Magnetic circuit mounting structure for detachable open-loop-type Hall current sensor

A technology of Hall current and installation structure, applied in the direction of measuring current/voltage, measuring current only, voltage/current isolation, etc., can solve the problems of increasing labor cost, not increasing much, processing grounding wire, and time-consuming welding, etc. Current measurement accuracy, stable temperature characteristics, and the effect of expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical solutions of the present invention clearer and clearer for those skilled in the art, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

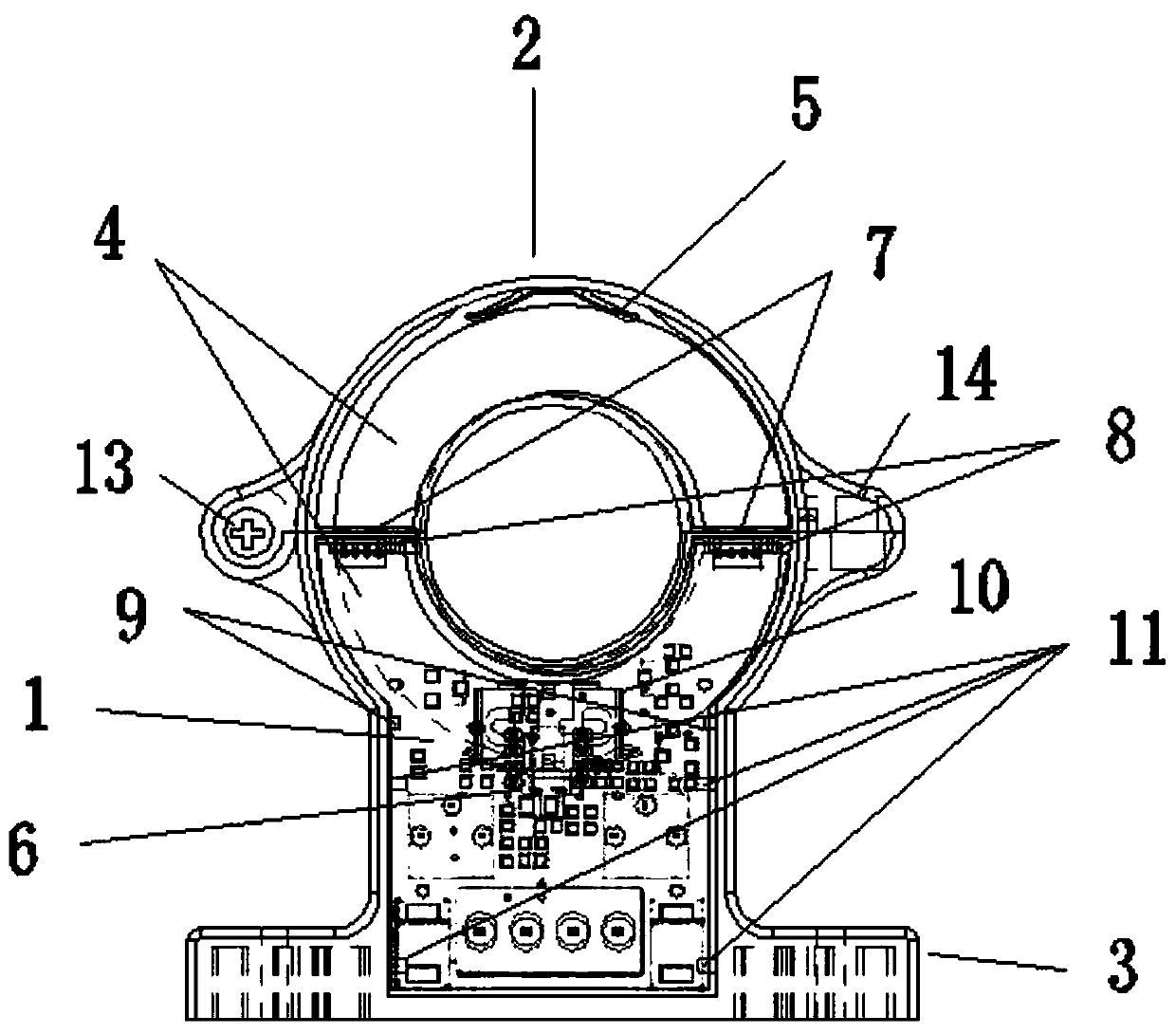

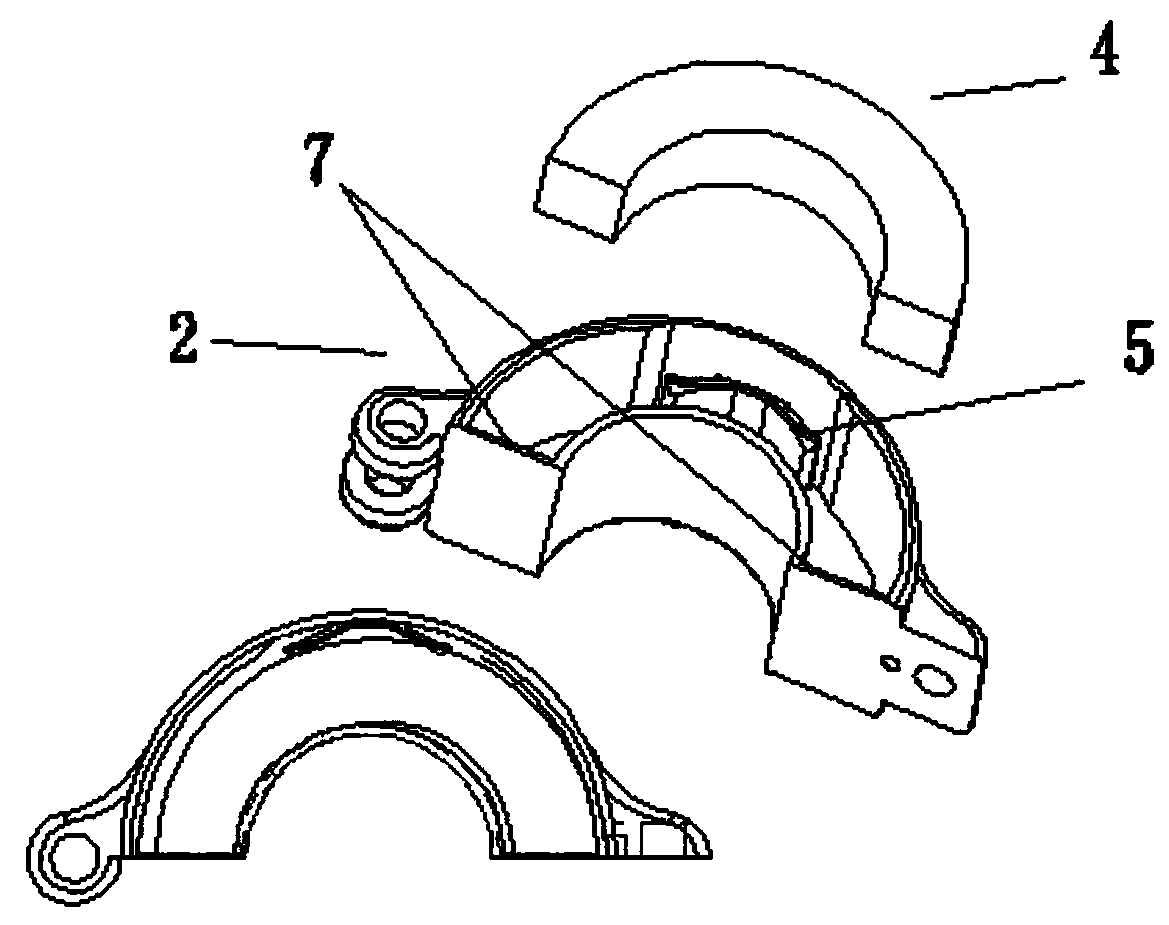

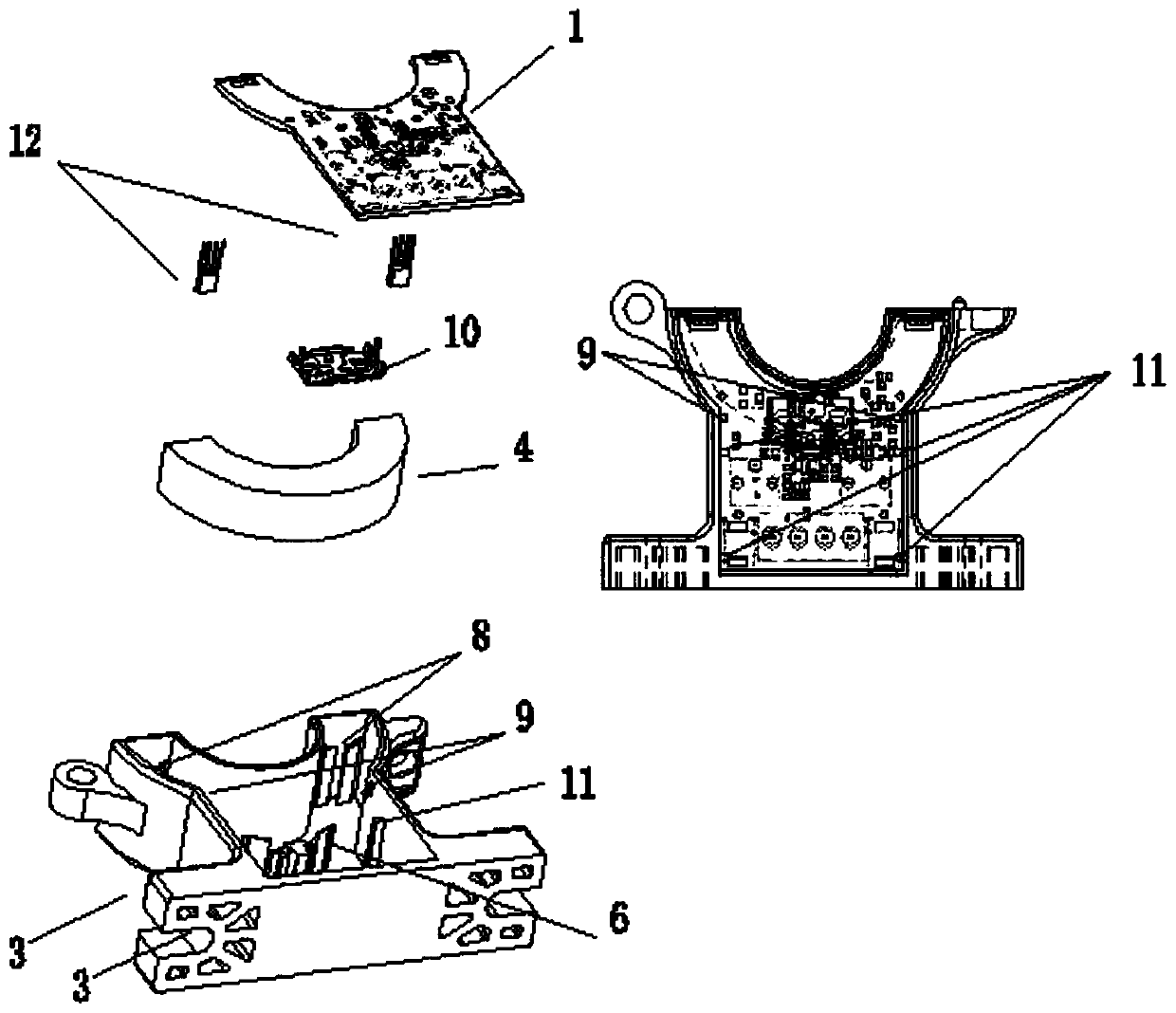

[0031] Such as Figure 1-Figure 4 As shown, the magnetic circuit mounting structure for a detachable open-loop Hall current sensor provided by this embodiment includes a housing and a magnetic core 4 with two symmetrically distributed air gaps of the same width and installed in the housing. The PCB board 1 and the shielding frame 10 installed on the PCB board 1, the shape of the core hole and the magnetic core on the shell are circular, the size of the core hole is 21mm in diameter, and the shell is divided into upper and lower parts based on the center line of the core hole. Remove the two parts: the upper shell body 2 and the lower shell body 3. The upper sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com