Auxiliary piston method for sealing oil cylinder

A technology for assisting pistons and oil cylinders, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of easy cracks in the sealing ring, large pressure difference of the oil cylinder sealing ring, and accelerated wear speed, so as to save sealing costs and reduce Effect of front and rear pressure difference, reducing wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

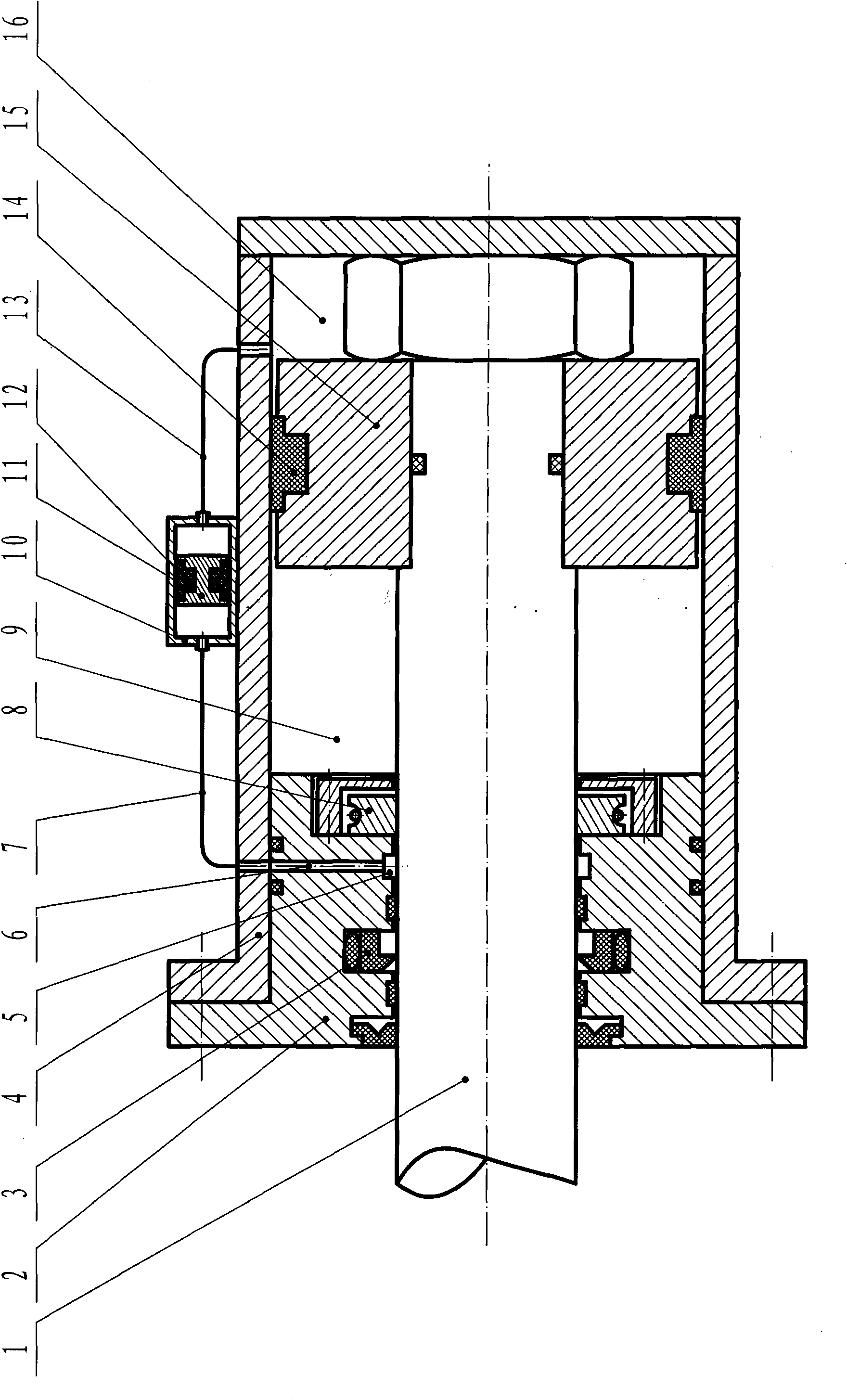

[0014] Combine below figure 1 The specific implementation mode when the present invention is used as oil cylinder piston rod seal will be further described in detail.

[0015] A floating seal 8 is installed on the oil cylinder guide sleeve 2 near the front chamber 9 of the oil cylinder, and an oil groove 5 is processed at the oil cylinder guide sleeve 2 near the floating seal 8, and an outer cylinder body 10 is installed on the outer cylindrical surface of the cylinder barrel 4 of the oil cylinder. 10 is installed with an outer piston 11, and a sealing ring 12 is installed on the outer piston 11. The outer piston 11 can reciprocate for a certain distance in the axial direction in the outer cylinder body 10. One end of the outer cylinder body 10 has an oil pipe 7 through the oil circuit 6 and The oil groove 5 communicates with each other, and the other end of the outer cylinder body 10 has an oil pipe 13 to communicate with the oil cylinder rear cavity 16 .

