Full optical fiber current sensor

A current sensor and all-fiber technology, applied in voltage/current isolation, light guide, optics, etc., can solve problems such as no practical value, unstable Sagnac interference optical path, etc., to eliminate imperfection problems, stabilize Sagnac interference optical path, reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

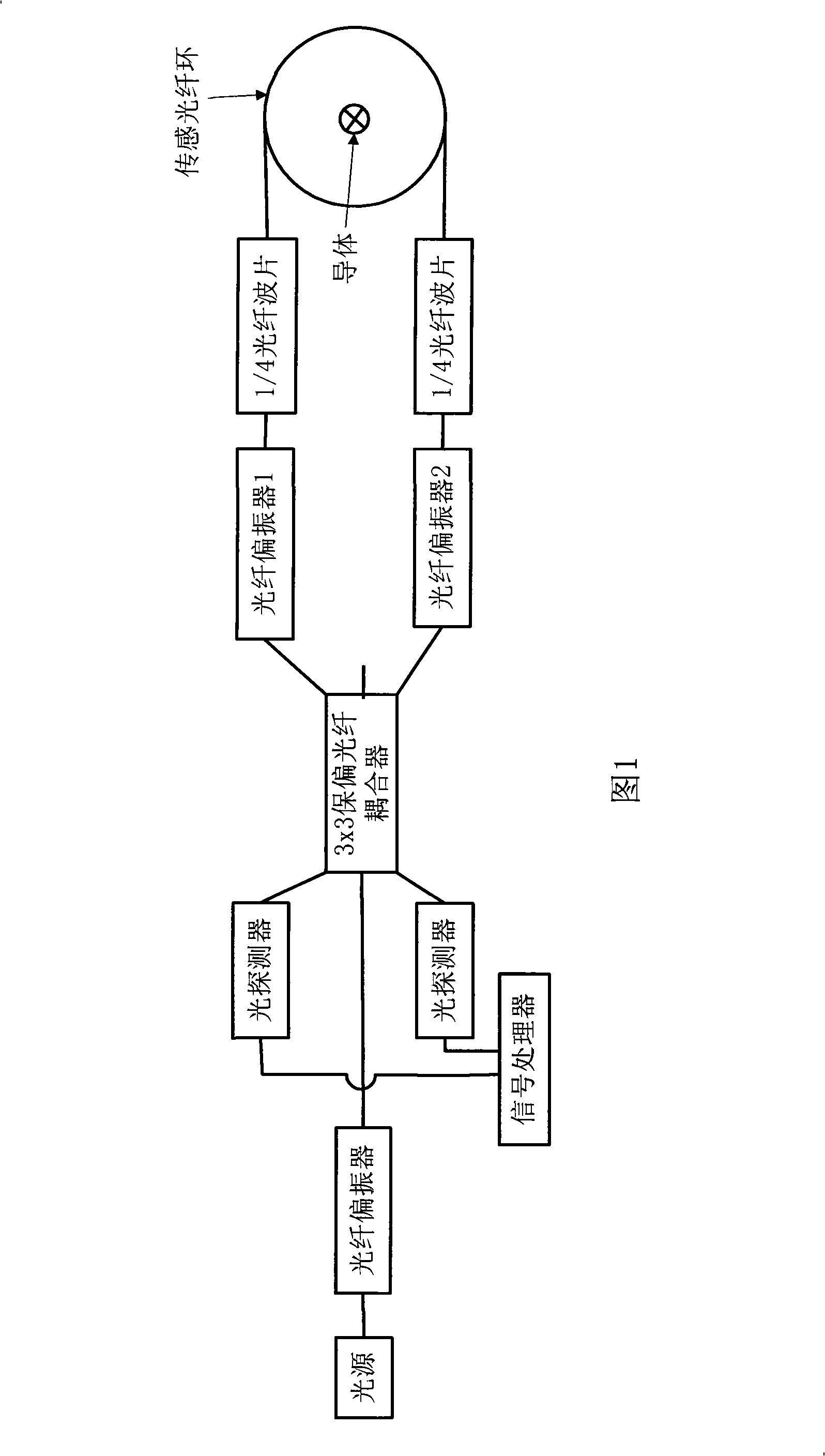

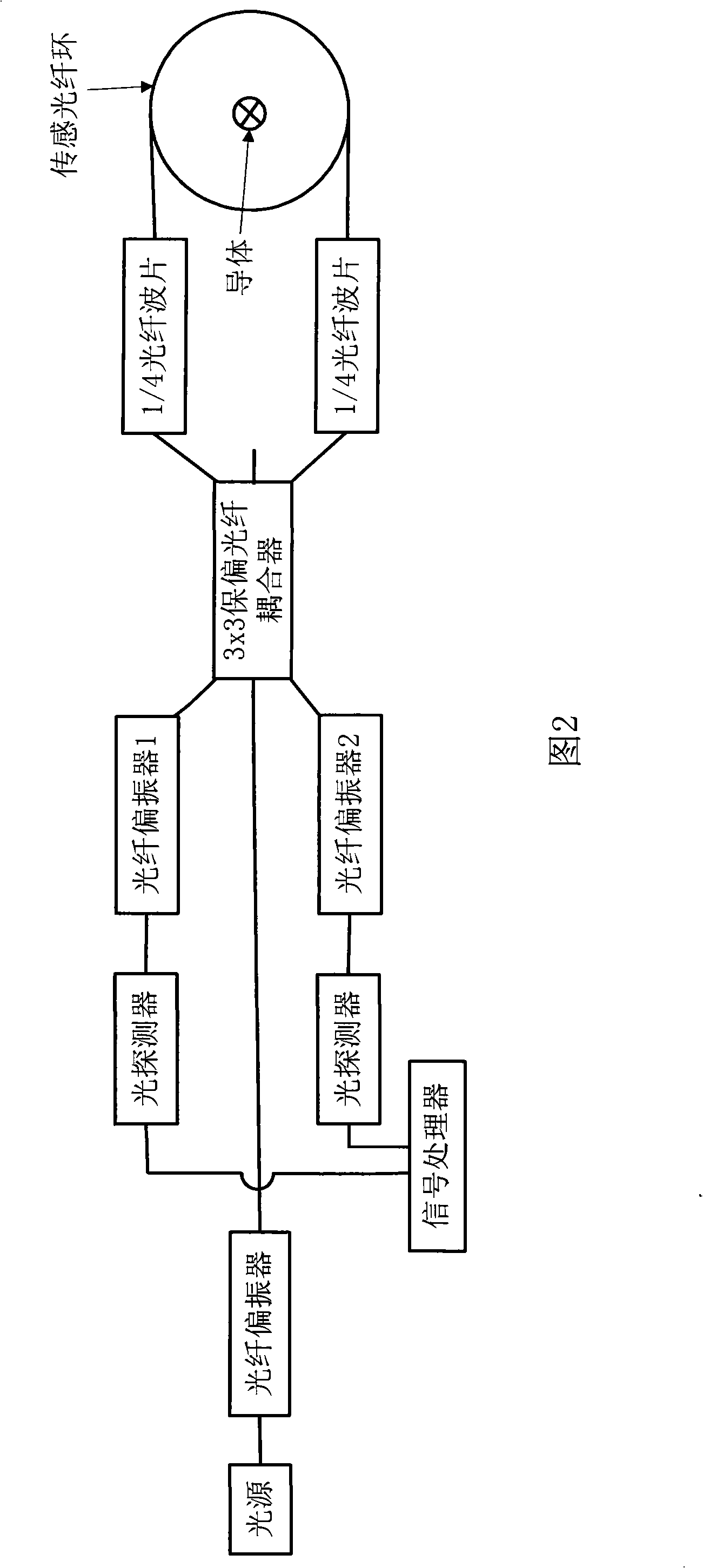

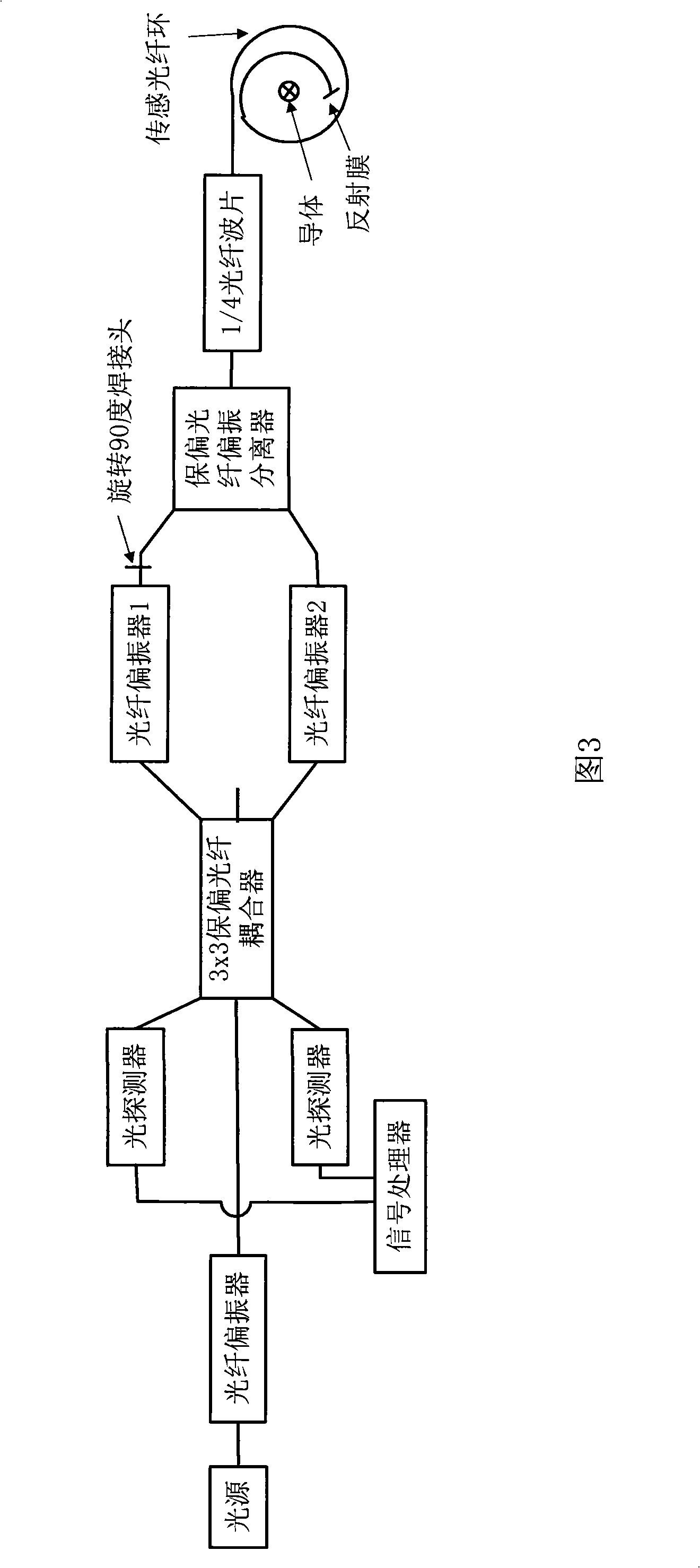

[0018] The optical coupler in the all-optical current sensor of the present invention adopts 3x3 polarization-maintaining optical fiber coupler, and the following introduction adopts two kinds of all-optical-optic current sensors of the present invention: the first kind of all-optical current sensor mainly consists of light source, 3x3 polarization-maintaining optical fiber coupler , fiber polarizer, 1 / 4 fiber wave plate, polarization-maintaining fiber polarization splitter (1x2 polarization-maintaining fiber coupler can also be used) and sensing fiber ring (surrounding the conductor), called reflective interference type all-fiber current Sensor; the second type of all-fiber-optic current sensor is mainly composed of a light source, 3x3 polarization-maintaining fiber coupler, fiber-optic polarizer, 1 / 4 fiber-optic wave plate and sensing fiber-optic ring, which is called a straight-through interferometric all-fiber-optic current sensor.

[0019] Fig. 1 is an embodiment of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com