Gas decomposition eliminating liquid and coal mine gas control method

A technology for coal mine gas and gas, which is applied in the field of gas decomposition and elimination liquid and coal mine gas treatment, can solve the problems of large investment, difficult gas elimination and high production cost, etc., and achieves the effect of reducing coal road gas and reducing treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

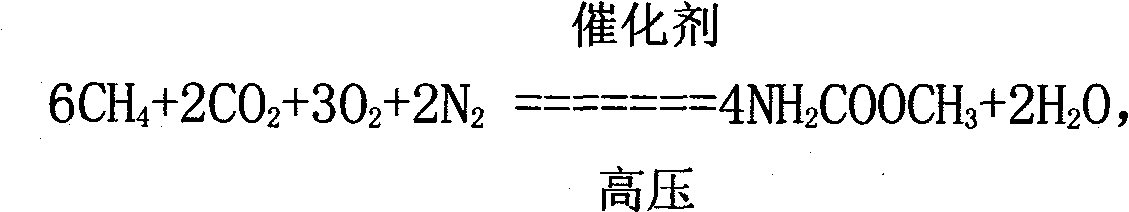

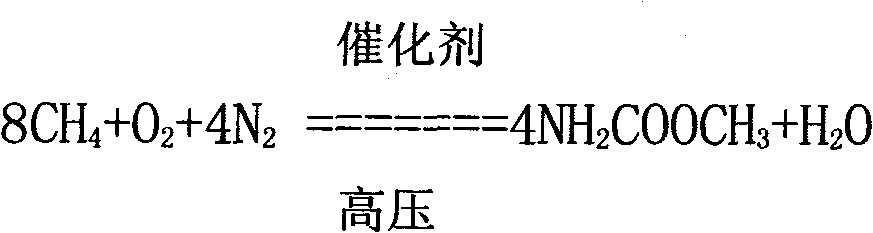

Method used

Image

Examples

Embodiment 1

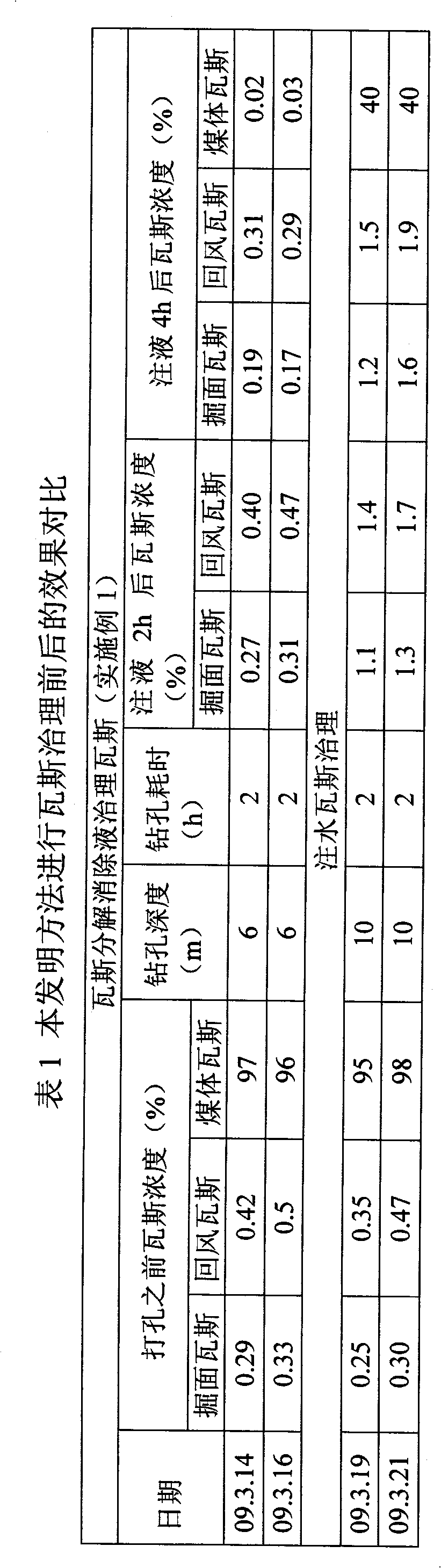

[0037] Embodiment 1 effect comparative test

[0038] In the middle and late March of 2009, the effect verification test was carried out on the 9011 tunneling surface of a coal mine in Xinmi City. The method is as follows:

[0039] (1) First purchase various raw materials according to the amount required for calculation, and prepare the gas decomposition and elimination liquid after uniform mixing according to the following composition ratios (weight percentages): beer (10°P) 2%, acetic acid 12%, acetic acid Cobalt 0.08%, the balance is water.

[0040] (2) On March 14th, the coal seam A section (10m 2 Drill 4 liquid injection holes (Φ42mm, hole depth 6m, hole spacing 1m) in the middle area. The drilling direction and the coal seam trend are at an angle of 15°. Before the liquid injection starts, measure and record the gas concentration, return Wind gas concentration and coal gas concentration (measured multiple times with multiple data points, taking the average value), and t...

Embodiment 2

[0045] Embodiment 2 Application example of a coal mine in Gongyi City

[0046] In August 2008, at the M coal seam working face of the mine (with an area of nearly 9m 2 ) Drill four liquid injection holes (Φ42mm, hole depth 6m, hole spacing 80cm), the drilling direction is consistent with the coal seam inclination direction; before the gas elimination liquid is injected, the detected gas concentration in the coal body is 95%. To each hole, inject 14kg of gas elimination solution, after the sealing reaction for 4 hours, the gas concentration in the coal body is detected to be down to 19%. Cobalt acetate 0.07%, the rest is water.

Embodiment 3

[0047] Embodiment 3 Application example of a coal mine in Pingdingshan City

[0048] In March 2009, at the W coal seam working face of the mine (with an area of 12m 2 ) Drilling 5 liquid injection holes (Φ42mm, hole depth 6m, hole spacing 70cm), the drilling direction is consistent with the inclination direction of the coal seam; before injecting the gas decomposition and elimination liquid, the gas concentration in the coal body is detected as high as 96%, with a pressure of 12Mpa Inject 11kg of gas elimination solution into each hole, and after 3.5 hours of sealing reaction, the gas concentration in the detected coal drops to 16%. Cobalt acetate 0.1%, the rest is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com