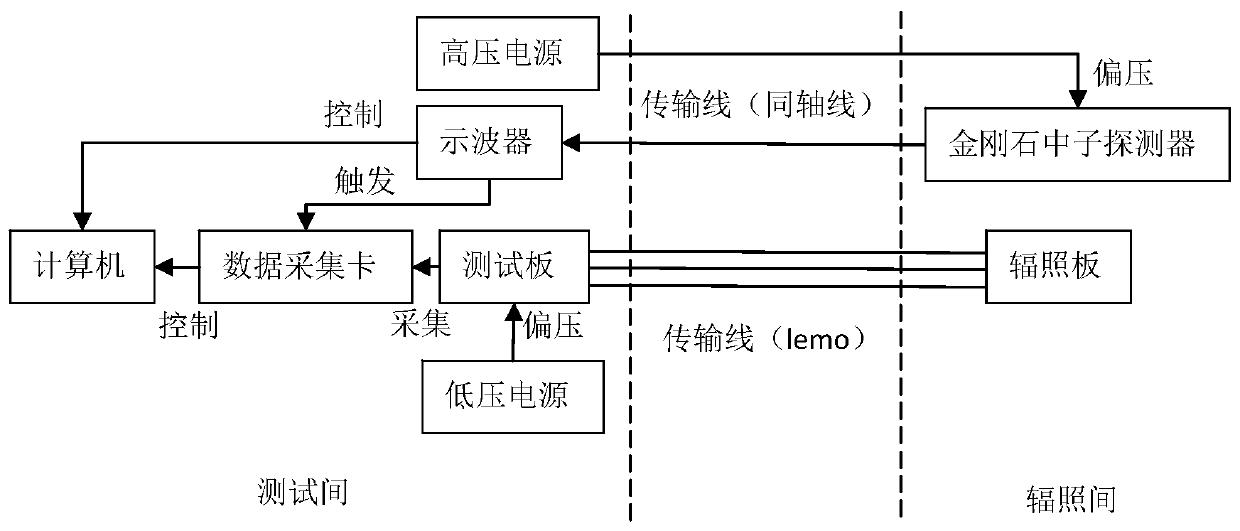

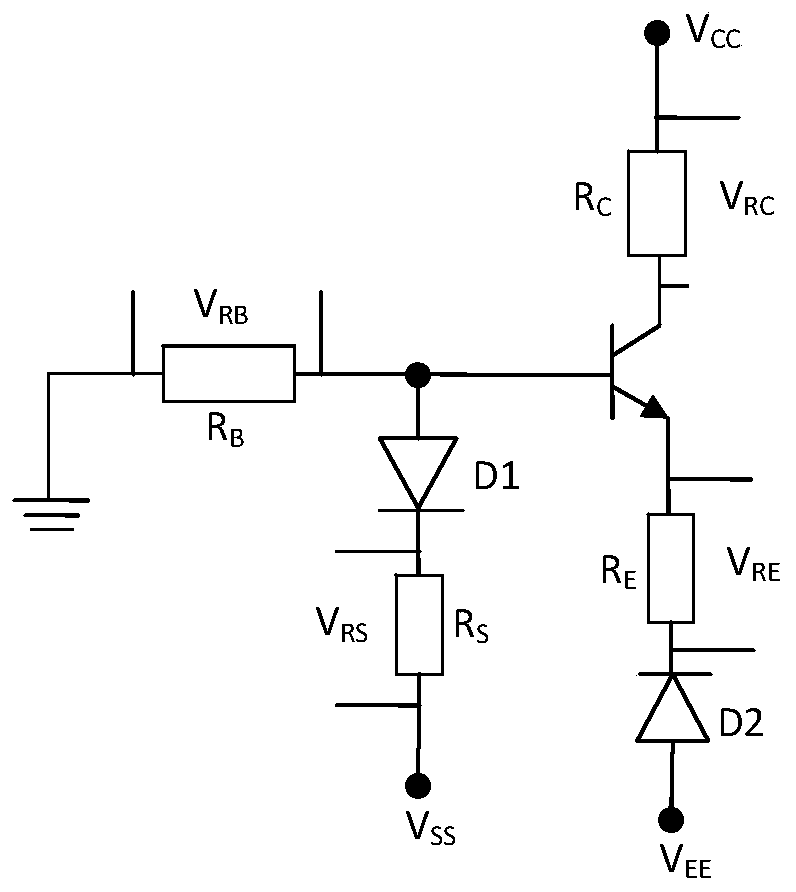

Triode three-terminal current waveform measuring system and method, triode annealing effect measuring system and method, and neutron fluence measuring method

ActiveCN110376499AAccurate measurementReduce common mode signalMeasurement with semiconductor devicesIndividual semiconductor device testingNeutron irradiationPhotocurrent

In order to accurately measure three-terminal currents of a triode, a triode annealing effect and the neutron fluence under the pulse neutron irradiation, the invention provides a triode three-terminal current waveform measuring system and method, a triode annealing effect measuring system and method, and a neutron fluence measuring method. According to the invention, under the circumstance that the current of an emitter of a to-be-measured triode is fixed, the response to the pulse neutron by the three-terminal currents of the to-be-measured triode is measured and the bias of the triode is not affected by the photocurrent during the irradiation, so that accurate measurement of the triode annealing effect under the pulsed neutron irradiation and the neutron fluence in an unknown irradiation field.

Owner:NORTHWEST INST OF NUCLEAR TECH

Current sensor

InactiveUS8847591B2Precise managementImprove current measurement accuracyTesting electric installations on transportVoltage/current isolationInduction fieldCurrent sensor

A current sensor includes a magnetic sensor including magnetoresistive sensors configured to detect induction fields generated by a measurement current passing through a current line, a magnetic field application unit configured to apply to the magnetoresistive sensors a magnetic field having a direction perpendicular to sensitivity directions of the magnetoresistive sensors; and a computing unit configured to calculate from an output of the magnetic sensor a compensation value for the output. The computing unit is configured to be capable of calculating the compensation value from the outputs of the magnetic sensor obtained in at least two states in which magnetic fields applied by the magnetic field application unit are different from each other.

