Coal mine methane preheating catalytic oxidation device with multiple reaction chambers

A catalytic oxidizer, multi-reaction chamber technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of large TFRR resistance loss, high maintenance cost, large TFRR footprint, etc., and reduce the volume. And the effect of reducing the floor space, improving operating economy, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

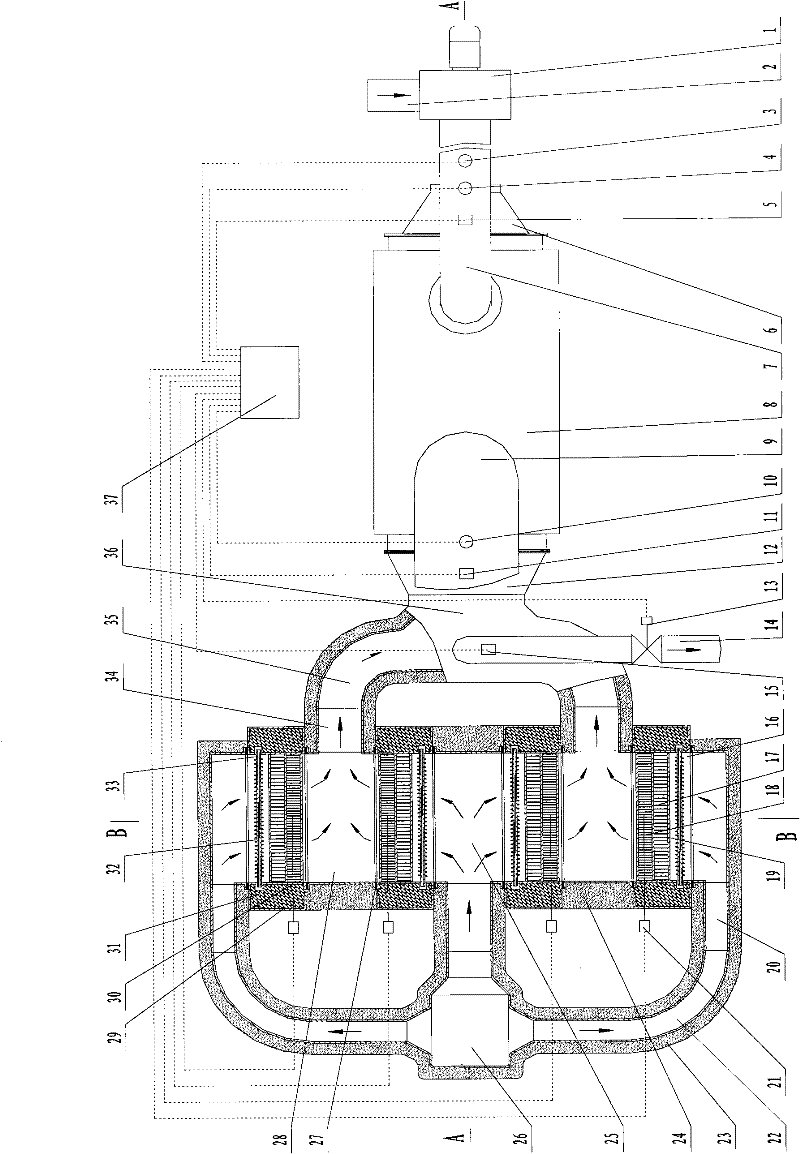

[0030] exist Figure 1-4 In the shown embodiment 1: the coal mine exhaust air gas preheating catalytic oxidizer with four reaction chambers 16 includes an exhaust air supply system, a preheater 8, a reaction chamber 16, an intake and exhaust system, and air extraction and heat extraction. systems, measurement and control systems. in:

[0031] The exhaust air supply system includes a fan 1, a first exhaust air conveying pipeline 2 and a second exhaust air conveying pipeline 7, one end of the first exhaust air conveying pipeline 2 is connected with the exhaust exhaust outlet of the mine, and the other end is communicated with the exhaust fan 1 The second exhaust air conveying pipeline 7;

