Coal mine gas pre-draining borehole sealing method adopting aerated capsule as temporary hole bottom

An inflatable capsule and coal mine gas technology, which is applied in the direction of gas discharge, mining equipment, earthwork drilling, etc., can solve the problems of cement mortar injection process implementation difficulties, cement mortar unsealed, orifice pipe wear, etc., to achieve simple structure, reduce The cost of sealing holes and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

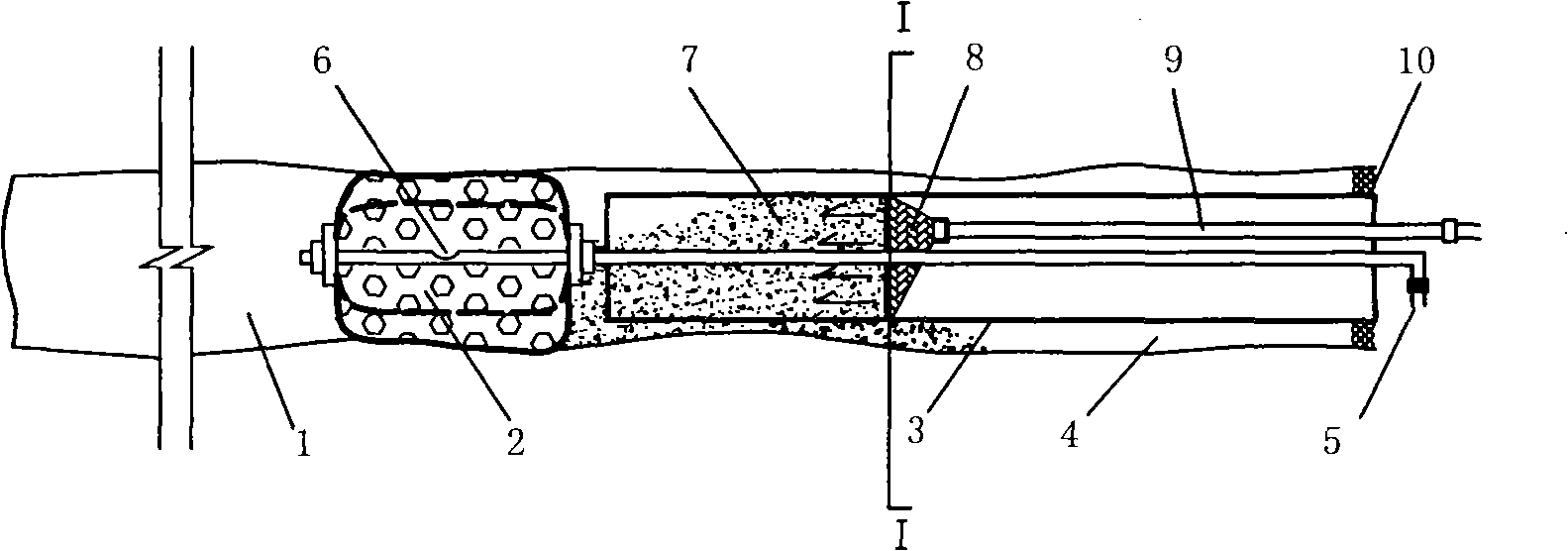

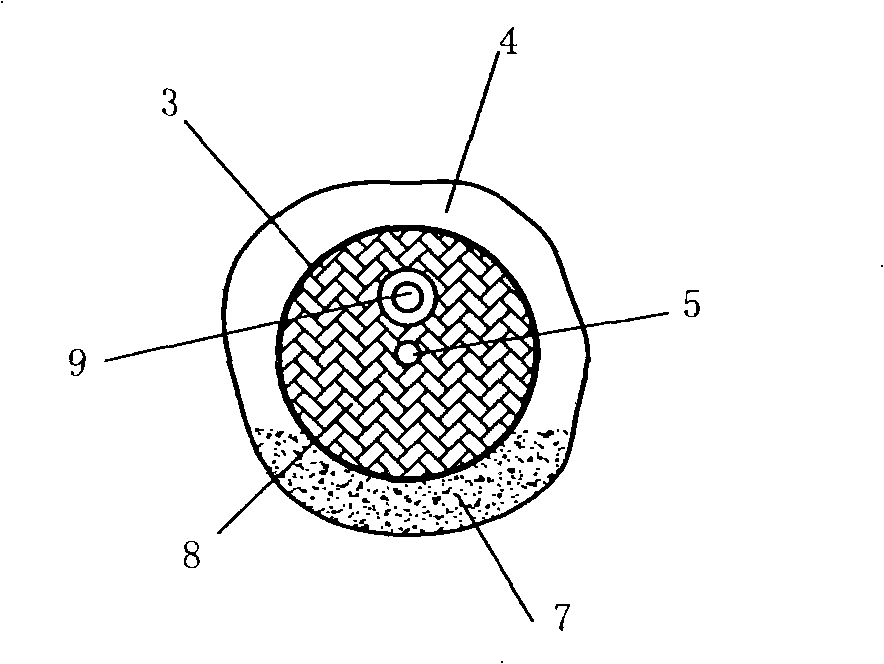

[0021] Such as figure 1 with figure 2 As shown, the hole sealing method of coal mine gas pre-extraction boreholes using inflatable capsules as temporary hole bottoms in this embodiment is suitable for boreholes using large-diameter orifice pipes. It includes the following steps:

[0022] a. When the gas pre-extraction hole is drilled to the depth of the final hole, the drilling tool is pulled out, and the orifice pipe 3 is placed in the drill hole 1;

[0023] b. Send the inflatable capsule 2 from the orifice tube 3 into the drill hole 1, so that the inflatable capsule 2 is located below the bottom of the orifice tube 3. The distance between the inflatable capsule 2 and the bottom of the orifice tube 3 must be 5-15 cm, and then pass through the inflatable tube 5 and the air hole 6 inflate the inflatable capsule 2, so that the inflatable capsule 2 expands and closely contacts with the borehole wall, and then closes the gate valve of the inflatable tube 5 to form a temporary h...

