Coal-rock simultaneous production protecting seam and protected seam collaborative mining method

A technology of simultaneous coal and rock mining and protected layers, which is applied in the fields of mining fluid, ground mining, earthwork drilling, etc., can solve the problems of environmental pollution, gangue lifting and energy consumption, etc., and achieves the advantages of simple method, efficient treatment, and wide practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

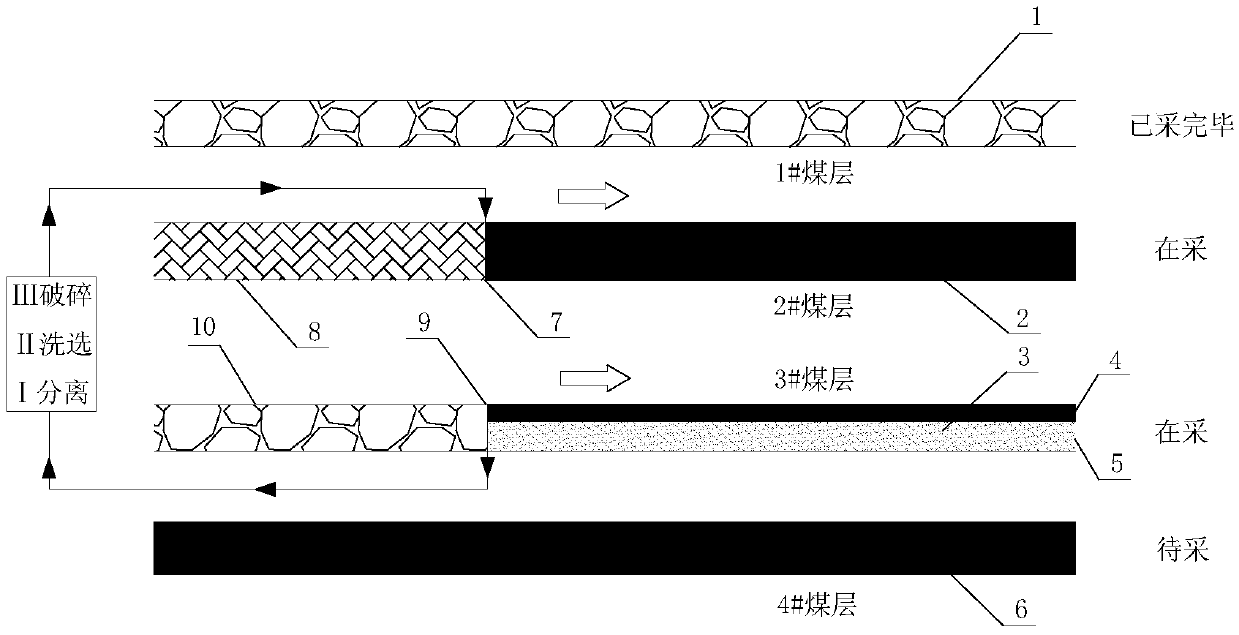

[0025]Embodiment 1, during coal seam group mining, 1# coal seam and 2# coal seam distance are closer, promptly 2# coal seam is within the maximum protective vertical distance of 1# coal seam, and 1# coal seam can be used as the protective layer exploitation of 2# coal seam, 2# coal seam There is also a 4# coal seam under the coal seam. Since the distance between the 2# coal seam and the 4# coal seam is far away, the distance is greater than the maximum protection vertical distance determined in accordance with the "Regulations on the Prevention and Control of Coal and Gas Outbursts". The 3# coal seam is extremely thin, so the mining conditions of the 4# coal seam protection layer are very poor; the 1# coal seam is used as the protection layer of the 2# coal seam for normal mining, and the 2# coal seam is mined after the 1# coal seam is mined; that is, the 2# coal seam It is the last protected layer 2, the 1# coal seam is the mining protection layer 1 of the previous coal seam, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com