Owner:ALPS ALPINE CO LTD

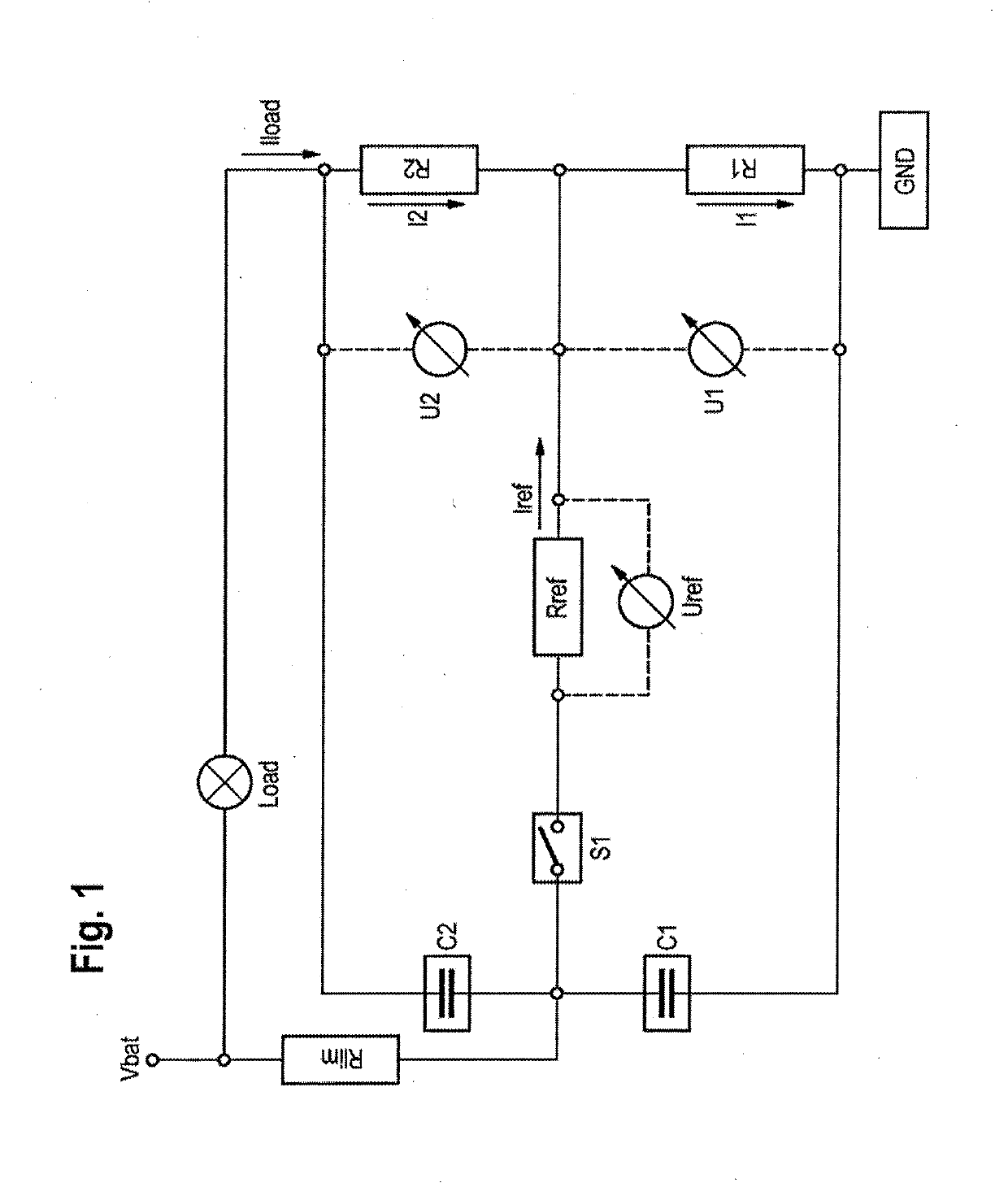

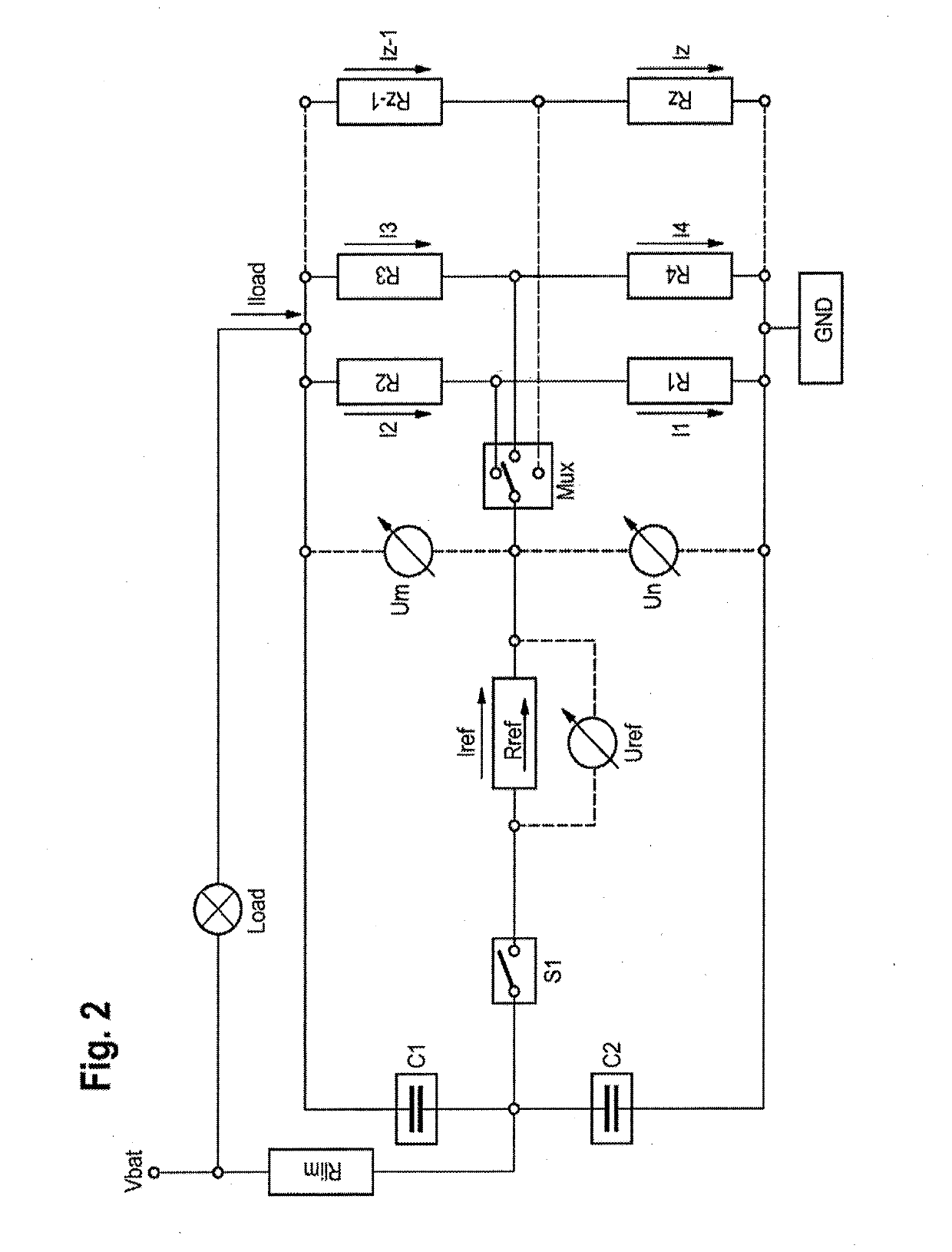

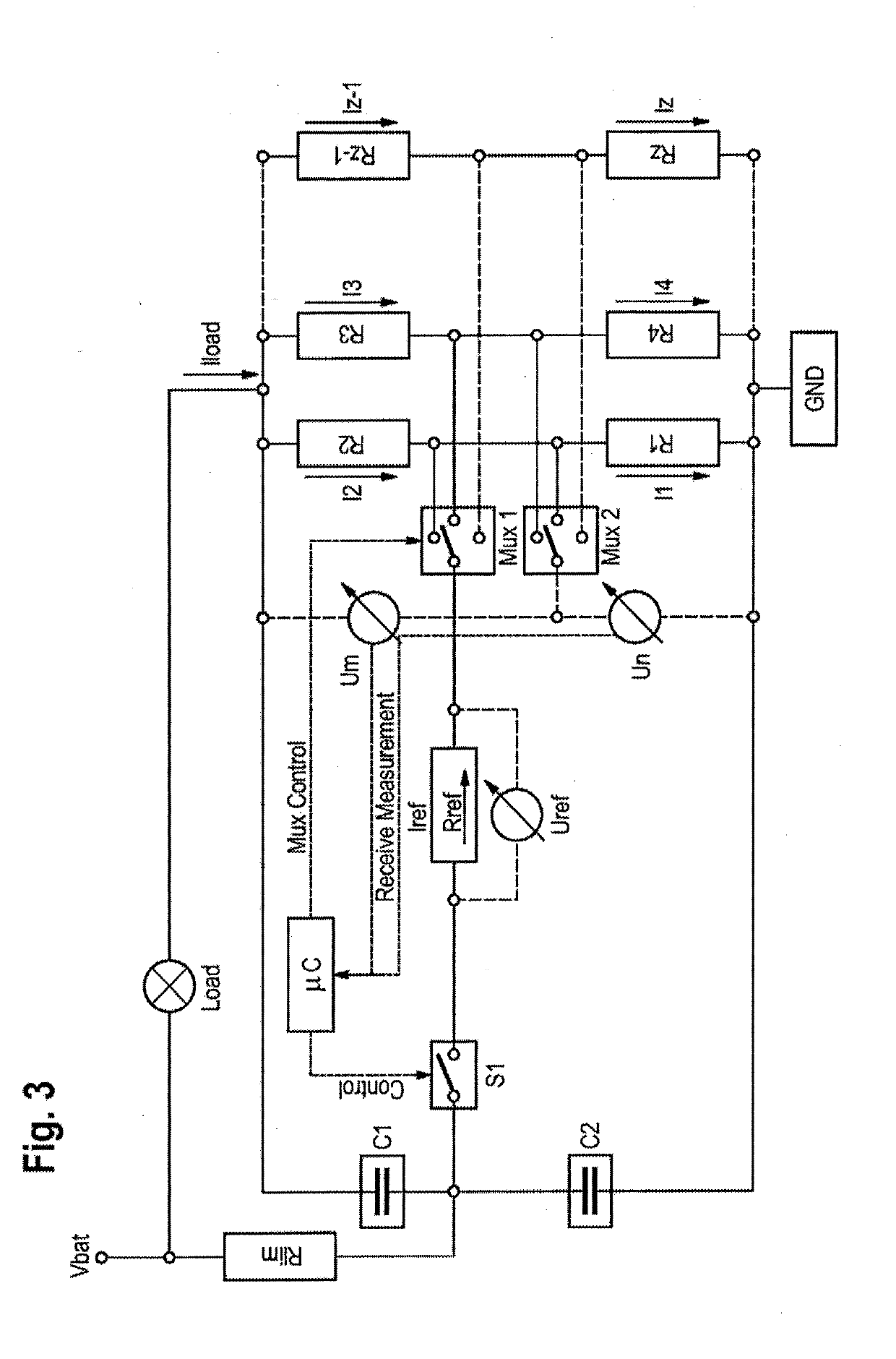

Method for determining a load current and battery sensor

ActiveUS20190094304A1Improve current measurement accuracyCost-effective materialBase element modificationsElectrical testingEngineeringCalculation methods

The invention relates to a method for determining a load current, which is based on conducting a calibration current in a particular manner and on particular calculation methods.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Full optical fiber current sensor

InactiveCN101320055BEliminate imperfectionsEliminate measurement errorsVoltage/current isolationOptical light guidesFiber couplerPhase difference

The invention discloses an all-fiber current sensor consists of a 3x3 polarization-maintaining fiber coupler. One embodiment of the invention, a straight-through type interferometric all-fiber current sensor, comprises a light source, a 3x3 polarization-maintaining fiber coupler, fiber polarizers, a 1 / 4 fiber wave sheet and a transduction fiber ring. The light source is connected with one end of the 3x3 polarization-maintaining fiber coupler; the two ports of the 3x3 polarization-maintaining fiber coupler are respectively connected with two fiber polarizers; and the other ends of the two fiber polarizers are respectively connected with the transduction fiber ring by the 1 / 4 fiber wave sheet; one port of the 3x3 polarization-maintaining fiber coupler is vacant; and the rest two ports of the 3x3 polarization-maintaining fiber coupler are respectively connected with a signal