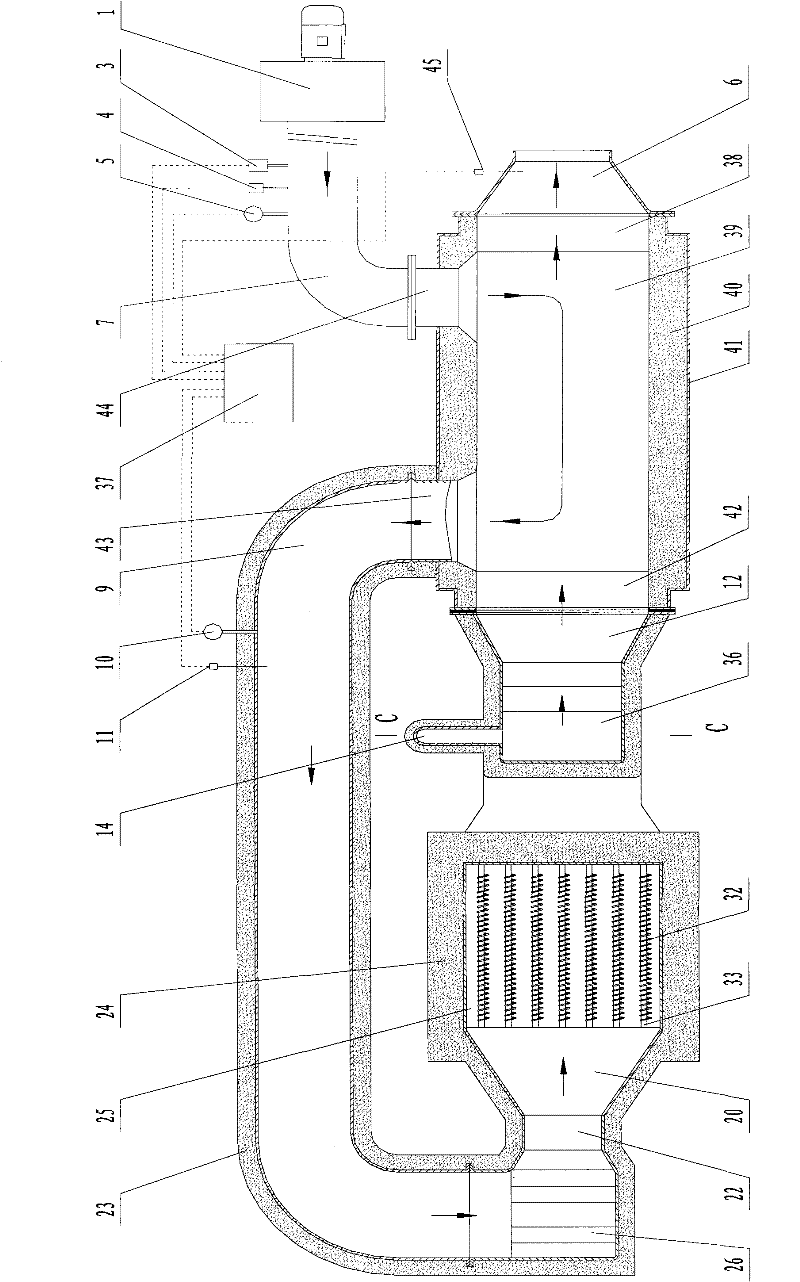

[0032] The preheater 8 includes a preheater core 39, a preheater exhaust air inlet 44, a preheater exhaust air outlet 43, a preheater exhaust gas inlet 42, a preheater exhaust gas outlet 38, a preheater housing 41 and a fourth Insulation layer 40, wherein the preheater core 39 adopts an air...

Embodiment 2

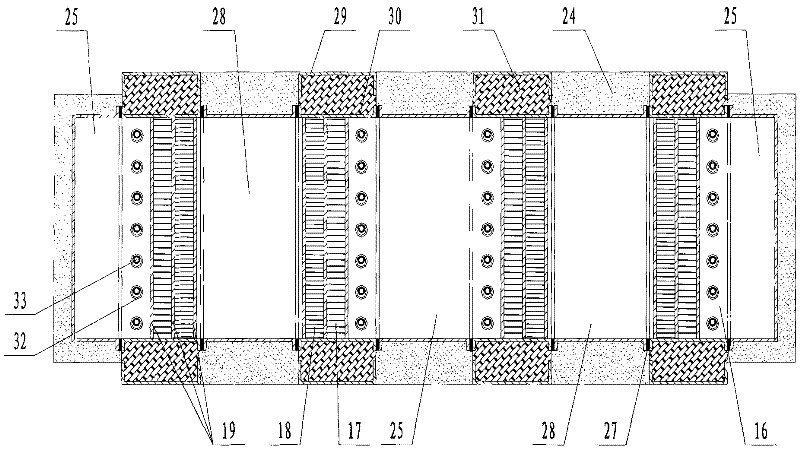

[0038] exist Figure 5-6 In the shown embodiment 2: the coal mine exhaust gas preheating catalytic oxidizer has six reaction chambers 16; Air distribution bellows 25, three waste gas collection boxes 28, three shrink tubes 34, waste gas pipe 36, waste gas flaring pipe 12, the intake pipe 26 is provided with four intake branch pipes 22, and the waste gas pipe 36 is provided with three waste gas branch pipes 35, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com