Low-carbon environment-friendly high-efficiency sintering method for grading and adding sintered fuels

A low-carbon, environmentally friendly, sintering method technology, applied in the field of metallurgy, can solve the problems of low utilization rate of fine-grained fuel and serious pulverization, and achieve the effects of improving sintering technical indicators, small changes, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

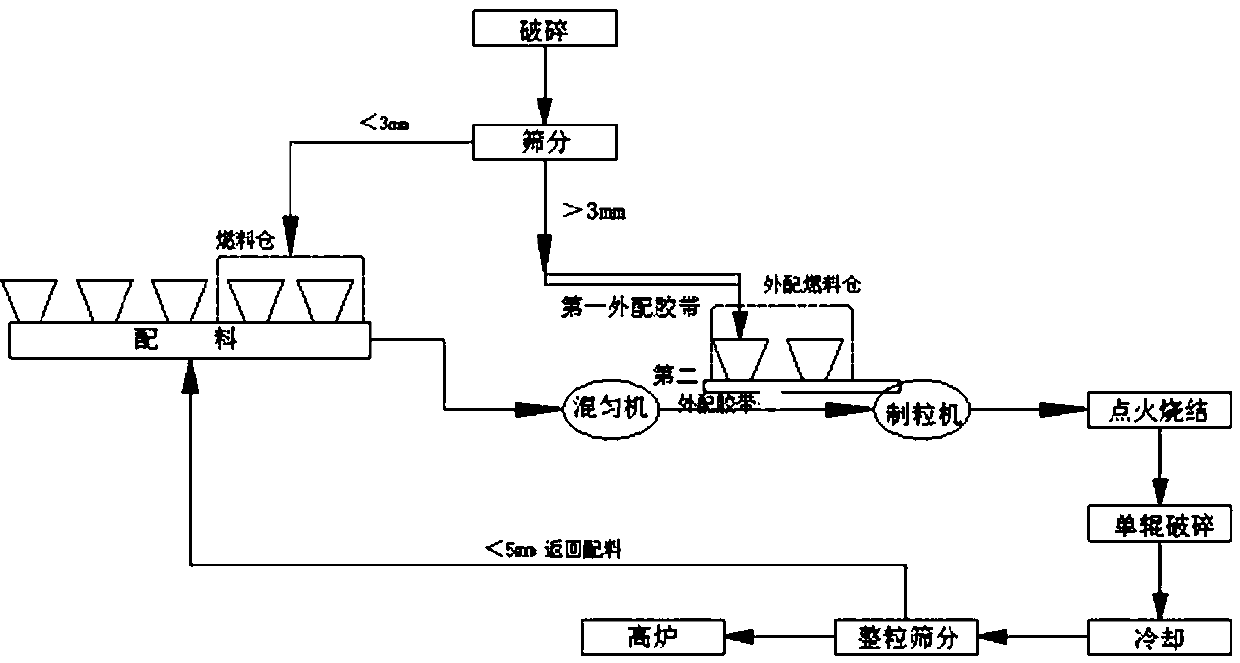

Method used

Image

Examples

Embodiment 1

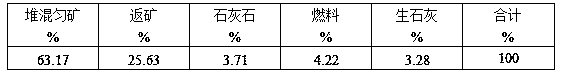

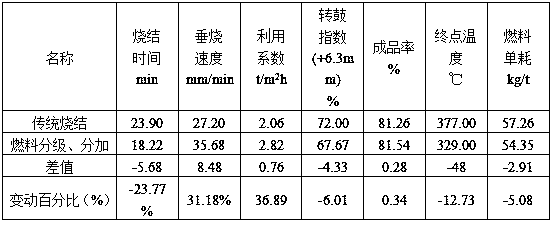

[0046] Carry out raw material proportioning according to the proportioning of Table 1, under the same sintering condition, according to the sintering method that the fuel is provided by the present invention has been carried out the sintering effect contrast of traditional method, as shown in Table 2 and Table 3:

[0047]1. The ratio of raw materials for sintering is shown in Table 1:

[0048] Table 1 Raw material ratio for sintering (%)

[0049]

[0050] 2. The particle size composition of sintered ore is shown in Table 2:

[0051] Table 2 Sinter particle size composition

[0052]

[0053] As can be seen from Table 2, compared with traditional sintering, the "fuel classification and addition" provided by the present invention has little change in sintering return ore rate and uniformity coefficient, but the average particle size is reduced, mainly due to the 31.18% increase in down-sintering speed, The sinter is broken under the condition of rapid cooling.

[0054] 3...

Embodiment 2

[0058] Embodiment 2: Carry out sintering test comparison of Kulan powder single mineral species through the method of the present invention and the traditional method for sintering

[0059] Carry out raw material proportioning according to the proportioning of Table 4, under the same sintering condition, according to the sintering method provided by the present invention, the fuel is classified and added and compared with the sintering effect of the traditional method as shown in Table 5 and Table 6:

[0060] 1. The ratio of raw materials for sintering is shown in Table 4:

[0061] Table 4 Raw material ratio for sintering (%)

[0062]

[0063] 2. The particle size composition of sintered ore is shown in Table 5:

[0064] Table 5 Sinter particle size composition

[0065]

[0066] It can be seen from Table 5 that the traditional sintering method was adopted for the single ore of Kulan powder, and the relevant experimental data could not be obtained because the sintering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com