processor by two photoelectric detectors. In addition, another embodiment of the invention, a reflection type interferometric all-fiber current sensor, also uses the 3x3 polarization-maintaining fiber coupler. The all-fiber current sensor avoids phase differences made artificially and makes the current transduction system woke more stably.

Owner:上海康阔光智能技术有限公司

Optical fiber current transformer with optical fiber temperature acquisition and temperature compensation

ActiveUS8861899B2Improve current measurement accuracyImprove accuracyCurrent/voltage measurementThermometers using physical/chemical changesBeam splitterData treatment

An optical fiber current transformer includes a broadband light source, a depolarizer, a beam splitter, a temperature acquisition unit, a current acquisition unit, a modulation waveform generating unit, a data processing unit and a calculating compensation unit. The broadband light source is connected with the beam splitter by the depolarizer. A first output of the beam splitter is connected with the calculating compensation unit by the temperature acquisition unit. A second output of the beam splitter is connected with the data processing unit by the current acquisition unit. The data processing unit is connected with the calculating compensation unit. The calculating compensation unit is connected with the current acquisition unit by the modulation waveform generating unit. The optical fiber current transformer uses the temperature-current compensation curve in the calculating compensation unit to synchronously process the temperature and current, thereby improving the accuracy of real-time current measurement.

