Coal mine underground mobile gas beam tube sampling and monitoring device

A monitoring device and gas sampling technology, applied in the direction of measuring devices, mining devices, mining equipment, etc., can solve problems such as difficult to remove, many ground equipment, long pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

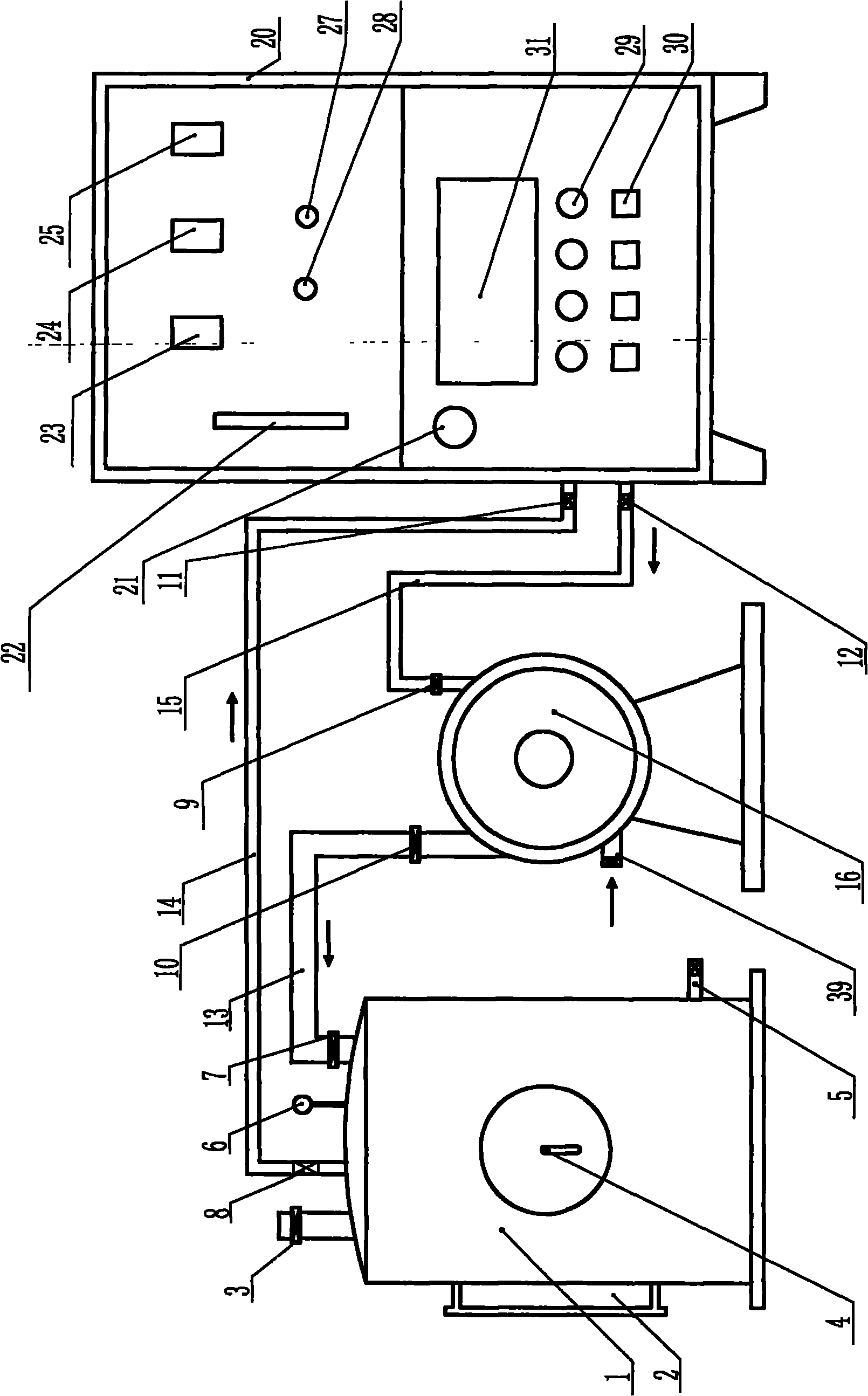

[0041] Bundle tube sampling and monitoring methods are as follows:

