A clustered deep seabed ore gathering equipment based on vortex hydrodynamic characteristics

A hydrodynamic and cluster technology, applied in special mining, mineral mining, earthwork drilling, etc., can solve the limited effect of the adsorption force of the spiral deflector, affect the correct guidance and determination of the travel path, and affect the controllability and reliability of the equipment. To solve problems such as stability, the efficiency of ore collection is stable, the adaptability of seabed topography is strong, and the scope of mining is expanded.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

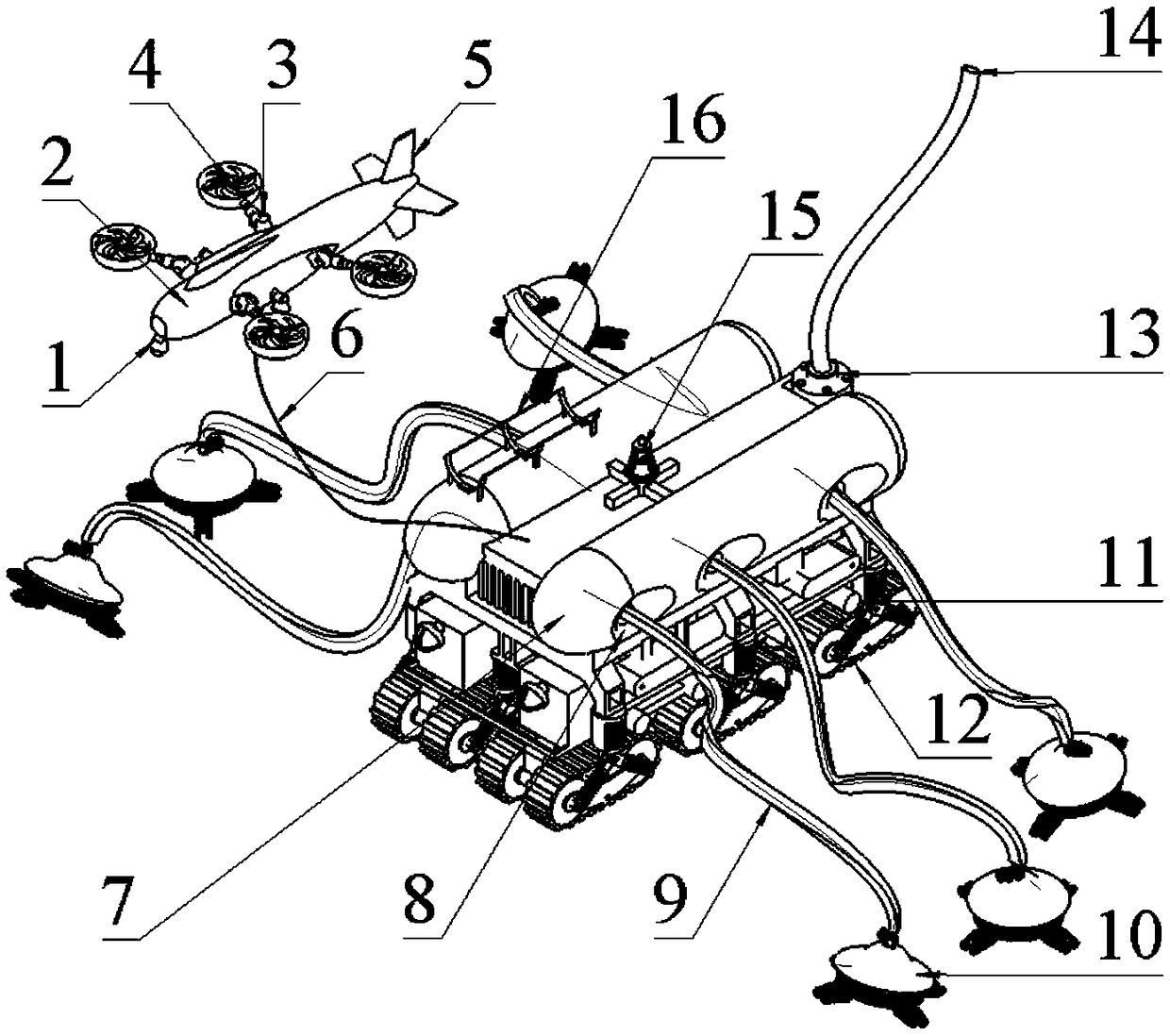

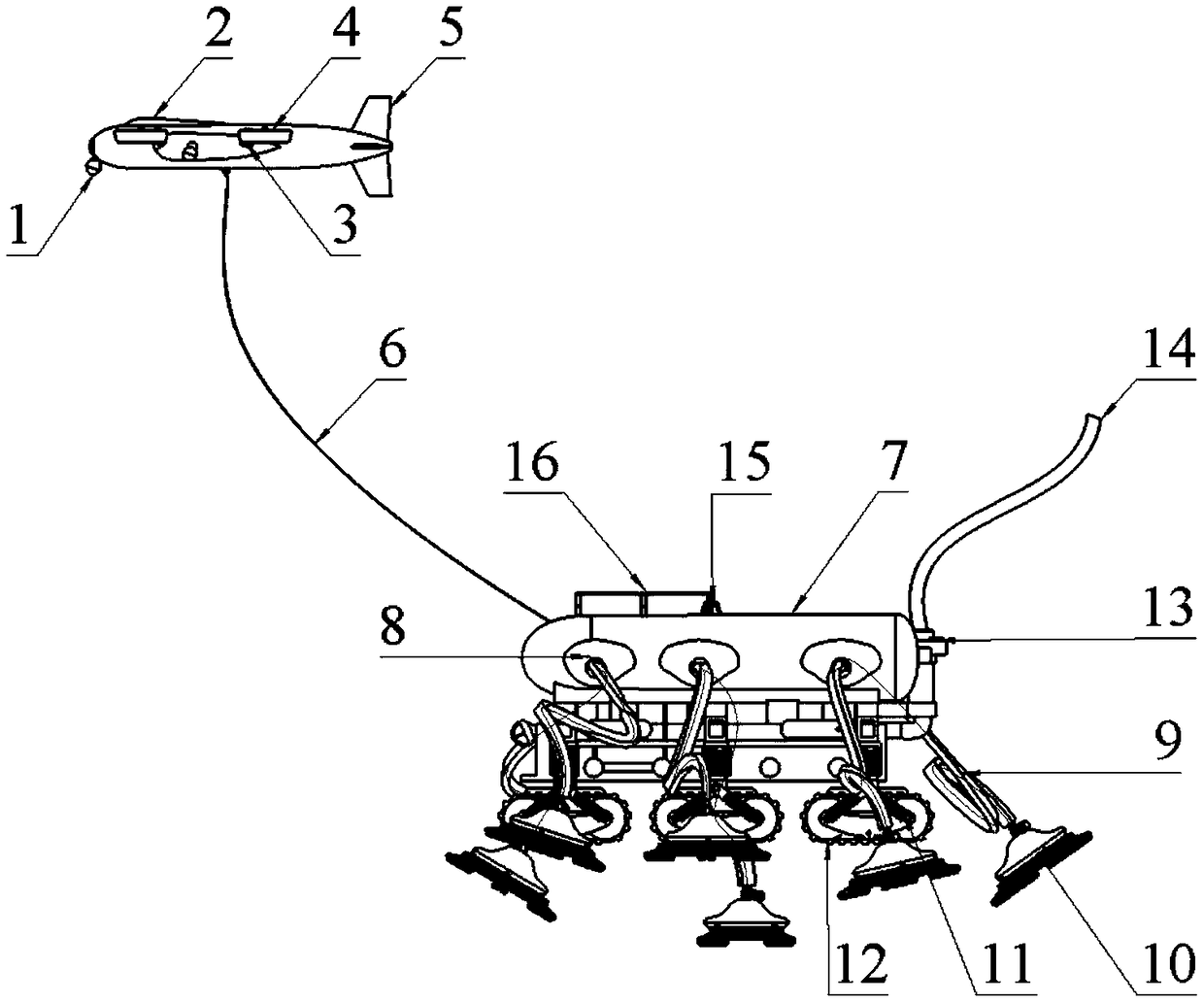

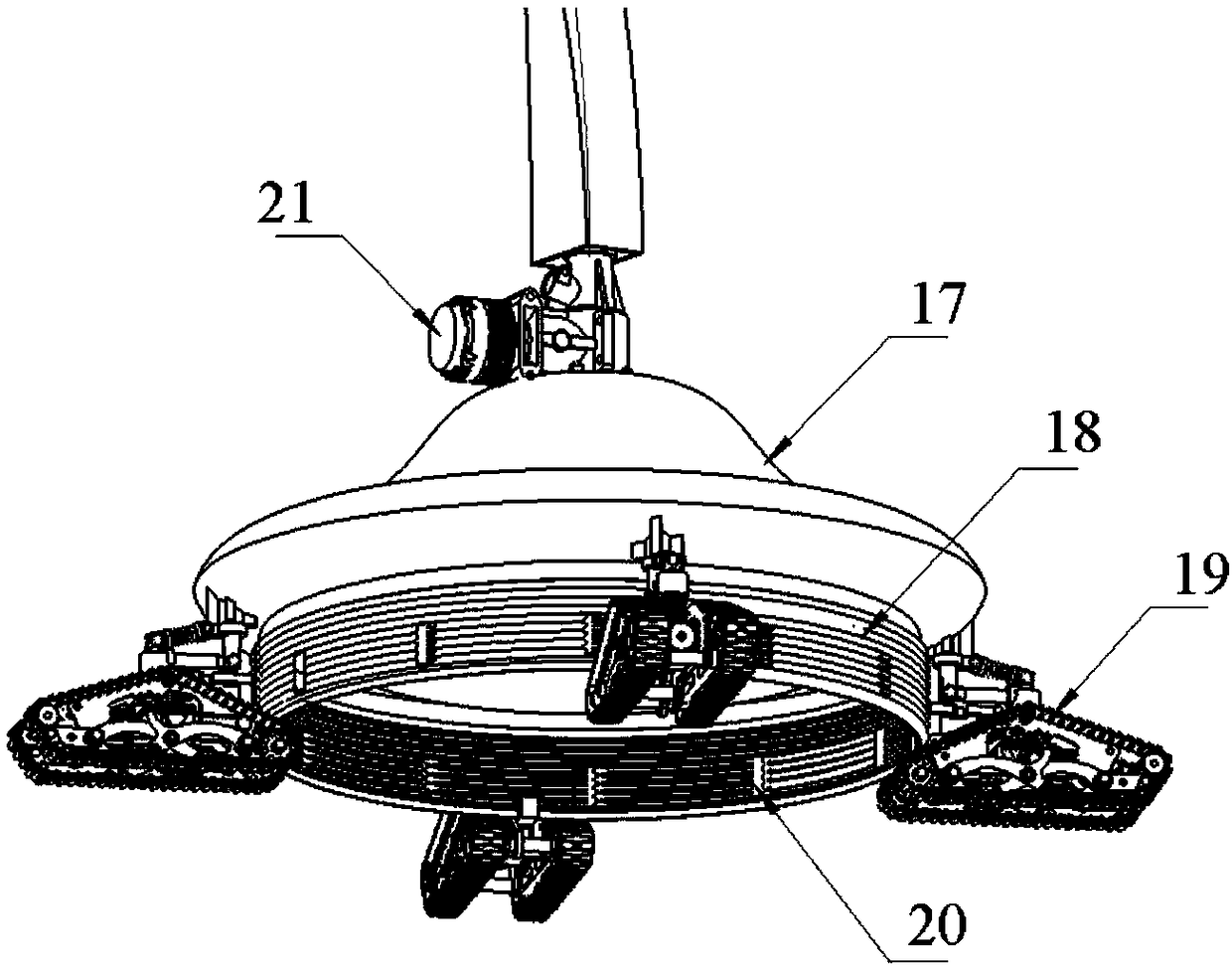

[0057] Such as Figure 1-3 As shown in the figure, a seabed ore collection equipment includes multiple parts such as underwater detectors, crawler mine storage vehicles, and seabed adaptive ore collection devices. The underwater detector