Method used for preparing AgSbTe2 thermoelectric material

A technology of silver antimony telluride and thermoelectric materials, applied in the direction of binary selenium/tellurium compounds, etc., can solve the problems of increasing the preparation cost of the final product silver antimony telluride compounds, restricting the large-scale production and development of thermoelectric materials, and simplifying the preservation of raw materials and operating conditions, optimized electrical transport performance, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing silver antimony telluride thermoelectric material, comprising the steps of:

[0030] 1) Ingredients: Silver telluride and antimony telluride are used as the main raw materials, and a small amount of elemental tellurium is used as a thermoelectric property adjustment component. Silver telluride, antimony telluride and elemental tellurium are weighed as reaction raw materials according to the molar ratio of 1:1:x, x The mass purity of silver telluride is better than 99.99%, the mass purity of antimony telluride is better than 99.999%, and the mass purity of elemental tellurium is better than 99.999%. Both tellurides are in powder form, and the particle size is preferably 200 Under the mesh, the elemental tellurium is in block shape, and it is pre-crushed under the air atmosphere before ball milling to a particle size of less than 1mm;

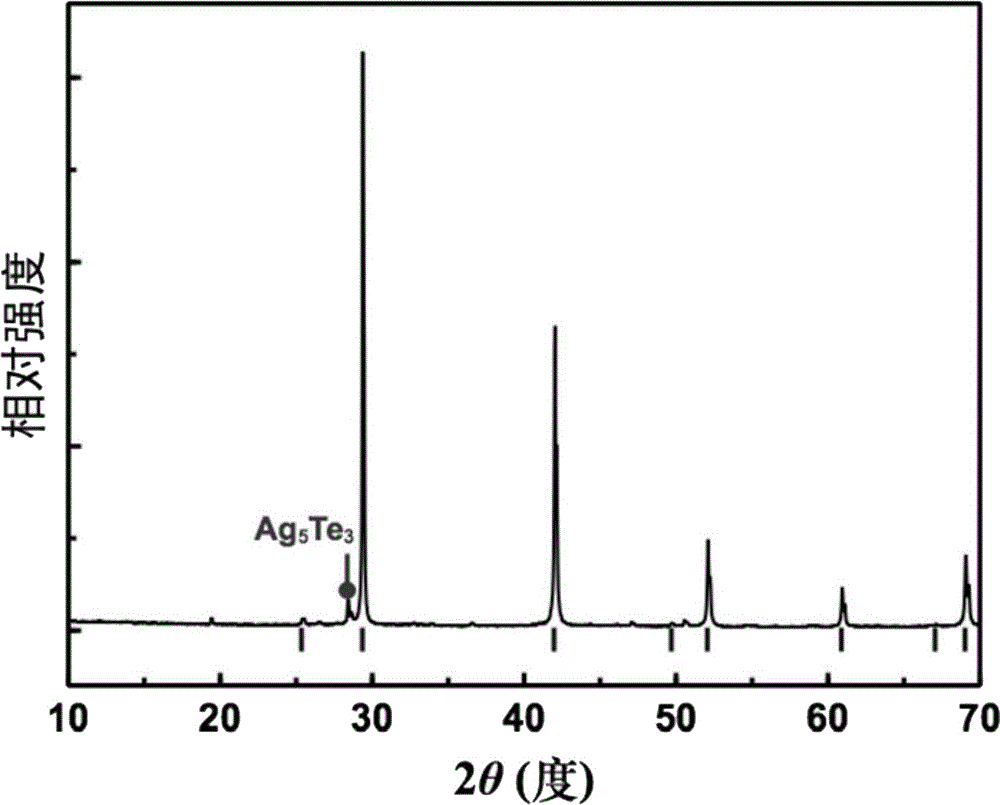

[0031] 2) High-energy ball milling: Pour the reaction materials described in step 1) into a stainless steel ball m...

Embodiment 2

[0037] A method for preparing silver antimony telluride thermoelectric material, comprising the steps of:

[0038]1) Ingredients: Weigh silver telluride and antimony telluride as the reaction raw materials according to the molar ratio of 1:1, x is taken as 0 (equivalent to the elemental tellurium powder without adding the thermoelectric property adjustment component); the mass purity of silver telluride is better than 99.99% %, the mass purity of antimony telluride is better than 99.999%, both tellurides are in powder form, and the particle size is preferably below 200 mesh;

