Vision measuring apparatus of large size part

A measuring device and large-scale technology, applied in the field of optical measurement, can solve the problems of inability to achieve rapid measurement and handle a large number of other problems, and achieve the effects of reducing errors, improving measurement accuracy and good visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

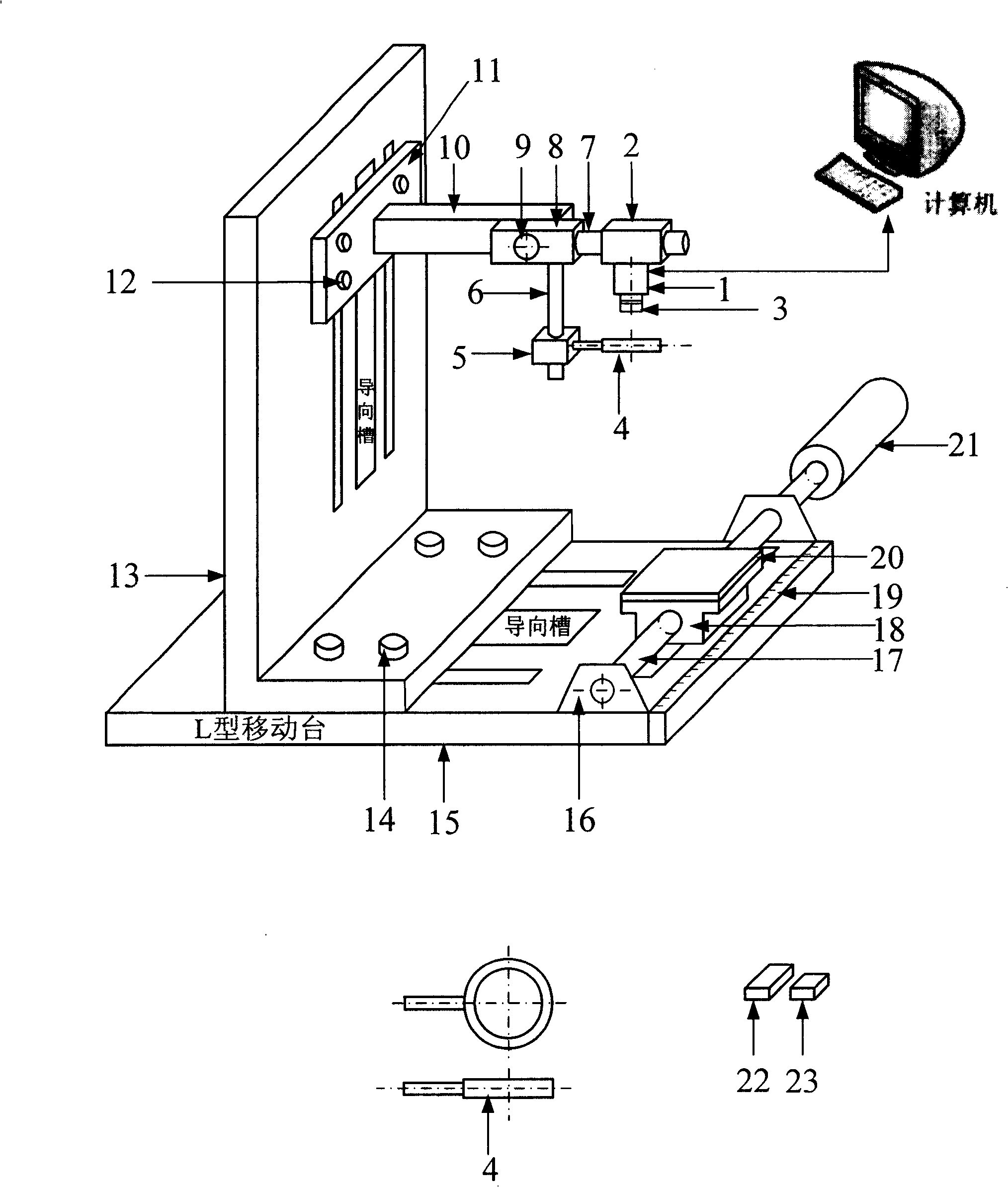

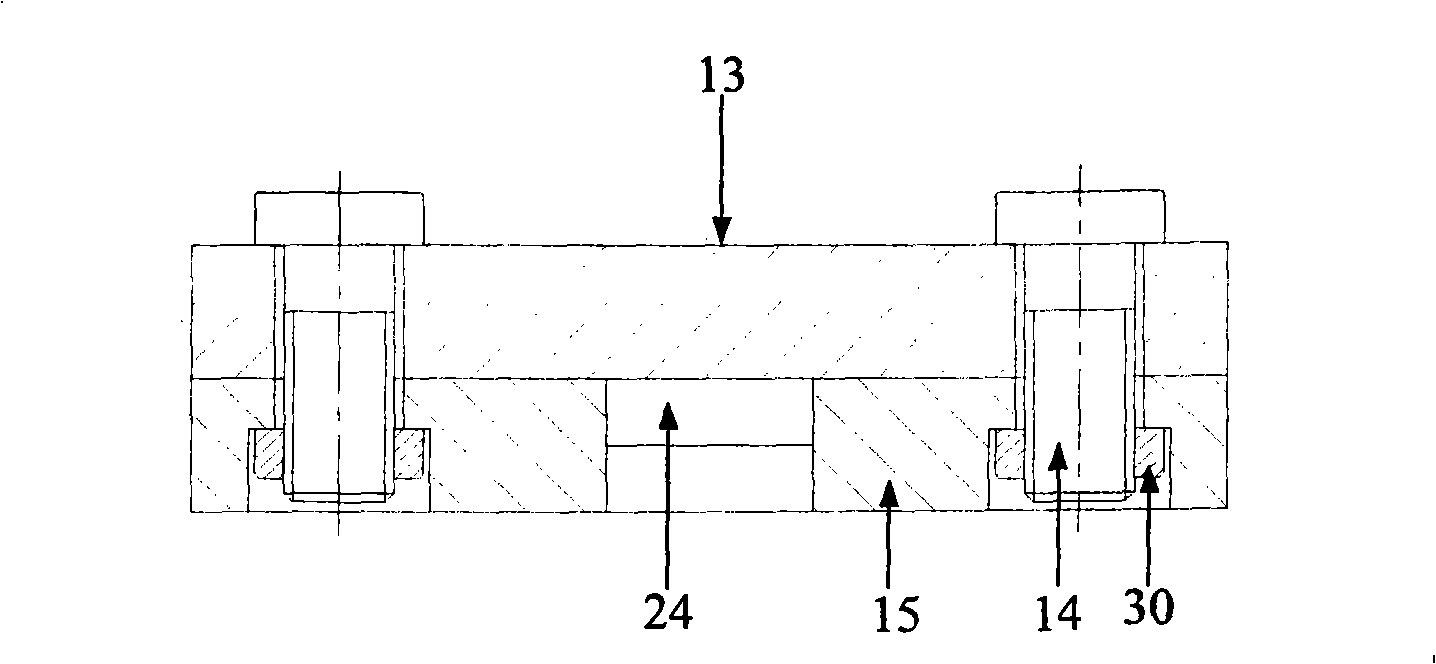

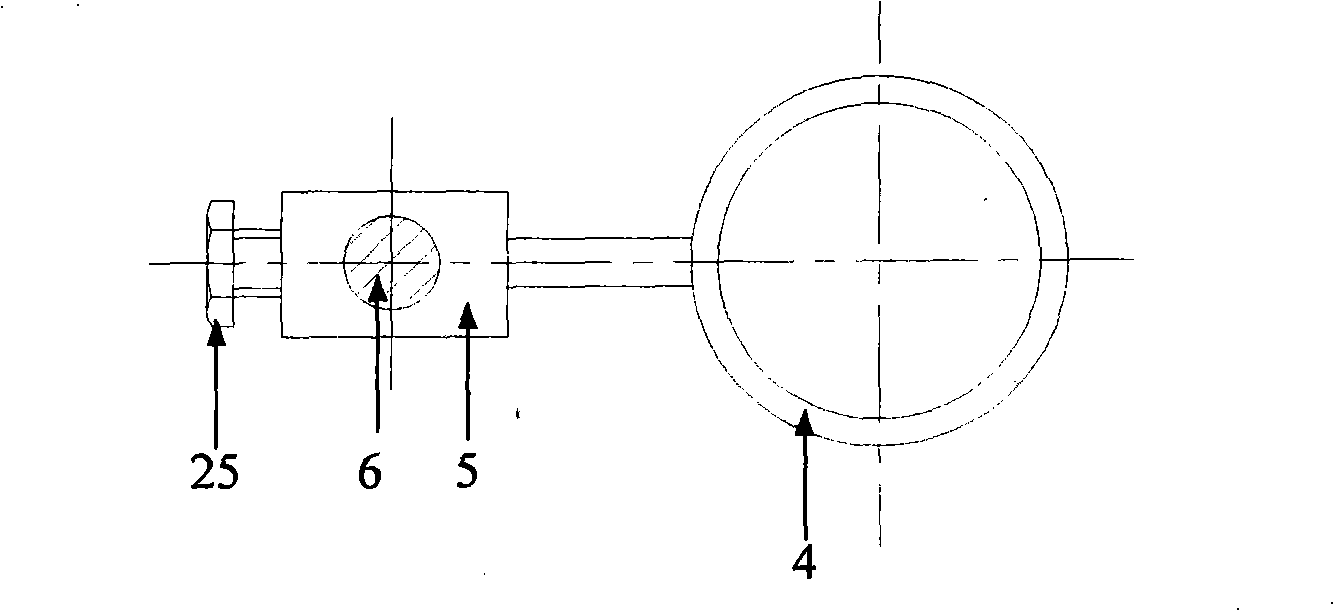

[0025] A measuring device for large-size parts based on machine vision, comprising a base 15 and large and small calibration blocks 22, 23. The length ratio of the large calibration block 22 and the small calibration block 23 is 3:2~2:1, In this embodiment, you can choose 3:2, 1.8:1 or 2:1. An L-shaped mobile station 13 is slidably connected to the base 15 and a support rod 10 is slidably connected to the vertical arm of the L-shaped mobile station 13. The sliding direction of the L-shaped mobile platform 13 is perpendicular to the sliding direction of the support rod 10. A rotating block 8 is rotatably connected to the support rod 10, and the rotational motion plane of the rotating block 8 is located between the sliding direction of the L-shaped mobile platform 13 and the support rod 10. The plane determined by the sliding direction is parallel, the camera support plate 2 is rotatably connected to the horizontal axis 7 of the rotating block 8, and the rotation motion plane of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com