Millisecond multilevel directional blasting dry ice fracturing method and exploding pipe

A technology of directional blasting and blasting pipe, which is applied in blasting, blasting cylinder, earth-moving drilling and mining, etc., to achieve the effects of easy implementation, simple method, novel and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Drill the blast hole 9 and the drainage hole 10 on the coal seam working face, and the distance L between the blast hole 9 and the drainage hole 10 is 2000mm;

[0035] 2. Making blasting tubes;

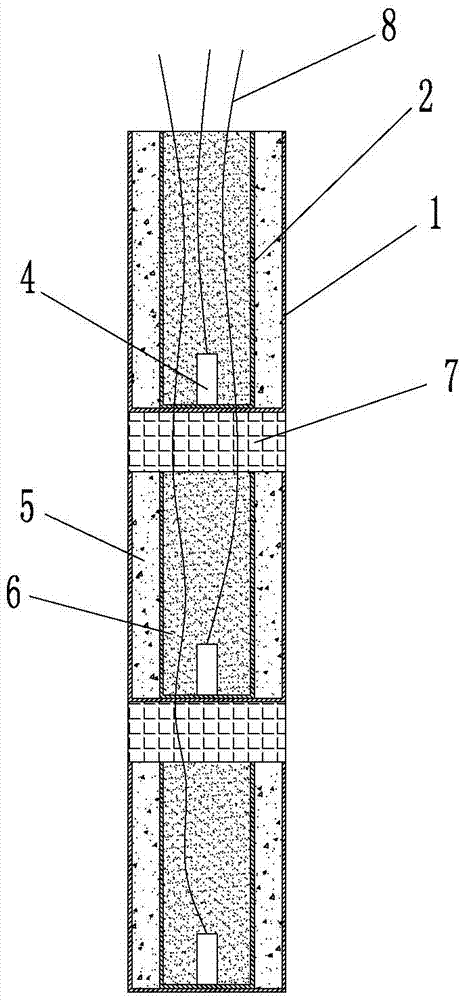

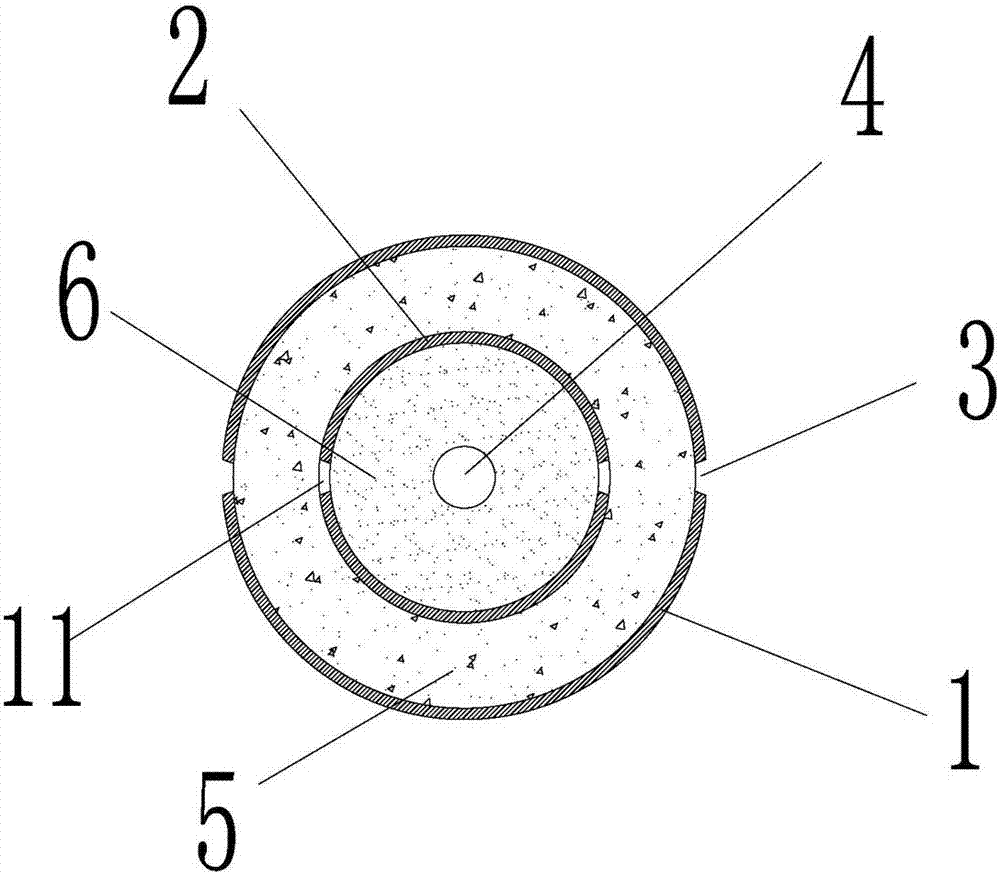

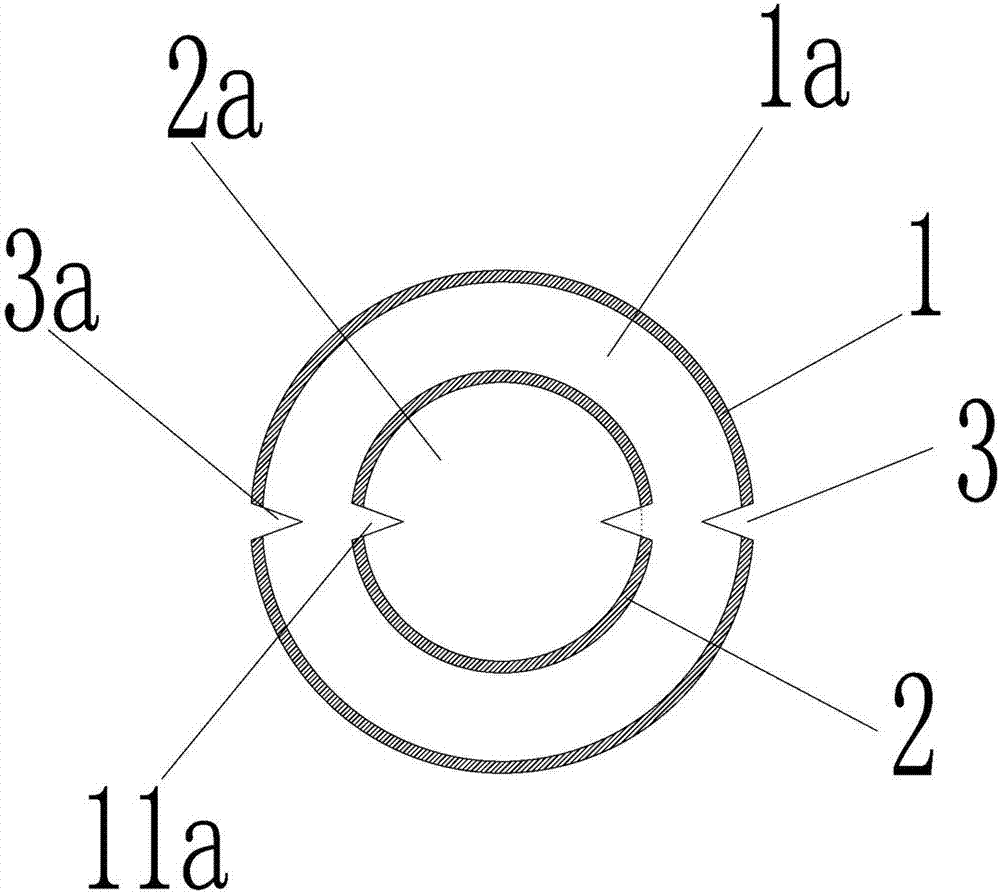

[0036] The blasting tube includes a plurality of blasting units, which are separated by gun mud 7 between two blasting units, and each blasting unit includes an outer tube 1 and an inner tube 2 made of PVC material, and the outer tube 1 and the inner tube 2 Both are hollow tubular structures with one end open and one end sealed. The inner tube is set inside the outer tube. The outer wall of the inner tube, the inner wall of the outer tube, and the sealed end wall of the outer tube together form an outer filling cavity 1a for filling dry ice. The inner cavity of the inner tube An inner filling cavity 2a for filling explosives is formed, the outer filling cavity 1a is filled with dry ice 5, the inner filling cavity 2a is filled with explosives 6, and the explosives 6 are provi...

Embodiment 2

[0040] 1. Drill the blast hole 9 and the drainage hole 10 on the coal seam working face, and the distance L between the blast hole 9 and the drainage hole 10 is 2000mm;

[0041] 2. Making blasting tubes;

