High-precision tool setting device and tool setting method of micro-diameter milling tool

A tool setting device and high-precision technology, applied in feeding devices, automatic control devices, measuring/indicating equipment, etc., to achieve the effects of simple operation, avoiding depth of field errors, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the drawings and embodiments.

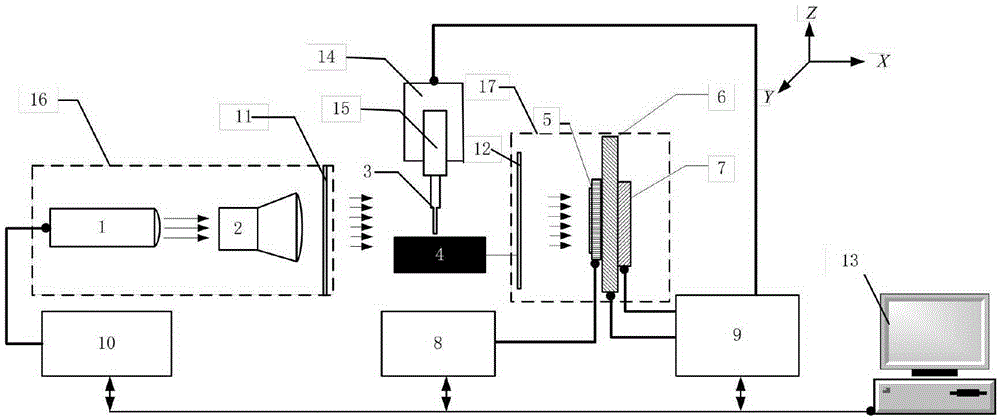

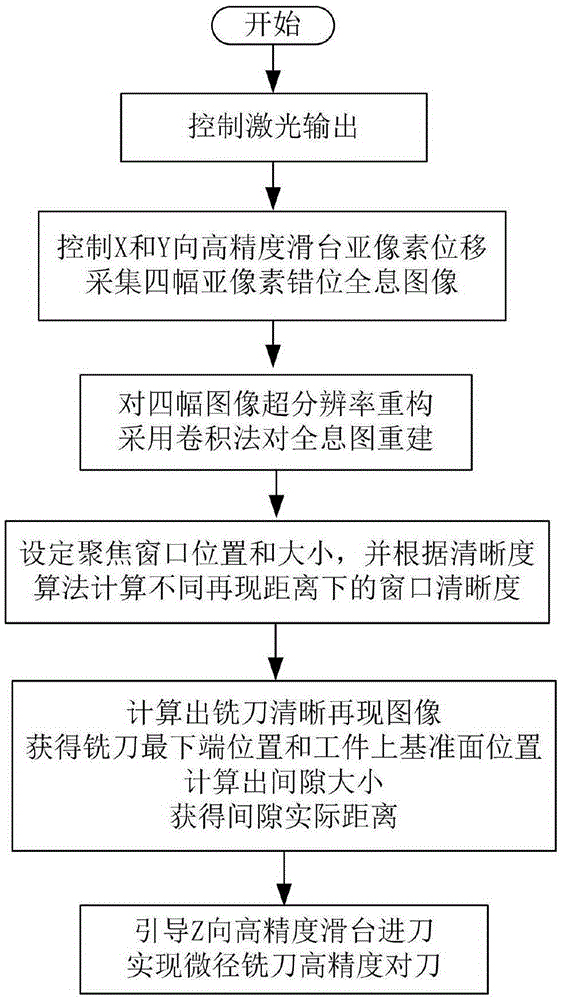

[0017] Such as figure 1 As shown, the micro-diameter milling cutter high-precision tool setting device includes: a semiconductor laser 1, a beam expanding collimator lens 2, a micro-diameter milling cutter 3, a workpiece 4, an area CCD chip 5, an X high-precision sliding table 6, Y high-precision sliding table 7, image signal processing unit 8, motor control unit 9, laser control unit 10, first high transmission glass window 11, second high transmission glass window 12, computer main control unit 13, Z-direction high-precision sliding The table 14, the electric spindle 15, the first dark box 16 and the second dark box 17. The computer main control unit 13 sends instructions to the image signal processing unit 8, the motor control unit 9 and the laser control unit 10 respectively; the motor control unit 9 controls the Z-direction high-precision sliding table 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com