Coal-mine gas extraction drilling pressurized grouting rapid hole packer and use method thereof

A pressure grouting and drainage drilling technology, which is applied in gas discharge, mining equipment, earthwork drilling and mining, etc., can solve the problems of unsealable drilling, inaccurate pressure measurement by pressure gauge, poor sealing performance of drilling, etc. problem, to achieve the effect of simplified and reliable sealing operation, simple overall structure and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

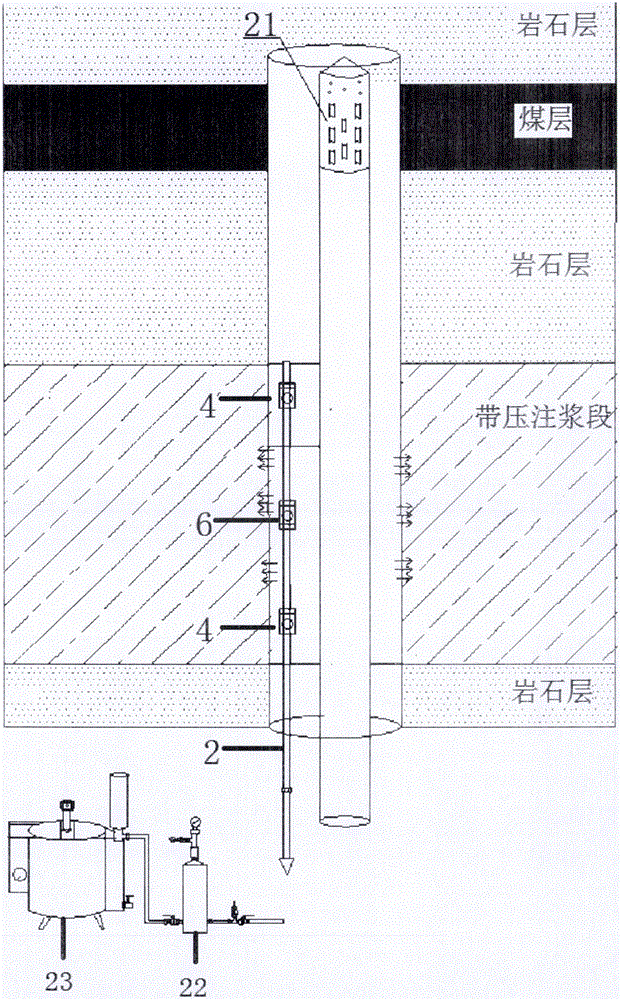

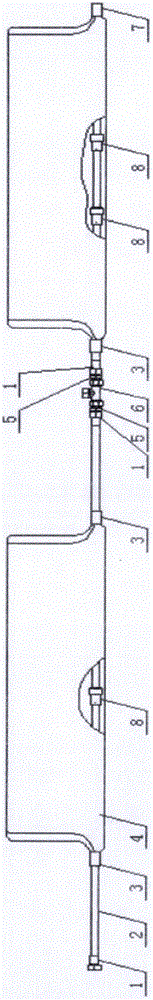

[0040] see Figure 1-10 , in the embodiment of the present invention, the coal mine gas drainage borehole pressure grouting fast hole sealing device includes a grouting pipe 2 and a bladder 4, the grouting pipe 2 is an aluminum-plastic pipe with an outer diameter of 16mm, and the grouting pipe 2 It is divided into two sections, the front and the back, and the double-ring air pressure blasting valve 6 is arranged between the front and back two sections of grouting pipes 2, and the double-ring air pressure blasting valve 6 is connected to the grouting pipes 2 on both sides through the wire head 5 and the buckle-type rubber hose joint 1; The front section grouting pipe 2 and the rear section grouting pipe 2 are respectively covered with a bag 4, and the two ends of the bag 4 on the front section grouting pipe 2 are buckled and fixed on the grouting pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com