Deep low-permeability high-gas coal seam drilling-cutting-sealing-pressing drilling equipment and method

A drilling equipment and low-permeability technology, which is applied in drilling equipment and methods, drilling equipment, gas discharge, etc., can solve the problems of poor coal seam anti-permeability effect, process repeatability, and low gas discharge efficiency, etc. The structure is reasonable, the construction is flexible and convenient, and the effect of simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

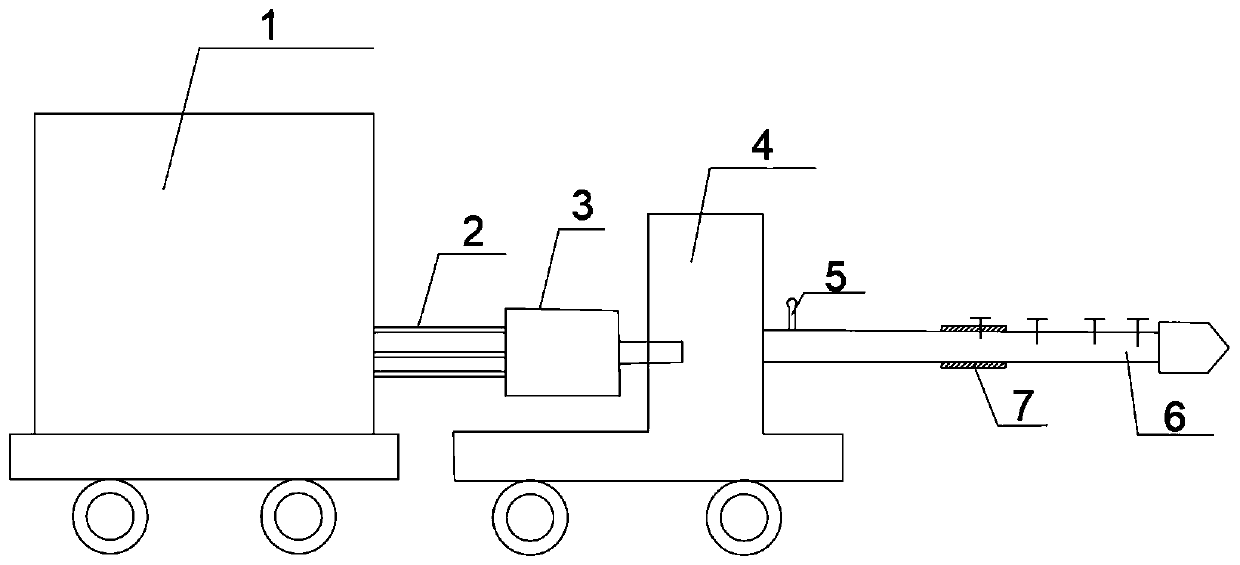

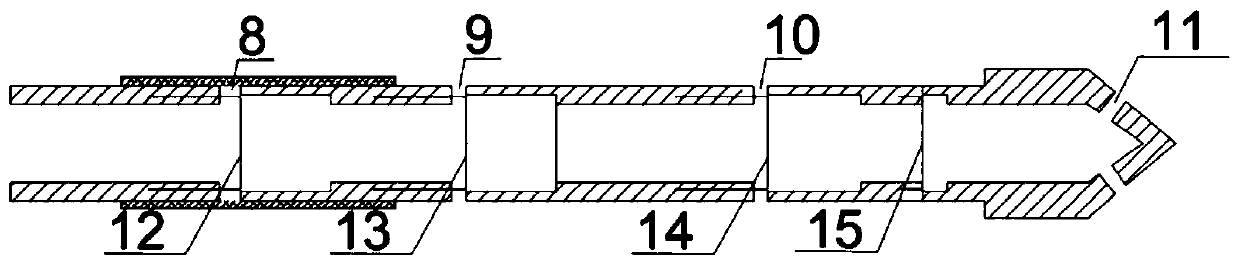

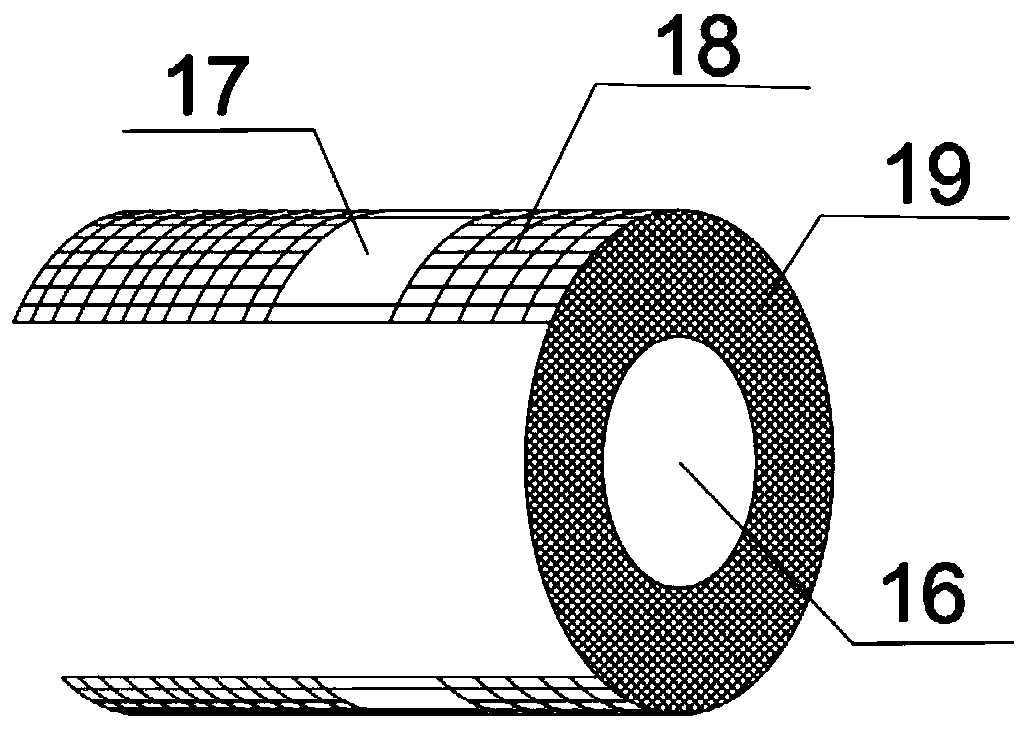

[0028] A drilling-cut-seal-pressure drilling equipment for deep low-permeability and high-gas coal seams, including water tanks, high-pressure water pipes, high-pressure pumps, overflow valves, drill bits, drill pipes, sealing capsules and control valves, and high-pressure pumps through the water pipes and water tanks After the high-pressure pump is pressurized, the high-pressure water pipe sends the water to the hydraulic pressure classification control system, the drill bit is set at the end of the drill pipe, and the sealing capsule is set on the drill pipe. The equipment has a drilling control system, a high-pressure hydraulic system, a hydraulic classification control system and a fracturing plugging control system. The drilling control system is set at the front end of the equipment. The size of the pressure controls the construction drilling, slotting, sealing and fracturing respectively. The fracturing plugging control system is set on the drill pipe, and the coal body ...

Embodiment 2

[0043] This embodiment is based on the first embodiment, and illustrates the beneficial effect of the device and method through practical application.

[0044] Among them, in the north mining area of a certain mine, the drilling water injection anti-permeability field construction technology of the east wing of the +500 horizontal 43# coal seam and the upper stratified gas-containing coal seam and the actual situation of coal seam water injection in multiple mines optimized the selection of the hydraulic pressure classification control system to adjust the drilling The water pressure for scouring drill cuttings is less than 5MPa, the water pressure for cutting joints perpendicular to the length of the drill pipe is 25-35MPa, the water pressure for sealing holes in the sealing capsule is 35-40MPa, and the pressure relief water for hydraulic fracturing of coal seams The pressure is 40-50MPa. The rationality and effectiveness of the parameter selection are verified by applying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com