Low-concentration methane combustion catalyst and its preparation method

A methane combustion and catalyst technology, applied in combustion methods, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as lack of stability test data, and achieve good activity and stability, uniform dispersion, and high economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

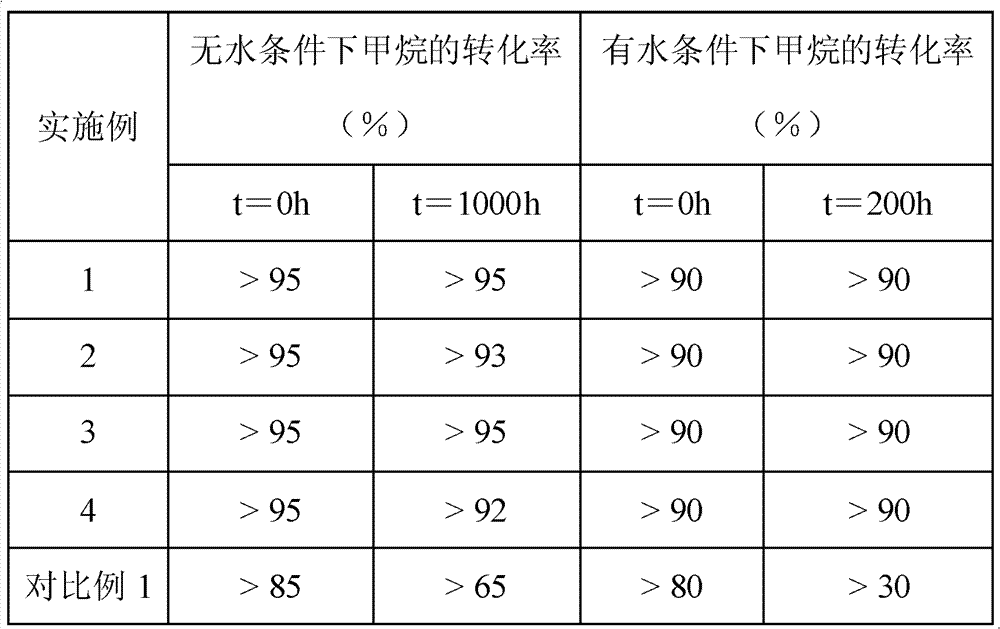

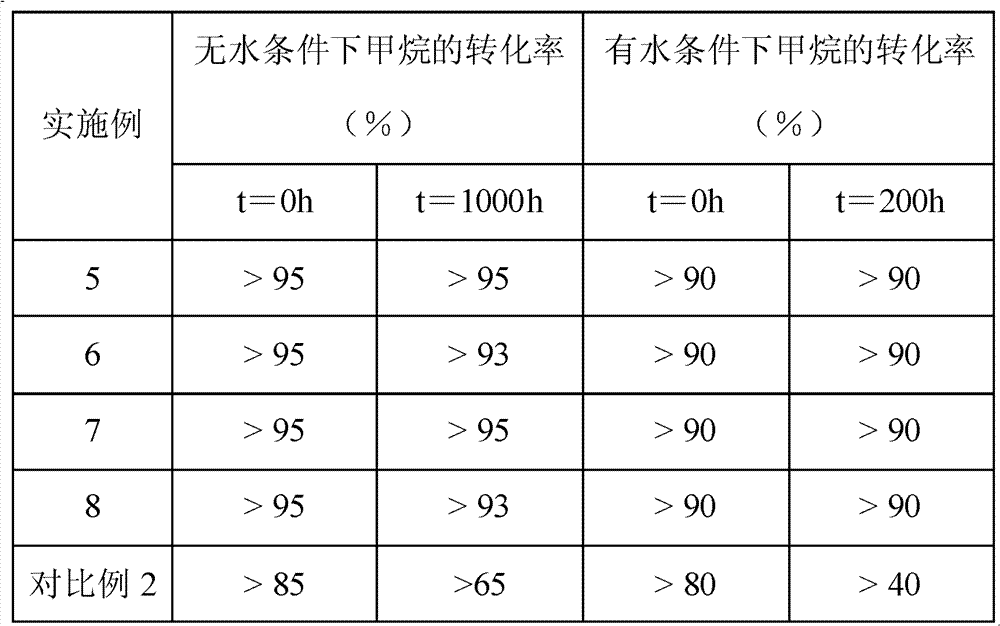

Examples

Embodiment 1

[0041] Weigh 5g of γ-alumina, 2g of aluminum nitrate and 3g of pseudo-thin aluminum powder in a ball mill jar, add 22ml of ball milling acid and mill for 2 hours to obtain an aluminum slurry used as a carrier coating for honeycomb ceramics. The diameter is 10mm, the length is 20mm, and the opening rate is 400cell / in 2 The cordierite honeycomb ceramics were immersed in the aluminum slurry for impregnation and adsorption, and were taken out after 5 minutes, and the residual solution in the honeycomb channels was blown out. The impregnated cordierite honeycomb ceramics were dried in an oven at 80°C for 2 hours, and then fired in a muffle furnace at 600°C for 3 hours. That is, a honeycomb ceramic carrier with a 5 wt% solid alumina coating was prepared. The honeycomb ceramic carrier loaded with alumina coating was placed in Ce(NO 3 ) 3 , Zr(NO 3 ) 4 in the mixed solution, soaked for 5 minutes, dried, and baked at 500°C, so that the additive CeO 2 -ZrO 2 The loading amount is ...

Embodiment 2

[0044] Weigh 6g of γ-alumina, 4g of aluminum nitrate and 2g of pseudo-thin aluminum powder in a ball mill jar, add 25ml of ball milling acid and mill for 8 hours to obtain an aluminum slurry used as a carrier coating for honeycomb ceramics. The diameter is 10mm, the length is 20mm, and the opening rate is 400cell / in 2 Immerse the cordierite honeycomb ceramics in the aluminum slurry for impregnation and adsorption, take them out after 30 minutes, blow out the residual solution in the honeycomb channel, dry the impregnated cordierite honeycomb ceramics in an oven at 100°C for 4 hours, repeat the impregnation once, and place them in a muffle furnace after drying Calcined at 500°C for 4 hours, the honeycomb ceramic carrier with 10wt% solid alumina coating was prepared. The honeycomb ceramic carrier loaded with alumina coating is placed in a nitrate mixed solution with a zirconium-lanthanum-titanium molar ratio of 2:2:1, soaked for 10 minutes, dried, and calcined at 1000°C, so that...

Embodiment 3

[0047] Weigh 7g of γ-alumina, 1g of aluminum nitrate and 3g of pseudo-thin aluminum powder in a ball mill jar, add 20ml of ball milling acid and mill for 18 hours to obtain an aluminum slurry as a carrier coating for honeycomb ceramics. The diameter is 10mm, the length is 20mm, and the opening rate is 400cell / in 2 Immerse the cordierite honeycomb ceramics in the aluminum slurry for impregnation and adsorption, take them out after 10 minutes, blow out the residual solution in the honeycomb channel, dry the impregnated cordierite honeycomb ceramics in an oven at 120°C for 5 hours, repeat the impregnation three times, and place them in a muffle furnace after drying Calcined at 1100°C for 2 hours, the honeycomb ceramic carrier with 20wt% solid alumina coating was prepared. The honeycomb ceramic carrier loaded with alumina coating is placed in a nitrate mixed solution with a cerium-lanthanum-titanium molar ratio of 1:2:1, soaked for 3 minutes, dried, and calcined at 800°C for 3 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com