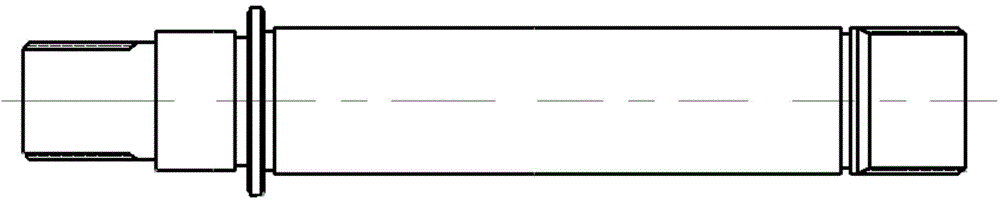

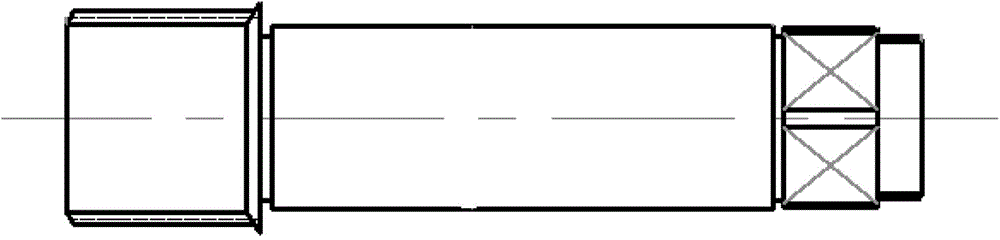

Transmission measuring device for dimension measurement of shaft parts

A technology of shaft parts and measuring devices, which is applied in the field of measuring the length and diameter of washing machine shaft parts and transmission measuring devices for shaft part size measurement, can solve the problems of inconvenient use and low precision, and avoid human errors, The effect of improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

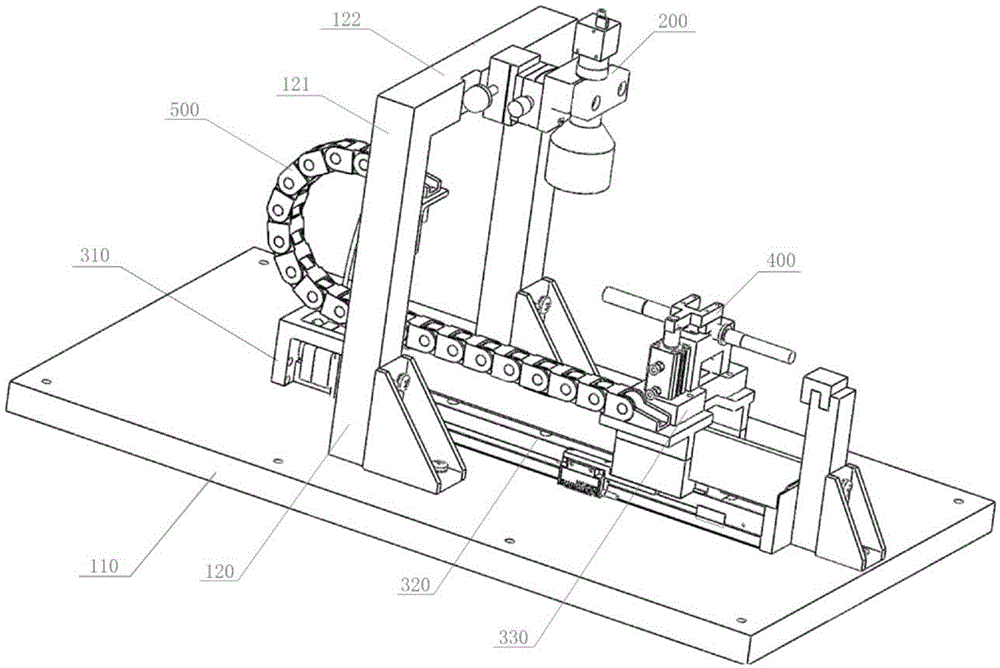

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] like figure 2 As shown, the embodiment of the present invention includes a horizontal base 110, a bracket 120, a vision system 200, a stepper motor 310, a ball screw 320, a slide table 330, a positioning fixture 400 and a drag chain 500, and the bracket 120 is composed of A door frame structure composed of an integrated column 121 and a beam 122 is vertically fixed on the horizontal base 110, and the vision system 200 is fixed at the middle position of the beam 122 of the bracket;

[0029] like figure 2 , image 3 As shown, the ball screw 320 is located between the two columns 121 of the bracket 120, is fixed on the horizontal base 110 and is in an orthogonal relationship with the two columns, and the slide table 330 is positioned between the two columns 121 of the bracket 120. The rod 320 is fixedly connected with the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com