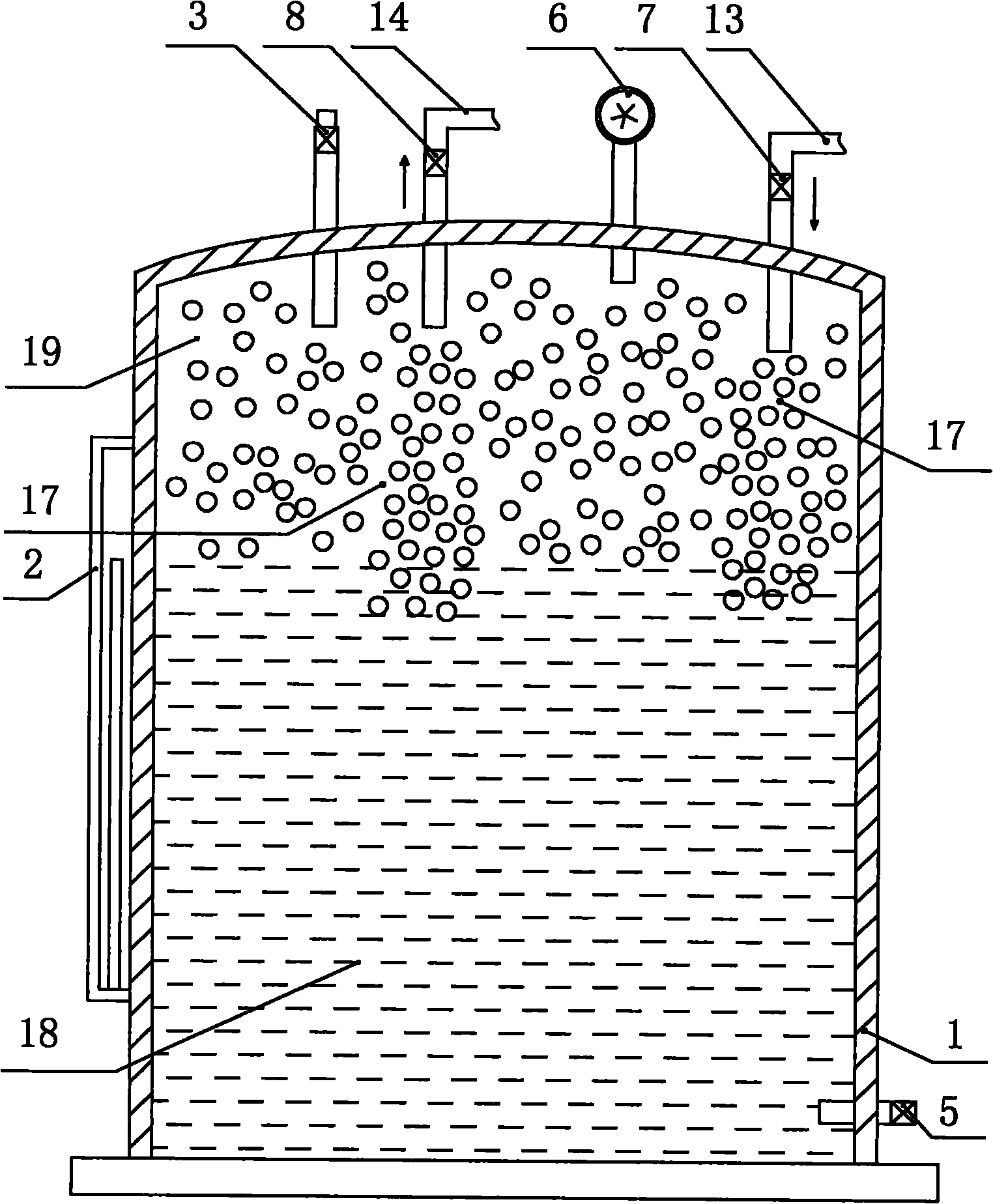

[0042] ①Bundle tubes, dust collectors, moisture proof devices, gas control valves, vacuum pumps, gas-water separators, gas sampling monitoring control cabinets, etc. are all in the quasi-working state;

[0043] ②The water inlet valve inputs water into the vacuum pump;

[0044] ③Eight-way sampling bundle tube for long-distance collection of gas in coal mine goaf or confined space;

[0045] ④The gas enters the dust collector to remove dust;

[0046] ⑤The gas enters the dehumidifier to dry;

[0047] ⑥ Negative pressure gauge to measure the negative pressure of the vacuum pump;

