Needle bar assembly structure of sewing machine and control method thereof

A component structure and control method technology, applied in the direction of sewing machine components, sewing machine needle holders, sewing equipment, etc., can solve the problems of large sewing machine casing internal space, difficult needle bar and hook synchronous rotation, complex structure, etc., to achieve thread The effect of perfect trace, simplified structure and reduced twist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

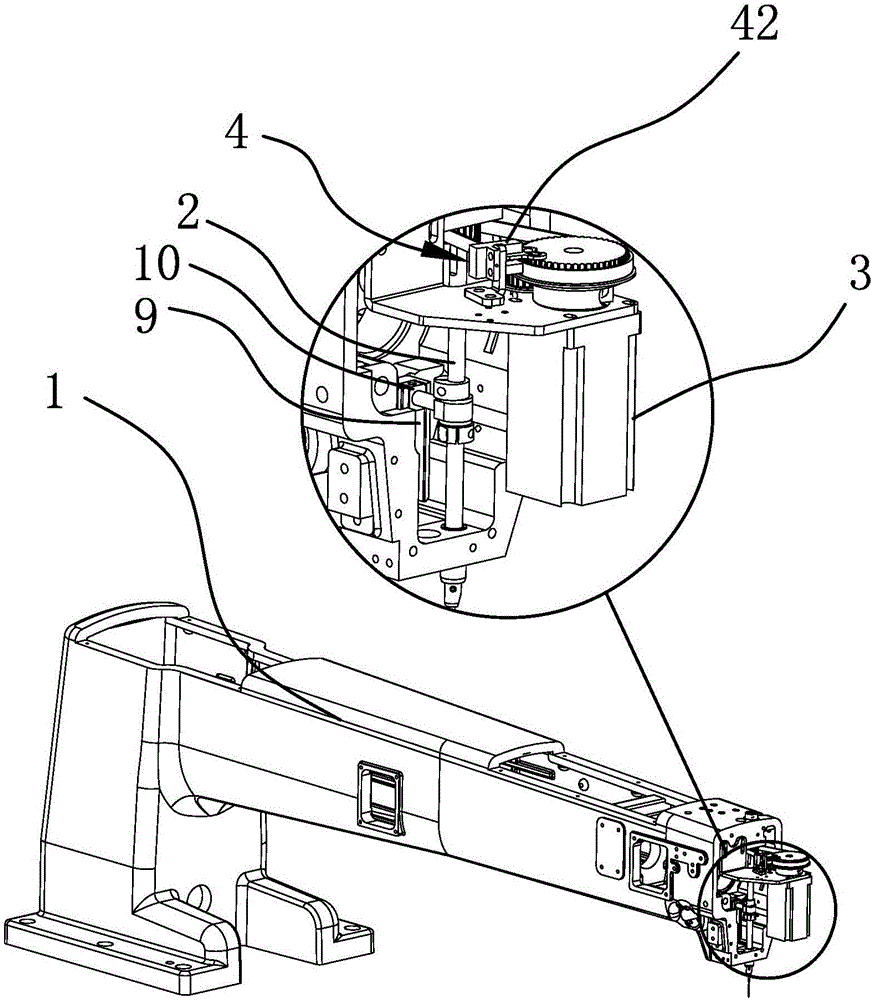

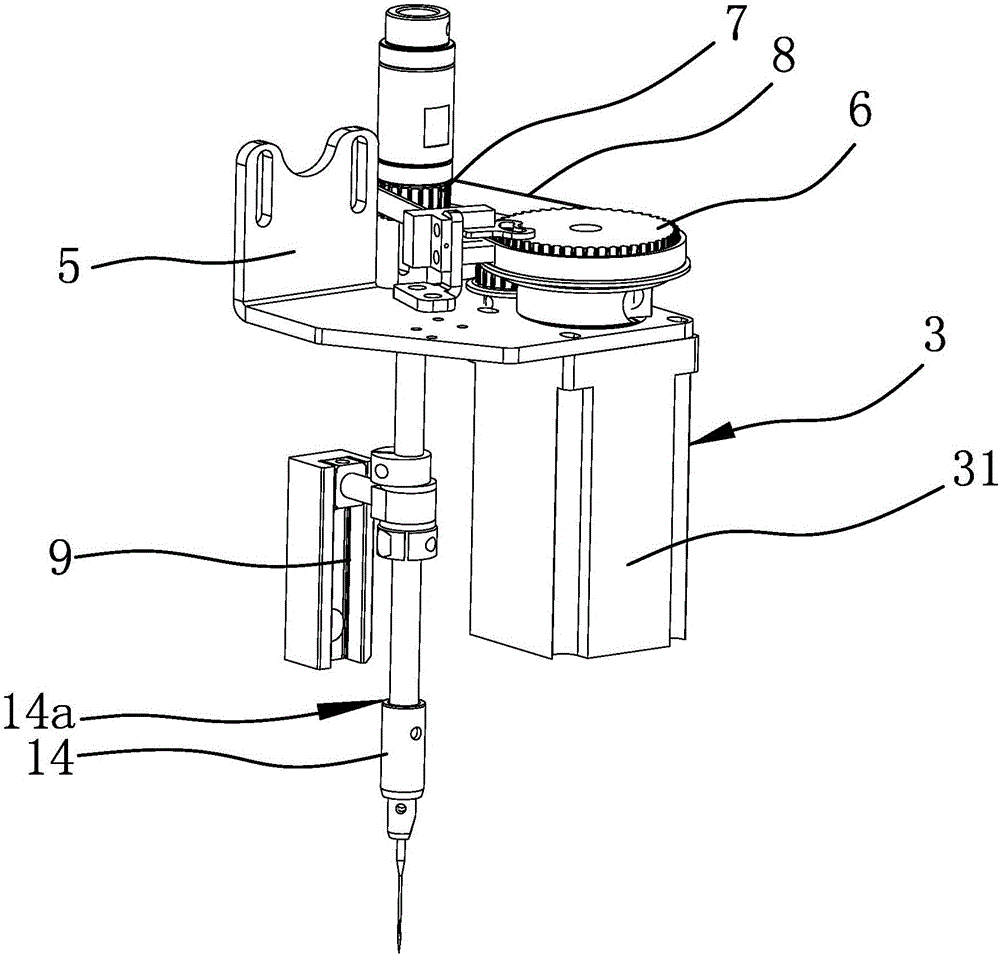

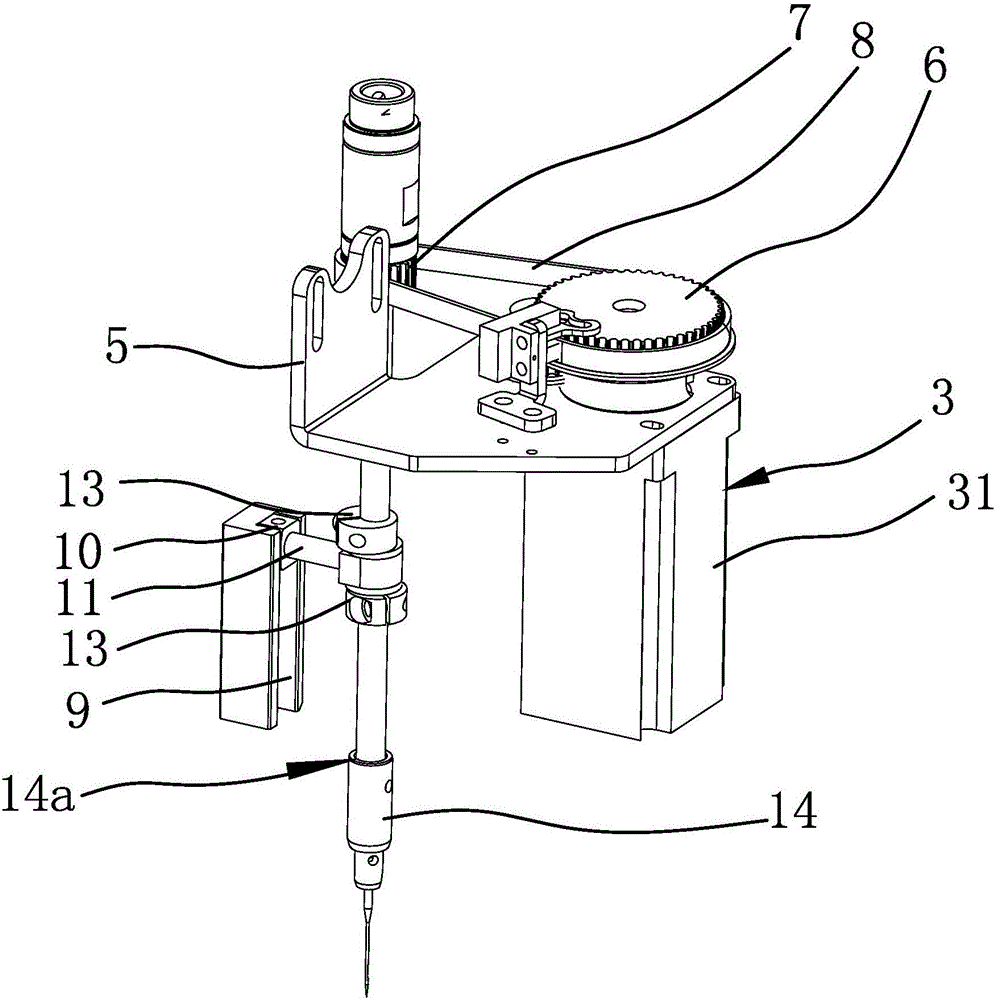

[0035] Such as figure 1As shown, the sewing machine includes a casing 1, the structure of the needle bar assembly includes a needle bar 2 and a driving part 3, the needle bar 2 is connected to the casing 1 for circumferential rotation and axial sliding, and the driving part 3 is fixedly connected to the casing 1 And it can drive the needle bar 2 to continuously reciprocate; further, as figure 2 with image 3 As shown, the casing 1 is fixedly provided with a mounting plate 5, the drive member 3 is a vertically arranged drive motor 31, the drive motor 31 is fixed on the mounting plate 5, and the output shaft of the drive motor 31 is fixedly provided with a large gear 6 The pinion 7 is fixed on the needle bar 2, and the large ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com