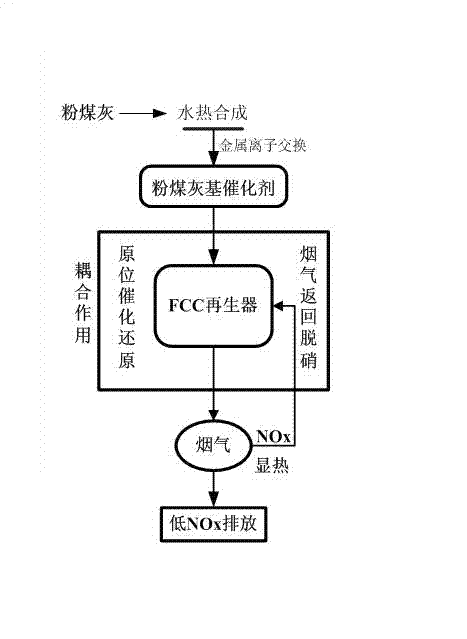

Method for reducing NOx emission in FCC (Fluid Catalytic Cracking) regeneration process

A regeneration process and regenerator technology, applied in separation methods, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high cost and poor denitration adaptability, and achieve the effects of low cost, easy operation and simple denitration process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

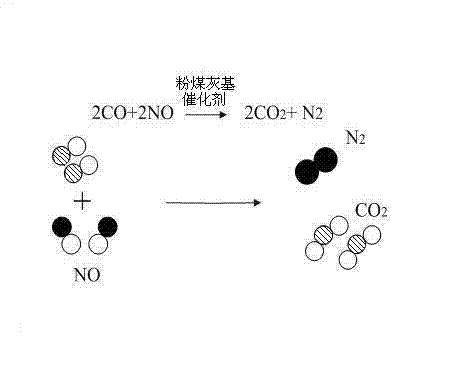

Problems solved by technology

Method used

Image

Examples

Embodiment 1

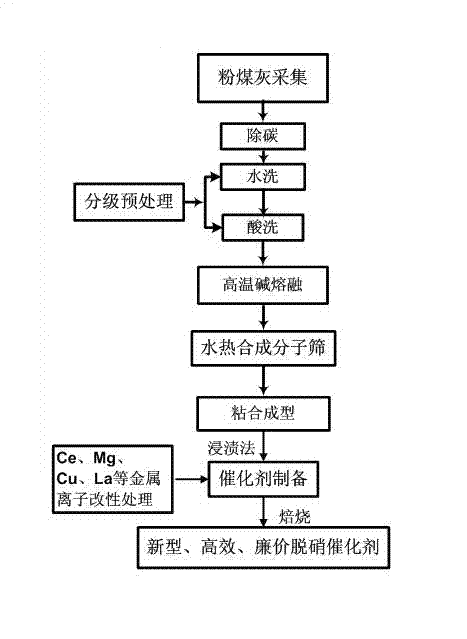

[0038] Preparation of fly ash-based denitration catalyst:

[0039] to combine image 3 As shown, the method of using fly ash to prepare fly ash-based denitrification catalyst: collect fly ash from the site, grind it into subdivisions, pass through a 40-mesh sieve, take 50g of fly ash and place it in a muffle furnace, and heat it at 600°C Calcined at high temperature for 10h, washed with water at 60°C for 2.5h, filtered and dried, added 2mol / L dilute hydrochloric acid with a volume of 500ml to wash, and the two reacted at a temperature of 50°C and a rotor of 100r / min. After reacting for 6 hours, the acid solution and the fly ash were separated into solid and liquid, and the separated solid was washed with distilled water until it was neutral, and dried for later use. Mix the treated fly ash with 40% NaOH solution at a solid-to-liquid ratio of 1:5, calcinate at 450°C for 1 h, and take it out to room temperature for later use. Then, the calcined fly ash was hydrothermally synth...

Embodiment 2

[0045] Preparation of fly ash-based denitration catalyst:

[0046] Collect fly ash from the site, grind it into subdivisions, pass through a 40-mesh sieve, put 50g of fly ash in a muffle furnace, calcinate at 700°C for 8 hours, wash with water at 20°C for 4 hours, and filter and dry Finally, add 2mol / L dilute hydrochloric acid with a volume of 600ml to wash, and the two react at a temperature of 40°C and a rotor of 200r / min for 2 hours, and then separate the acid solution from the fly ash solid-liquid, and the solid Wash with distilled water until neutral, dry for later use. Mix the treated fly ash with 40% NaOH solution at a solid-to-liquid ratio of 1:1, calcinate at 600°C for 2 h, and take it out to room temperature for later use. Then, the calcined fly ash was hydrothermally synthesized at a temperature of 100°C and a synthetic pressure of 0.5Mpa for 4h, aged at 40°C for 2h, crystallized at 110°C for 24h, and the synthesized sample was washed and filtered with distilled wa...

Embodiment 3

[0051] Preparation of fly ash-based denitration catalyst:

[0052] Collect fly ash from the site, grind it into subdivisions, pass through a 40-mesh sieve, put 50g of fly ash in a muffle furnace, calcinate at 900°C for 6 hours, wash with water at 80°C for 1 hour, filter and dry Finally, add 4mol / L dilute sulfuric acid with a volume of 750ml to wash, and the two react at a temperature of 20°C and a rotor of 300r / min for 10 hours, and then separate the acid solution from the fly ash solid-liquid, and the solid after separation Wash with distilled water until neutral, dry for later use. Mix the treated fly ash with 40% NaOH solution at a solid-to-liquid ratio of 1:10, calcinate at 500°C for 1.5 h, and then take it out to room temperature for later use. Then, the calcined fly ash was hydrothermally synthesized at a temperature of 95°C and a synthesis pressure of 0.2Mpa for 8 hours, aged at 50°C for 4 hours, crystallized at 120°C for 18 hours, and the synthesized samples were wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com