Processing system of heating by using waste heat of hot water for slag flushing in blast furnace

A blast furnace slag flushing and processing system technology, applied to hot water central heating systems, heating systems, household heating, etc., can solve problems such as unusable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

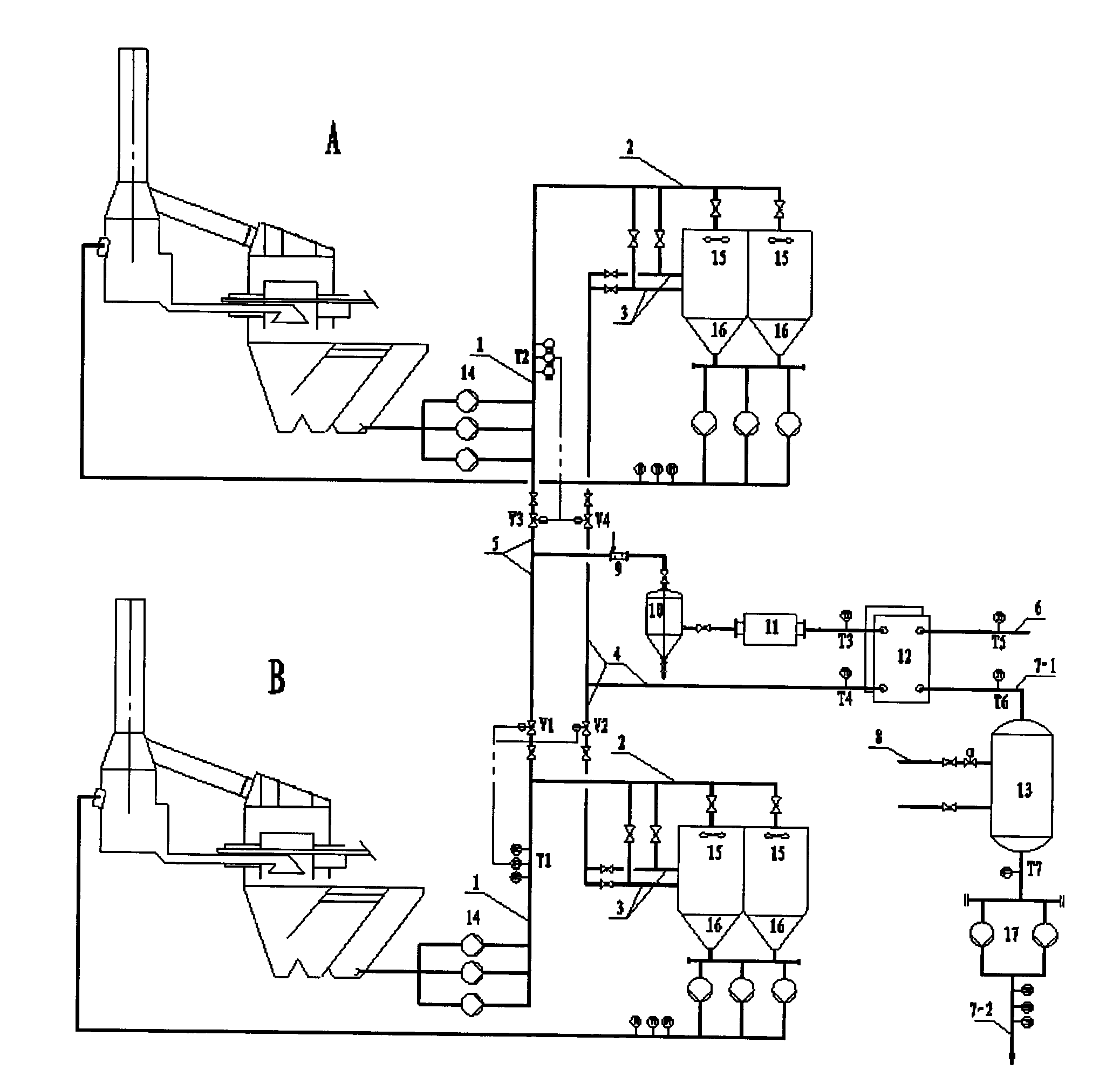

[0023] The present invention will be further described below with reference to the accompanying drawings, but the present invention is not limited thereto.

[0024] In this embodiment, there are two sets of slag flushing water circulation systems A and B, and the outlet main pipe 1 of the slag flushing water hot water lift pump 14 of each set of slag flushing water circulation system is respectively connected to the cooling tower inlet pipe 2 and the slag flushing water input pipeline 5. The slag flushing water input pipeline 5 enters the shared heating treatment system. The heating treatment system is composed of pipeline mixer 9, coarse filter equipment 10, fine filter equipment 11 and primary heat exchanger 12 in series; the heating return pipe 6 of the heating system is connected to the primary heat exchanger 12, and the heating water supply pipe 7-1 The secondary heat exchanger 13 is connected with the heating water supply pump unit 17; the heated hot water is sent into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com