Device for measuring rheological parameters of fresh concrete

A rheological parameter and concrete technology, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems of inaccurate measurement results, limitations of the adaptability of existing technologies, etc., to expand the measurement range, accurate and reliable measurement data, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

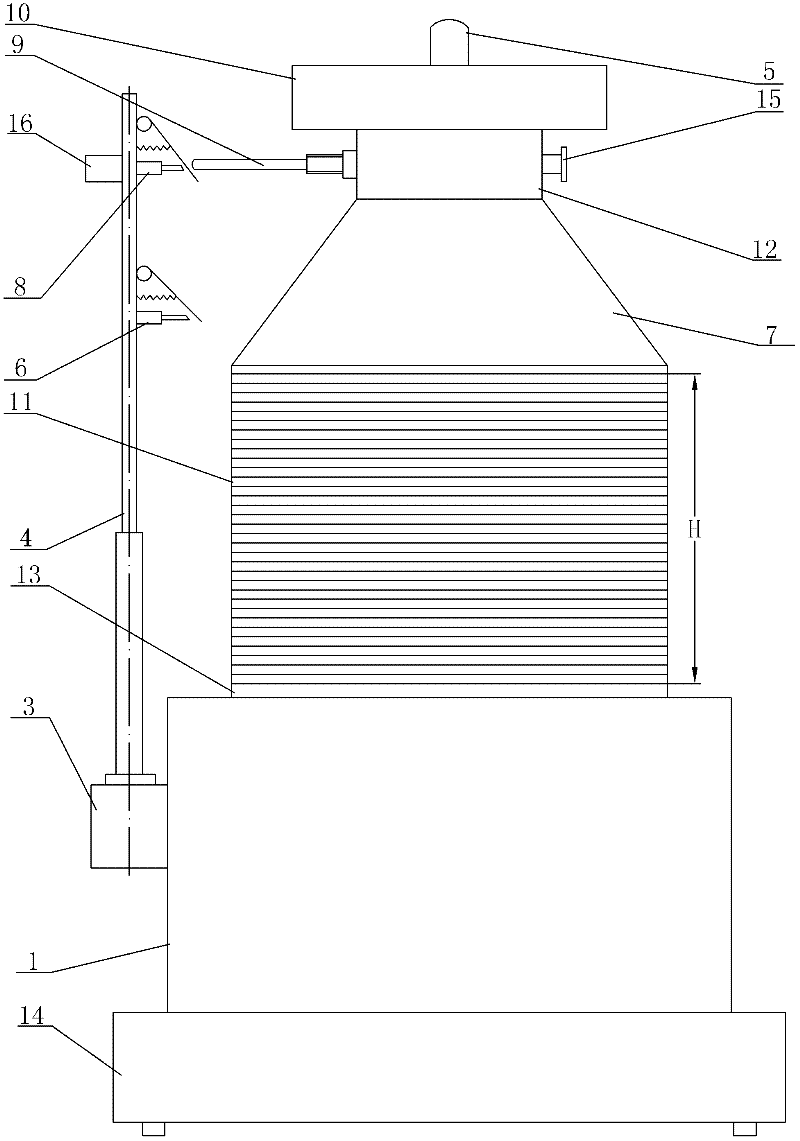

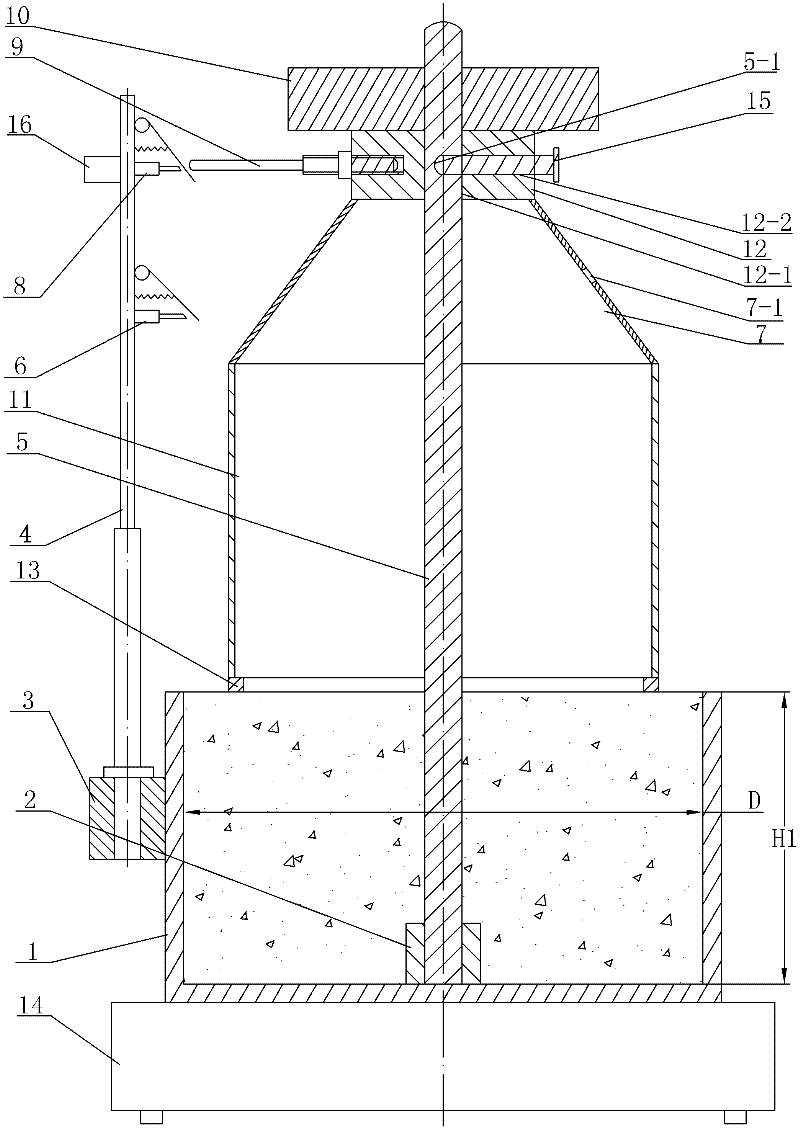

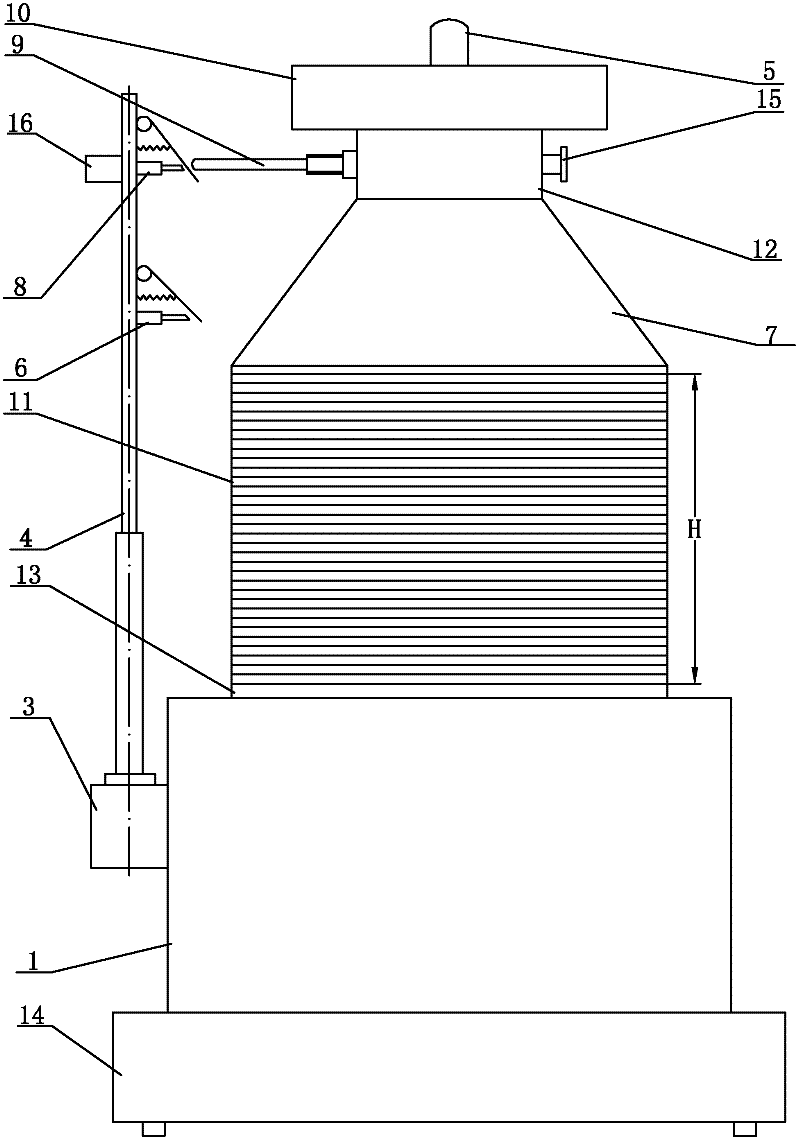

[0009] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a device for measuring the rheological parameters of fresh concrete in this embodiment includes a cylindrical container 1, a first casing 2, a second casing 3, a vertical rod 4, a shaft rod 5, and a conical cylinder 7. The first timing switch 6, the second timing switch 8, the pulling rod 9, the weight 10, the cylinder 11, the disk 12, the ring 13, the concrete vibrating table 14 and the timer 16, the cone cylinder 7 Both the small diameter end and the large diameter end are open ends, the two ends of the cylinder 11 are both open ends, the small diameter end and the large diameter end of the conical cylinder 7 are coaxially arranged, and one end of the first sleeve 2 The end face of the cylindrical container 1 is fixedly installed on the end face of the bottom of the cylindrical container 1, the first sleeve 2 is coaxially arranged with the cylindrical container 1, and a disc 12...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the cylindrical container 1, shaft rod 5, cone 7 and cylinder 11 described in this embodiment are all made of steel plates, the disc 12 is a steel disc, and the ring 13 is a steel ring . With such setting, the durability performance is high, and the design requirements and actual needs are met. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 2 The present embodiment will be described. The inner diameter D of the cylindrical container 1 according to the present embodiment is 100 mm to 110 mm, and the height H1 is 80 mm to 90 mm. This setting can meet the measurement needs. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com