Owner:BEIJING QIRED ELECTRO OPTIC TECH LIMITED

A High Accuracy Electronically Compensated Current Transformer

InactiveCN103592490BImprove current measurement accuracyEliminate sources of errorVoltage/current isolationExcitation currentSources of error

The invention relates to a high-accuracy electronic compensation type current transformer, which belongs to the field of current measurement. The invention consists of iron core, winding and auxiliary circuit for compensating excitation current. The iron core consists of a detection iron core and a shielding iron core to form a nested structure. The detection iron core detects the zero flux state of the iron core through the winding on the upper side, and then controls the auxiliary circuit to provide the excitation current necessary for the current transformer, which eliminates the error source of the current transformer and greatly improves the accuracy of the current transformer . By applying the invention, a 0.001-level high-accuracy current transformer that is insensitive to secondary loads and an open-type current transformer with an accuracy better than 0.01-level can be developed.

Owner:STATE GRID CORP OF CHINA +2

A free-winding optical fiber current sensor sensitive coil and manufacturing method

ActiveCN103713180BSignificantly bendable stateWinding is simpleCurrent/voltage measurementFibre mechanical structuresPower flowCurrent sensor

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

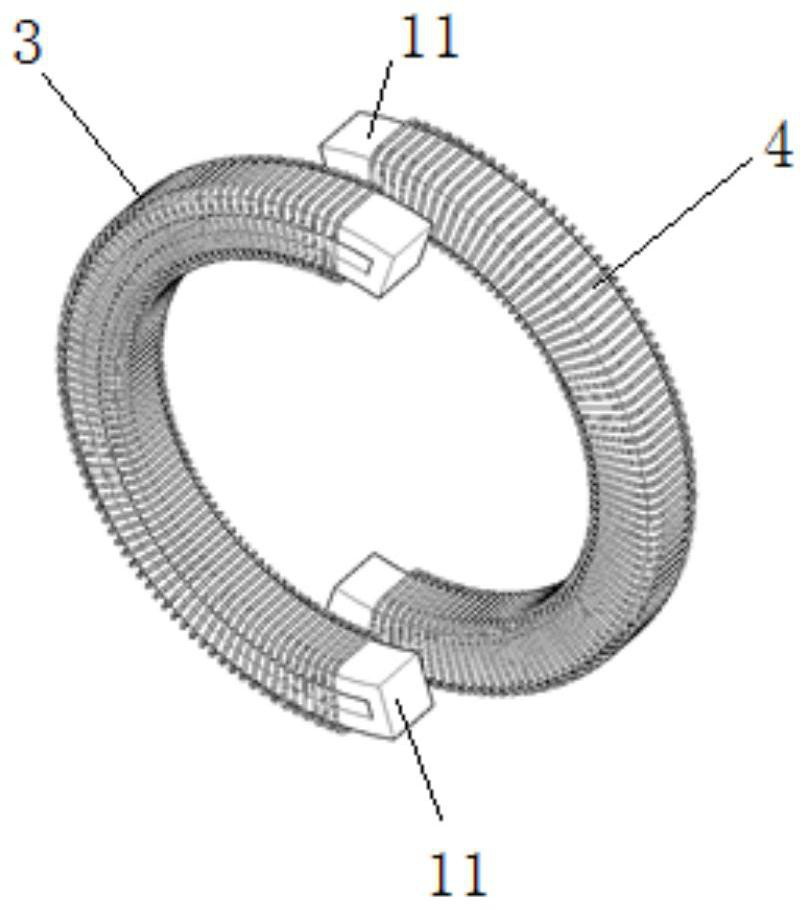

A Broadband Current Transformer

ActiveCN105575639BImprove measurement accuracyAvoid enteringTransformersTransformers/inductances coils/windings/connectionsCapacitanceBroadband

The invention provides a broadband current transformer. The broadband current transformer comprises a detection iron core (1), wherein a detection winding (2), a detection winding copper screen (3), an inner magnetic screen (4), an inner compensation winding (5), an outer magnetic screen (6), an outer compensation winding (7), an outer compensation winding copper screen (8), a secondary winding (9), a secondary winding copper screen (10) and a primary winding (11) are arranged outside the detection iron core (1) from an inner layer to an outer layer in sequence; compensation capacitors (13) are connected at two ends of the outer compensation winding (7) in parallel, and compensation capacitors (14) are connected at two ends of the secondary winding (9) in parallel; and the number of windings of the inner compensation winding (5) is equal to that of the outer compensation winding (7). According to the broadband current transformer, main error sources of the current transformer are eliminated, the capacitive error of the broadband current transformer is reduced, and the measurement accuracy of high-frequency current is improved.

Owner:STATE GRID CORP OF CHINA +1

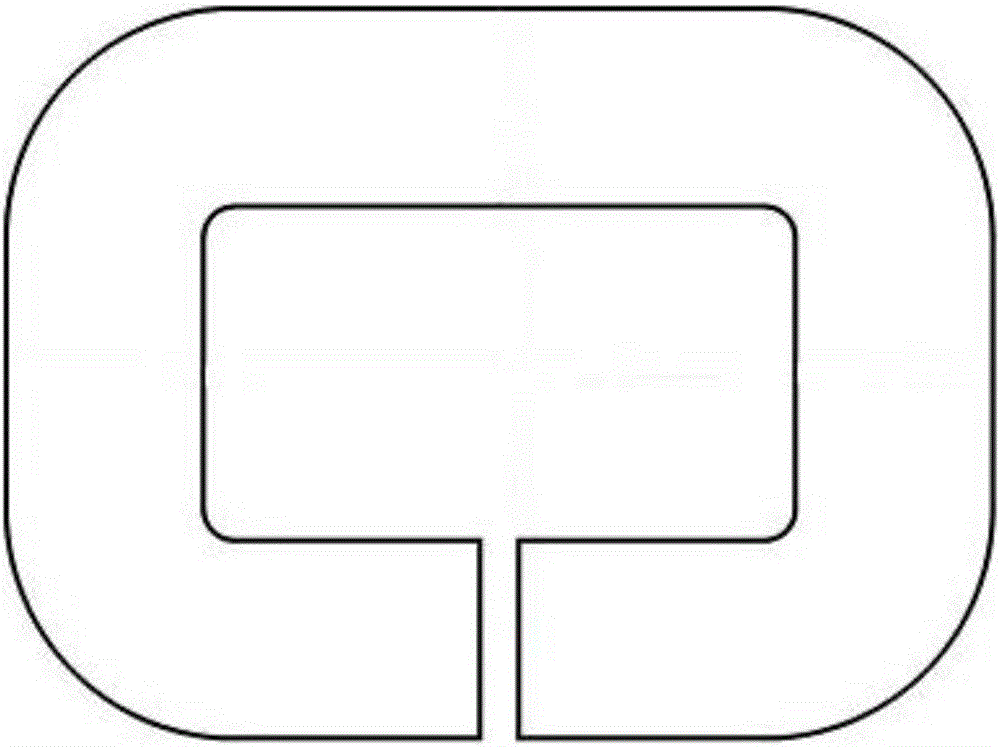

Bus bar module

ActiveUS10393774B2Improve current measurement accuracyImprove accuracyConversion constructional detailsVoltage/current isolationTransducerComputer module

A bus bar module equipped with a current sensor includes a first bus bar, a second bus bar, a substrate, and a first magnetoelectric transducer. The first bus bar has a first notch. The second bus bar has a second notch and is placed in parallel to the first bus bar. The second notch is provided at a position different from the first notch in an extending direction of the first bus bar. The substrate is fitted to both the first notch and the second notch. Further, the substrate is sandwiched between those side surfaces of the first bus bar and the second bus bar which are opposed to each other. The first magnetoelectric transducer is placed inside the first notch and fixed to the substrate.