mainly includes: a sonar detector 1, an electronic equipment compartment 2, a multi-degree-of-freedom connector 3, a propeller propeller 4 and an empennage 5, etc. The underwater detector is connected with the crawler mine storage vehicle through the optical cable 6. The crawler type ore storage vehicle mainly includes: ore storage cabin 7, ore inlet 8, shock absorber 11, crawler type traveling device 12, ore outlet 13, outbound ore delivery pipe 14, pressure reducing valve 15 and detector berth 16, etc. . The seabed adaptive ore collector mainly includes: a dish-shaped cover 17, a skirt-type cover 18, a small crawler belt 19, a diversion groove 20, and a water pump 21. The ore collector is connected with the ore inlet 8 of the ore storage ...

Embodiment 2

[0078] The difference with Embodiment 1 is: see Figure 5 , the skirt-type outer cover is a multi-section structure, and two adjacent sections are partially staggered, so that when the external seawater enters the seabed adaptive ore collector 10, a certain swirl effect is generated; The guide direction of the plate 23 is suitable.

Embodiment 3

[0080] The difference with embodiment one and two is: see Figure 6 , Figure 7 , the deflector 23 is arranged at the bottom of the ore collector, and a number of tangential holes 24 are opened on the surface of the lower edge of the dish-shaped outer cover at the same time, so that the ore collector can adopt two methods of inducing swirling flow according to the working conditions. When the seabed is flat and the ore collector is closely attached to the seabed, a certain swirling effect can be produced by means of the suction of the water pump and the deflector's deflector; when the seabed is rough, the ore collector cannot be closely attached to the seabed When , the tangential holes can generate lateral water jets and provide the angular momentum of the water flow, thereby ensuring the generation of swirl flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com