Process and system for purifying, separating and liquefying nitrogen-and-oxygen-containing coal mine methane (CMM)

A coal mine gas and process technology, which is applied in the field of coal mine gas purification and separation liquefaction process and purification and separation liquefaction system, can solve the problems of waste of resources, low recovery rate, freezing and blocking of liquefaction refrigerators, etc., and reduce the connection of pipelines and reduce the occupation of land Space, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

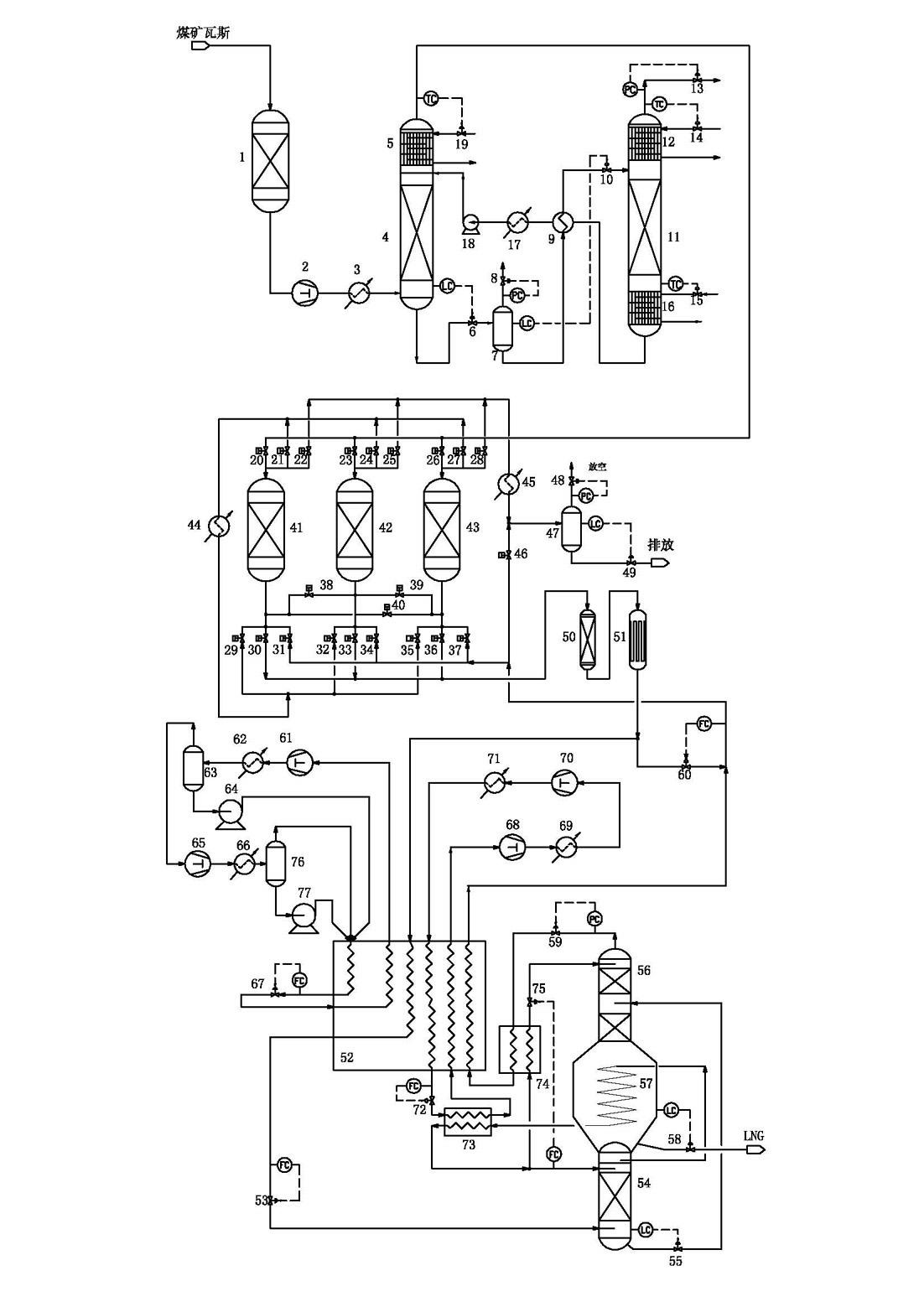

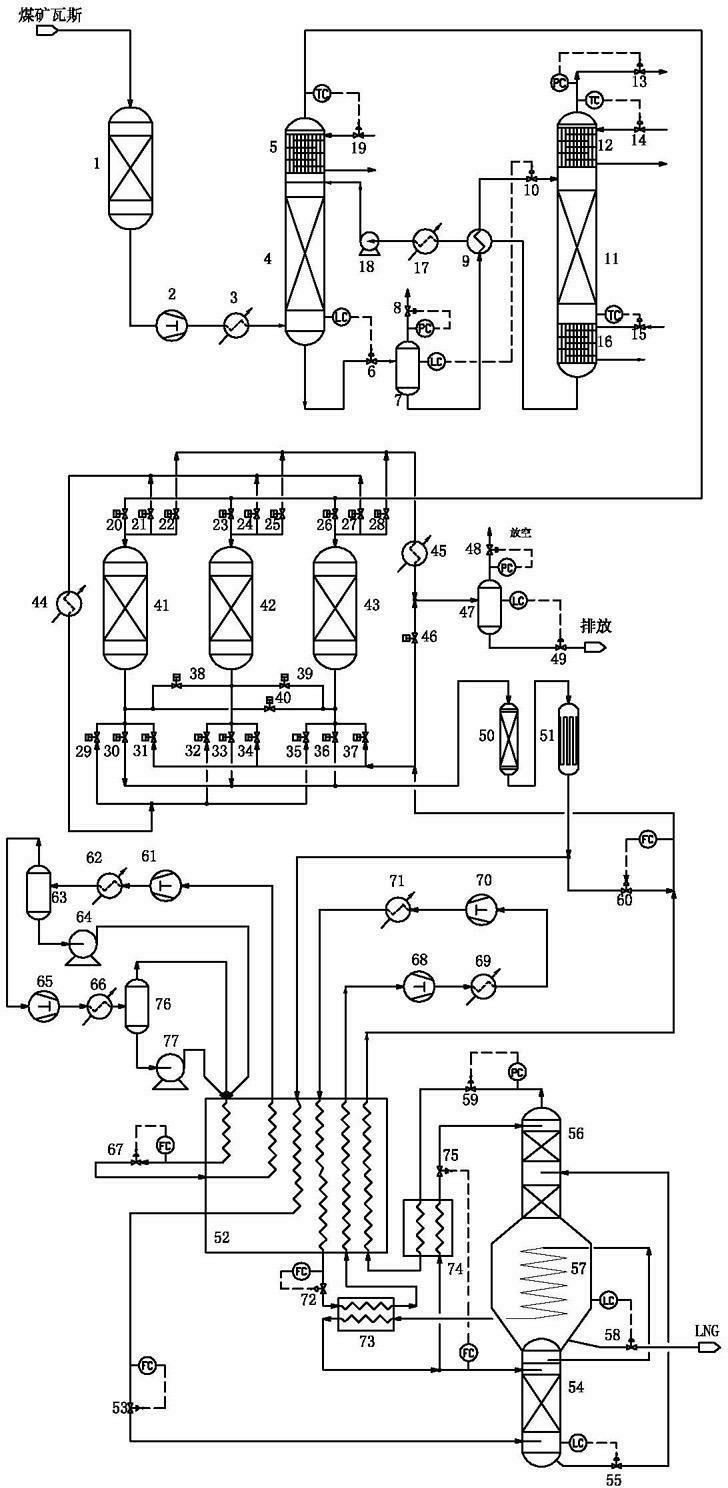

[0063] Embodiment: A kind of nitrogen and oxygen-containing coal mine gas separation and liquefaction process includes the following main process steps:

[0064] (1) Nitrogen-oxygen-containing coal mine gas from different mining areas uses different pre-deoxidation units to remove oxygen, reaching O 2 ≤0.5% (V / V).

[0065] (2) After the deoxidized coal mine gas is mixed, it enters the coal mine gas compressor and is compressed to 4.0MPa~5.0MPa, and then cooled to 40°C.

[0066] (3) The pressurized coal mine gas enters from the bottom of the absorption tower, and countercurrently contacts with the activated MDEA solution entering from the upper part of the absorption tower to remove the acid gas in the coal mine gas and achieve the purification index: CO 2 ≤50ppm(V / V),H 2 S≤4ppm (V / V). A cooler is built in at the top of the absorption tower to control the outlet temperature of the coal mine gas at the top of the absorption tower to not exceed 40°C.

[0067] (4) The coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com