Owner:DENSO CORP

Detection circuit for monitoring the status of current transformers

ActiveCN102590591BOvercome the disadvantage of status signal influenceAvoid disadvantagesCurrent/voltage measurementVoltage/current isolationCurrent electricEngineering

The invention discloses a detection circuit for monitoring state of a current transformer, which is serially connected between the transformer and a microprocessor circuit, wherein a microprocessor is used for judging the working state of the existing current transformer according to signals from the detection circuit. The detection circuit is independent to a current signal collecting circuit and overcomes the disadvantage that a current collection signal is affected by a state signal of the current transformer, so that the current measurement precision of an intelligent circuit breaker is improved.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

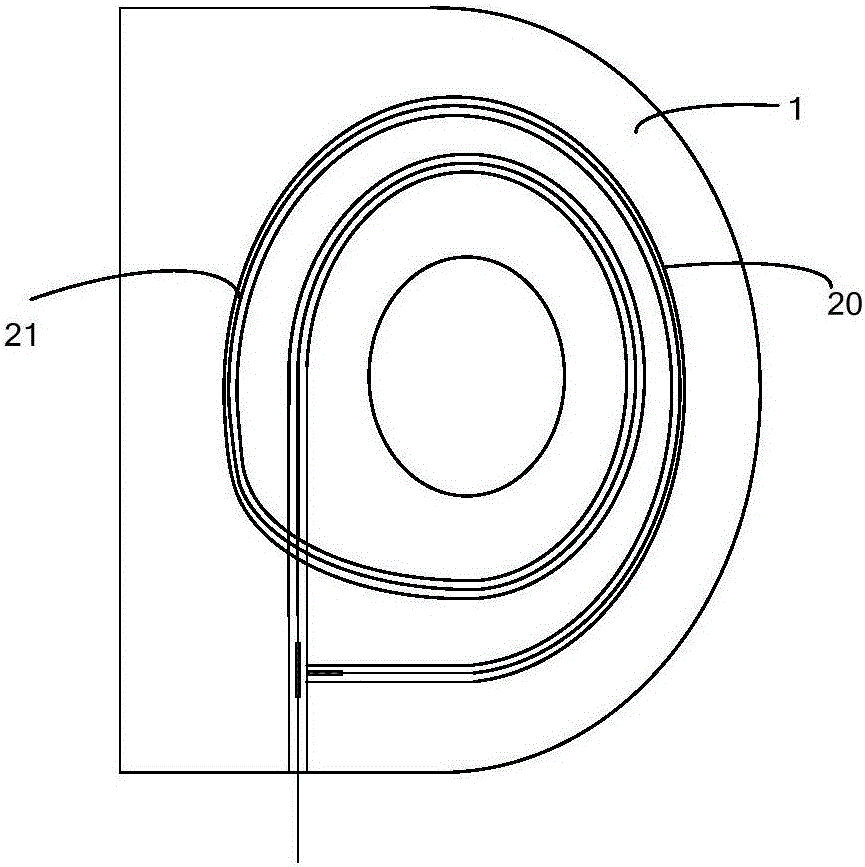

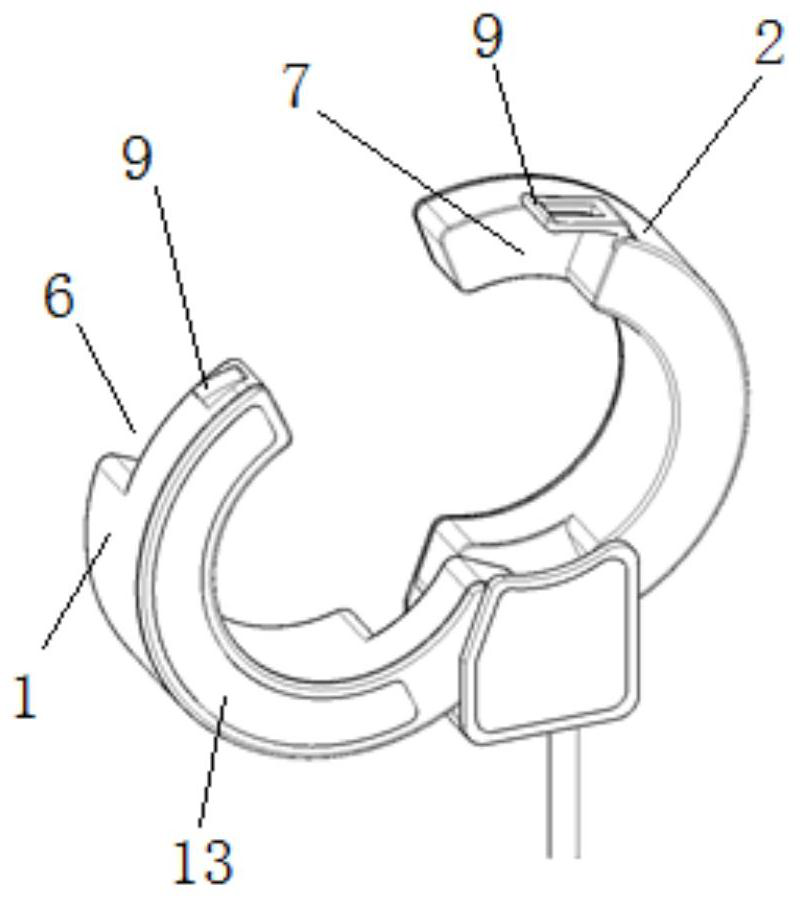

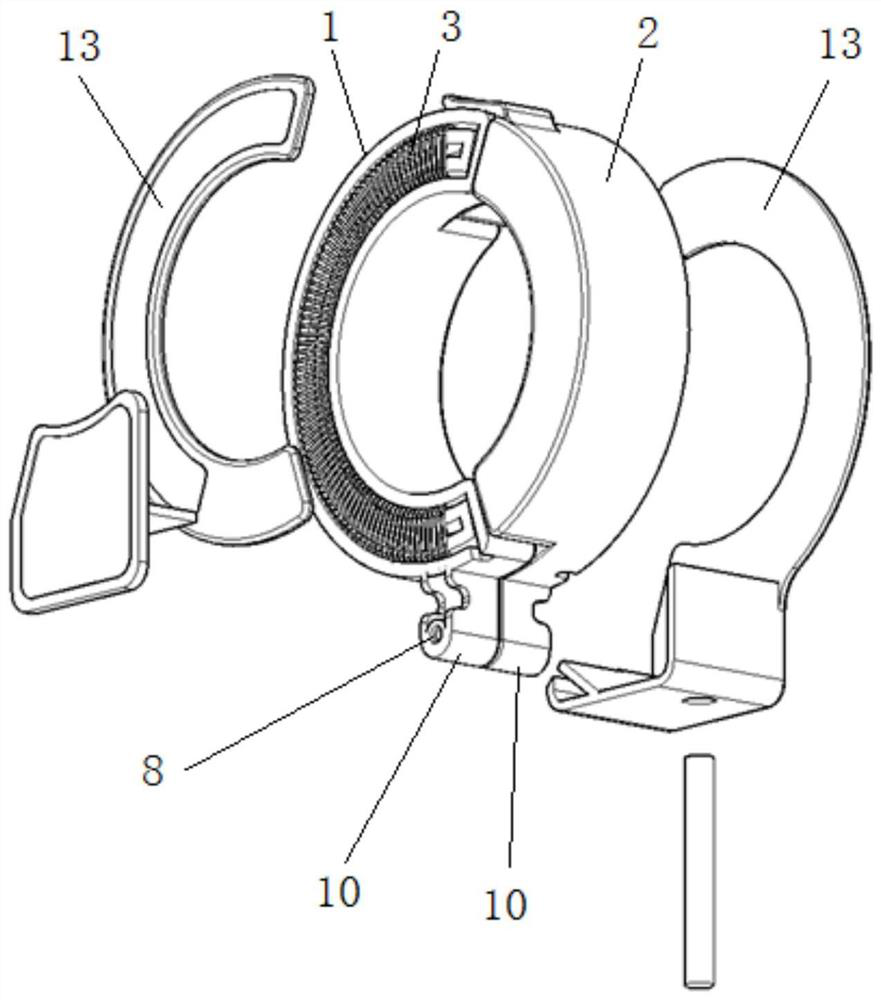

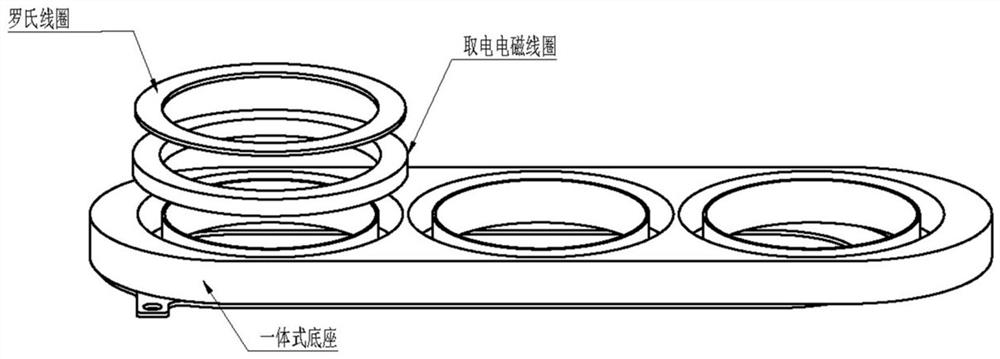

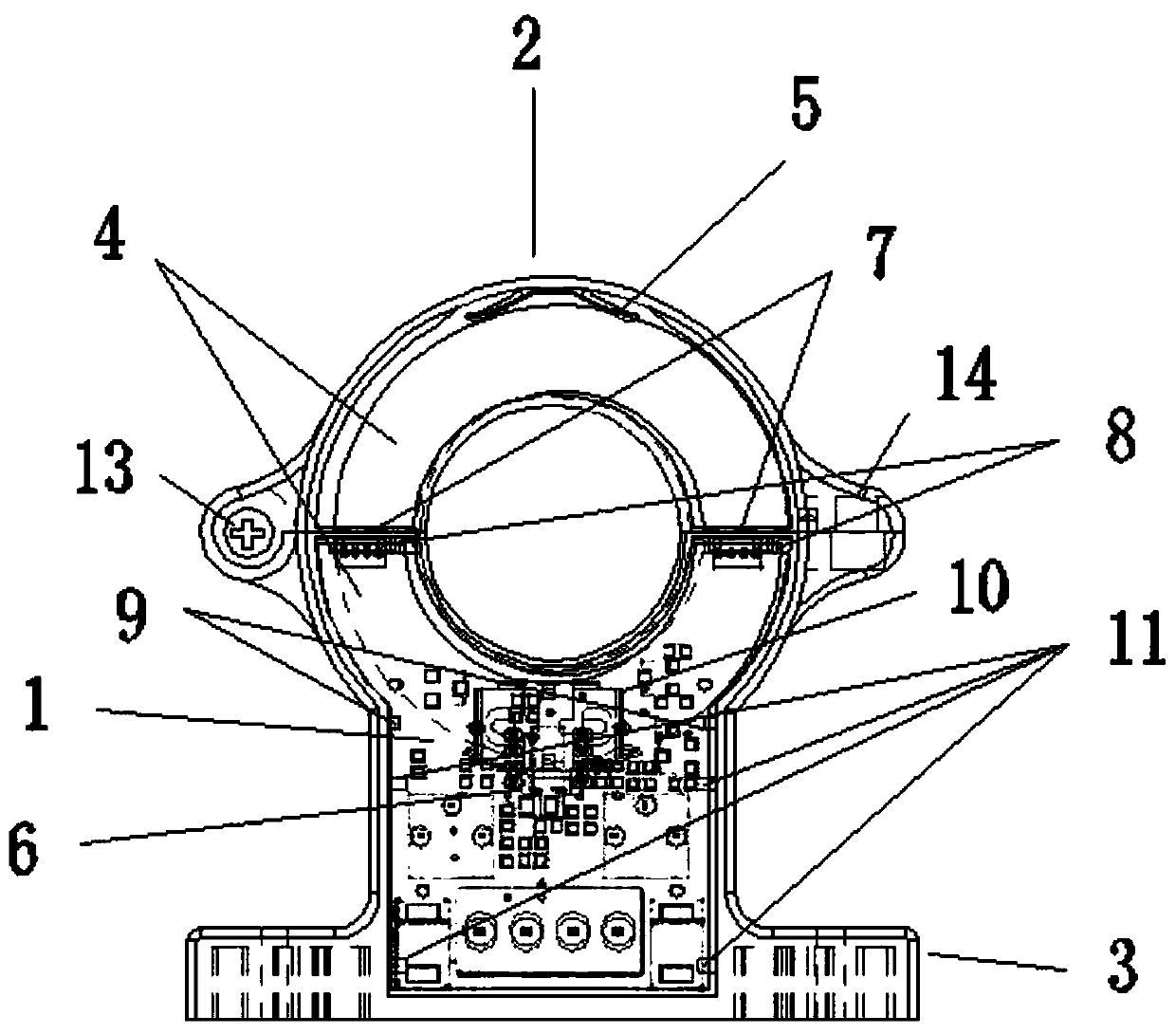

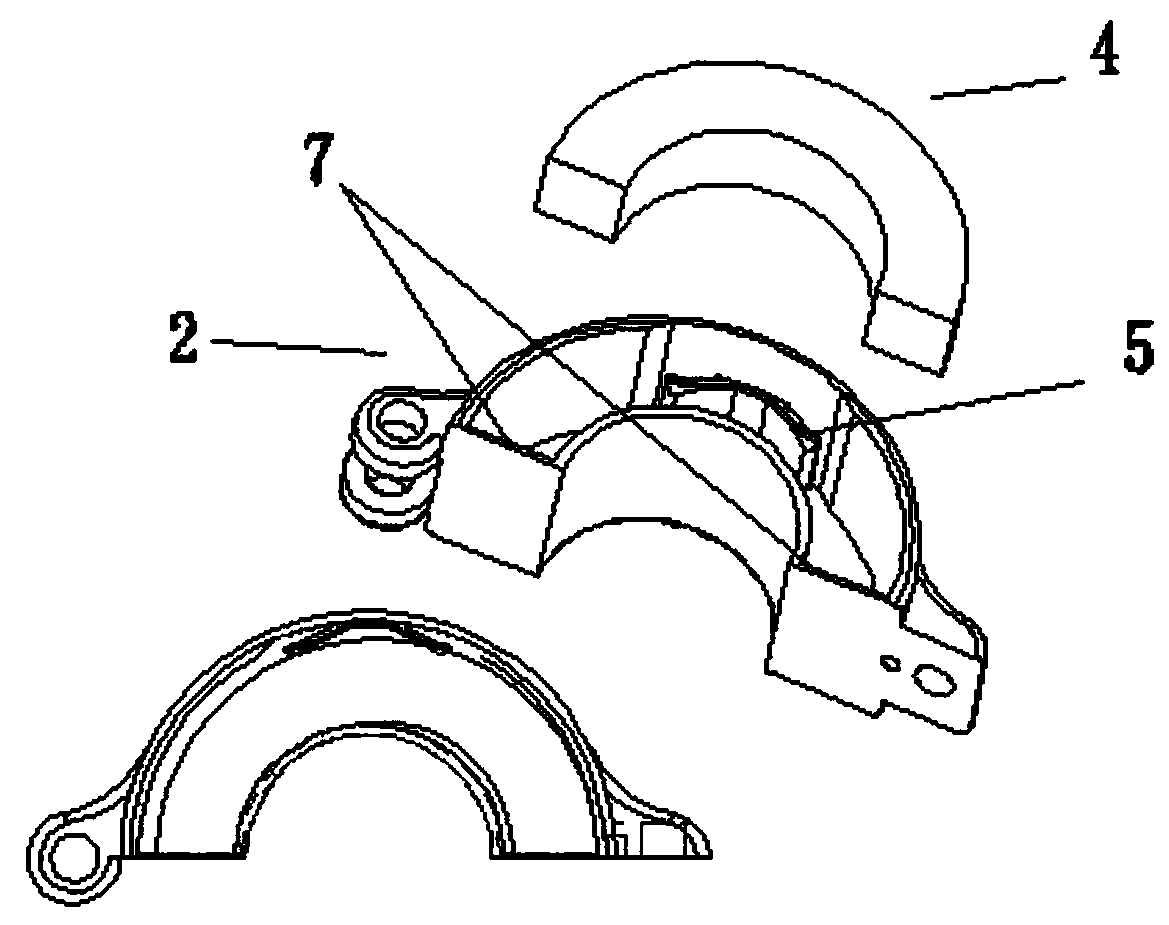

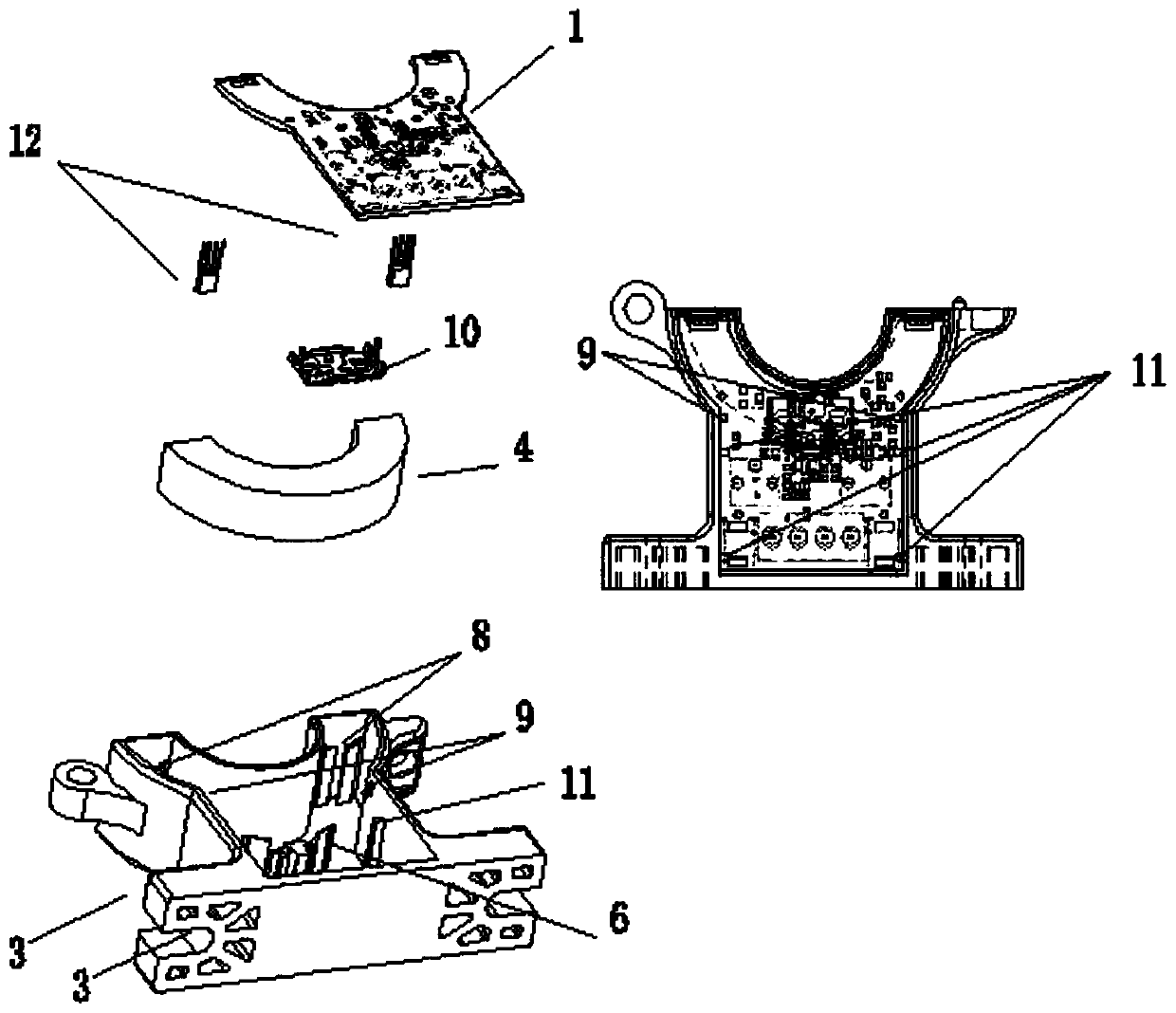

Rigid opening and closing type Rogowski coil

InactiveCN113009203AImprove current measurement accuracyReduce Flux LeakageVoltage/current isolationCoilsMechanical engineeringElectrical current

The invention relates to the technical field of Rogowski coils, in particular to a rigid opening and closing type Rogowski coil which comprises a left semi-annular shell, a right semi-annular shell and a Rogowski coil body composed of a left semi-annular coil body and a right semi-annular coil body, the left semi-annular shell and the right semi-annular shell are mutually