Nearly horizontal high pressure-bearing drilling sealing method and sealing structure

A high pressure bearing and hole sealing technology, which is applied in sealing/isolation, earthwork drilling, gas discharge, etc., can solve problems such as low sealing efficiency, long sealing time, and difficulty in meeting pressure-bearing hole sealing requirements. Achieve high sealing efficiency, low sealing cost and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

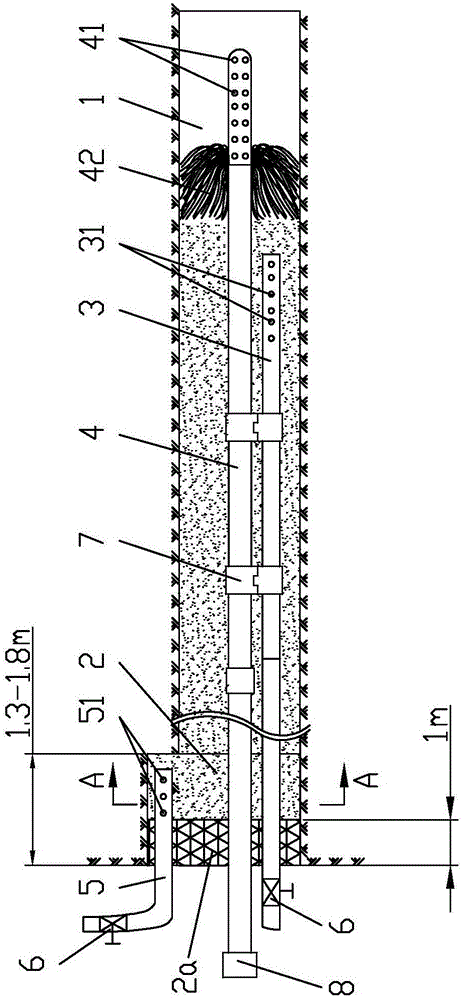

[0027] Example 1, see figure 1 , figure 2 , A near-level high-pressure drilling and sealing method, including the following steps:

[0028] a. An enlarged hole 2 with a depth of 1.3~1.8m and a diameter larger than that of the high pressure drilled hole 1 is formed at the orifice of the high pressure drilled hole 1, and the enlarged hole 2 is connected to the high pressure drilled hole at the lower bus bar. 1Inside cutting, so that the inner step formed between the enlarged hole 2 and the high-pressure-bearing borehole 1 has a part located above the bus bar of the high-pressure borehole 1;

[0029] b. Send the grouting pipe 3 for hole sealing and the fracturing pipe 4 for fracturing or drainage that are fixed together by the holding clamp 7 into the high pressure borehole 1 to set the depth, and the return pipe 5 into The depth is set in the enlarged hole 2, and the nozzles of the grouting pipe 3, the fracturing pipe 4 and the grouting pipe 5 are located outside the orifice of the...

Embodiment 2

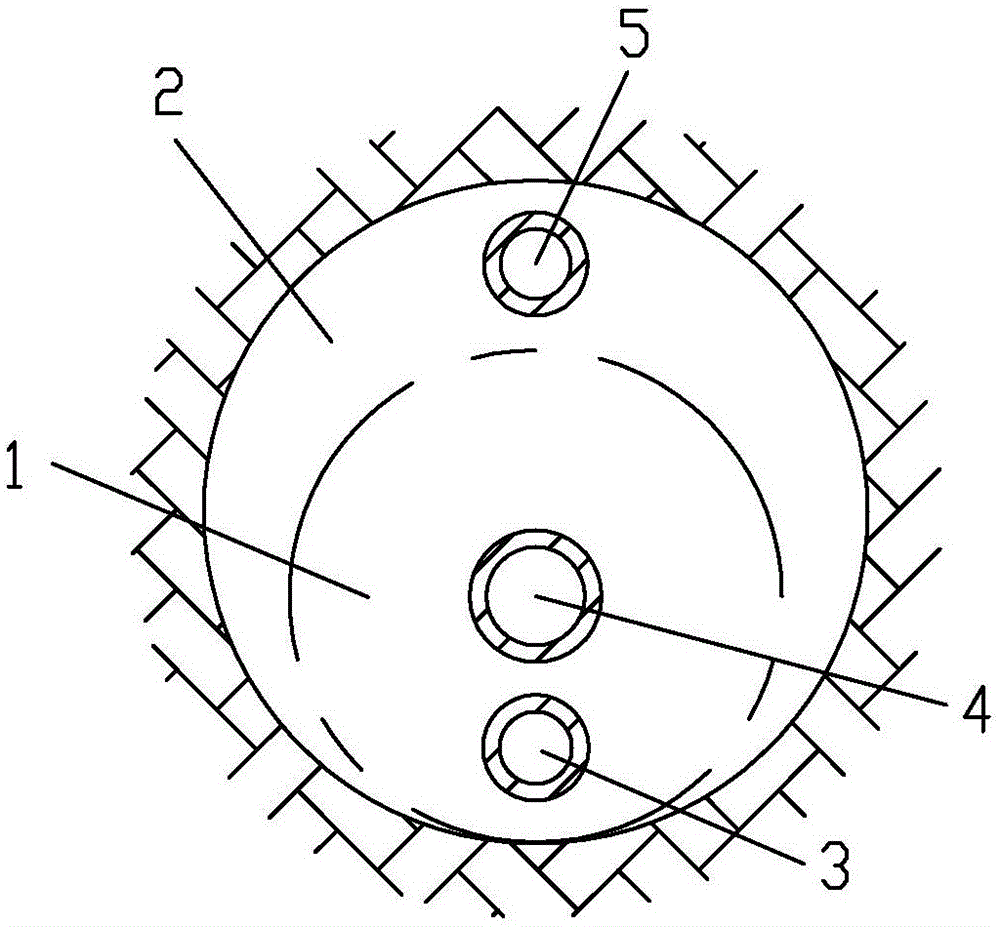

[0032] Example 2, see figure 1 , figure 2 , A near-level high-pressure-bearing drilling and sealing structure, composed of an inner sealing section and an outer sealing section. The connecting section connected to the inner sealing section on the outer sealing section is infused with cement slurry simultaneously with the inner sealing section The inner and outer sealing sections are respectively formed in the high-pressure-bearing borehole 1 and the enlarged hole 2. The enlarged hole 2 is located at the orifice of the high-pressure borehole 1, and the enlarged hole 2 is at the lower bus bar and the height The pressure-bearing borehole 1 is cut inward so that the inner step formed between the enlarged hole 2 and the high-pressure-bearing borehole 1 has a part located above the bus bar of the high-pressure borehole 1.

[0033] A part of the grouting pipe 3 and the fracturing pipe 4 are sealed in the inner sealing section and the outer sealing section. The grouting pipe 3 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com