Heat accumulation type super-low calorific value fuel gas treatment and energy utilization device

A regenerative, calorific value technology, applied in the direction of burners, combustion methods, combustion types, etc., can solve problems such as no involvement, and achieve the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

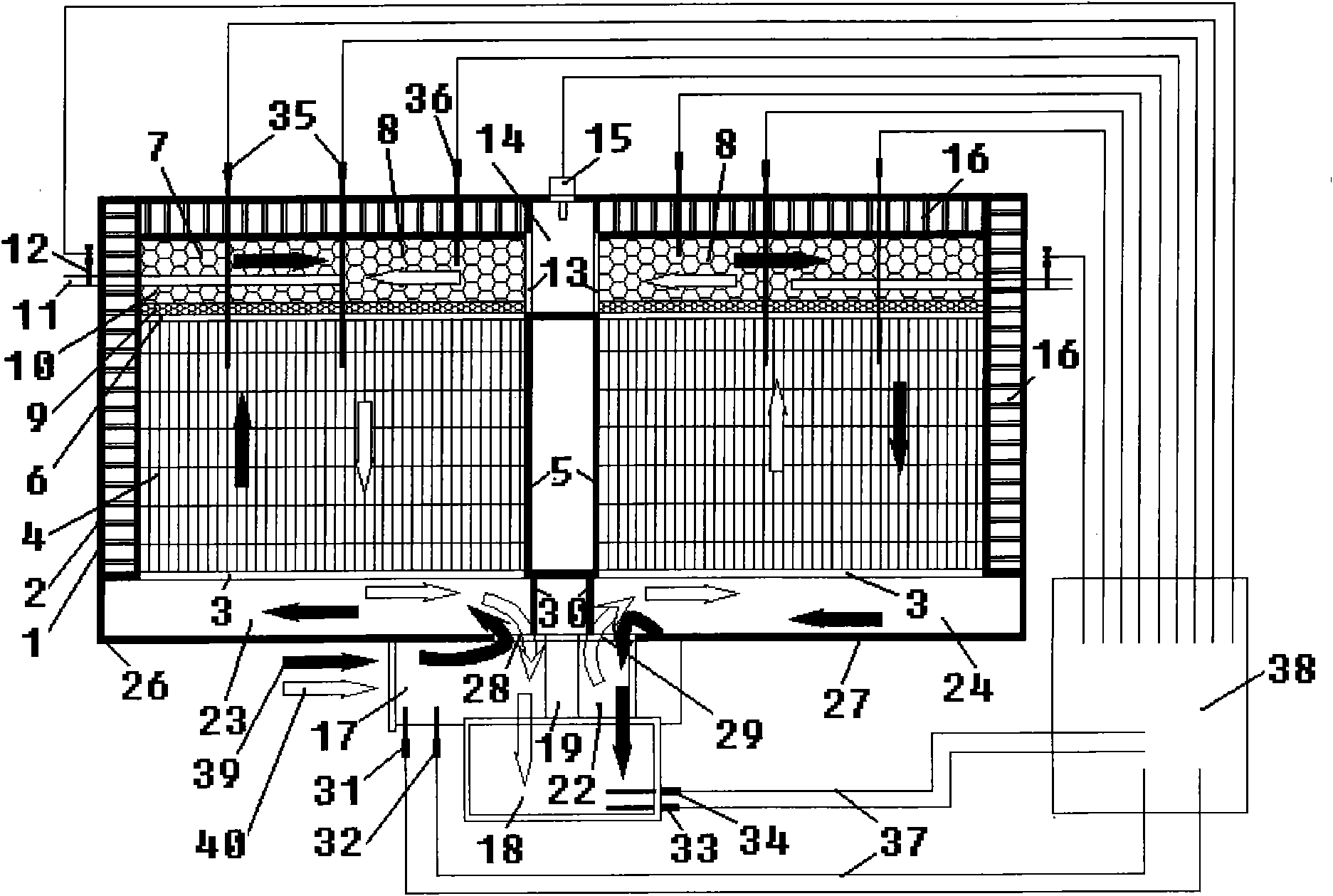

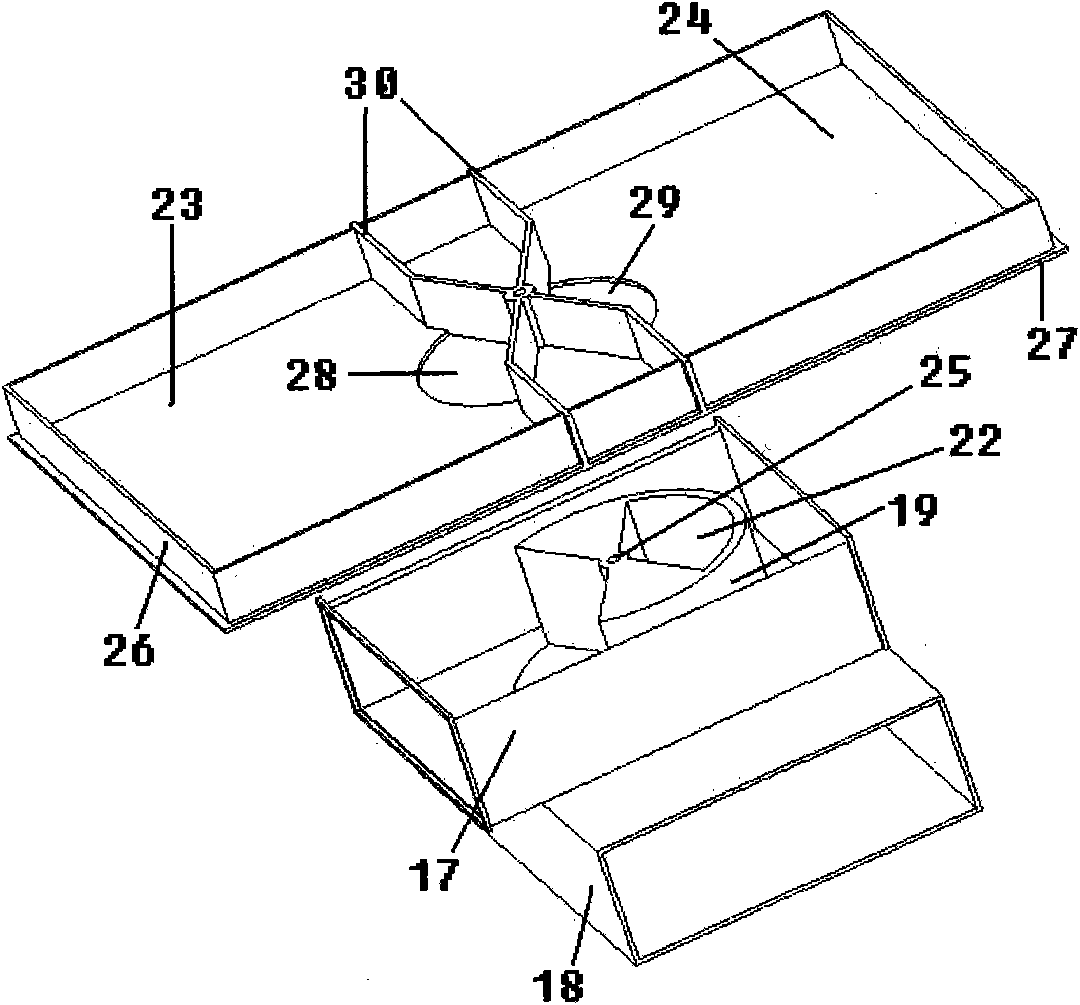

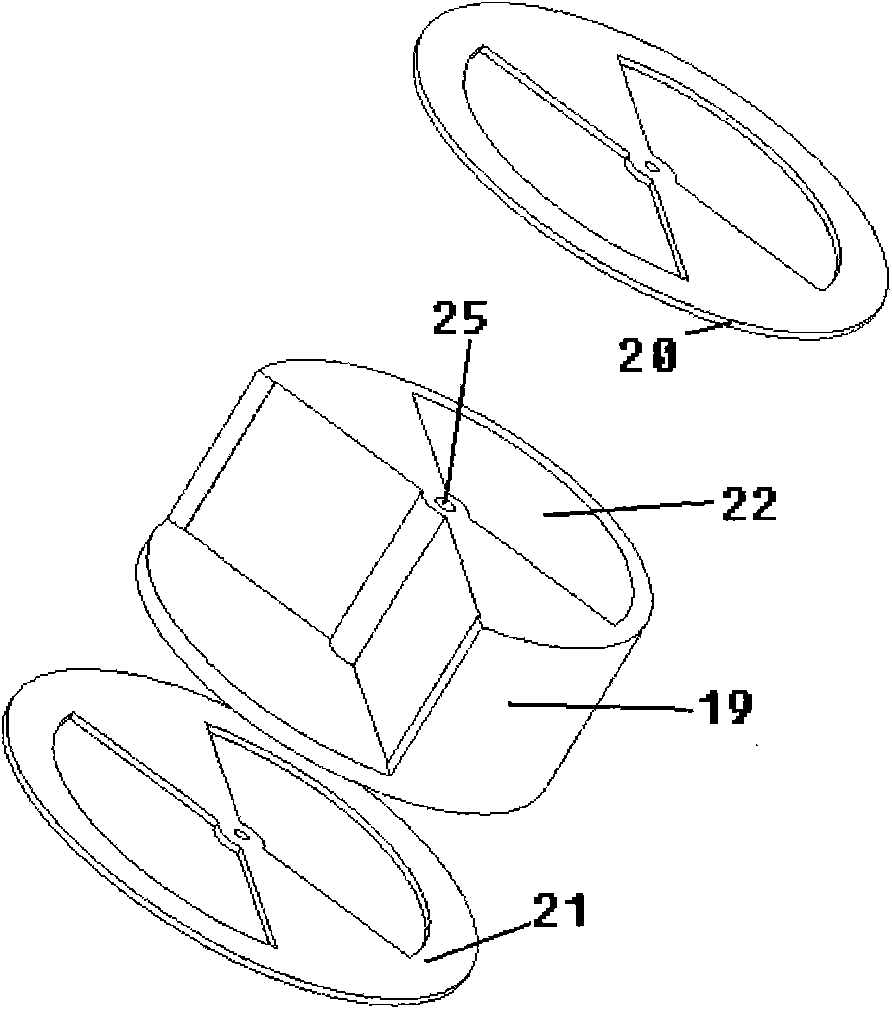

[0012] Such as figure 1 , figure 2 and image 3 As shown, the regenerative ultra-low calorific value gas treatment and energy utilization device includes the main body of the device, the periodic reversing air flow pipeline and the measurement and control system. The main body 1 of the device consists of a shell 2, a porous plate A3, a regenerative heat exchanger 4, a partition A5, a porous plate B6, a combustion chamber 7, a porous medium packed bed 8, a small-porosity foam ceramic 9, and a large-porosity foam ceramic 10. It is composed of a smoke suction device 11 , a valve 12 of the smoke suction device, a perforated plate C13 , an ignition space 14 , a burner 15 and an insulating layer 16 . The partition B30 divides the bottom airflow channel into the bottom airflow channel A23 and the bottom airflow channel B24. Bottom air flow channel housing 26 and partition B30 support perforated plate A3, and porous plate A3 holds up two regenerative heat exchangers 4 arranged sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com