connected in an involution manner, the left semi-annular shell and the right semi-annular shell are respectively overlapped in a staggered manner at involution connection parts at two ends, the left semi-annular coil is mounted in the left semi-annular shell, and the right semi-annular coil is mounted in the right semi-annular shell; when the left semi-annular shell and the right semi-annular shell are in a closed state, the left semi-ring coil and the right semi-ring coil are arranged in a front-back staggered mode and form a closed whole ring in the front-back projection direction. According to the invention, the current measurement precision of the open-close Rogowski coil is improved.

Owner:JIANGYIN SPARK ELECTRONICS TECH

Transformer state detection device and breaker

ActiveCN103308807BImprove securityOvercoming sampling effectsElectrical testingPower flowInternal resistance

The invention discloses a transformer state detection device. The transformer state detection device is characterized in that according to internal distance changes under various working states of transformers, the internal resistance changes are converted into changes of level waveforms by the aid of independent detection circuits and a level conversion circuit, and the current working states of the transformers are judged according to different level waveforms. The invention further discloses a breaker with the transformer state detection device. Compared with the prior art, the transformer state detection device and the breaker have the advantages that disconnection faults of the transformers can be detected, internal resistance changes of the transformers caused by other faults can be detected accurately, and integral system safety can be improved greatly. The independent detection circuits are used, so that influences of transformer state detection on current signal sampling are eliminated, and current measurement precision of the intelligent breaker is improved.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

