Automatic calibration and automatic measurement device of fluid flow test probe

A technology for testing probes and automatic calibration, which can be used in measuring devices, fluid dynamics tests, and machine/structural parts testing, etc. It can solve problems such as cumbersome work, low work efficiency, and judgment errors, so as to speed up and save time. and human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

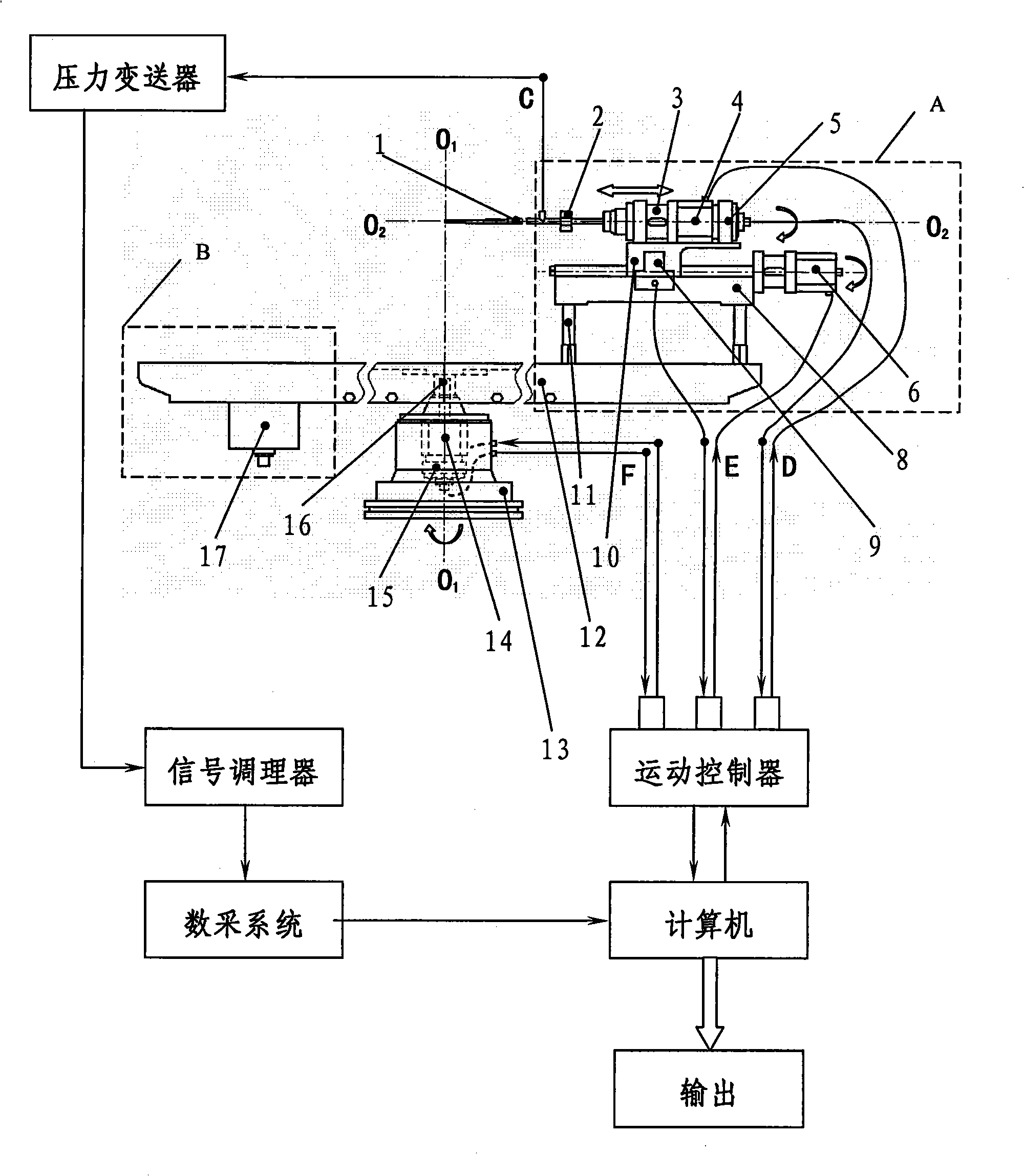