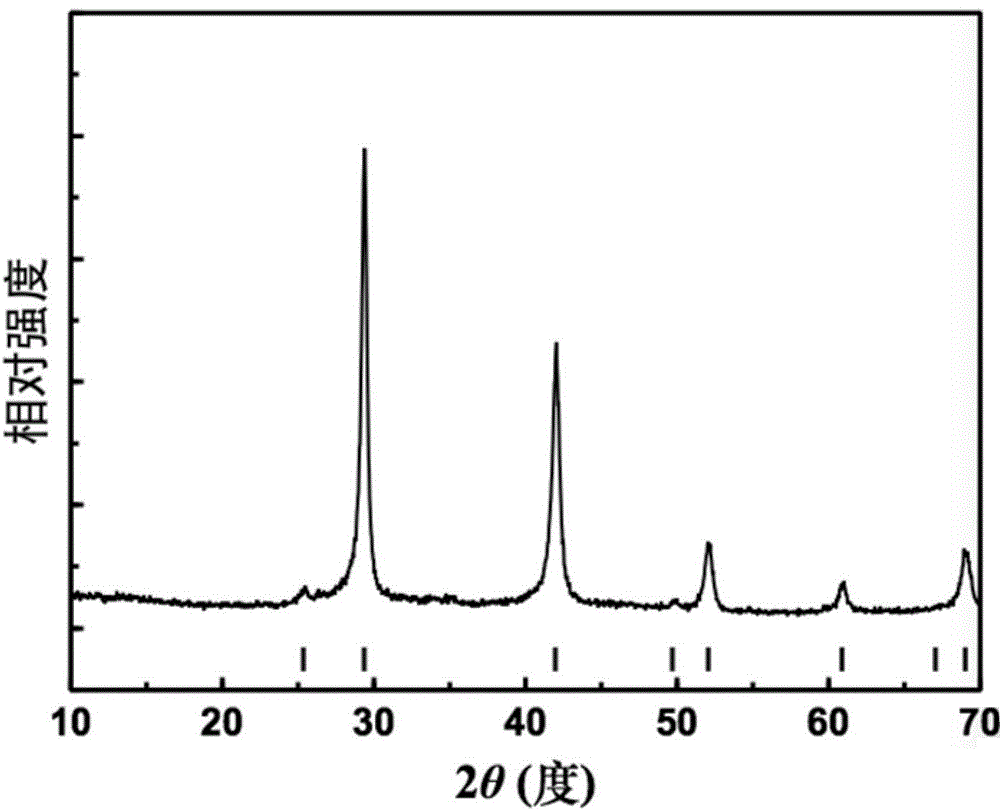

[0039] 2) High-energy ball milling: Pour the reaction materials described in step 1) into a stainless steel ball milling tank, and ball mill for 8 hours under an inert gas protective atmosphere, with a milling speed of 420 rpm and a ball-to-material ratio of 20, to obtain single-phase silver antimony telluride powder;

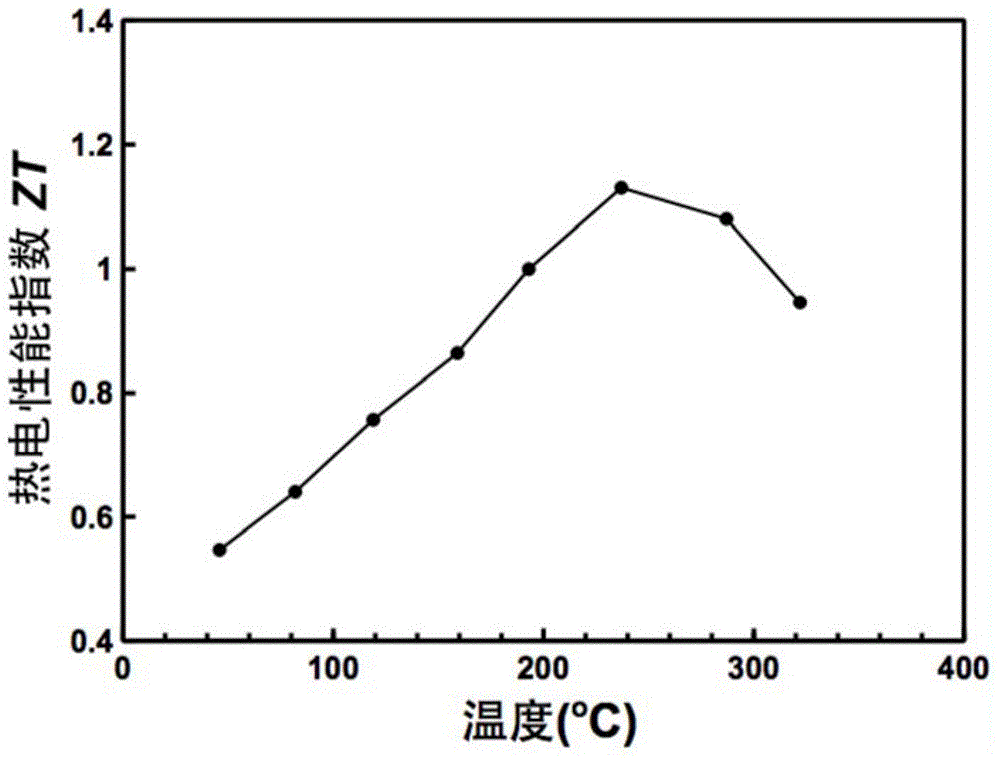

[0040] 3) Spark plasma sintering: put the single-phase silver-antimony telluride powd...

Embodiment 3

[0043] A method for preparing silver antimony telluride thermoelectric material, comprising the steps of:

[0044] 1) Ingredients: Silver telluride and antimony telluride are used as the main raw materials, and a small amount of elemental tellurium is used as a thermoelectric property adjustment component. Silver telluride, antimony telluride and elemental tellurium are weighed as reaction raw materials according to the molar ratio of 1:1:x, x The mass purity of silver telluride is better than 99.99%, the mass purity of antimony telluride is better than 99.999%, and the mass purity of elemental tellurium is better than 99.999%. Under 200 mesh, the elemental tellurium is in the form of lumps, pre-crushed to a particle size of less than 1mm before ball milling;

[0045] 2) High-energy ball milling: Pour the reaction materials described in step 1) into a stainless steel ball milling tank, and ball mill for 20 hours under an inert gas protective atmosphere, the ball milling speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com