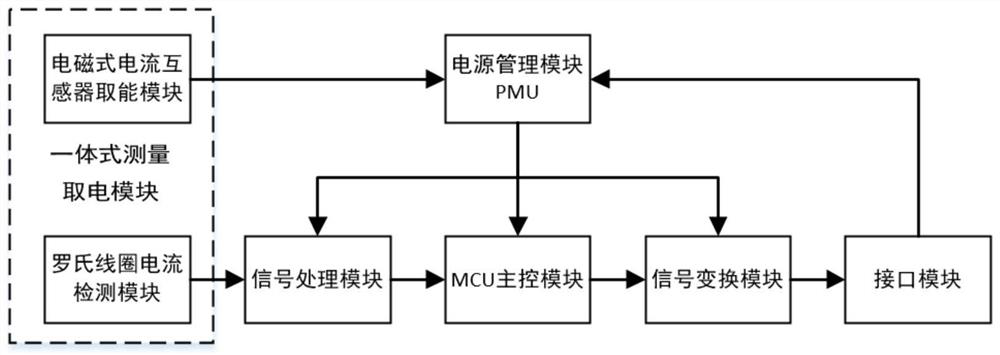

Current sensor system

PendingCN114325060ASmall sizeReduce volumeCurrent/voltage measurementElectrical batteryCurrent sensor

The invention provides a current sensor system, and belongs to the technical field of current sensors. The system comprises an electromagnetic coil and a Rogowski coil, wherein the electromagnetic coil and the Rogowski coil are arranged on a circuit to be detected in a penetrating manner; the Rogowski coil is connected with the signal processing module and is used for sending the sensed signal to the signal processing module, and the signal processing module is used for amplifying and integrating the sensed current; the electromagnetic coil is connected with the battery management module and is used for converting the electric energy obtained by the battery management module and supplying the converted electric energy to the signal processing module and the main control module; and the main control module is used for processing and outputting the signal output by the signal processing module. According to the current sensor, the electromagnetic coil is adopted for taking electricity, the Rogowski coil is adopted for current detection, the size of the electromagnetic coil can be properly reduced, the size of the current sensor is optimized, the problems that the magnetic field of the electromagnetic coil is easy to saturate and the frequency band is narrow are solved, and the current measurement precision is improved.

Owner:平高集团智能电力科技有限公司 +1