Embodiment 2

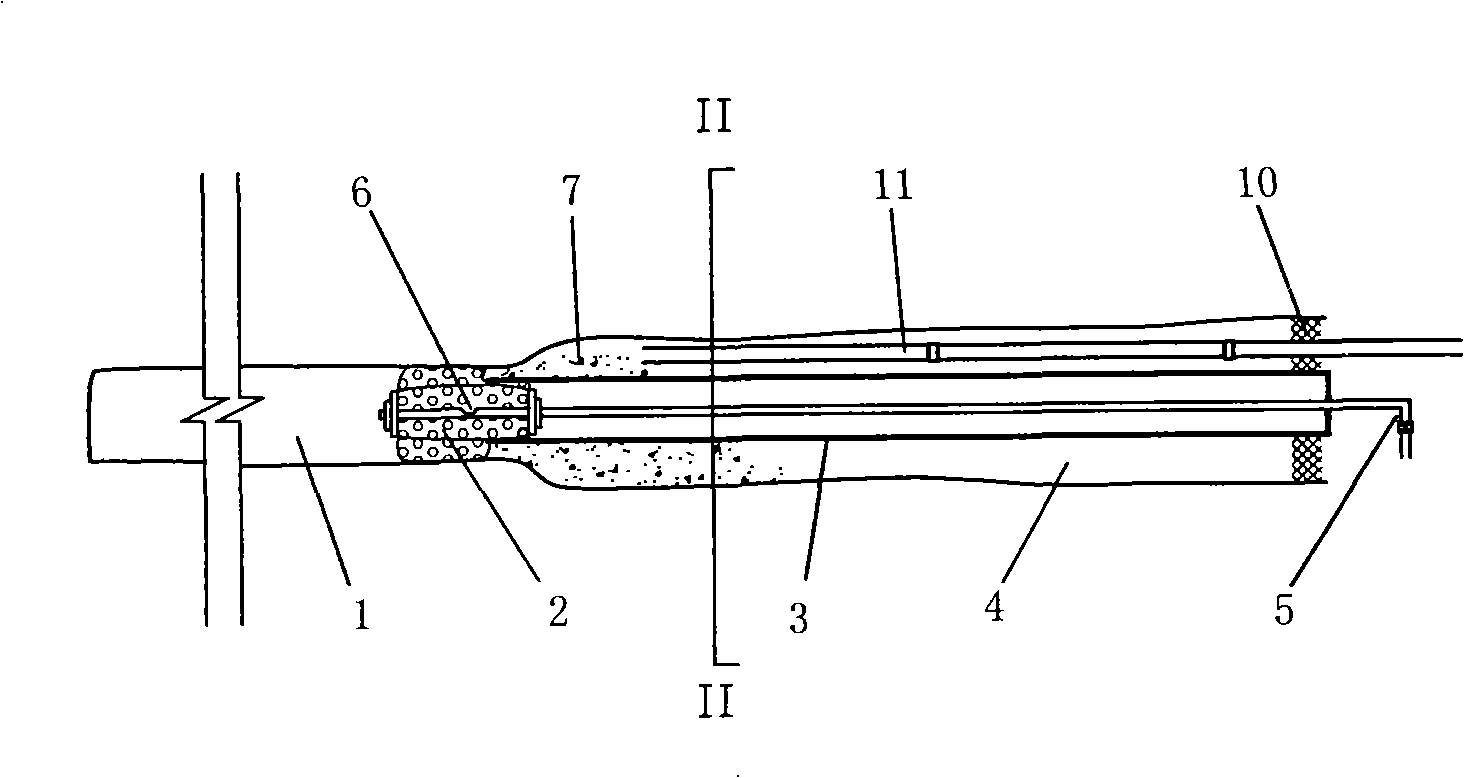

[0028] Such as image 3 with Figure 4 As shown, the hole sealing method of coal mine gas pre-extraction drilling using the air-filled capsule as the temporary bottom of the hole in this embodiment is suitable for drilling using small-diameter orifice pipes. It includes the following steps:

[0029] a. After the gas pre-extraction hole is drilled to the depth of the final hole, ream the hole sealing section, pull out the drilling tool, and then put the orifice pipe 3 into the drill hole 1;

[0030] b. Send the inflatable capsule 2 into the borehole 1 from the orifice tube 3, so that the inflatable capsule 2 is located below the bottom of the orifice tube 3, and the upper end of the inflatable capsule 2 is in contact with the bottom of the orifice tube 3, and then through the inflatable The tube 5 and the air hole 6 inflate the inflatable capsule 2, so that the inflatable capsule 2 expands and makes close contact with the borehole wall, and then closes the gate valve of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com