[0042] The blasting tube includes a plurality of blasting units, which are separated by gun mud 7 between two blasting units, and each blasting unit includes an outer tube 1 and an inner tube 2 made of PVC material, and the outer tube 1 and the inner tube 2 Both are hollow tubular structures with one end open and one end sealed. The inner tube is set inside the outer tube. The outer wall of the inner tube, the inner wall of the outer tube, and the sealed end wall of the outer tube together form an outer filling cavity 1a for filling dry ice. The inner cavity of the inner tube An inner filling cavity 2a for filling explosives is formed, the outer filling cavity 1a is filled with dry ice 5, the inner filling cavity 2a is filled with explosives 6, and the explosives 6 are provi...

Embodiment 3

[0046] 1. Drill the blasthole 9 and the drainage hole 10 on the coal seam working face, and the distance L between the drainage hole 10 and the blasthole 9 is 2000mm;

[0047] 2. Making the blasting tube

[0048] The blasting pipe includes a plurality of blasting units, and the two blasting units are separated by gun mud 7, and each blasting unit includes an outer tube 1 and an inner tube 2 made of PVC material, and the outer tube 1 and the inner tube 2 are both It is a hollow tubular structure with one end open and one end sealed. The inner tube is sleeved in the outer tube. The outer wall of the inner tube, the inner wall of the outer tube and the sealed end wall of the outer tube together form an outer filling cavity 1a for filling dry ice. The inner cavity of the inner tube constitutes The inner filling cavity 2a for filling explosives, the outer filling cavity 1a is filled with dry ice 5, the inner filling cavity 2a is filled with explosives 6, and the explosives 6 are pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com