Magnetic circuit mounting structure for detachable open-loop-type Hall current sensor

PendingCN110108922AEasy to fixAir Gap Width GuaranteeCurrent measurements onlyVoltage/current isolationHall elementCurrent sensor

The invention discloses a magnetic circuit mounting structure for a detachable open-loop-type Hall current sensor, and belongs to the technical field of magnetic circuit mounting. The magnetic circuitmounting structure comprises a shell, and further comprises a PCB, a magnetic core and a shielding frame which are mounted in the shell; an upper body of the shell is provided with a magnetic core mounting area, a baffle and an upper body elastic buckle structure; a lower body of the shell is provided with a magnetic core mounting area, two Hall element mounting areas and a PCB mounting area, wherein the magnetic core mounting area is provided with a lower body elastic buckle structure; the Hall element mounting areas are provided with PCB mounting table columns, Hall element inserting grooves and magnetic core baffles; the PCB mounting area is provided with mounting columns and buckles; and the shielding frame is provided with elastic sheets and grounding pins, and the grounding pins penetrate through grounding welding holes in the PCB to be welded and grounded. According to the magnetic circuit mounting structure, during mounting, the magnetic core is flatly pushed to the bottom through the magnetic core baffles and the elastic buckle structures, a ground wire is not welded to the magnetic core, the magnetic core is good in air gap width consistency and temperature stability, Hall elements do not need to be wrapped with insulation belts, and the PCB is mounted and not skewed.

Owner:南京普肯传感科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com