[0016] When worki...

Embodiment 2

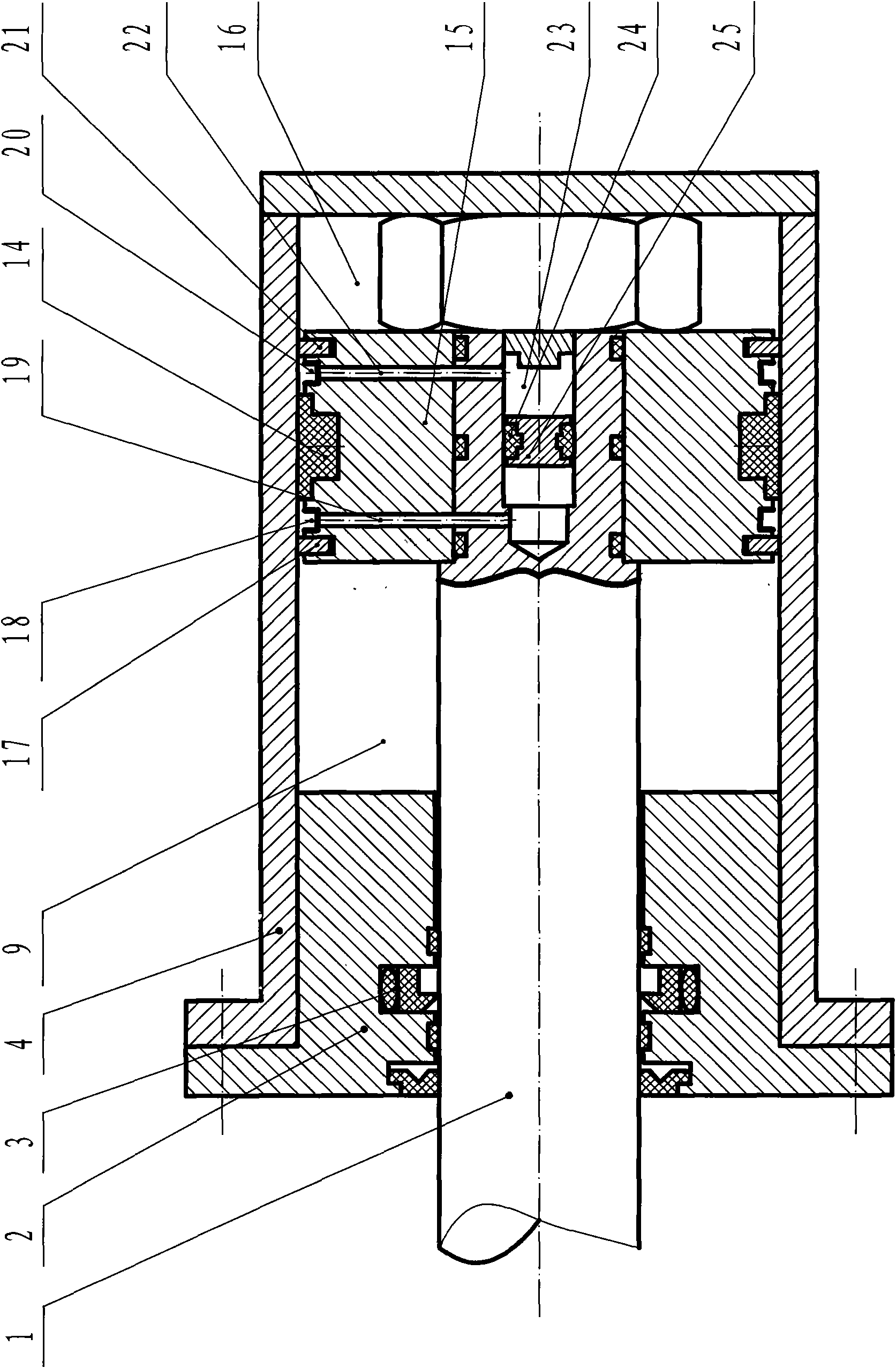

[0018] Combine below figure 2 Further detailed description will be given when the present invention is used as oil cylinder piston seal.

[0019] A front piston ring 17 and a rear piston ring 21 are respectively installed at both ends of the oil cylinder piston 15. The oil cylinder piston 15 is partially processed with an oil groove 18 between the front piston ring 17 and the piston seal 14, and the oil cylinder piston 15 is interposed between the rear piston ring 21 and the piston seal 14. The part between the piston seals 14 is also processed with an oil groove 20, and an inner cylinder body 23 is processed inside the shaft center of the piston rod 1 close to the 16 end of the cylinder rear cavity, and an inner piston 25 is installed in the inner cylinder body 23, and a sealing ring is installed on the inner piston 25 24. The inner piston 25 can reciprocate for a certain distance in the axial direction in the inner cylinder 23. The two ends of the inner cylinder 23 have oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com