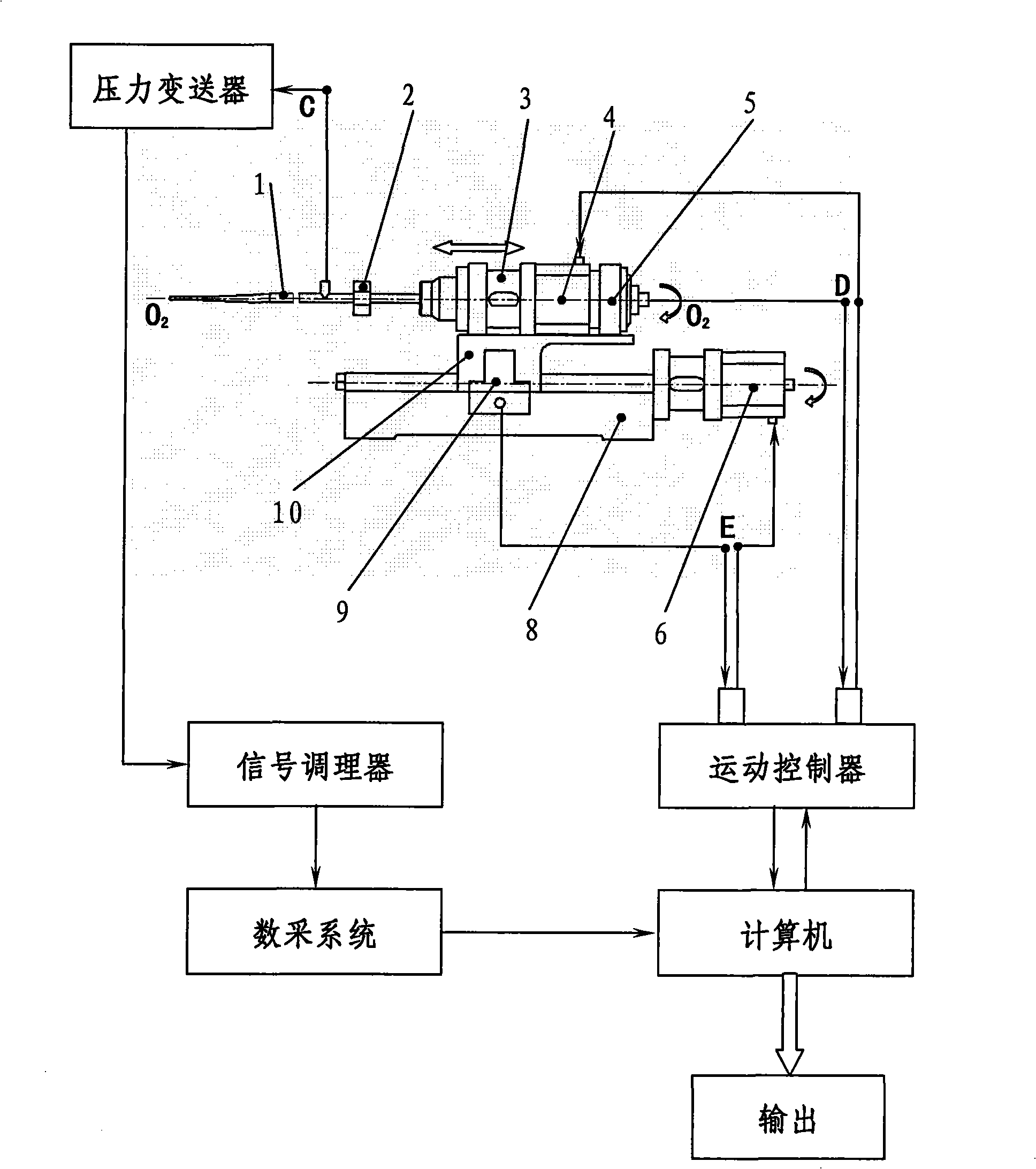

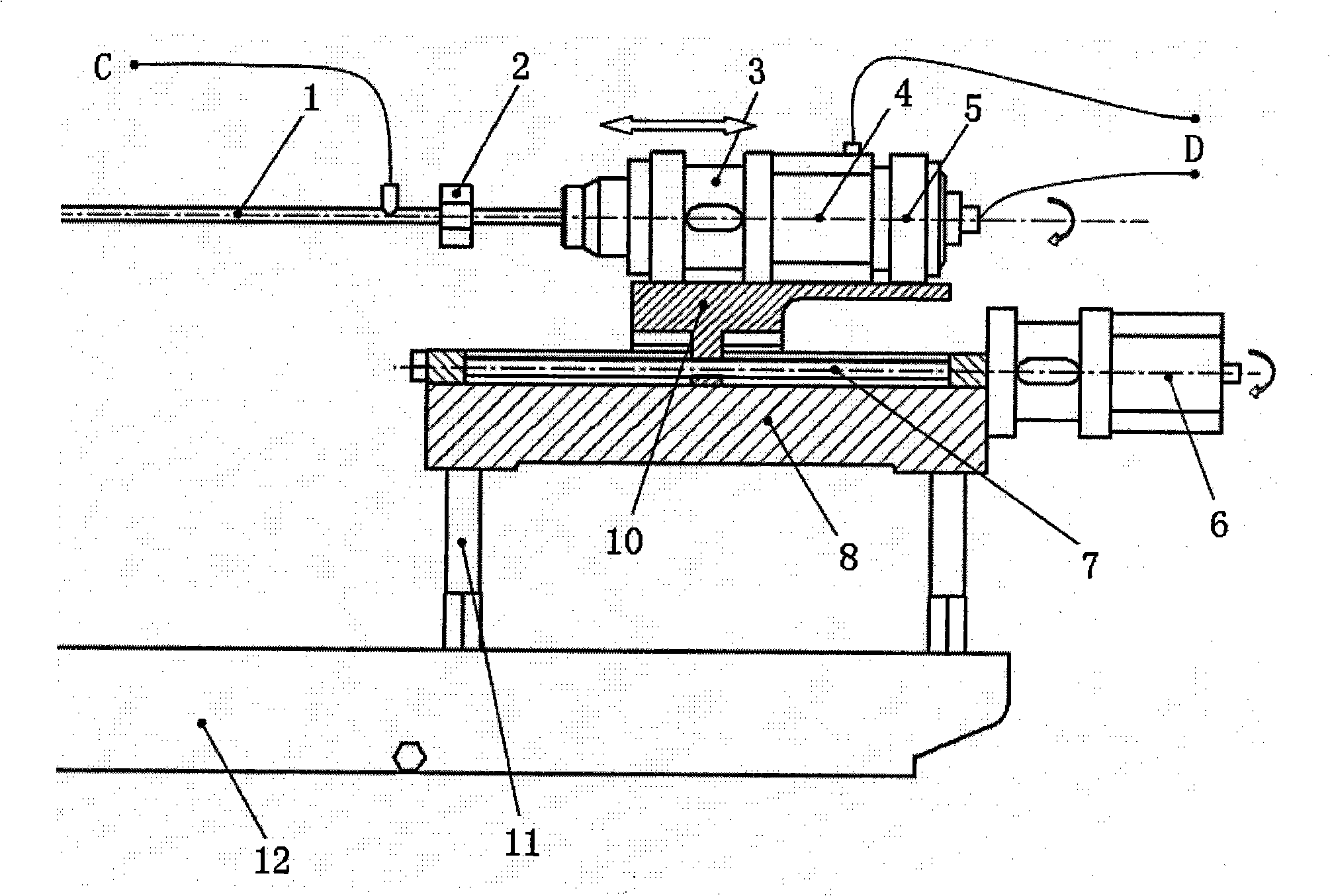

[0025] Such as figure 1 As shown, an automatic calibration device for a fluid flow test probe includes a probe pitch angle adjustment mechanism and a probe translation adjustment mechanism (see for details image 3 ), probe deflection angle adjustment mechanism and data acquisition and control system. The probe deflection angle adjustment mechanism includes a crossbeam 12, the components 1 to 10 of the probe pitch angle adjustment mechanism and the probe translation adjustment mechanism are installed on the crossbeam 12 through a strut 11, and the other end of the crossbeam 12 is equipped with a balance block 17. The block is adjusted in translation by a leading screw 18 ( Figure 4 ). Bearing 13 is equipped with below the middle of crossbeam, and numerical control motor 14 and encoder 15 are housed inside the bearing. The beam 12 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com