Detecting method for cloth quality and quantity of fuzzily controlled industrial washing machine

A technology of fuzzy control and detection method, which is applied in the direction of washing machine control device, adaptive control, general control system, etc., can solve the problems of inaccuracy, influence, fuzzy working precision and work efficiency of washing machine, so as to improve the accuracy, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

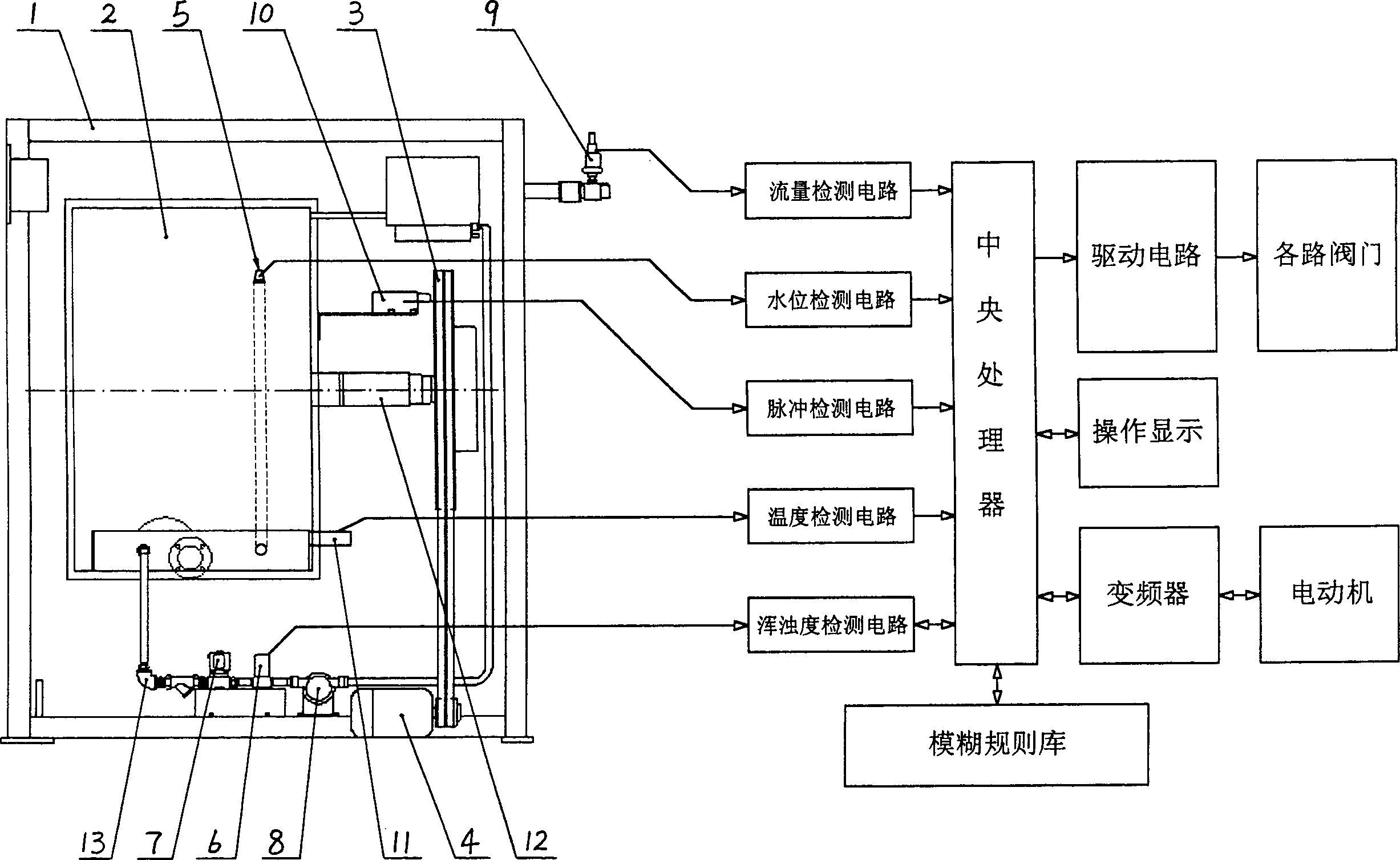