[0048] ⑦The gas enters the vacuum pump;

[0049] ⑧The gas-water mixture pumped out by the vacuum pump enters the gas-water separator for gas-water separation;

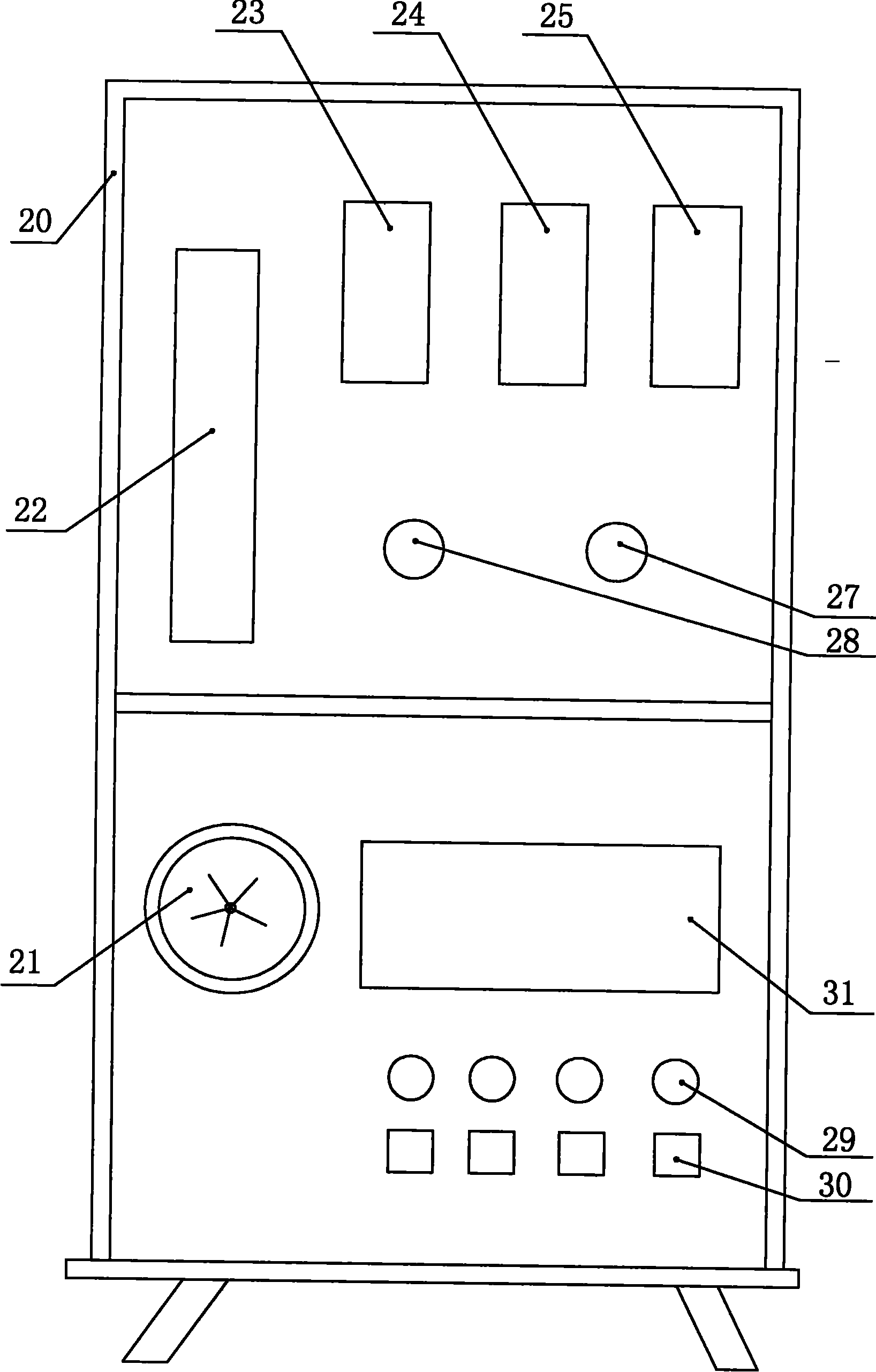

[0050] ⑨ After gas-water separation, enter the gas sampling monitoring control cabinet and gas flow meter;

[0051] ⑩The gas is diverted from the gas pipe to the oxygen sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com