Technique for extracting gas from L-shaped ground drilling well in mining area

A technology for gas drainage and mining areas, applied in directional drilling, gas discharge, mining equipment, etc., can solve the problems of large number of construction wells, strict connection requirements, large investment, etc., and achieve the goal of shortening the construction period and saving construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

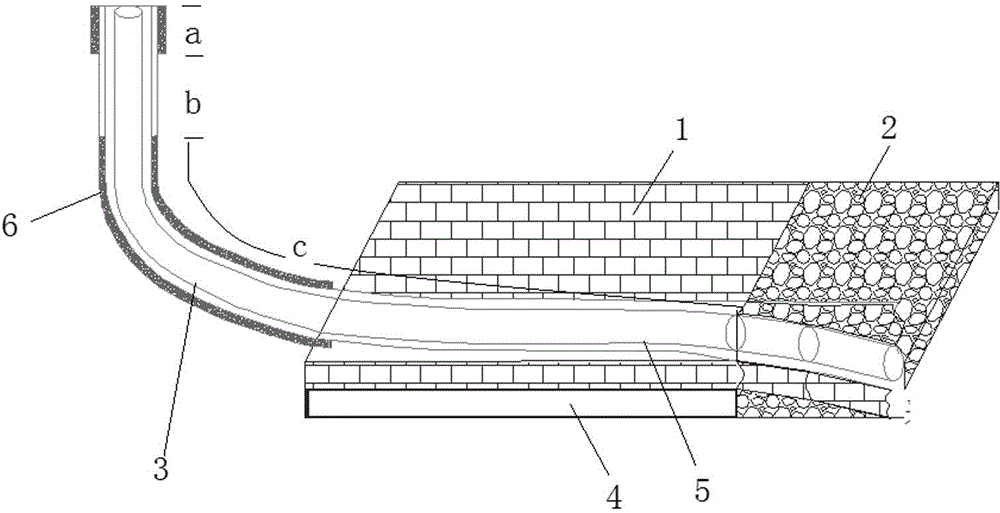

[0012] The technology of surface L-shaped well drilling and gas drainage in the mining area adopts the directional drilling technology of more than three openings in the surface drilling, and takes the key layer as the drilling target layer, and drills along the transportation roadway to the hole cutting position.

[0013] The specific steps are:

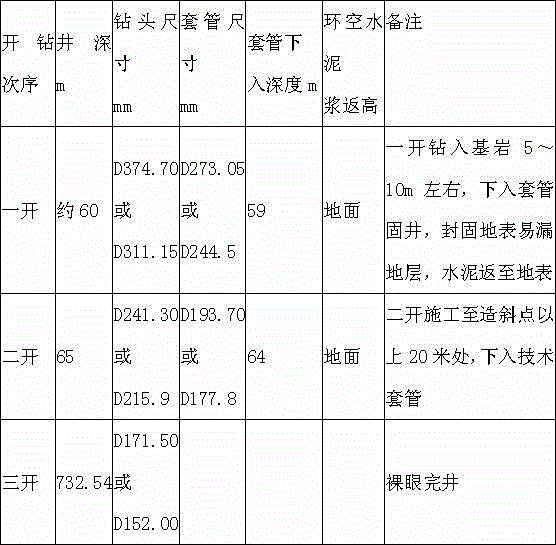

[0014] First opening: D374.70 or D311.15mm drill bit drills into the bedrock for about 5-10m, seals Quaternary quicksand and loose aquifer, runs into D273.05 or D244.5mm surface casing, and inserts cementing cement Return to the ground. Complete an opening section a.

[0015] Second opening: If water comes out of the upper formation, the casing must block the layer where a large amount of water comes out of the upper part of the coal seam. D241.30 or D215.9mm is constructed to about 20m above the kickoff point (6), and then lowered into D193.70 or D177. 8mm technical casing is sealed to the surface. Complete the second opening se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com