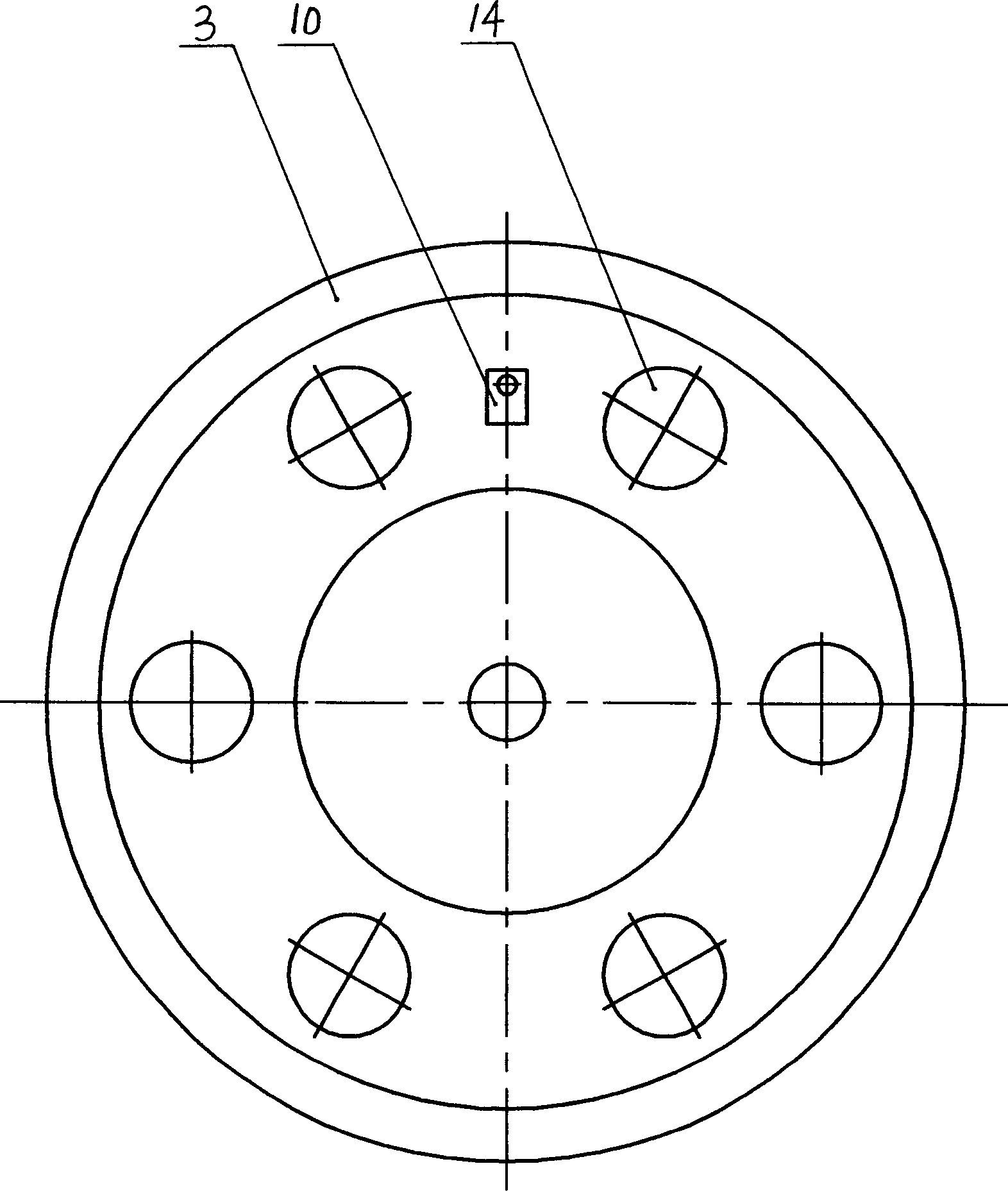

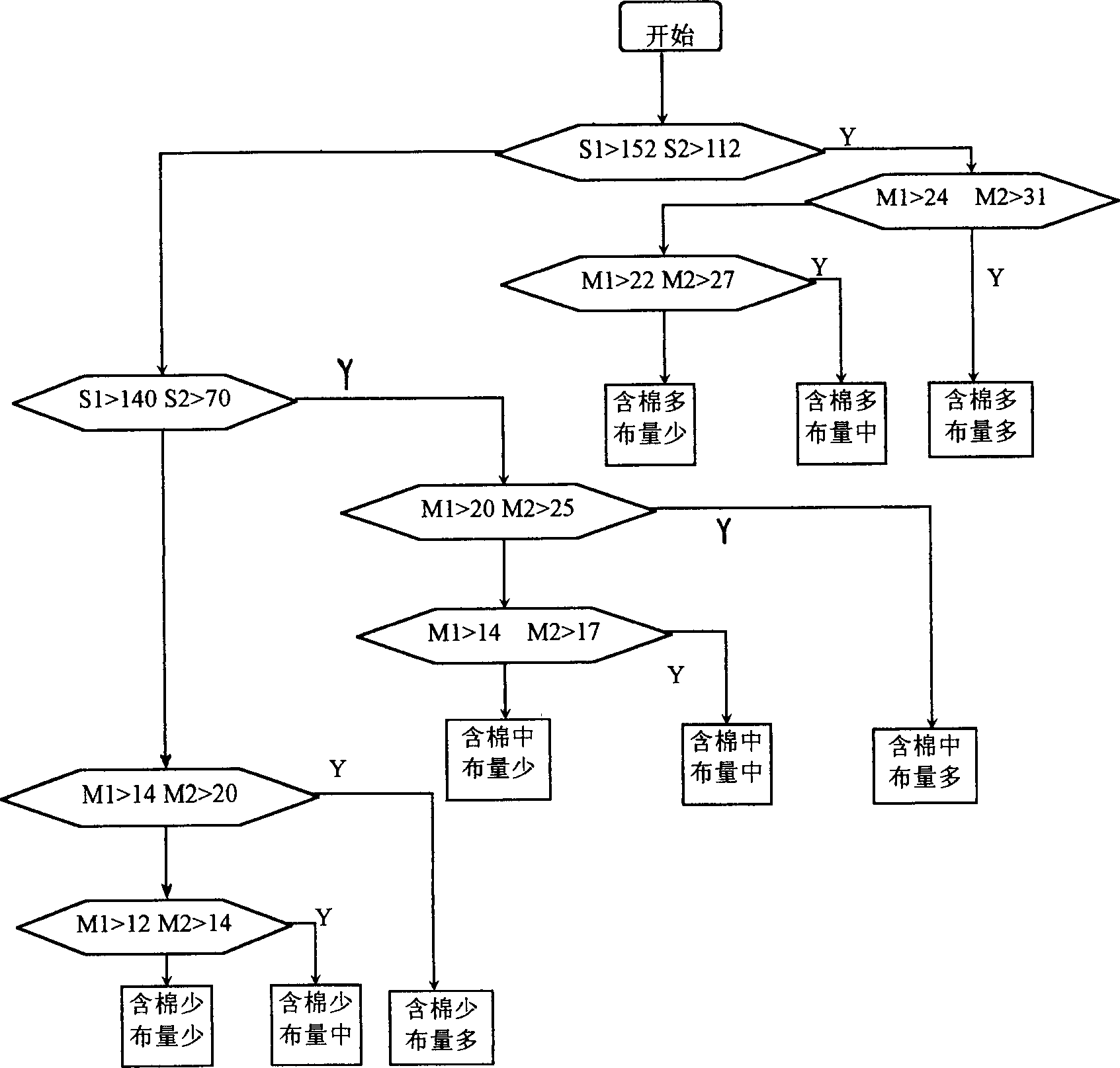

[0026] Such as figure 1 Shown is the functional block diagram of an embodiment of the fuzzy control industrial washing machine of the present invention, in the figure, 1 is the casing of washing machine, and 2 is washing drum, and washing drum 2 is connected with belt pulley 3 by transmission shaft 12, and motor The output force of 4 is transmitted to the washing drum 2 through the pulley 3 and the drive shaft 12; the water level sensor 5 is used to detect the water level in the washing drum 2, and the water level detection circuit transmits the signal of the water level sensor 5 to the central processing unit; the turbidity The sensor 6 is installed on the detection pipeline 13, and the electromagnetic valve 7 and the drainage pump 8 are also installed on the detection pipeline 13, and the turbidity detection circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com